Lead-free solder for electronic packaging

An electronic packaging, lead-free solder technology, applied in welding/cutting media/materials, welding media, metal processing equipment, etc., can solve the problems of high cost of high-silver solder, poor mechanical properties of low-silver solder, etc. Excellent anti-aging properties, reducing adverse effects and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] Specific Embodiment 1: In this embodiment, the lead-free solder for electronic packaging is composed of 0.35-0.90% Ag, 0.20-1.00% Cu, 0.005-0.20% Ni, 1.20-4.00% Bi, 0.50-2.00% Sb according to the mass percentage , 0.01 to 0.20% Ti, and the rest is composed of Sn.

[0013] The preparation method of lead-free solder for electronic packaging in the present embodiment is as follows:

[0014] Step 1: Weigh according to the composition mass percentage of 35-0.90% Ag, 0.20-1.00% Cu, 0.005-0.20% Ni, 1.20-4.00% Bi, 0.50-2.00% Sb, 0.01-0.20% Ti, and the rest is Sn each alloying element.

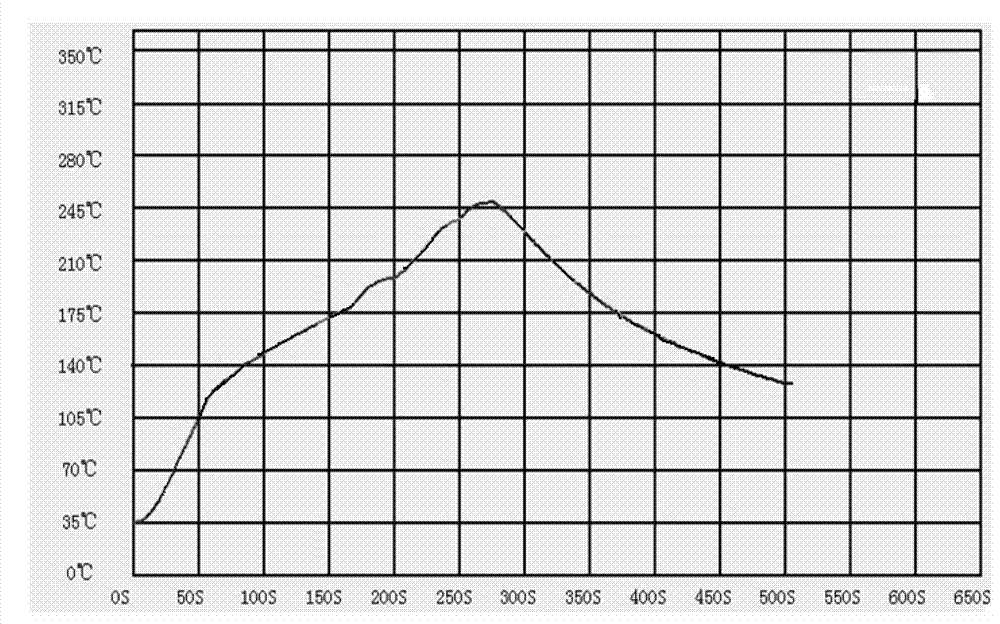

[0015] Step 2: Get the Cu weighed in Step 1, and calculate the corresponding metal Sn weight according to Cu and Sn mass percentages of 39.11% and 60.89%, weigh and take out the Sn of this weight from the Sn weighed in Step 1, and The Cu weighed in step 1 and the Sn weighed in step 2 are placed in a quartz tube, and heated by high-frequency induction method. The heating temperature is controll...

specific Embodiment approach 2

[0019] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the lead-free solder for electronic packaging is composed of 0.52-0.83% Ag, 0.45-0.68% Cu, 0.025-0.16% Ni, 2.10-3.80 %Bi, 0.80-1.85% Sb, 0.07-0.17% Ti, and the rest is composed of Sn. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the lead-free solder for electronic packaging is composed of 0.60-0.72% Ag, 0.45-0.55% Cu, 0.035-0.10% Ni, 2.50-3.50% %Bi, 1.25-1.60% Sb, 0.10-0.15% Ti, and the rest is composed of Sn. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com