Production line of CA grinding material

A production line and abrasive technology, applied in grinding devices, grinding/polishing equipment, and other chemical processes, etc., can solve the problems of high production efficiency, rough abrasive edges, and high cost, and achieve the effect of avoiding damage and facilitating discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0130] Attached below figure 1 - attached Figure 32 The production line disclosed in this embodiment is further described;

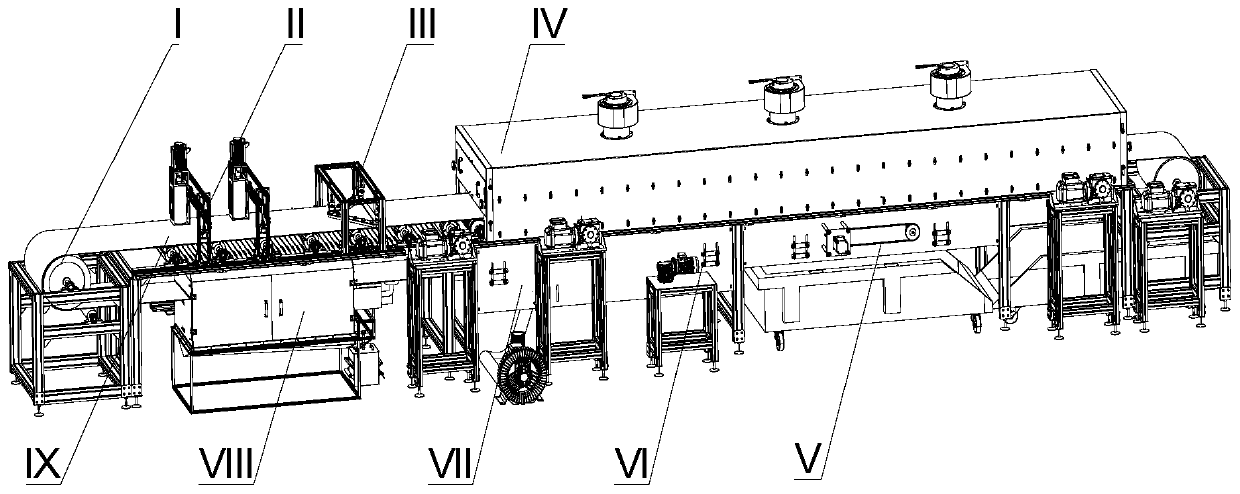

[0131] Refer to attached figure 1 As shown, the CA abrasive production line includes transmission device I, slurry coating mechanism II, leveling mechanism III, oven IV, blanking mechanism V, roller brush cleaning mechanism VI, air knife blowing mechanism VII, and release agent coating Mechanism VIII, Belt Die IX.

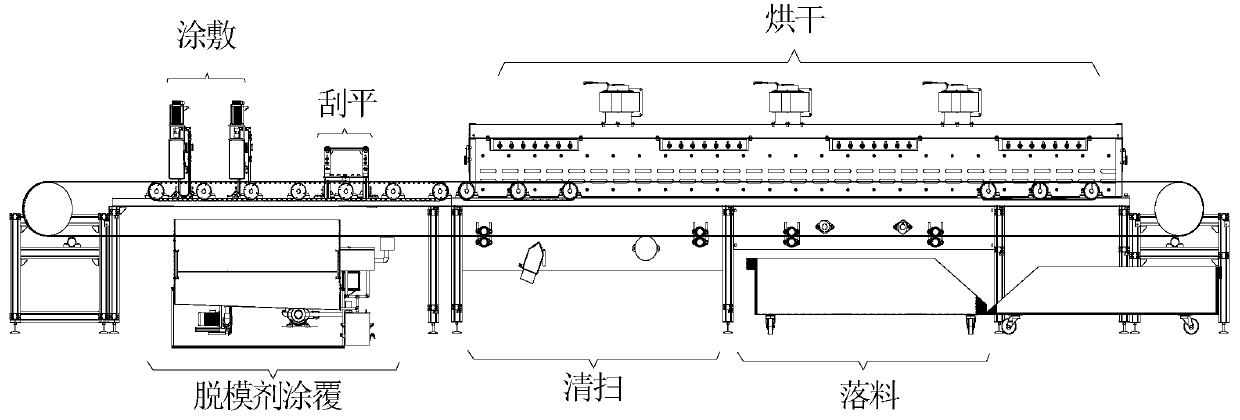

[0132] like figure 2 As shown, the production process of a single working cycle is: slurry coating, slurry leveling, slurry drying, blanking, belt mold cleaning, and release agent spraying six parts. Each of these places different demands on the transmission.

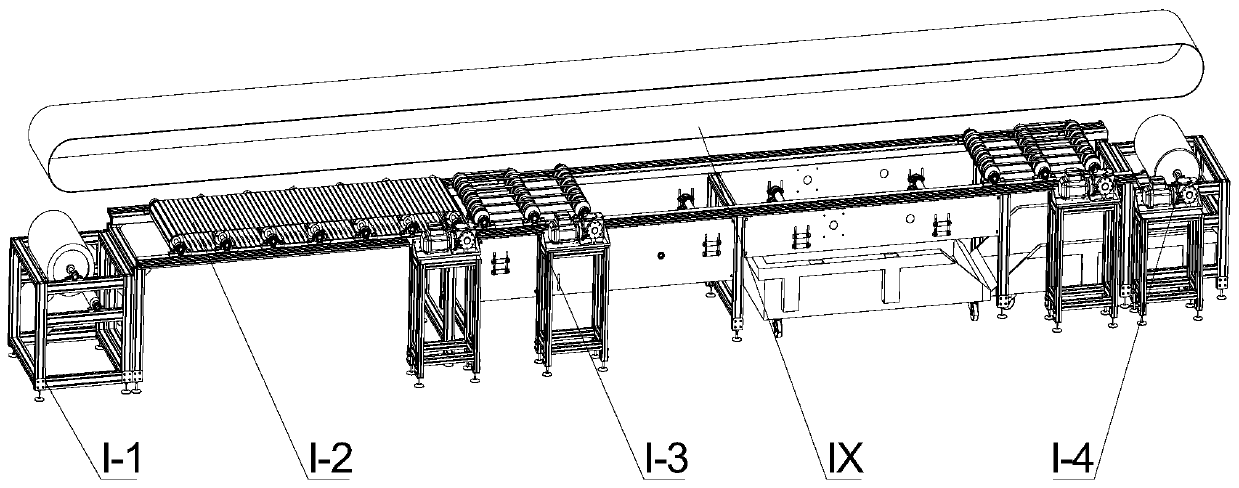

[0133] like Figure 3-4 As shown, the main function of the transmission device is to complete the conveying of the belt mold, and the structure mainly includes the machine frame I-1, the chain plate support mechanism I-2, the synchronous belt drive mechanism I-3, and the belt m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com