Patents

Literature

37results about How to "Avoid local instability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

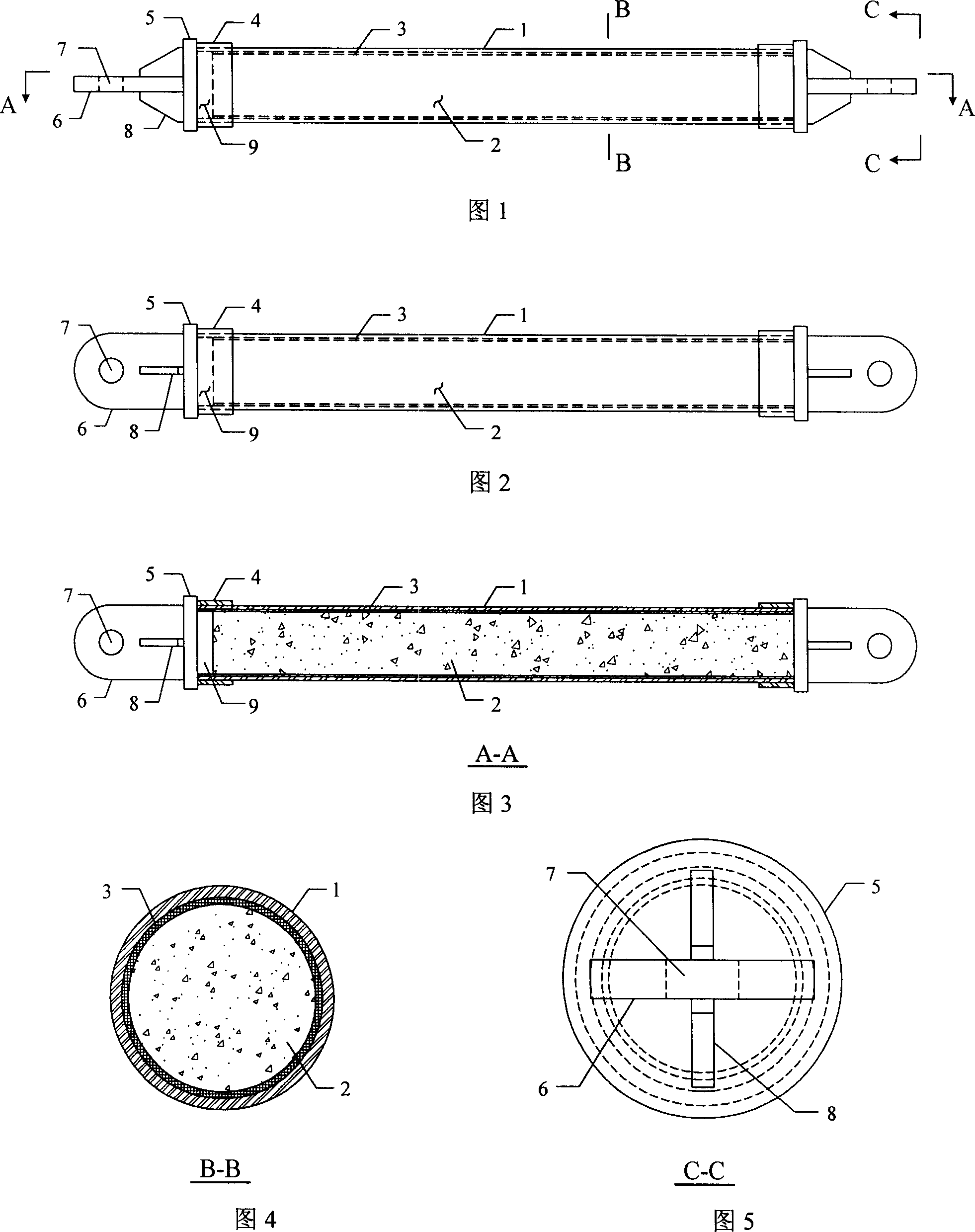

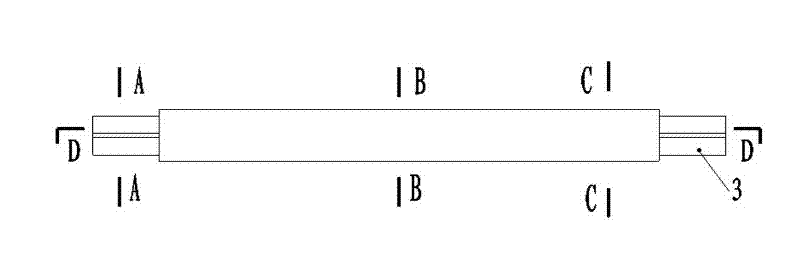

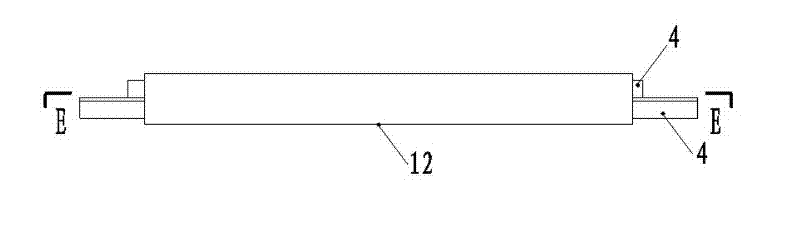

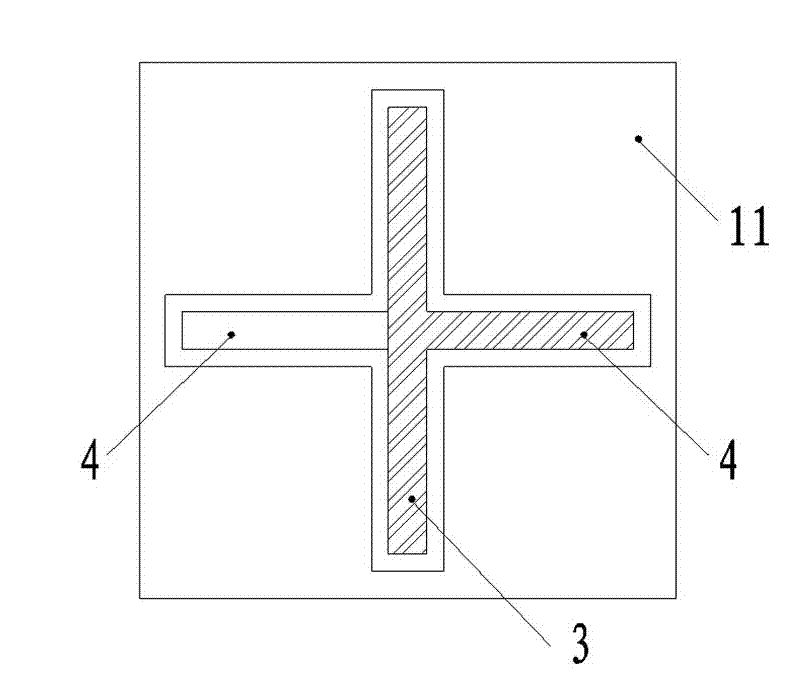

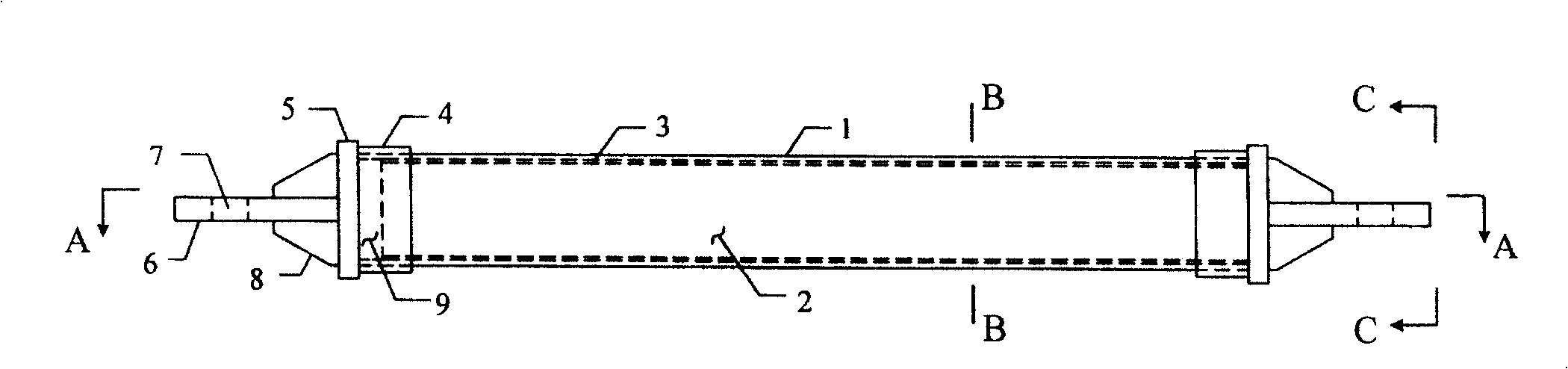

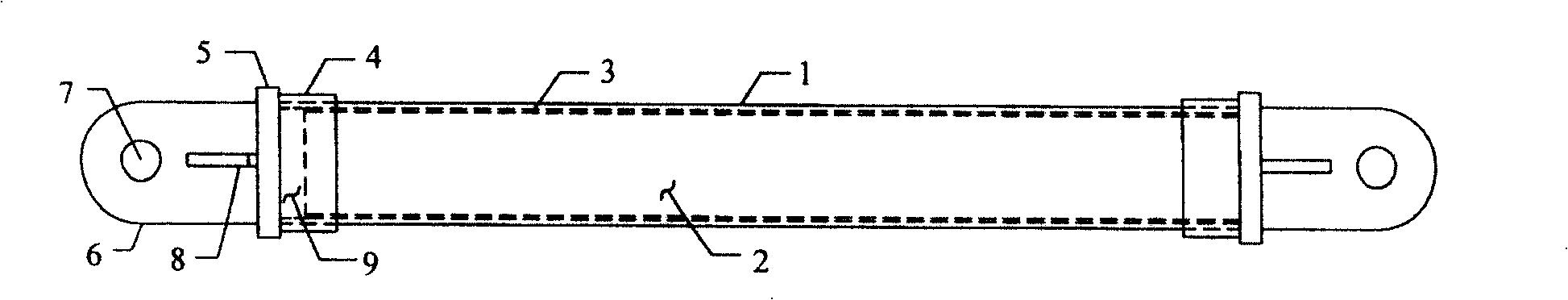

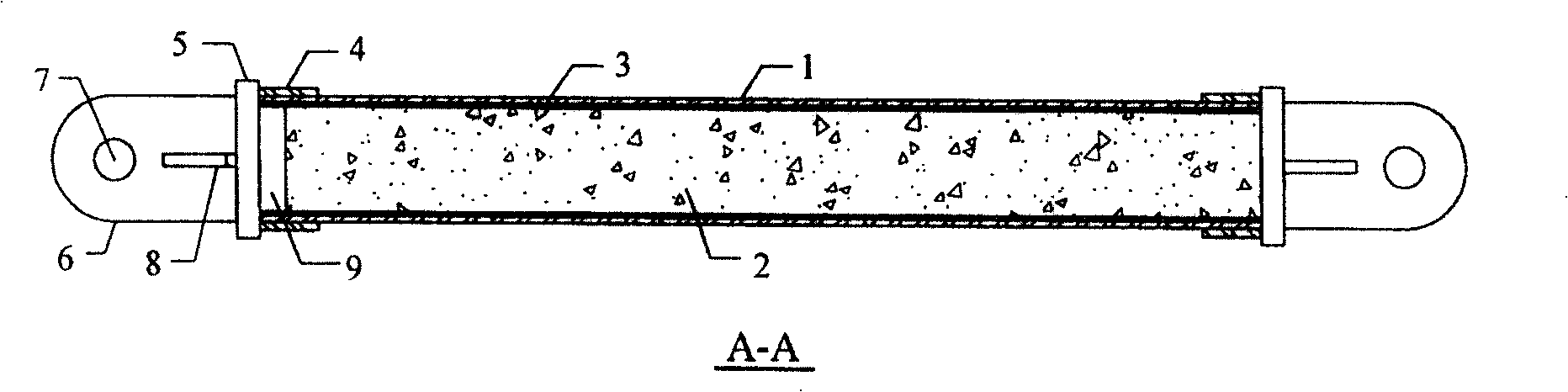

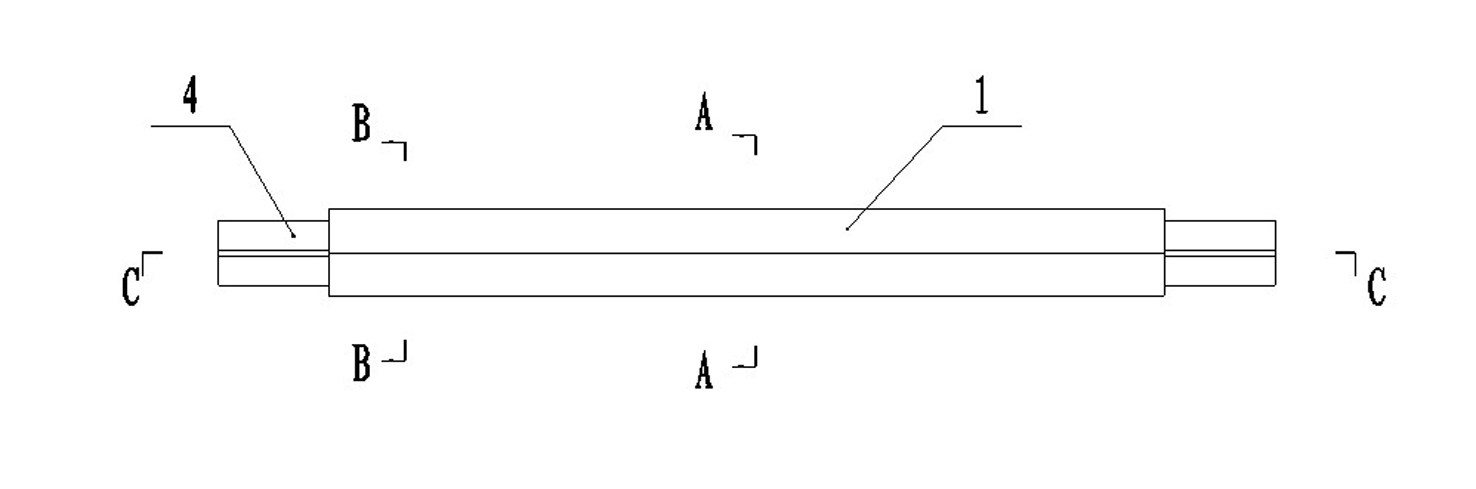

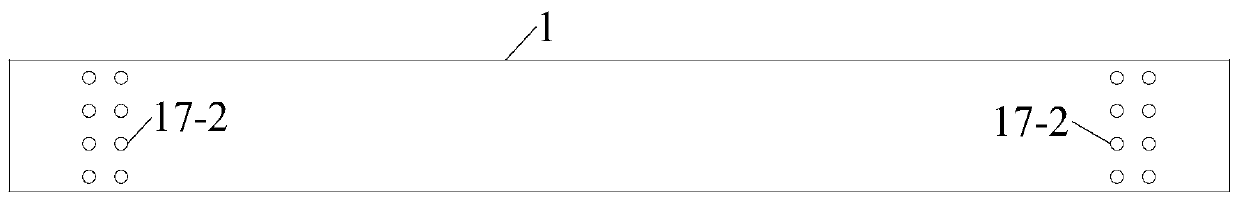

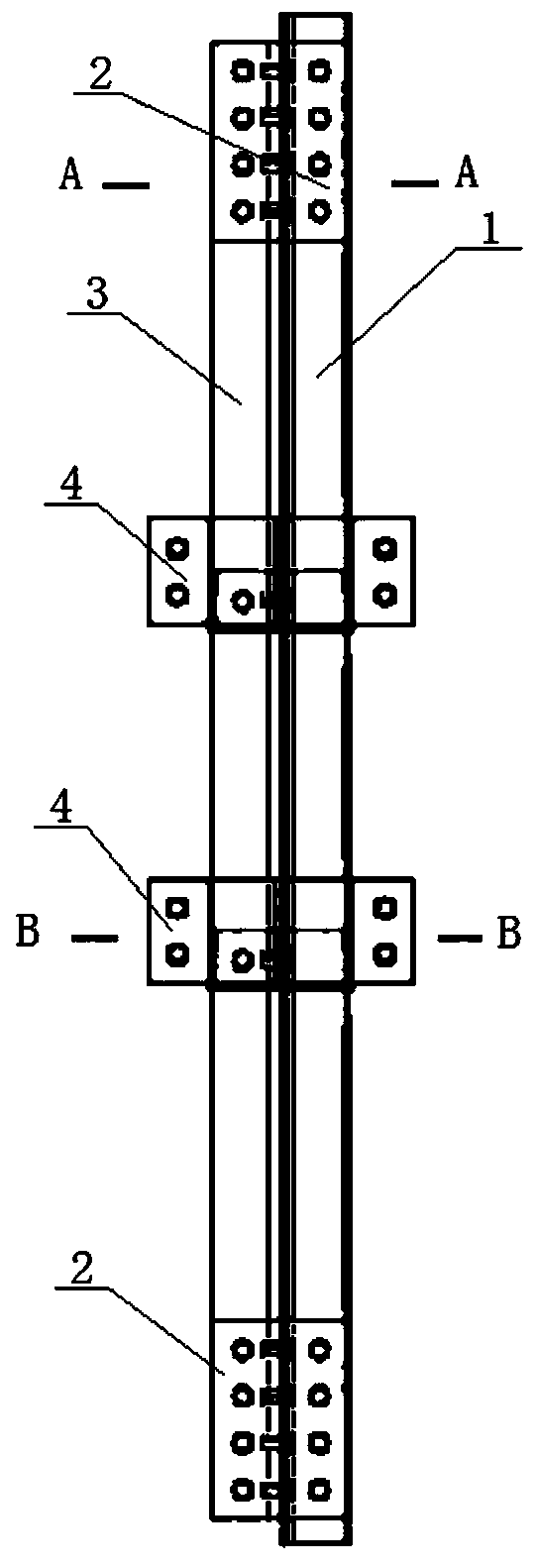

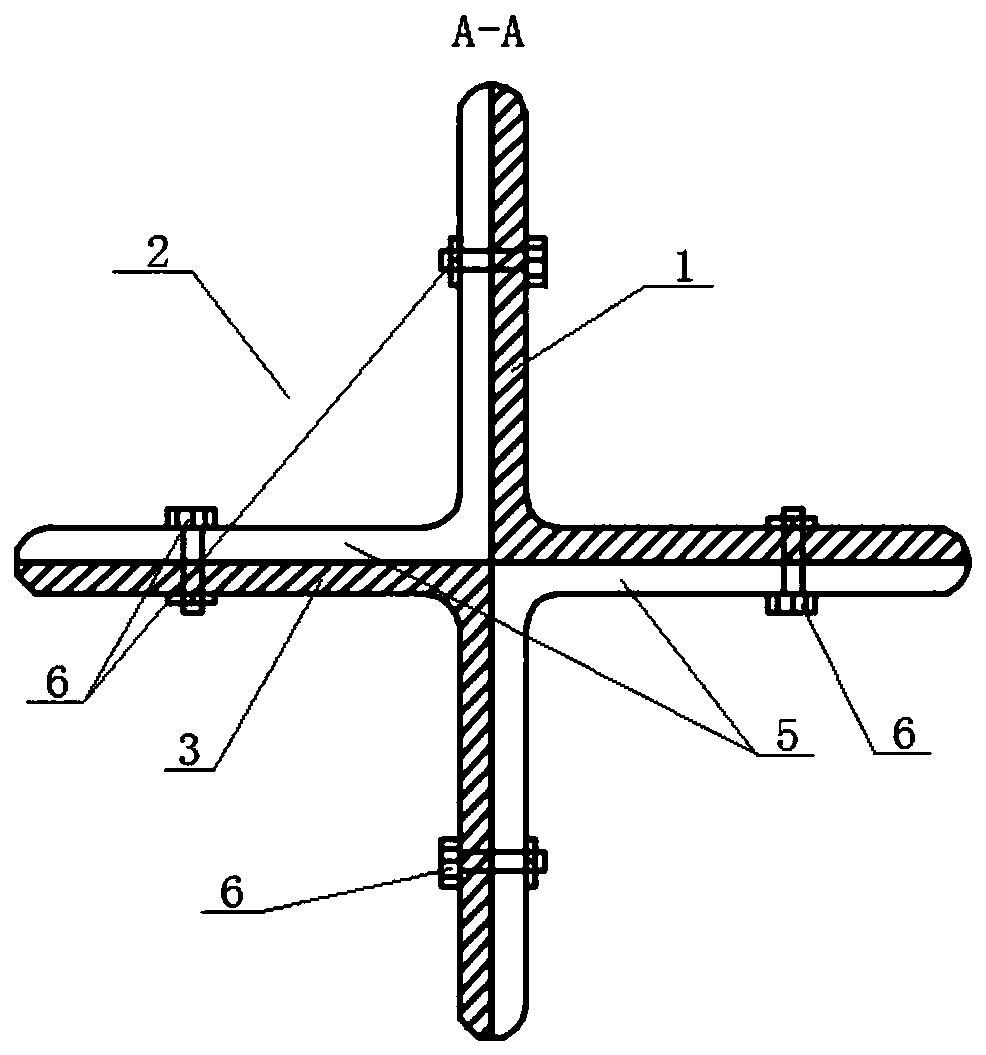

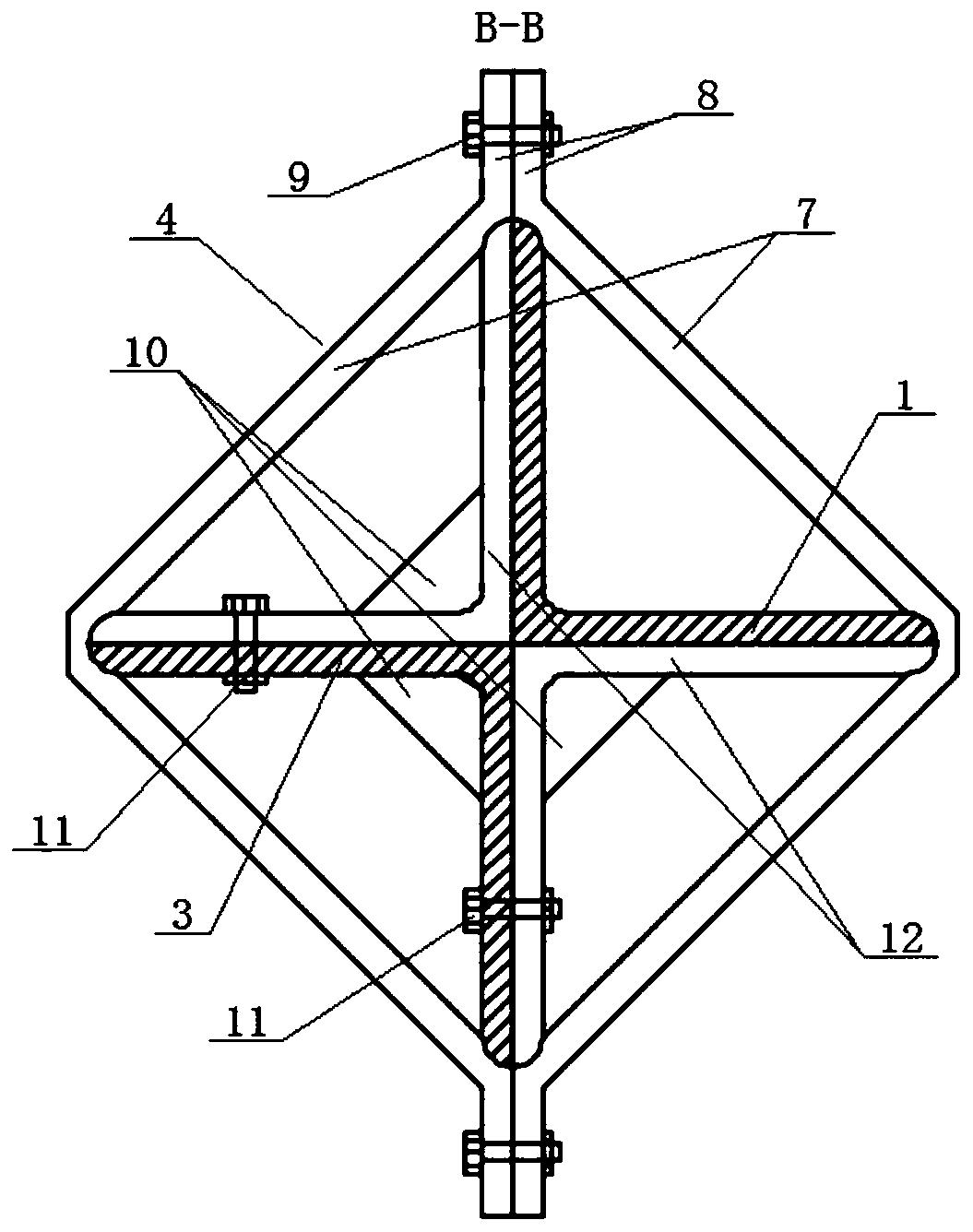

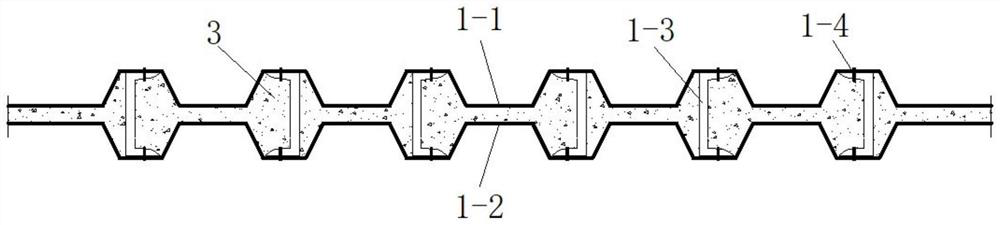

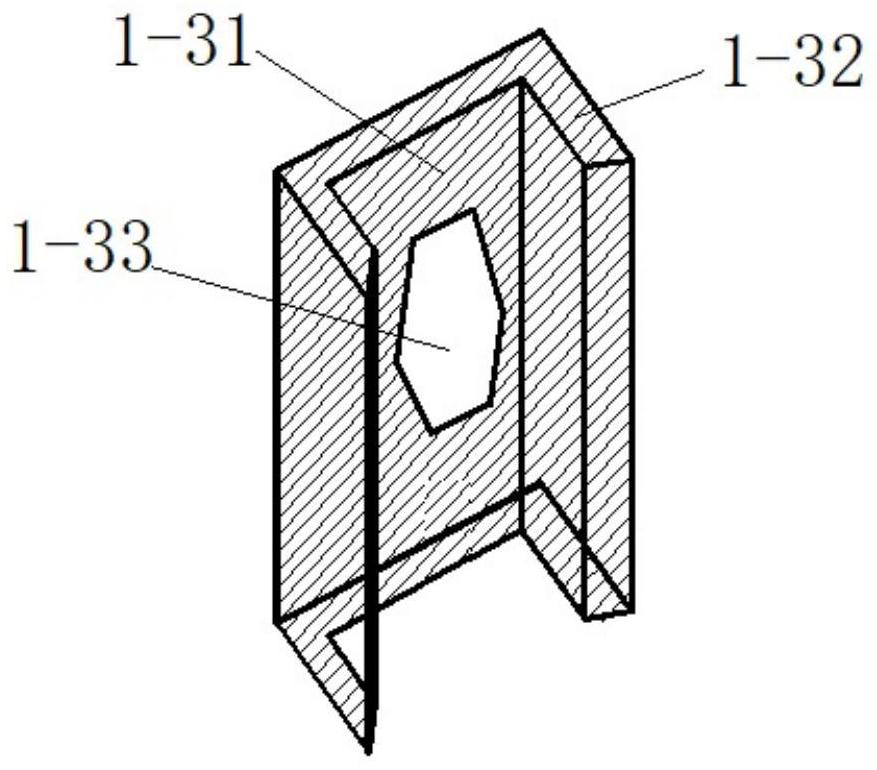

Steel tube anti-flex energy dissipation support

InactiveCN100999916AIncrease constraint stiffnessAvoid local instabilityLoad-supporting elementsShock proofingPipe supportSteel tube

The present invention relates to structural engineering technology, and is especially one kind of flexure preventing energy dissipating steel pipe support, which comprises axial force unit of circular steel pipe, constraint unit of concrete poured inside the steel pipe, isolating unit set between the circular steel pipe and the concrete, and connecting unit in the ends of the support for connection between the support and the frame structure. Of the present invention, the axial force unit has very high rigidity to avoid the integral unstability of the support effectively, the filled concrete can avoid local unstbility and high order flexure of the axial force unit, and the support has plump hysteresis curve in both compressed or pulled state.

