Granulation device

A technology of a granulating device and a distributing device, which is applied in the direction of granulation on an endless conveyor belt, can solve the problems of high maintenance costs, increased production costs, and can no longer operate normally, and achieves the effect of reducing maintenance costs and increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

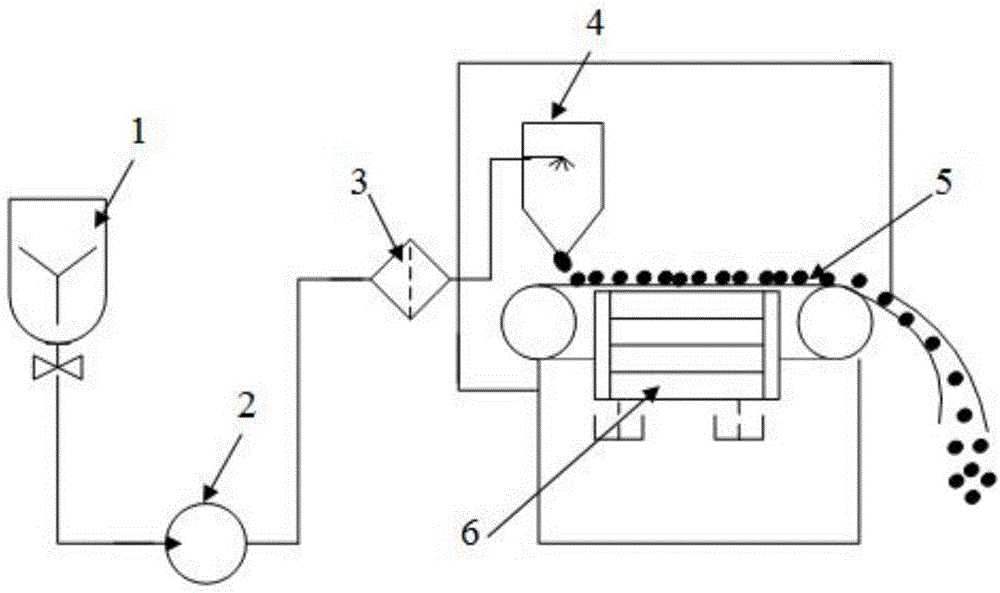

[0021] The embodiment of the present invention provides a granulation device. By superhydrophobic and oleophobic treatment on the surface of the conveyor belt, the chain-type stainless steel conveyor belt is used instead of the steel belt to produce nearly spherical particles, and since the chain-type conveyor belt is used instead of The steel belt and the conveyor belt run basically without stress, the service life of the conveyor belt is greatly increased, and the maintenance cost is also greatly reduced.

[0022] In order to make the purpose, features and advantages of the present invention more obvious and understandable, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the following The described embodiments are only some, not all, embodiments of the present invention. All other embodiments obtained by thos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com