Hydrogenated petroleum resin granulator and granulation method thereof

A technology of hydrogenated petroleum resin and granulator, which is applied in the methods of granulating raw materials, chemical instruments and methods, lighting and heating equipment, etc. problem, to avoid excessive temperature, good cooling effect, and solve the effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

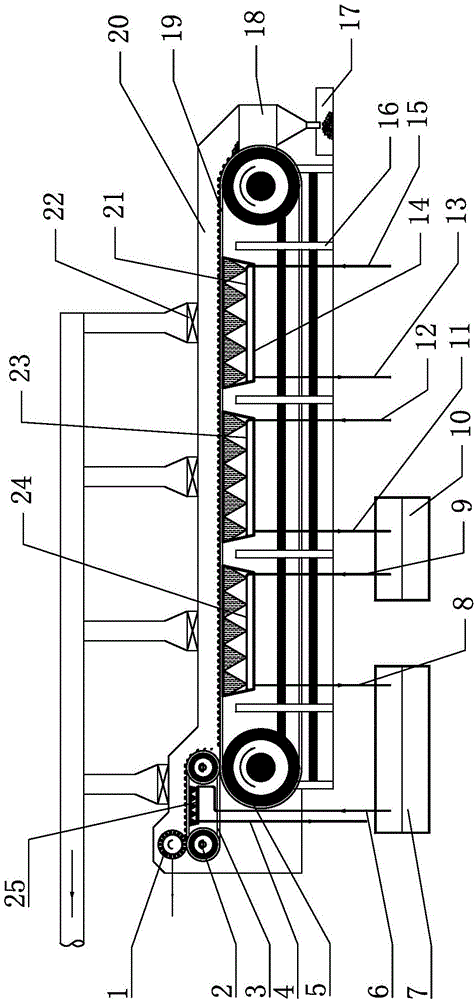

[0026] Such as figure 1 As shown, a hydrogenated petroleum resin granulator includes a distributor 1, a conveying device, a cooling device, and a discharge bin 18. The distributor 1 is arranged at the feeding end of the conveying device, the discharging bin 18 is arranged at the discharging end of the conveying device, and the lower part of the discharging bin 18 is provided with a trough 17 . The distributor 1, conveying device, cooling device, and discharge bin 18 are all arranged in the sealed casing 20, the bottom of the sealed casing 20 is connected to the equipment support 16, and the sealed casing 20 is provided with a plurality of air outlets, and the air outlets are connected to the draft hood 22 , the air-inducing hood 22 is connected to the exhaust gas treatment system.

[0027] Described conveying device comprises precooling conveying steel belt 3 and cooling conveying steel belt 19, and precooling conveying steel belt 3 blanks to cooling conveying steel belt 19, ...

specific Embodiment 2

[0034] This embodiment is basically similar to the specific embodiment 1, the difference is that

[0035] When working, measure the cooling temperature of each segment of the water spray pipeline as,

[0036]The inlet temperature of the pre-cooling inlet pipe is 50°C, the initial temperature of the material is 200°C, and the temperature is lowered to 150°C; the high-temperature cooling section: the inlet temperature of the high-temperature cooling inlet pipe is 40°C, the initial temperature of the material is 150°C, and the temperature is lowered to 100°C ℃; normal temperature cooling section: the inlet temperature of the normal temperature cooling inlet pipe is 32℃, the initial temperature of the material is 100℃, and the temperature is lowered to 60℃; the low temperature cooling section: the inlet temperature of the low temperature cooling inlet pipe is 10℃, the initial temperature of the material 60°C, cool down to 25°C.

[0037] This embodiment is the best embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com