Owner:TSINGHUA UNIV

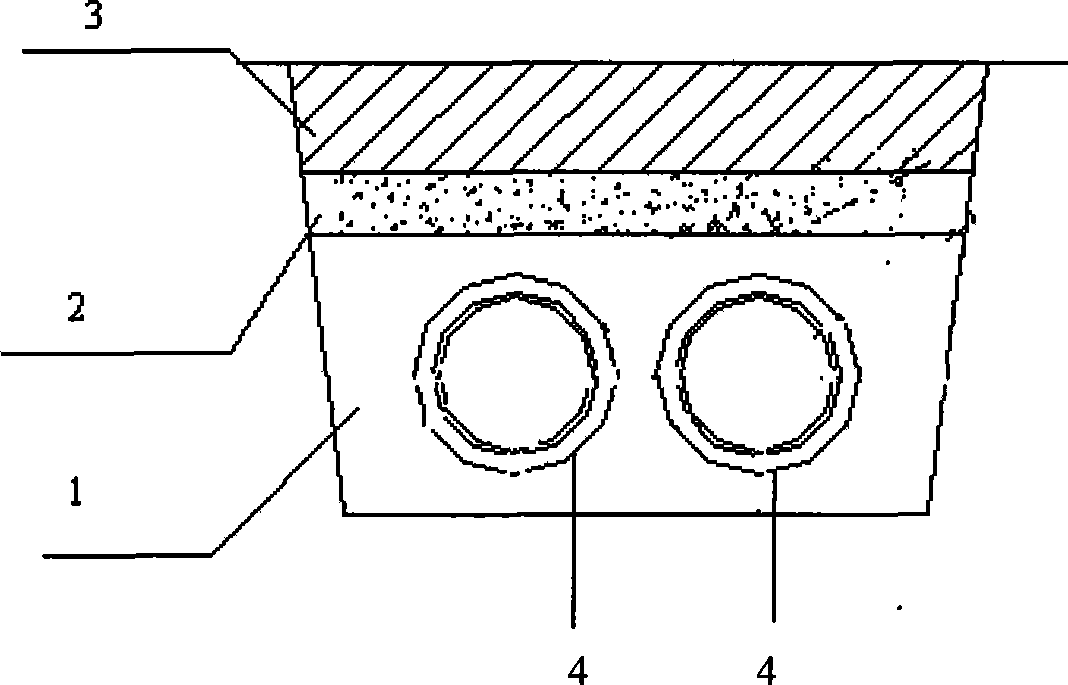

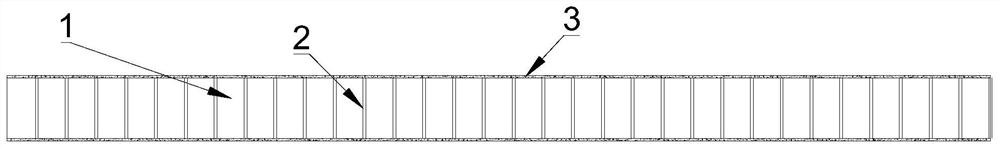

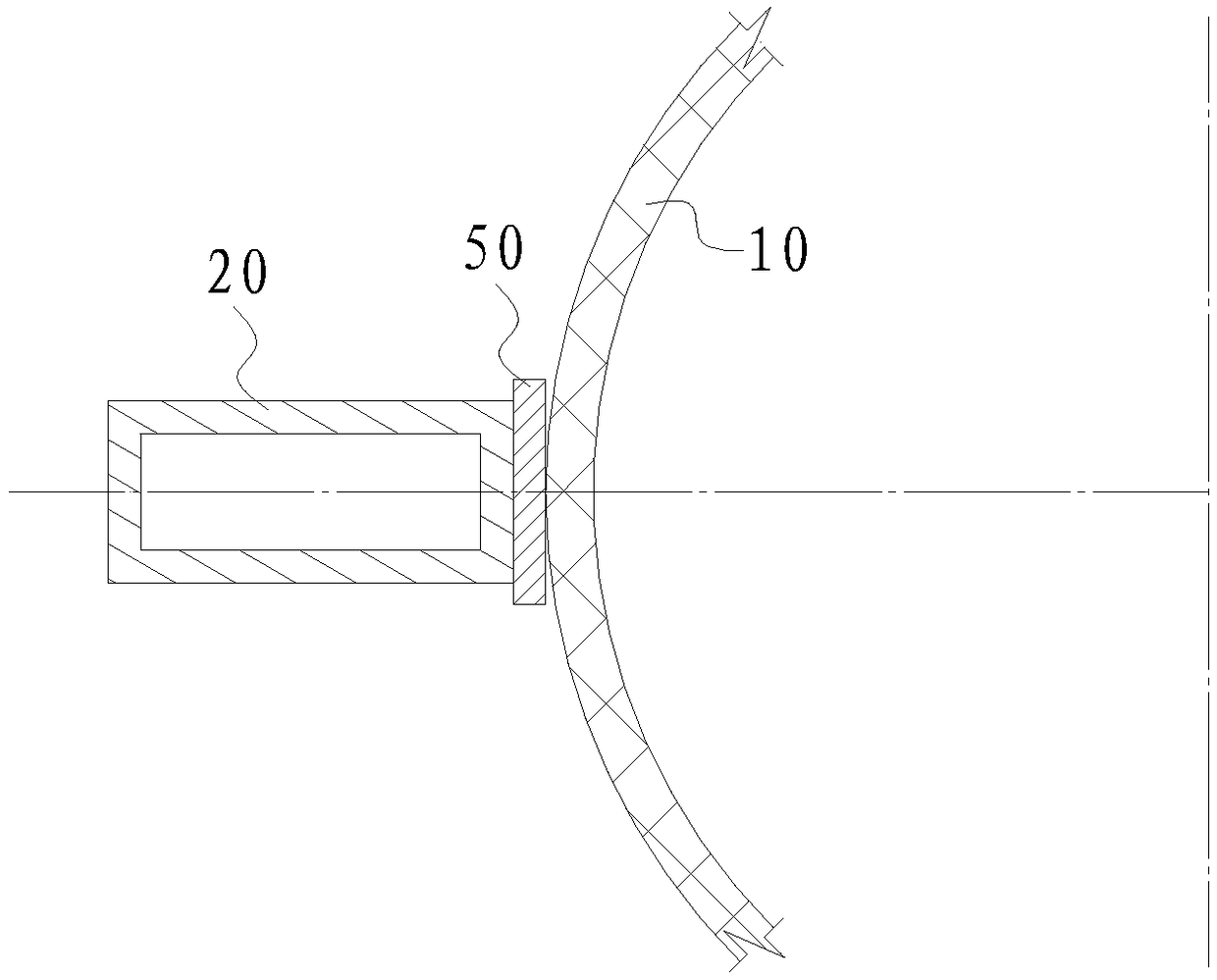

Non-compensation cold mounting method for large diameter heat supply pipeline

ActiveCN101482195AEasy to installLess anchoragePipe laying and repairThermal insulationEngineeringCaliber

The invention provides a large-caliber heat-supply pipeline uncompensated cold mounting method, comprising the following steps: digging a groove for arranging a heat-supply pipeline, and filling sand into the groove; mounting the heat-supply pipeline and a corresponding pipeline accessory into the groove; carrying out backfilling on the groove; wherein, the direct-buried net depth of the heat-supply pipeline is more than 1.7m; the pipeline accessory comprises an elbow with a large bending radius, bevel angles, a three-way pipe, a tapered pipe, and a valve; wherein, the bevel angles comprise a plurality of small bevel angles smaller than 1 degree or the elbow the radius of which is more than 5.0DN can be used for replacing; moreover, the mounting method provided by the invention is led to be suitable for paving the heat-supply pipelines the main tubular diameters of which are more than DN1000 by the processing technology on each node of the pipeline; moreover, the invention is simple to be mounted, has short construction period, reduces the maintaining cost, and is safe and reliable.

Owner:BERIS ENG & RES CORP

Reinforcement device for preventing flexural-torsional buckling of angle steel for iron towers

Owner:SHANDONG UNIV

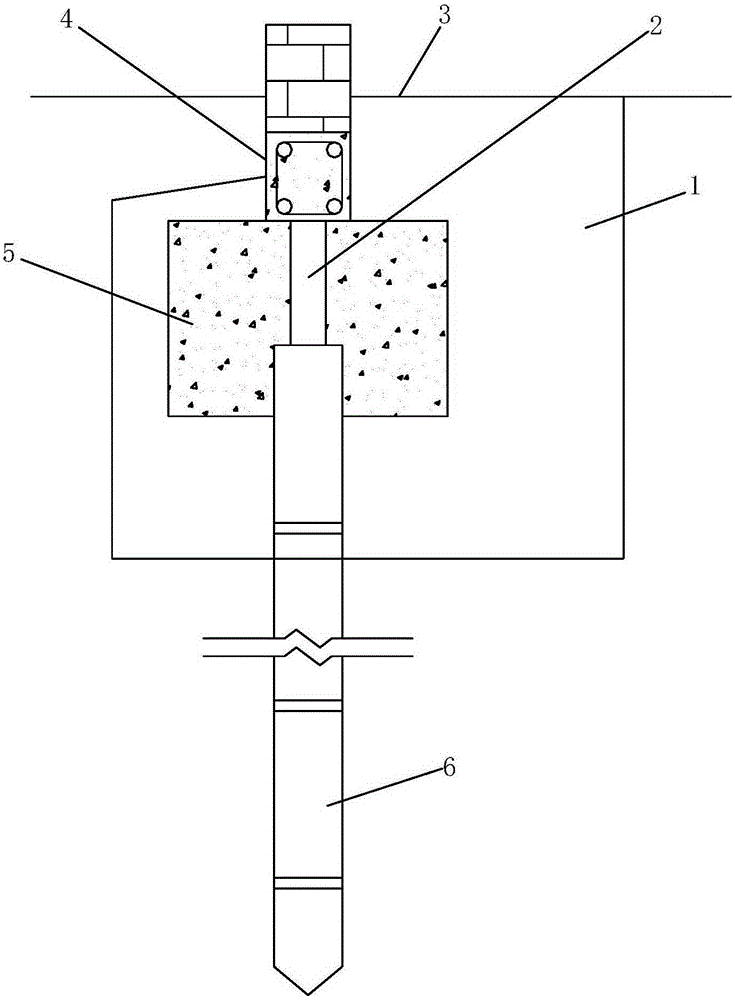

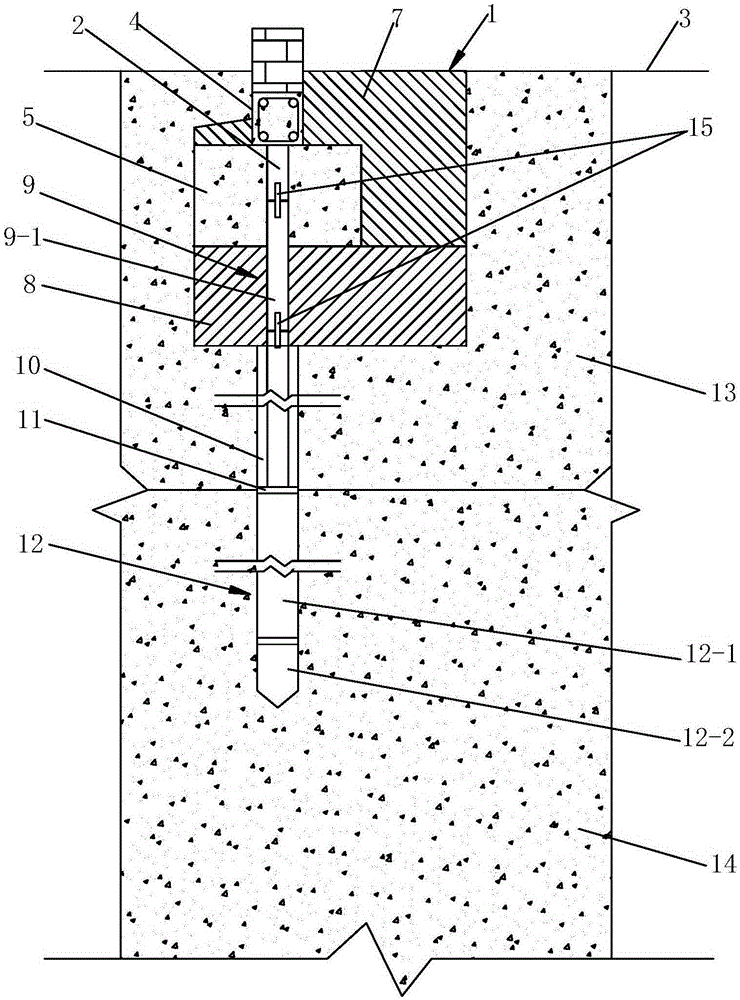

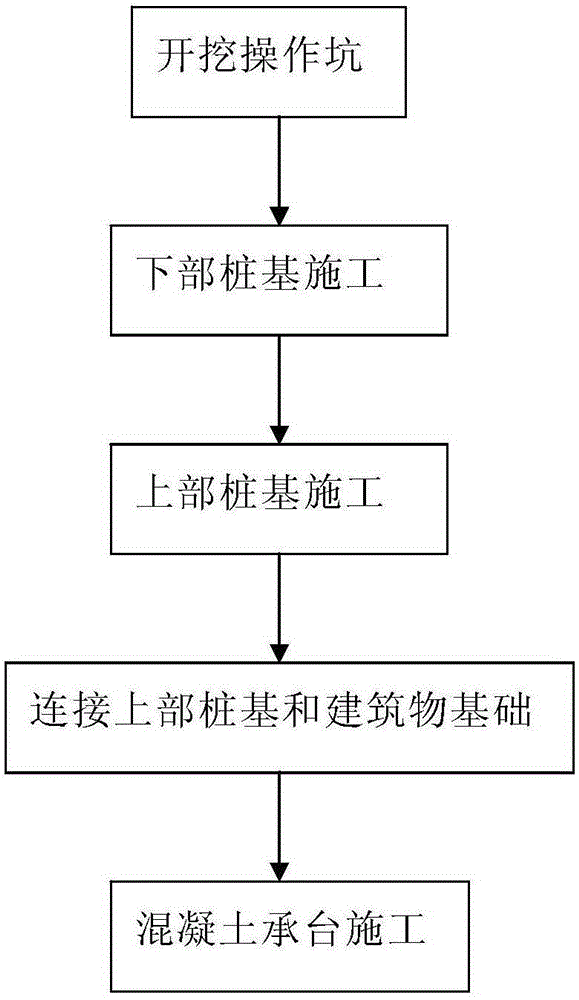

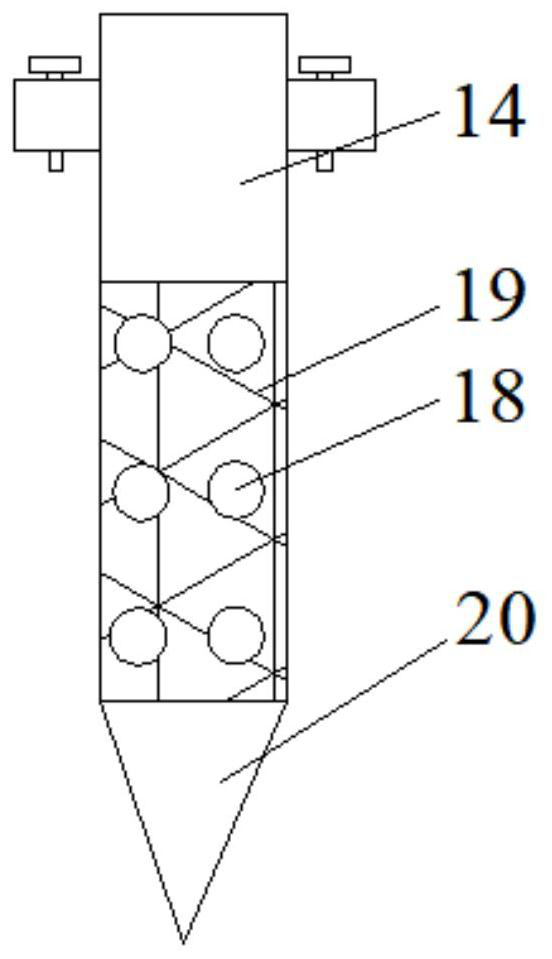

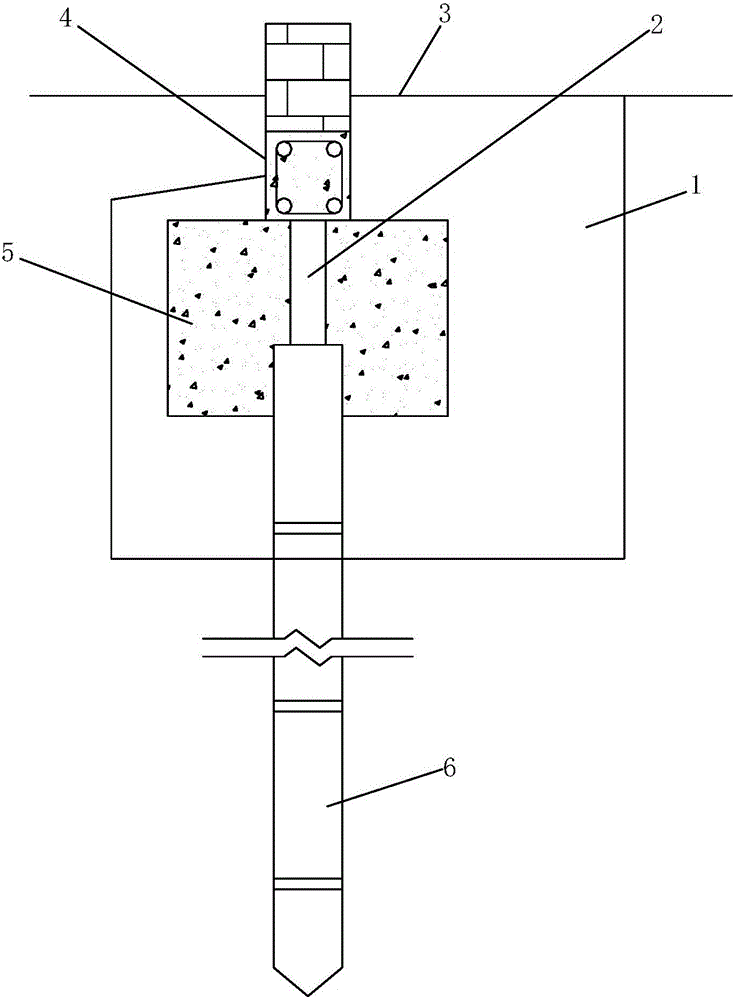

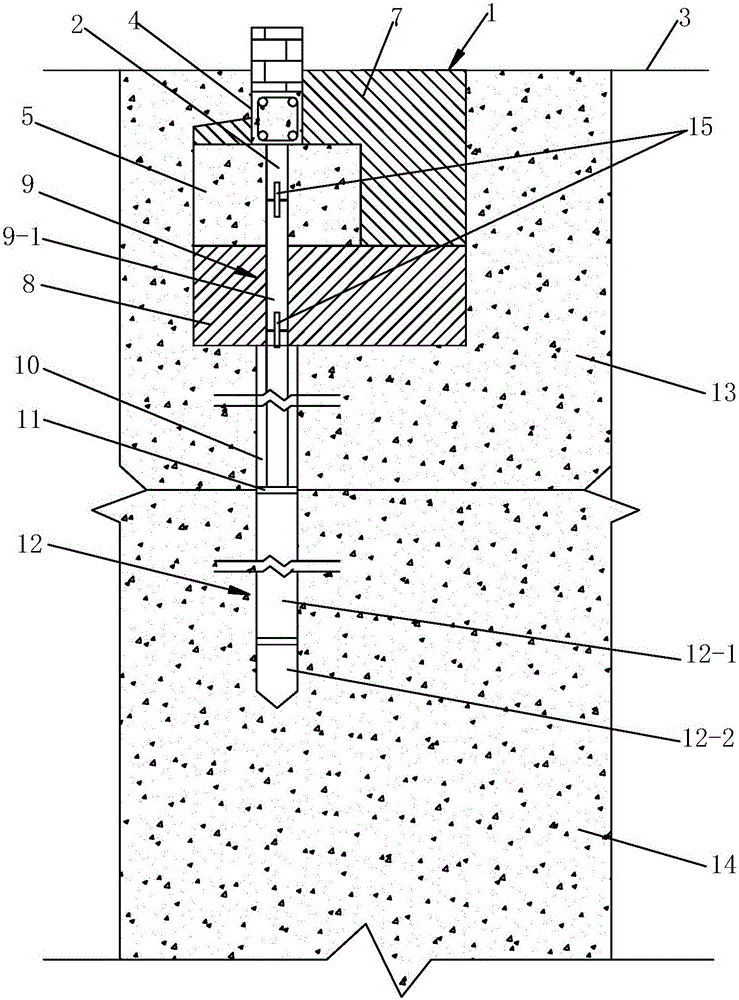

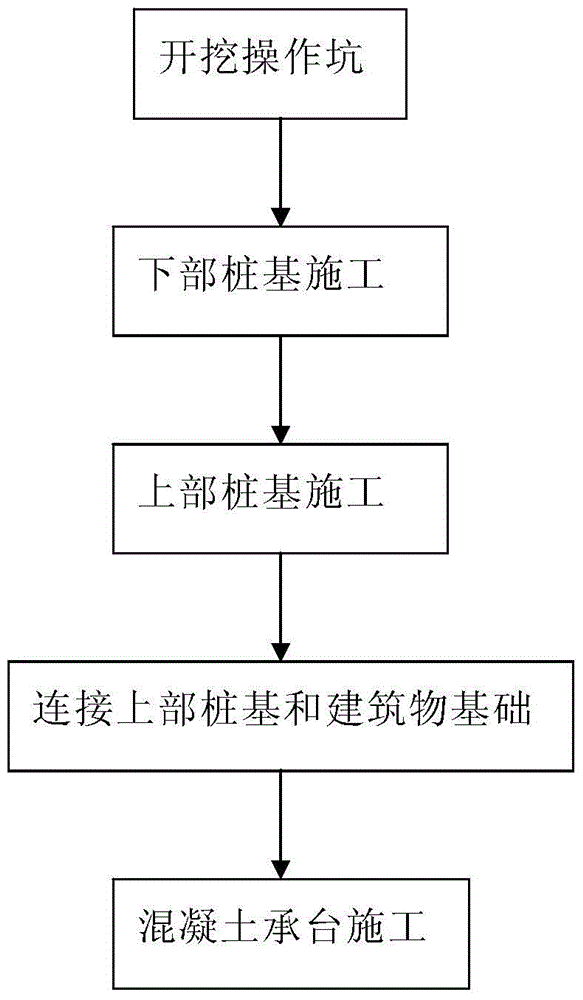

Collapsible loess area building foundation reinforcing pile and pile pressing construction method thereof

