System for preparing powder with gas phase and liquid phase

A powder, gas-liquid technology, applied in the field of gas-liquid dual-phase preparation of powder systems, can solve the problems of inability to manufacture metal powder, metal composite powder, lack of chemical activity, and high impurity content, and achieves high activity, high Full and fast mixing, large surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

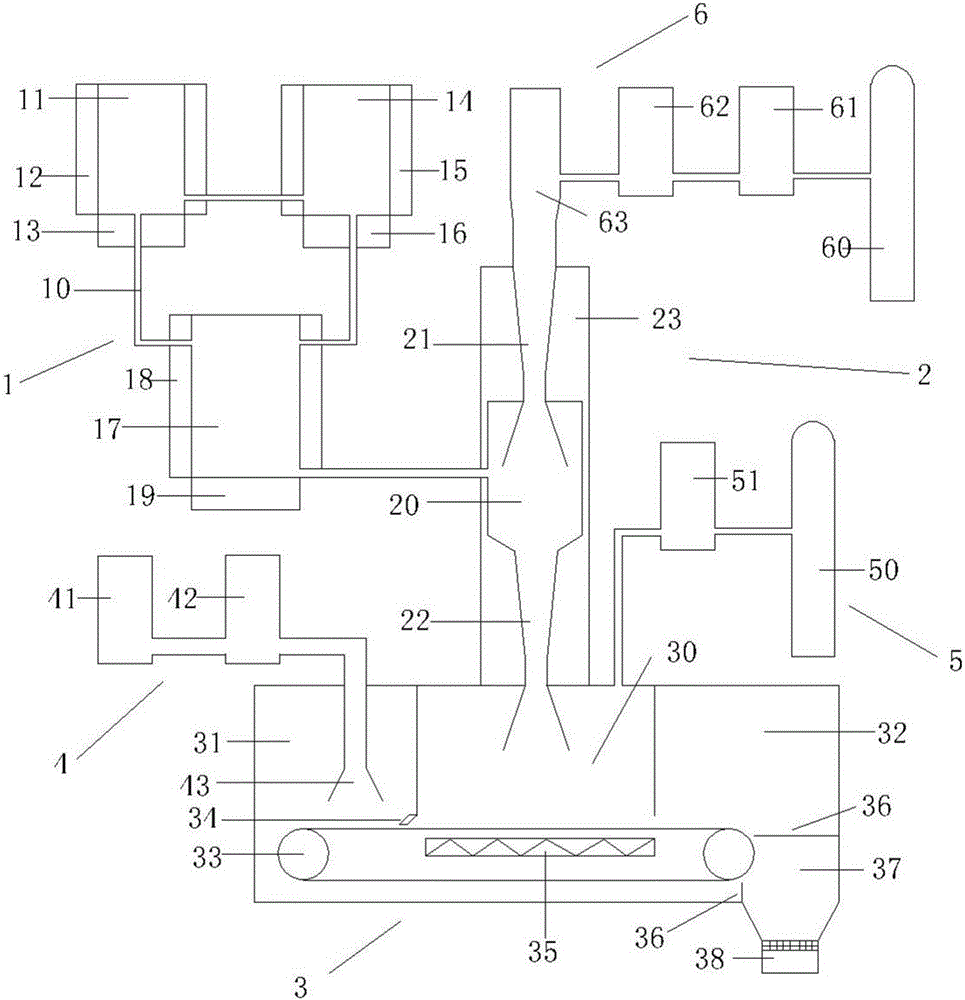

[0030] refer to figure 1 , is a schematic diagram of the system structure of the gas-liquid two-phase preparation of powder in the embodiment of the present invention.

[0031] In the embodiment of the present invention, a gas-liquid two-phase powder preparation system is proposed, including a raw material heat treatment device 1, a mixing device 2 and a spraying device 3;

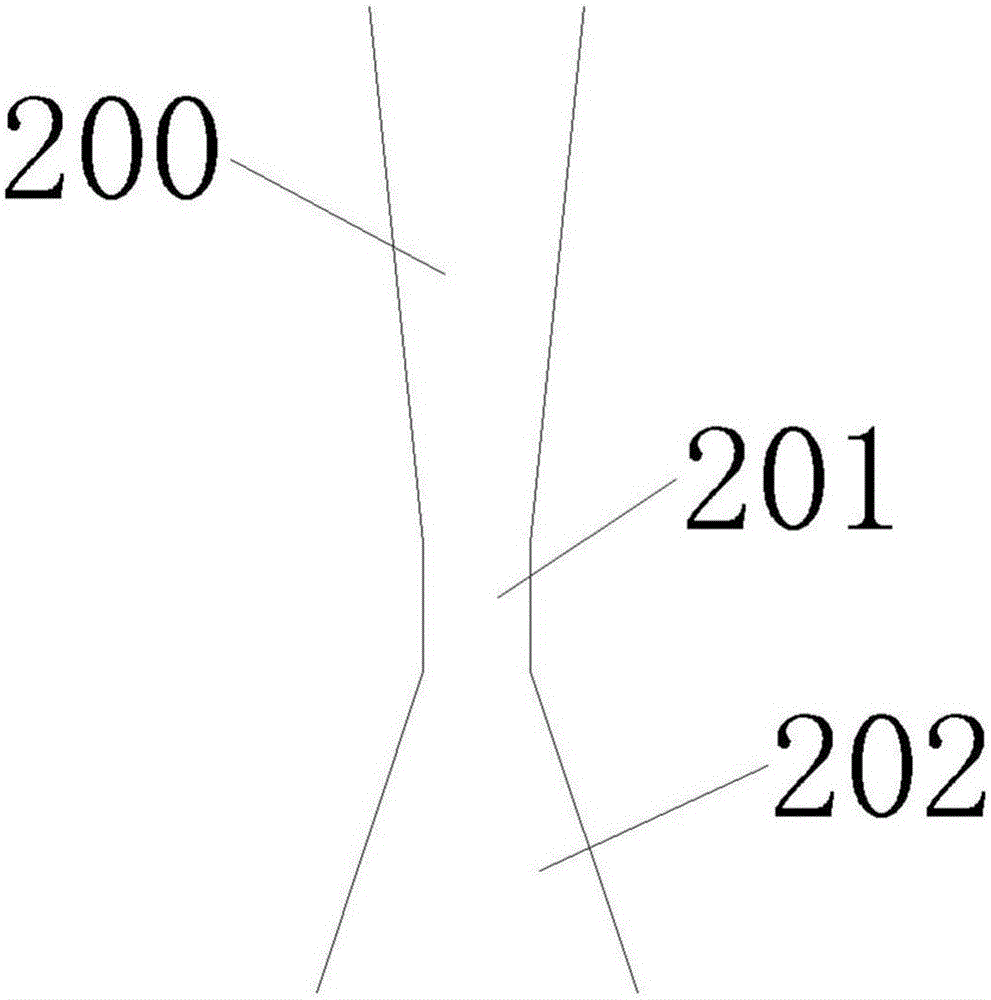

[0032] The above-mentioned mixing device 2 includes a mixing chamber 20, a first Laval nozzle 21 and a second Laval nozzle 22; the top of the above-mentioned mixing chamber 20 runs through the above-mentioned first Laval nozzle 21, and the bottom of the above-mentioned mixing chamber 20 communicates with the above-mentioned The second Laval nozzle 22 ; the end of the second Laval nozzle 22 leads into the spraying device 3 .

[0033] In this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com