ActiveCN105220720AEliminate the effects ofReduce the total pile lengthFoundation repairBulkheads/pilesSoil horizonSelf weight

The invention discloses a collapsible loess area building foundation reinforcing pile. The collapsible loess area building foundation reinforcing pile comprises an upper pile foundation, a lower pile foundation, an underpinning steel pipe and an operating pit. The lower end of the upper pile foundation is connected with the upper end of the lower pile foundation. The upper end of the upper pile foundation sequentially penetrates a self-weight collapsible loess layer and a lower backfill soil layer and stretches into a concrete bearing platform. The lower end of the underpinning steel pipe is connected with the upper pile foundation, the upper end of the underpinning steel pipe is connected with a building foundation, a pile foundation channel is formed in the self-weight collapsible loess layer, and a gap is formed between the upper pile foundation and the side wall of the pile foundation channel. According to the reinforcing pile, the influences of negative friction of the self-weight collapsible loess layer on the upper pile foundation can be effectively eliminated, and it is guaranteed that loads transmitted by the reinforcing pile are borne by friction between the lower pile foundation and a non-collapsible loess layer. The invention further discloses a pile pressing construction method. The method includes the steps of excavation of the operating pit; construction of the lower pile foundation; construction of the upper pile foundation; connection of the upper pile foundation and the building foundation; and construction of the concrete bearing platform. The pile pressing construction efficiency is improved through the pile pressing construction method.

Owner:XIAN UNIV OF SCI & TECH

Rod type core bar bending restrain steel support

InactiveCN101974950BImprove local stabilityImprove buckling resistanceShock proofingBuckling-restrained braceSteel frame

The invention relates to a rod type core bar bending restrain steel support which solves the problems of large difference of rigidity and stability of all directions of an energy dissipation section of the traditional bending restrain support, difficult support installation and complex restrain construction. A core main stress part comprises an energy dissipation section, conversion sections and an installation section, wherein the energy dissipation section is a solid steel bar or hollow steel pipe; an outer restrain steel part comprises a local restrain steel member and an integral restrainsteel member, the local restrain steel member comprises a core bar steel sleeve, the integral restrain steel member comprises a delay steel frame fixed outside the core bar steel sleeve and an auxiliary steel cylinder; one section of the two conversion section is in friction contact with the steel cylinder of the conversion section and a gap is remained between the core bar steel sleeve and the delay steel frame. The section of the energy dissipation section of the support has uniform size in all directions, which eliminates the difference of the rigidity and the stability of different directions, thus the local stable bearing capacity and the integral bending-preventing capacity are high, and the working reliability under large axial direction strain and strong shock is high; and the rodtype core bar bending restrain steel support is convenient for installation, and is suitable for engineering earthquake fortification and reinforcement.

Owner:山西恒晋减震科技股份有限公司

Lattice enhanced type composite material foam core sandwich supporting column and preparation method thereof

The invention discloses a lattice enhanced type composite material foam core sandwich supporting column and a preparation method thereof. A supporting column main body comprises a composite material inner skin and a composite material outer skin which are in cylindrical shapes, foam plate strips are arranged between the composite material inner skin and the composite material outer skin, compositematerial lattices are arranged between the foam plate strips, and the composite material lattices are distributed between the foam plate strips at equal intervals to connect the composite material inner skin with the composite material outer skin together. Supporting face connection flanges for being connected with a top structure or connected with another same supporting column are arranged at the two ends of the supporting column. End enhancing parts are arranged at the two ends of the outer skin of the supporting column. The lattice enhanced type composite material foam core sandwich supporting column can sharply improve the bearing efficiency under the precondition that the self weight of the structure is hardly increased, and meanwhile, the preparation method is low in cost and stable in property, and can prepare the lattice enhanced type composite material foam core sandwich supporting columns with large sizes.

Owner:ARMY ENG UNIV OF PLA

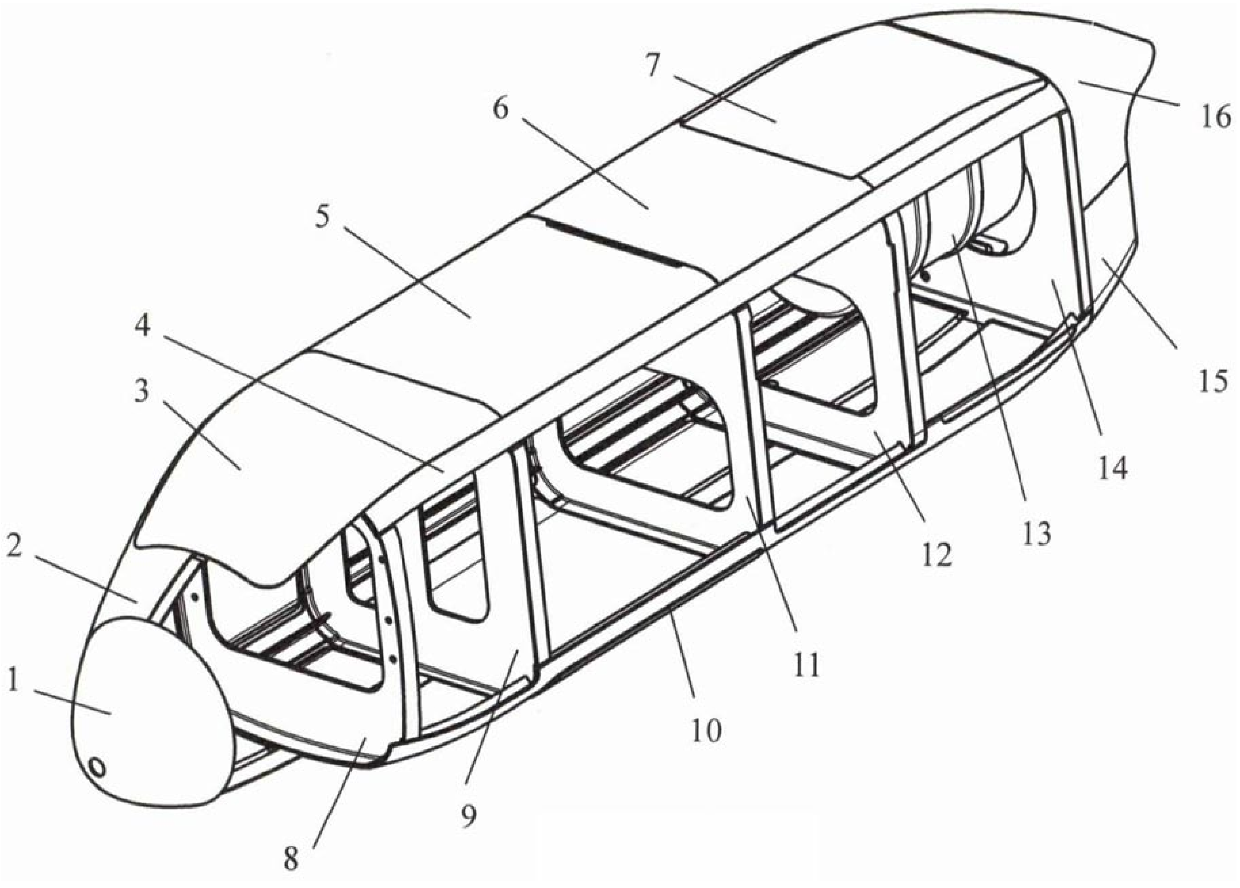

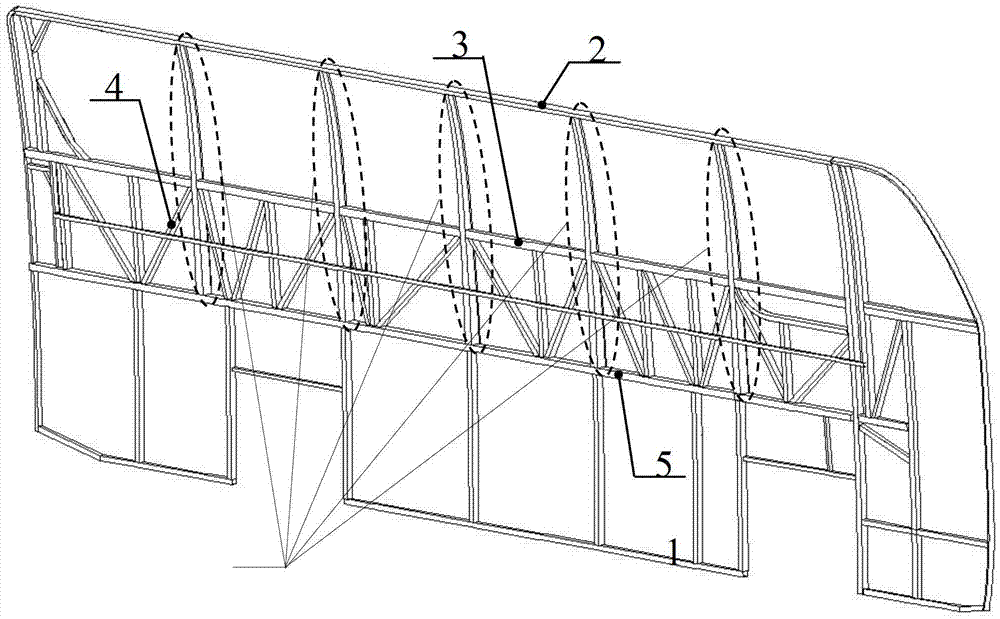

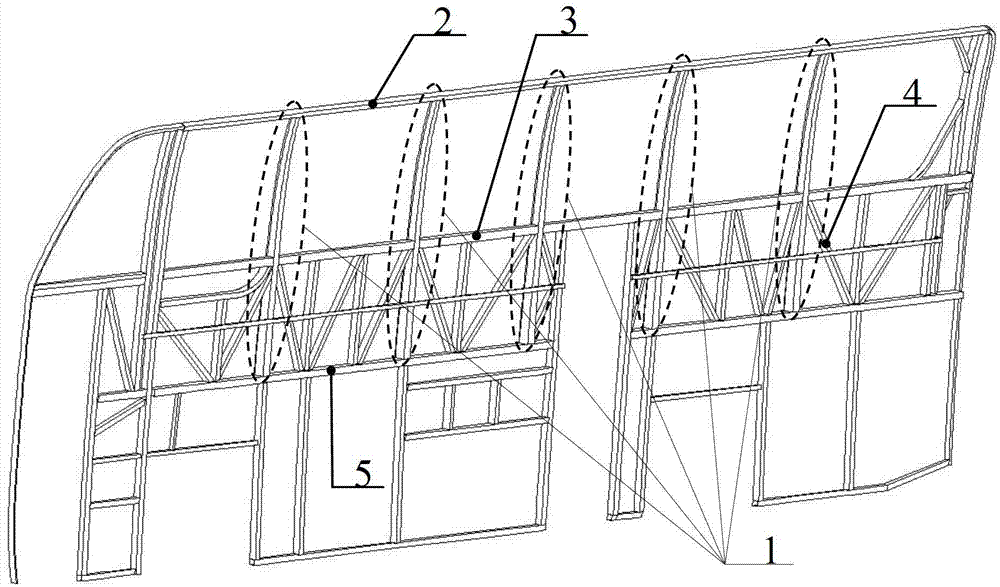

small drone body

The fuselage of a small unmanned aerial vehicle related to the present invention comprises a fuselage box-shaped shell composed of a frame beam as a skeleton and a skin attached thereon, and the frames and beams constituting the fuselage skeleton are made of glass fiber laminated boards. composition. The frame is a frame with ribs on the front and back of the web, and the section is I-shaped; the beam is a longitudinal member with ribs, a reinforcing rib in the middle, and a T-shaped section; The body skin is a non-metallic honeycomb core / glass fiber panel co-cured sandwich panel. The present invention adopts the glass fiber composite material cured at room temperature with lower cost and the main surface part adopts light non-metallic honeycomb core and glass fiber panel to co-cure the interlayer, and its reduced weight is more than 30% lighter than that of aluminum alloy material. The cost can be reduced by more than 60%. It not only greatly reduces the weight and cost of the aircraft, but also has higher specific stiffness and strength.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

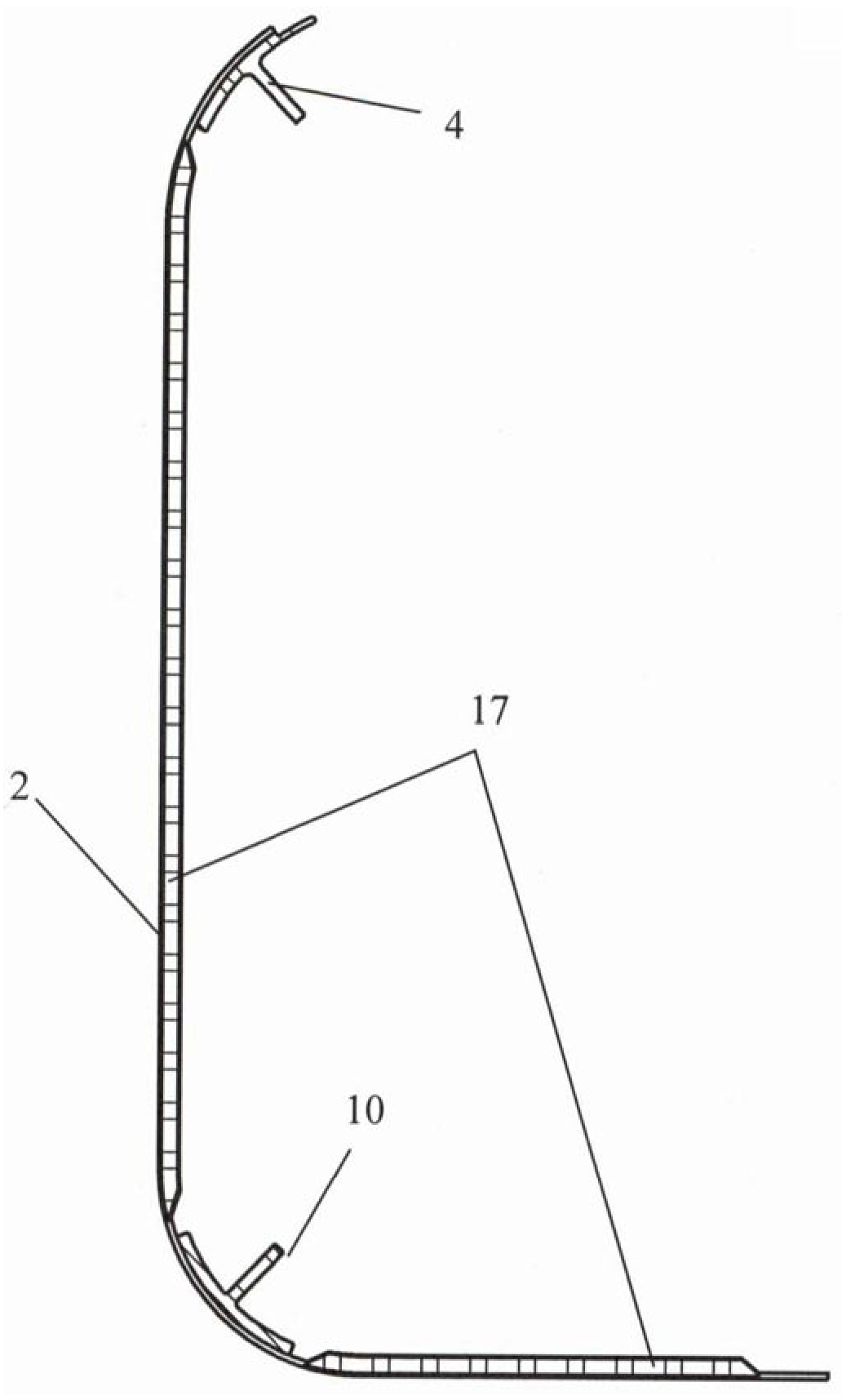

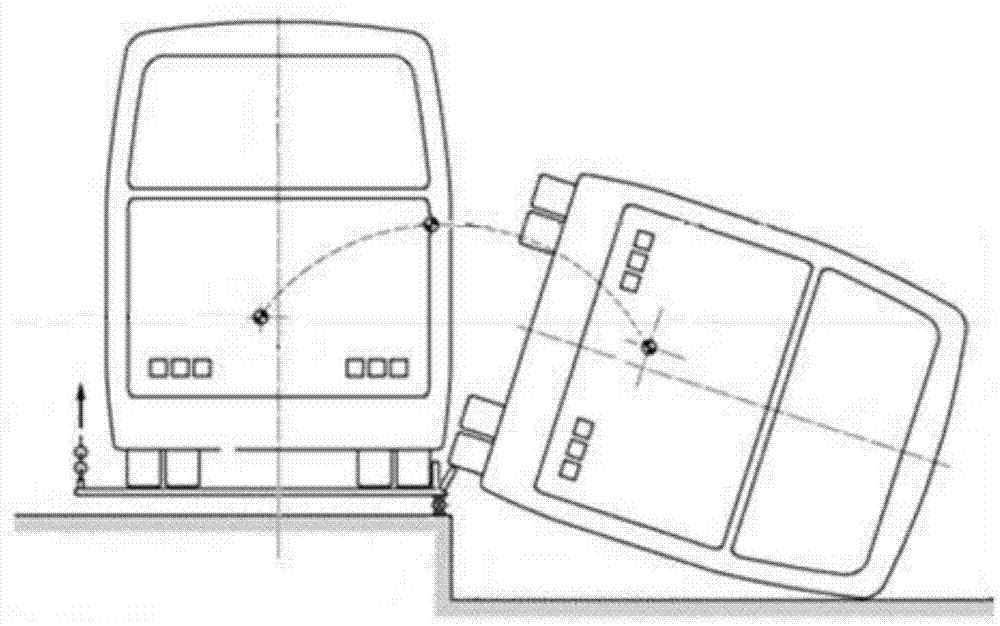

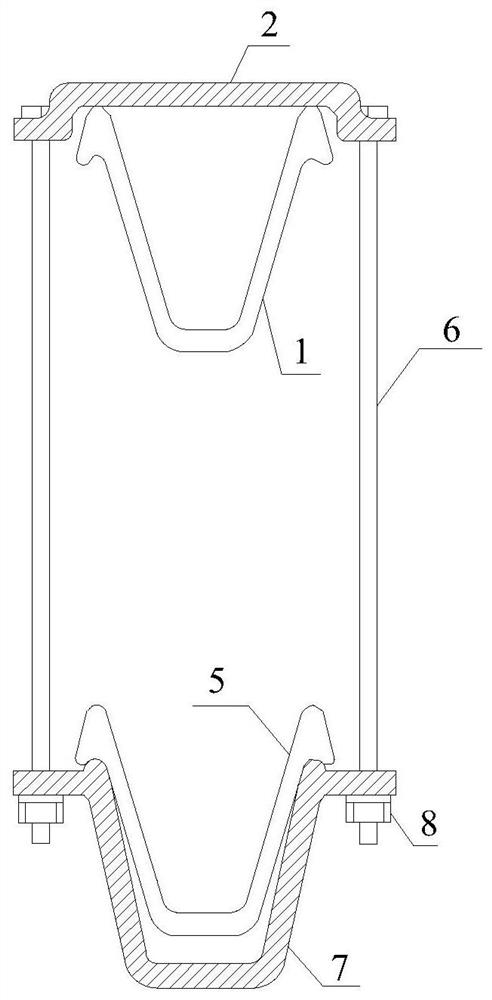

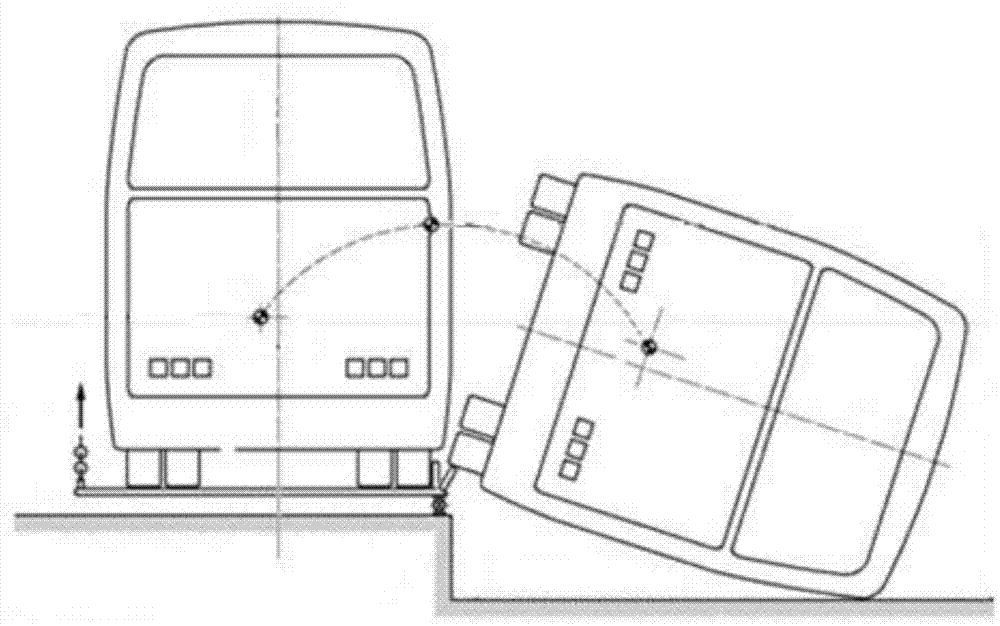

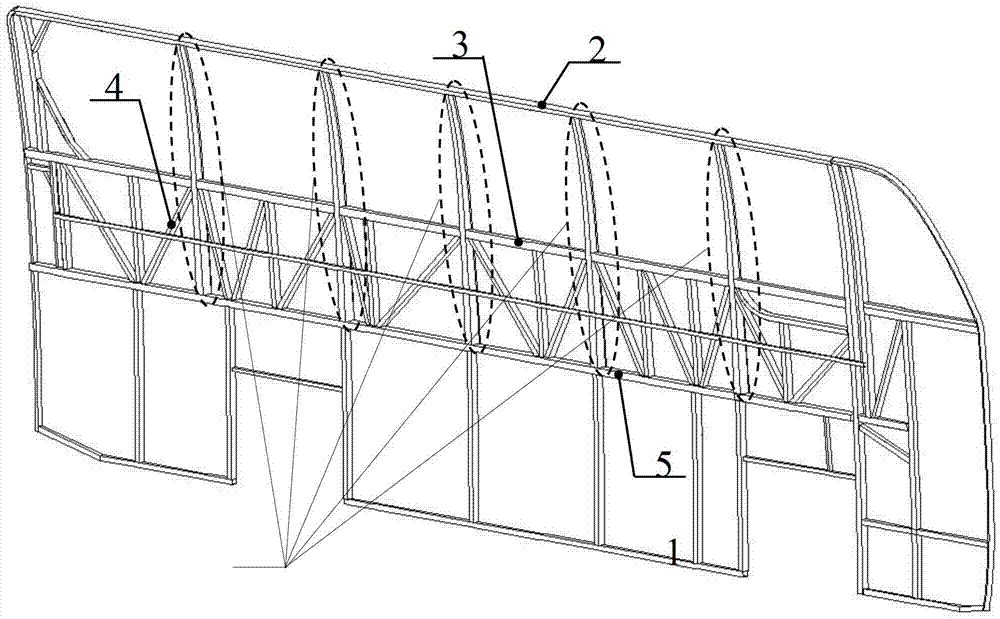

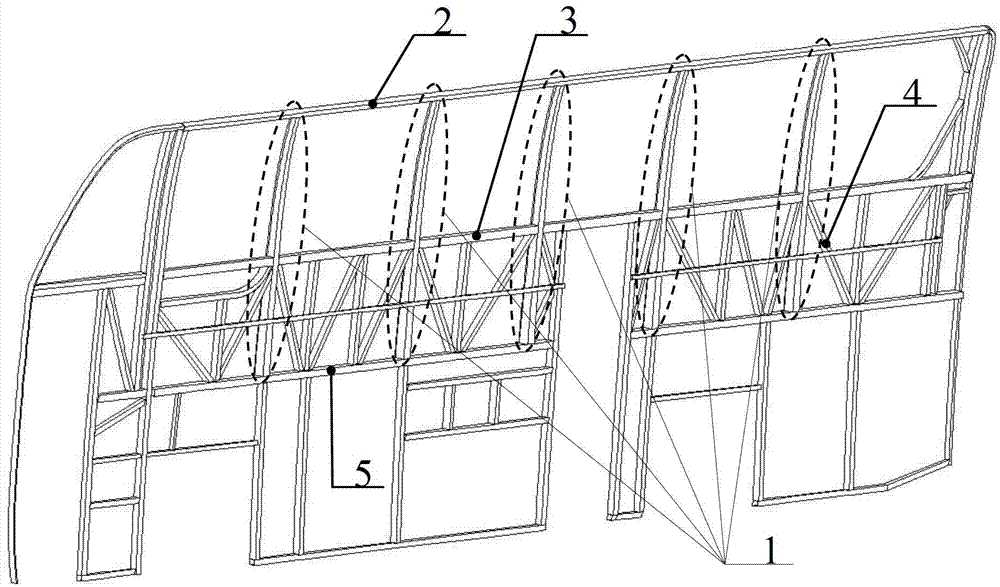

Side wall vertical pillar structure of variable-cross-section passenger car

InactiveCN103085887AImprove rollover safety performanceUniform denaturationSuperstructure subunitsRolloverEngineering

The invention relates to the technical field of passenger car security protection, in particular to a side wall vertical pillar structure which is capable of remarkably improving rollover security performance of a variable-cross-section passenger car. The side wall vertical pillar structure of the variable-cross-section passenger car is formed by an outside plate structure (6) and a U-shaped inner plate structure (7) in a welding mode, the width of the outside plate structure (6) from a top longitudinal beam (2) to a window waist beam (3) is the same, and from the window waist beam (3) to a lower waist beam (5), the width increases gradually from top to down. The cross-section size of the U-shaped inner plate structure (7) increases gradually along the vertical pillar length direction from top to bottom, the width of each cross-section of the U-shaped inner plate structure is (7) smaller than the cross-section width of the outside plate structure (6) at the same cross-section portion, a welding lap joint area with equal width is arranged on a joint of the U-shaped inner plate structure (7) and the outside plate structure (6). The side wall vertical pillar structure of the variable-cross-section passenger car is capable of guaranteeing that in the rollover process, the collision moment of the side wall vertical pillar of the passenger car body is matched with the pillar cross-section size, the degeneration of the side wall vertical pillar is enabled to become even, and the rollover security performance of the passenger car is improved. .

Owner:JILIN UNIV

Steel tube anti-flex energy dissipation support

InactiveCN100451259CIncrease constraint stiffnessAvoid local instabilityLoad-supporting elementsShock proofingHysteresisAxial force

Owner:TSINGHUA UNIV

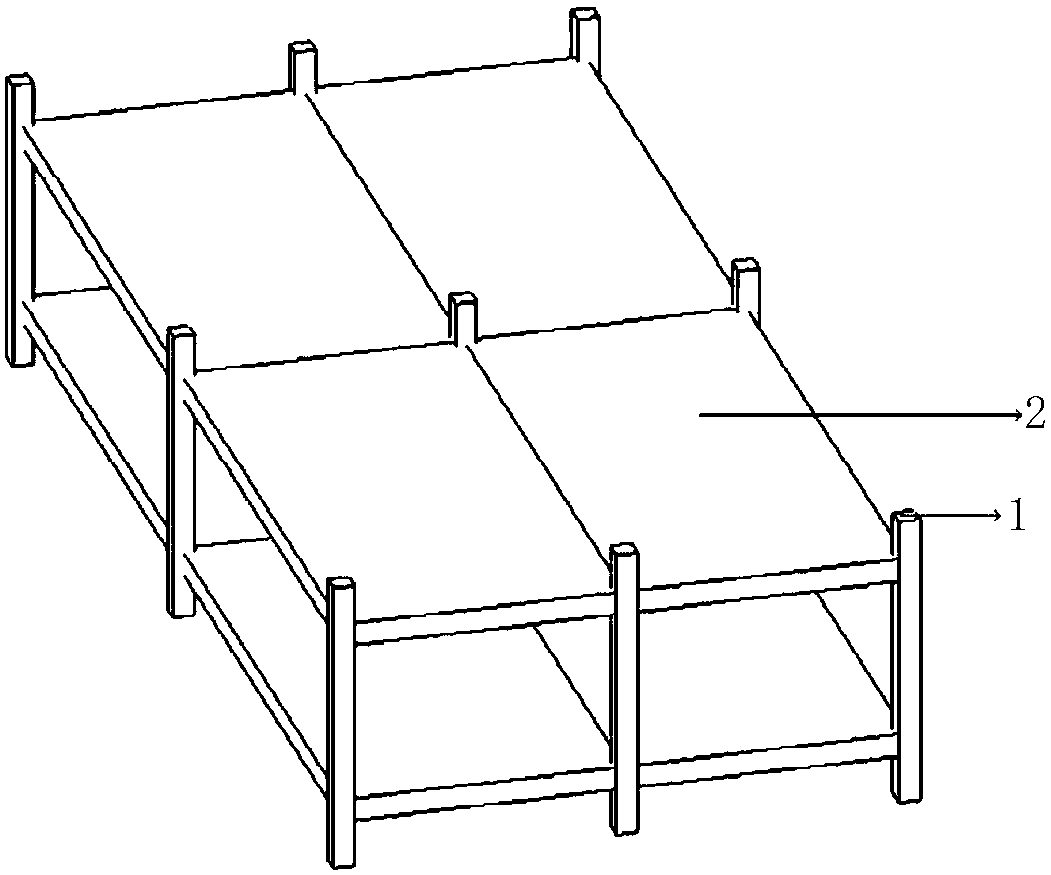

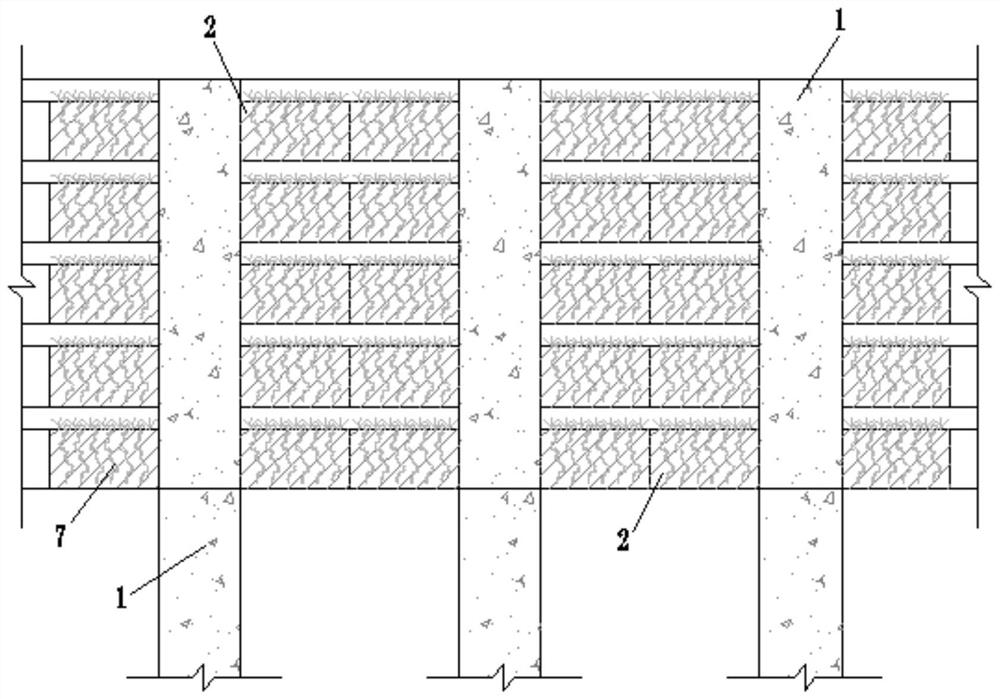

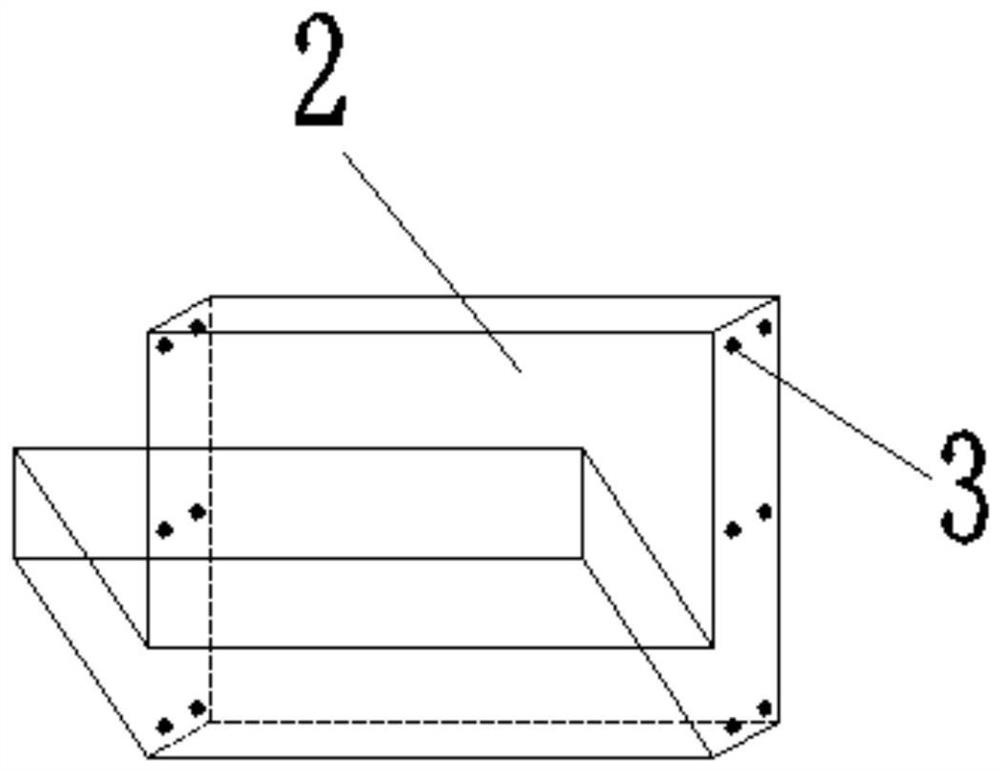

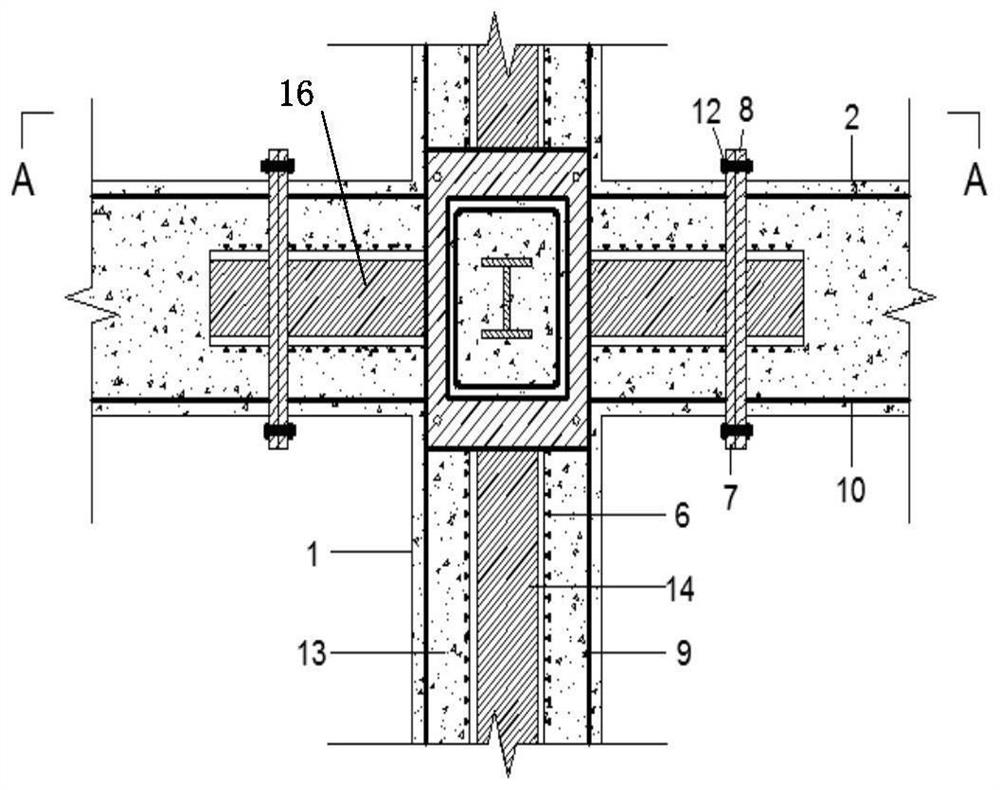

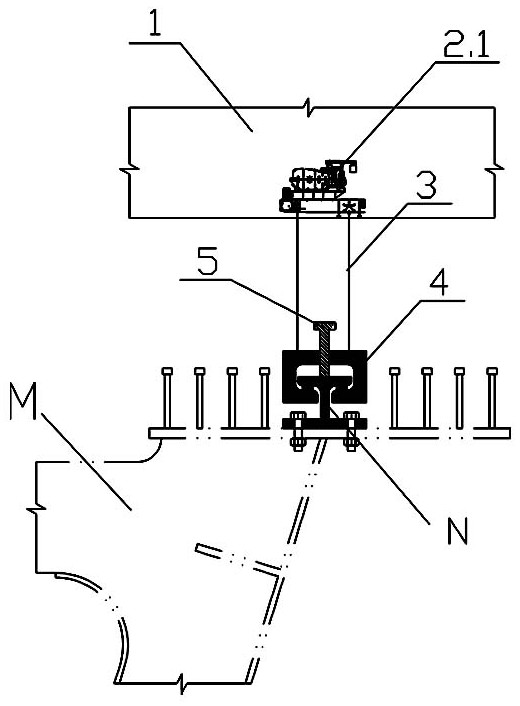

Square steel pipe column-concealed beam floor slab fabricated system adopting Z-shaped connecting

The invention provides a square steel pipe column-concealed beam floor slab fabricated system adopting Z-shaped connecting, and belongs to the technical field of structural engineering. The square steel pipe column-concealed beam floor slab fabricated system adopting Z-shaped connecting comprises square steel pipe columns, concealed beam floor slab modules and Z-shaped joints. Beams prefabricatedin a factory serve as frames of beam-slab overall modules, and prefabricated concrete is poured at the bottoms of the beams; in the construction site, the concealed beam floor slab modules and the square steel pipe columns are connected through the Z-shaped joints; then pipelines can be freely laid on prefabricated concrete layers, the pipelines between the different slabs penetrate through holesin beam webs, and after laying is completed, lightweight concrete is poured; and through beam-slab integration of the concealed beam floor slabs, upper flanges and lower flanges of the beams are pre-embedded in the concrete of the floor slabs, thus the local stability of components is improved, and the problems of fire protection and corrosion prevention of the steel structural beams are solved. Through the modes that the holes are formed in the webs and the floor slabs are poured in a layered mode, individualized arrangement of the pipelines is facilitated, and later maintenance and transformation are convenient; and factory and fabricated modes are combined, the construction speed is increased, and the square steel pipe column-concealed beam floor slab fabricated system adopting Z-shapedconnecting adapt to development of a fabricated steel structure.

Owner:BEIJING UNIV OF TECH

Double buckling-restrained steel brace for continuous restraint on yield thin wall surface

InactiveCN101949171AImprove stabilityConstraint structure is reasonable and effectiveShock proofingEarthquake intensitySheet steel

The invention specifically discloses a double buckling-restrained steel brace for continuous restraint on yield thin wall surface, which solves the problems of inferior reliability and durability and difficult engineering connection and installation of full-steel buckling restrained brace under the action of strong vibration; a core axial force steel comprises a yield segment, a transition segment and a connection segment, wherein the yield segment and the transition segment are sleeved with sealed outer layer restrained steel sleeves, the yield segment is a thin-wall steel slat with the rectangular cross section, the connection segment comprises two parallel connecting steel plates, the yield segment is circumferentially provided with a continuous restraint part comprising two restraint steels, and both the two restraint steels are continuously provided, in the axial direction of the yield segment, with thin-wall steel limbs which are close to the thin wall surface and parallel to the thin wall surface of the yield segment. Such a brace performs continuous restraint on the thin wall surface of the yield segment and is provided with the sealed outer layer restrained steel sleeves, thereby enhancing performance stability, reliability and durability thereof under the dynamic action of strong vibration, in addition, the brace according to the invention has easy manufacturing and convenient installation and is used for earthquake-against fortification and reinforcement, especially for the seismic disaster prevention of important projects in high-earthquake-intensity regions.

Owner:山西恒晋减震科技股份有限公司

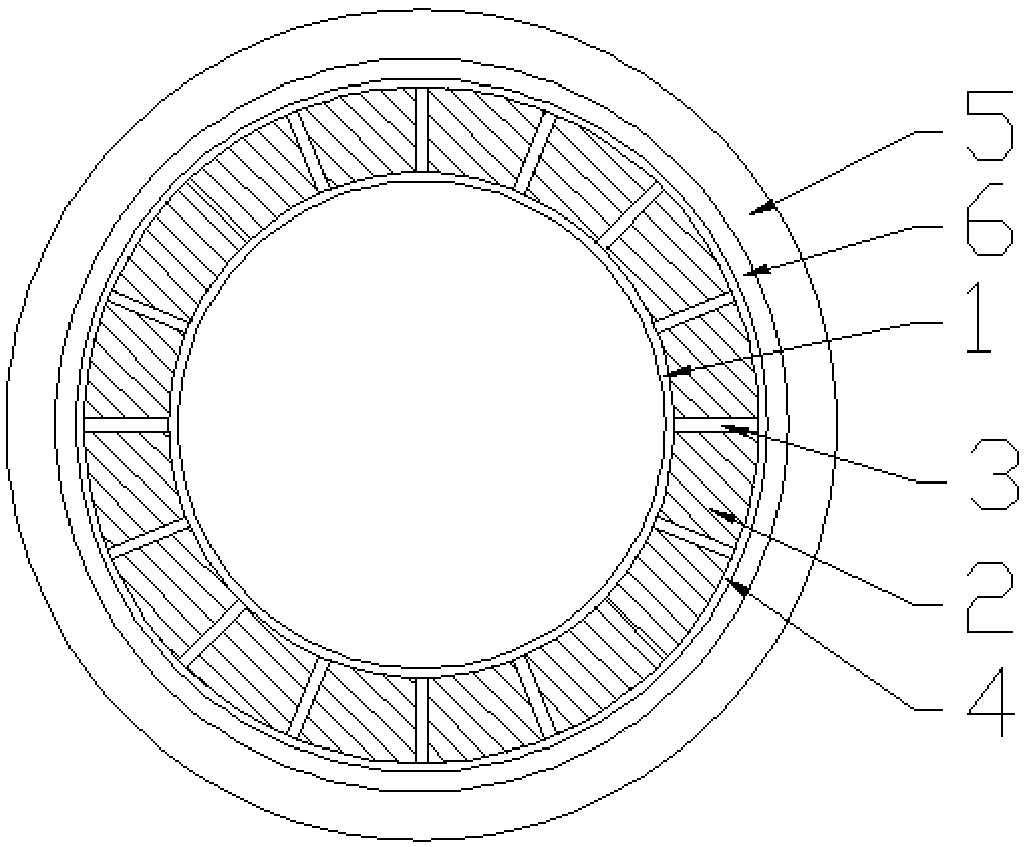

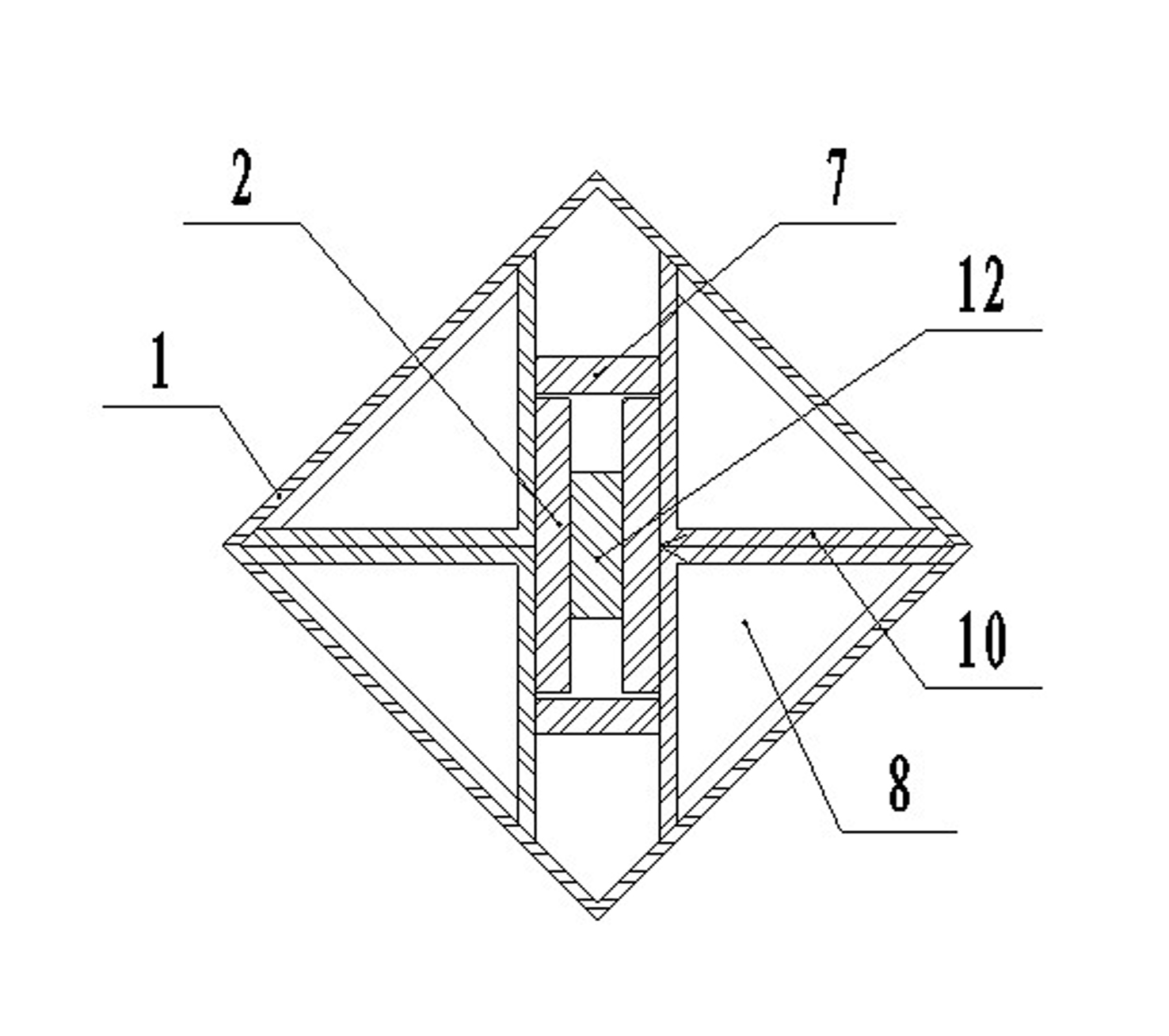

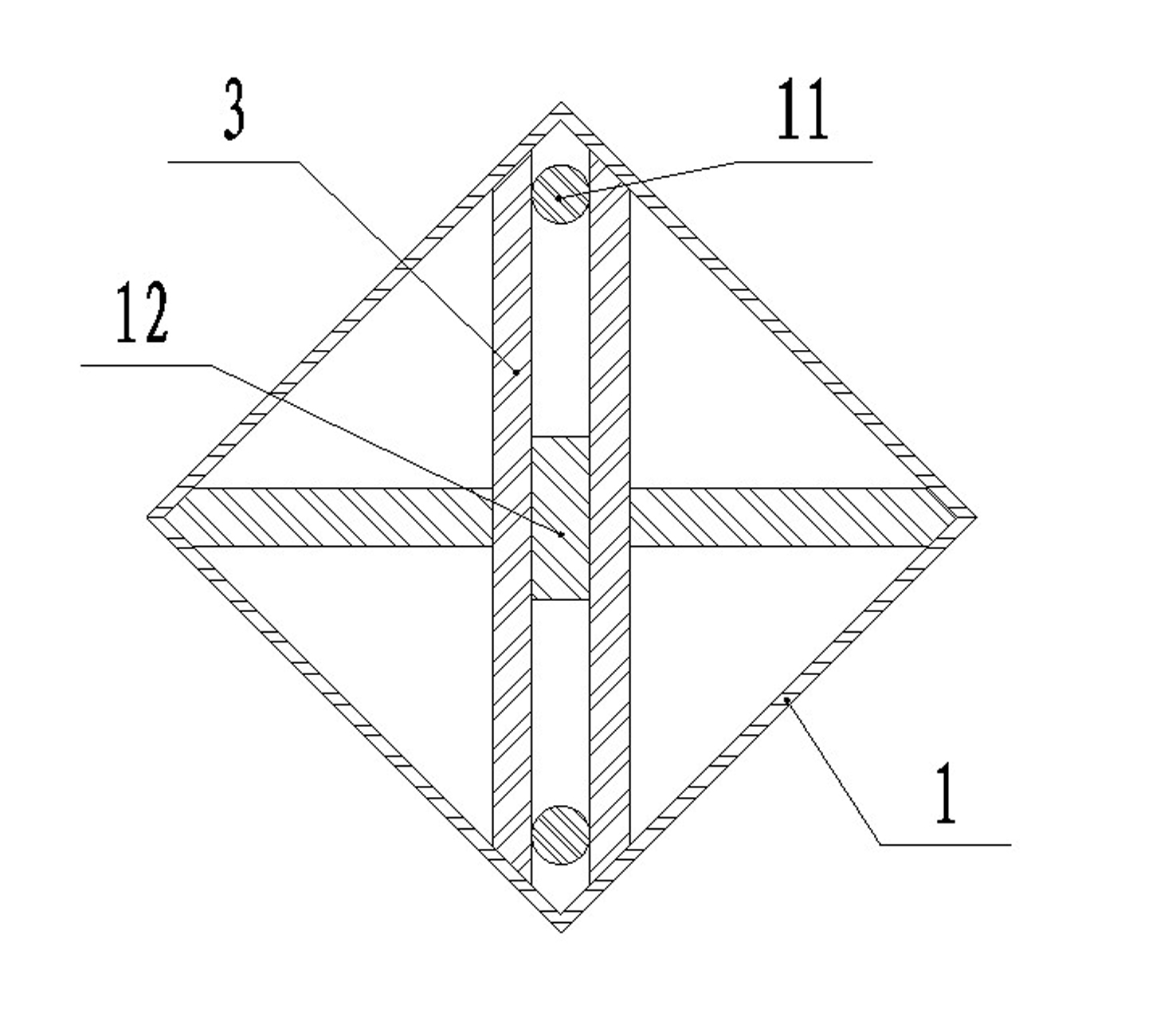

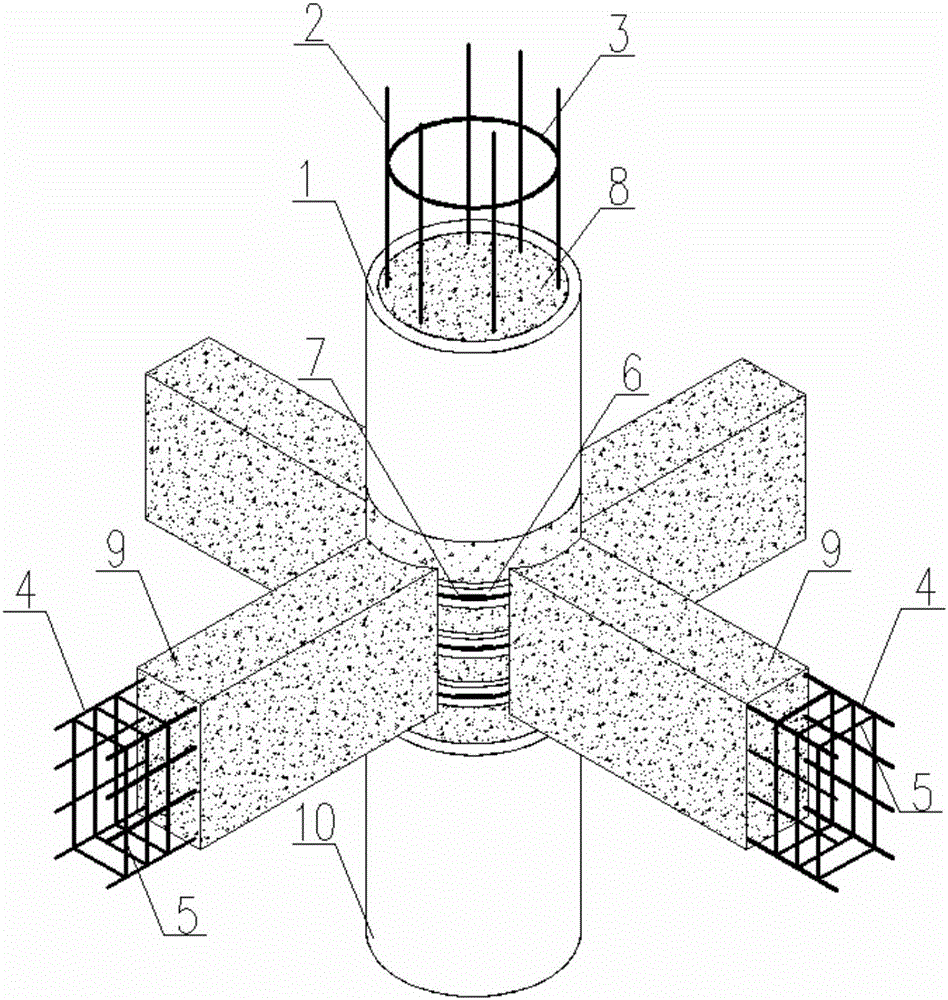

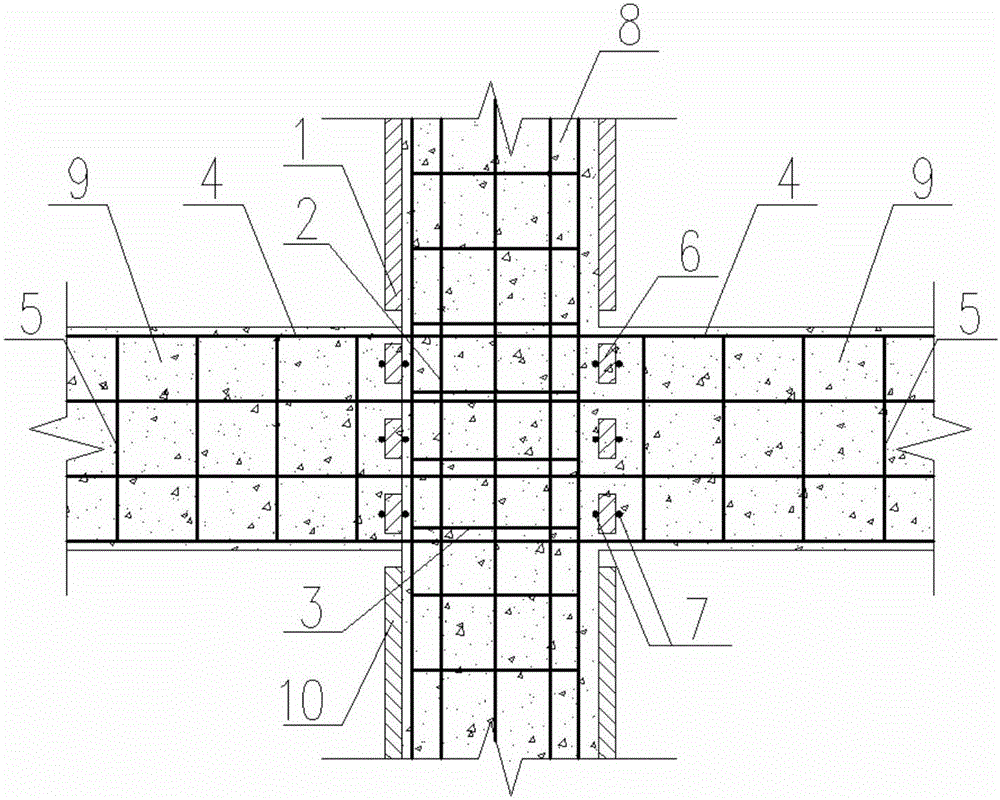

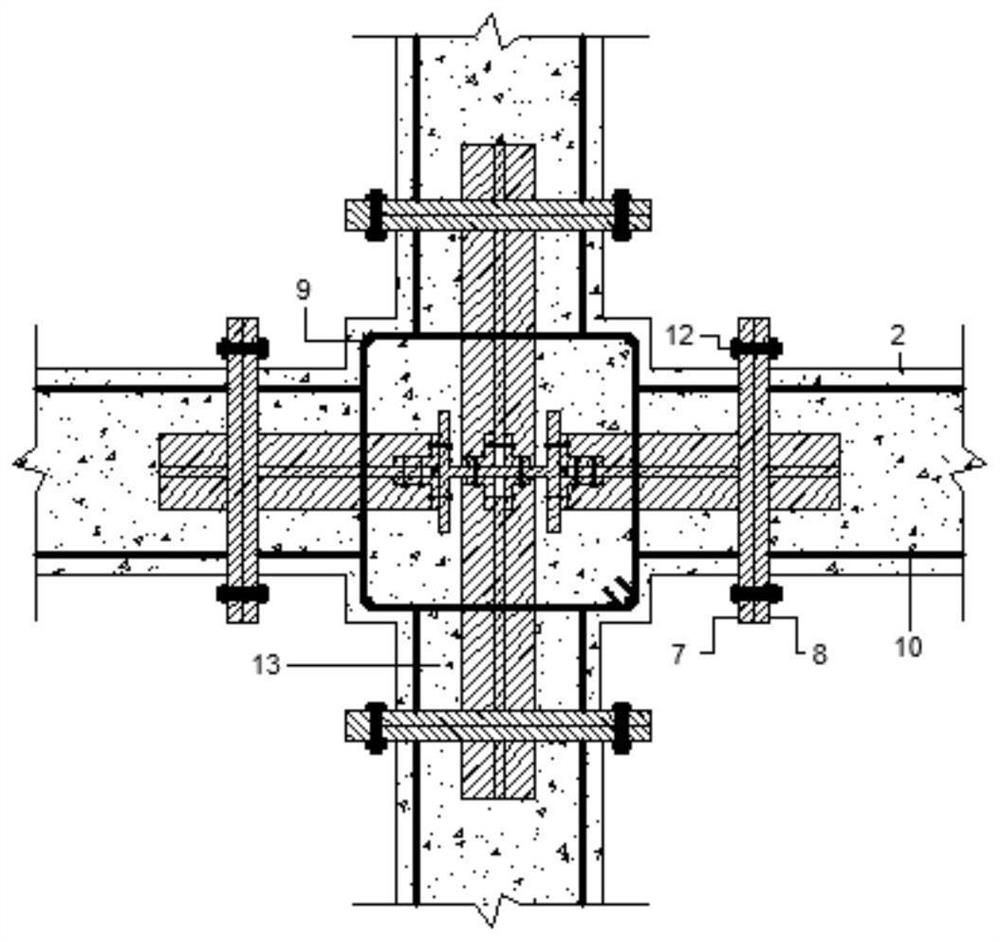

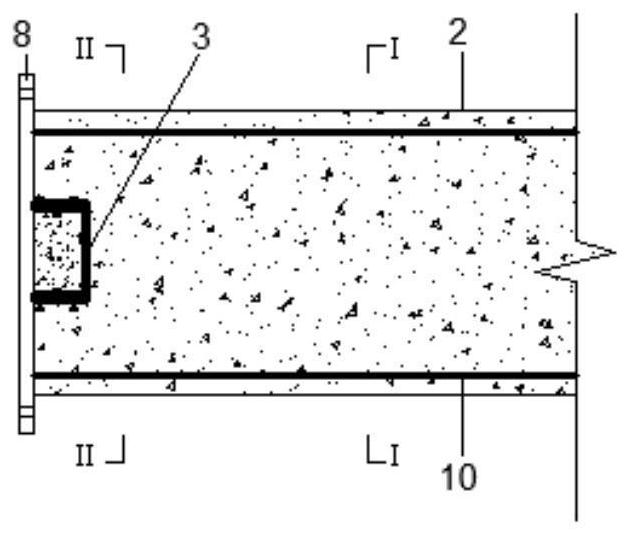

Structure of reinforced circular steel tube confined concrete column-beam joint

InactiveCN105937266AImprove axial compression performanceImprove deformation abilityBuilding constructionsAxial compressionConcrete beams

The invention discloses a structure of a reinforced circular steel tube confined concrete column-beam joint. According to the structure, joint area steel rings are arranged between an upper column body steel tube and a lower column body steel tube; anti-shear rings are welded to the inner surfaces and the outer surfaces of the joint area steel rings respectively; longitudinal beam bars penetrate through a joint area through gaps formed among the joint area steel rings and a gap formed between the joint area steel rings and the upper column body steel tube or a gap formed between the joint area steel rings and the lower column body steel tube; the longitudinal beam bars and beam stirrups are bound together to form steel bar concrete beam steel bar cages; longitudinal column bars penetrate through the upper column body steel tube, the joint area steel rings and the lower column body steel tube to be bound together with column stirrups to form tube-inside steel bar cages of the upper column body steel tube, the lower column body steel tube and the joint area steel rings; beam concrete is poured into the steel bar concrete beam steel bar cages; column concrete is poured into the tube-inside steel bar cages. According to the structure form of the steel tube confined concrete column-beam joint, manufacture is flexible, and the advantage of improving the axial compression resistance, the deformation performance and the seismic resistance of the joint area is achieved.

Owner:ARCHITECTURAL DESIGN & RES INST OF SOUTH CHINA UNIV OF TECH

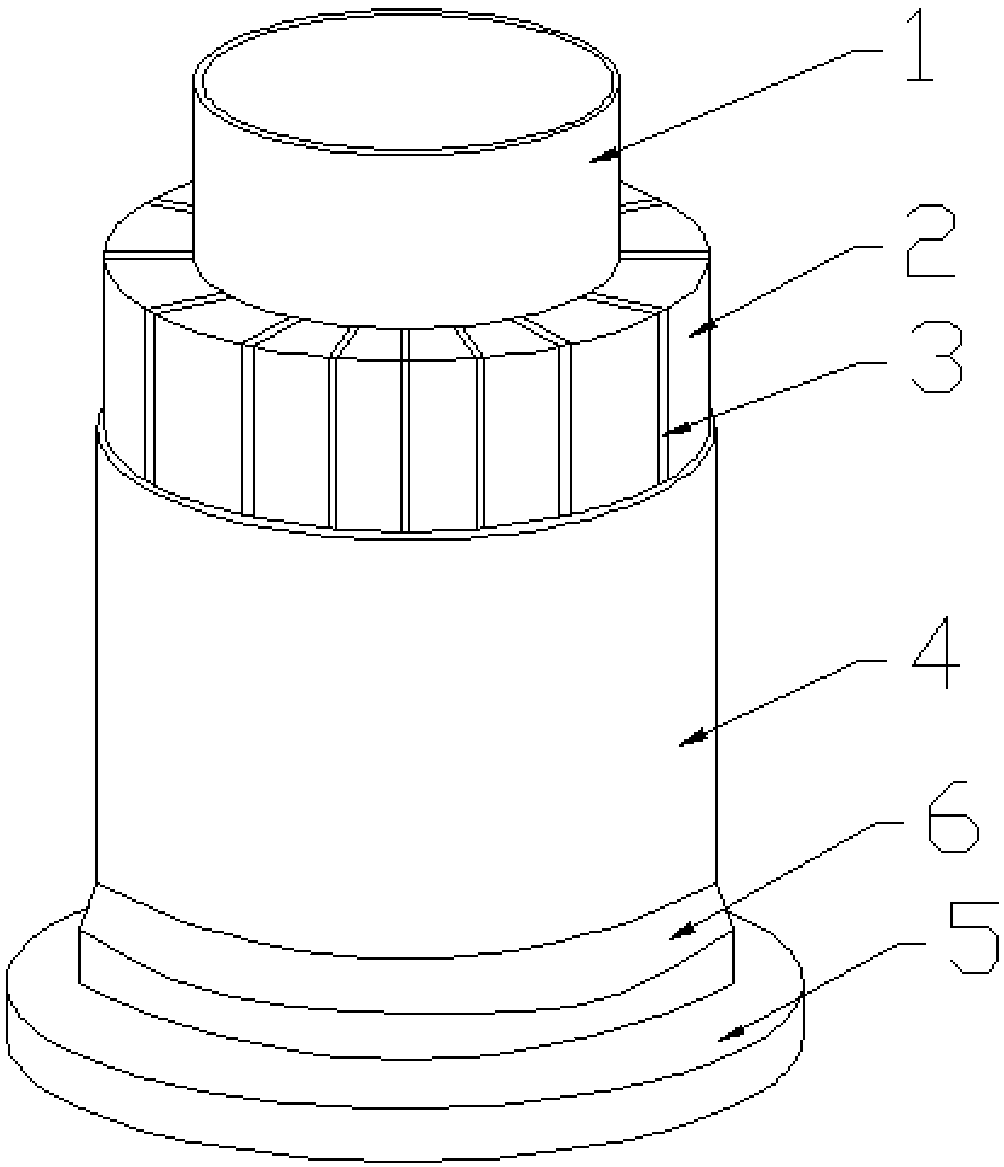

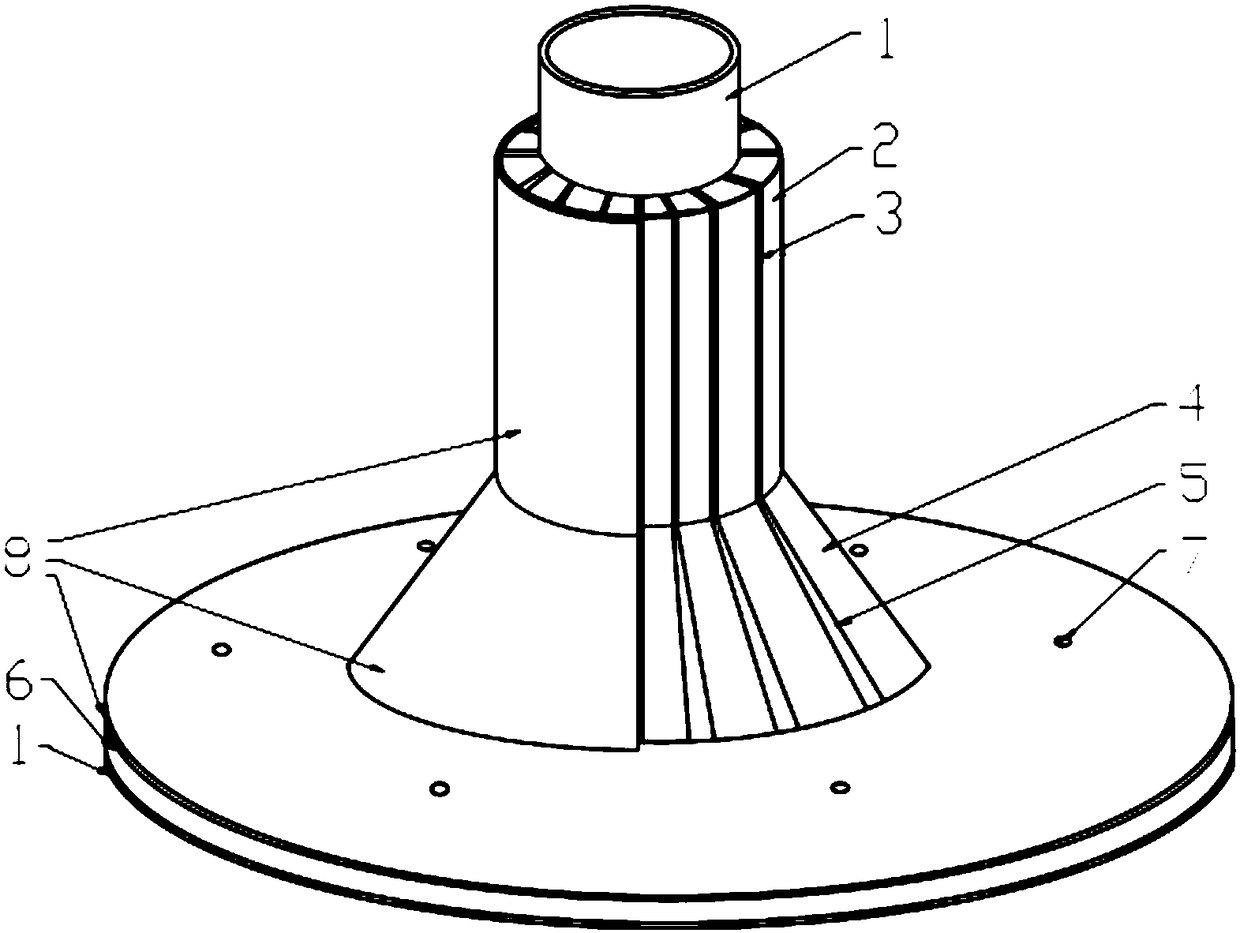

Hub type rigid flange of rib-added composite foam sandwich barrel and preparation method thereof

The invention discloses a hub type rigid flange of a rib-added composite foam sandwich barrel and a preparation method thereof. The hub type rigid flange is characterized in that a hub type rigid flange body comprises a hub part, a supporting part and a flange part, wherein the hub part is the foam sandwich barrel which is of a hollow cylindrical structure; the supporting part is of a hollow circular table shaped structure; the flange part is of a disc shaped or circular ring shaped structure; one end of the hub part is connected to one small end of the supporting part, and one big end of thesupporting part is connected to the flange part; a connecting flange is arranged at one end of the foam sandwich barrel and is connected to another hub type rigid frame; a steel plate is additionallyarranged in the middle of the flange part. With the adoption of the hub type rigid flange of the rib-added composite foam sandwich barrel, the problem of connecting of the composite foam sandwich barrel can be effectively solved on the premise that the dead weight of the structure is nearly not increased; and meanwhile, the preparation method is provided and is low in cost, stable in performance,and can be carried out to prepare large-size hub type rigid frame of the rib-added composite foam sandwich barrel.

Owner:ARMY ENG UNIV OF PLA

Temporary light soil retaining structure for side slope and construction method

PendingCN112323852AAvoid local instabilityEven by forceArtificial islandsExcavationsHydraulic cylinderSoil science

The invention discloses a temporary light soil retaining structure for side slope and a construction method, the side slope temporary light soil retaining structure comprises a fixing base, fixing rivets, a first sliding rod, a soil retaining plate, a hydraulic cylinder, a second sliding rod, a supporting rod and a drainage pipe, a concrete filling chamber is arranged in the bottom end of the fixing base, and a stainless steel wire mesh is installed at the bottom end of the concrete filling chamber. A pouring pipe communicated with the concrete filling chamber is arranged at one end of the fixing base, a first sliding rod is fixed to the position, close to the other end, of the fixing base, a first sliding sleeve is fixed to the bottom end of the soil retaining plate and slidably connectedwith the first sliding rod, the soil retaining plate is of a trapezoidal structure, and a hydraulic cylinder and a second sliding rod are fixed to the top of the fixing base. The second sliding rod is slidably sleeved with a push block. The push block is connected with the output end of the hydraulic cylinder, a second sliding sleeve is slidably connected to the second sliding rod, the top of thesecond sliding sleeve is hinged to one end of a supporting rod, the other end of the supporting rod is hinged to one side of a soil retaining plate, and a drainage pipe is installed on the other sideof the soil retaining plate. The breast board is firm in supporting and convenient to construct.

Owner:HUNAN UNIV OF SCI & TECH +1

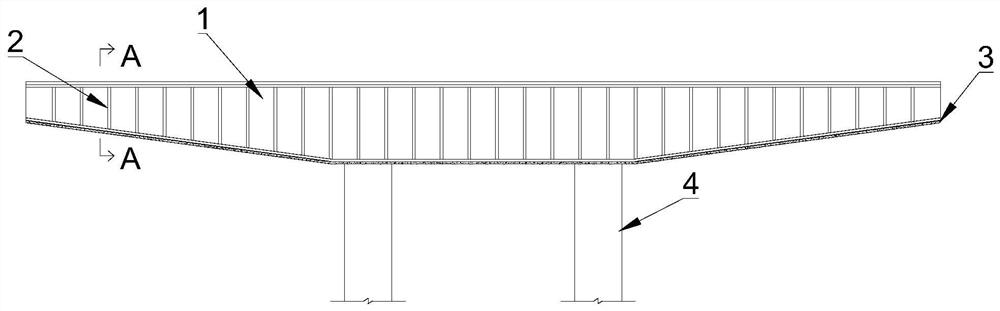

Prestressed UHPC shell-concrete inner core combined cover beam structure and construction method thereof

InactiveCN113605246AReduce usageSmall sizeBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

The invention discloses a prestressed UHPC shell-concrete inner core combined cover beam structure which comprises a cover beam shell, the cover beam shell comprises webs and a bottom plate, multiple webs are connected to the bottom plate, an inner cavity with an upward opening is defined by the webs and the bottom plate, the cover beam shell is a prefabricated UHPC shell, a plurality of reinforcing frames are vertically arranged in the inner cavity, multiple reinforcing frames are arranged in the length direction of the bent cap shell at intervals, and the inner cavity is filled with common concrete inner cores in a pouring mode. The structure has the advantages of being low in self weight, good in durability and high in bearing capacity.

Owner:HUNAN UNIV

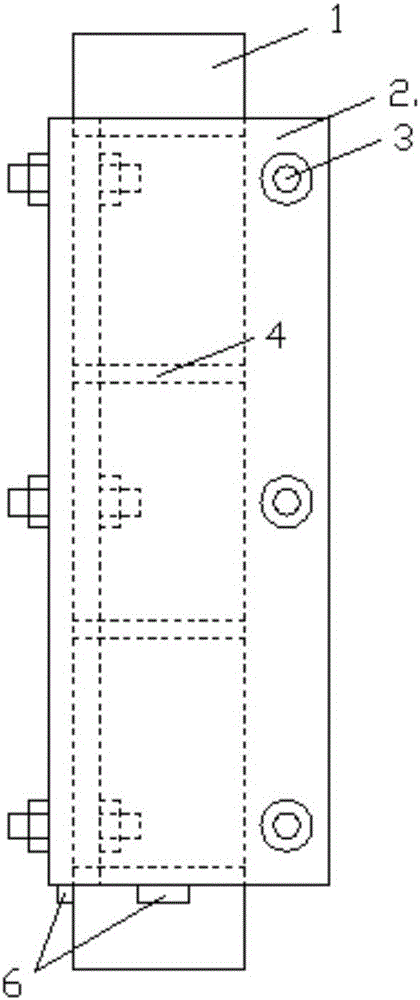

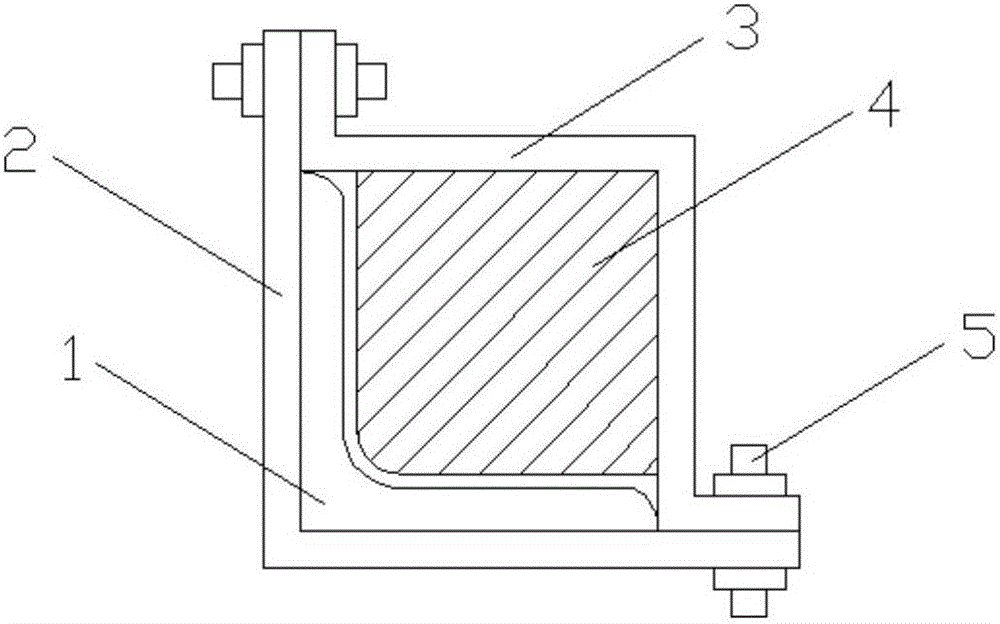

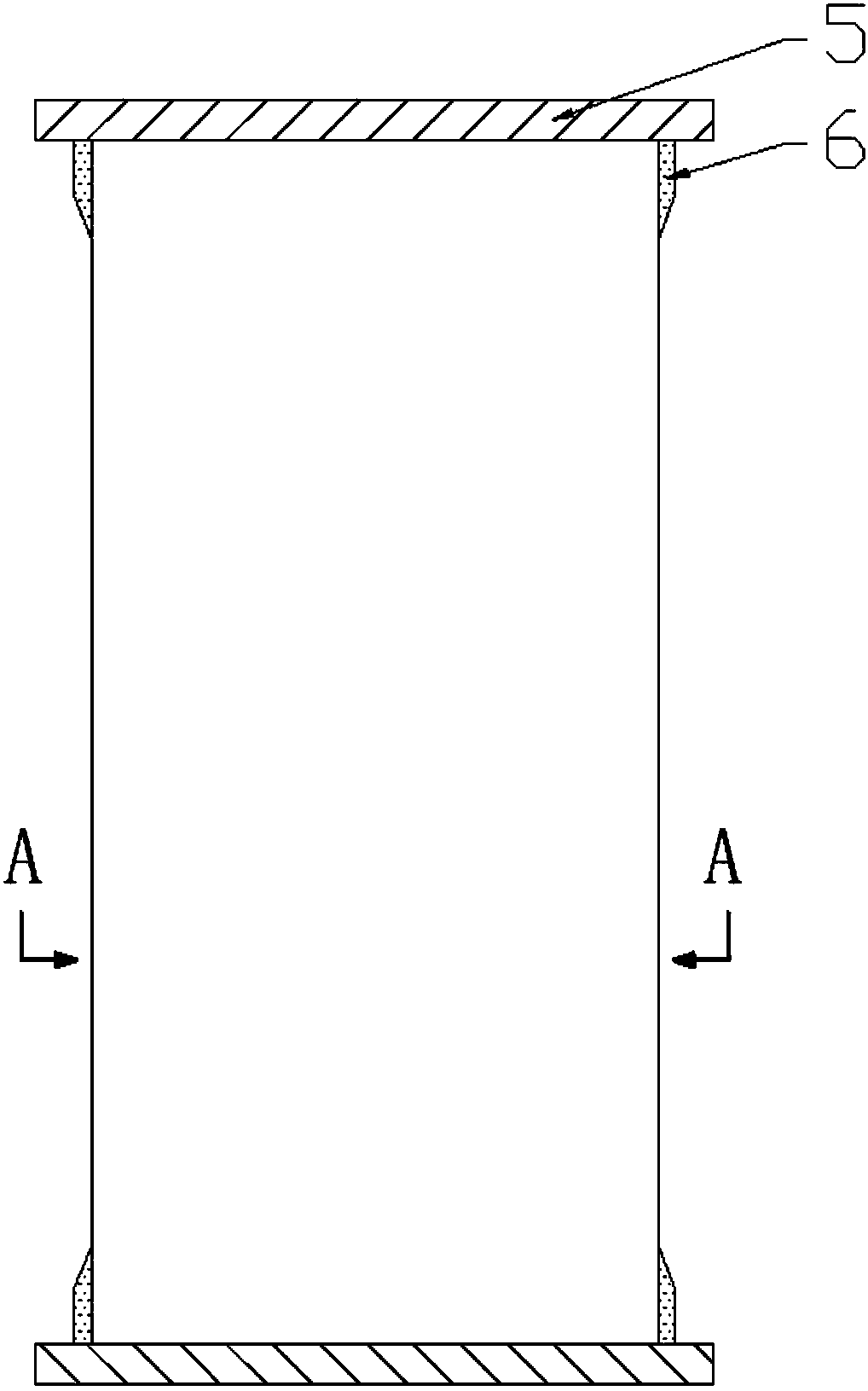

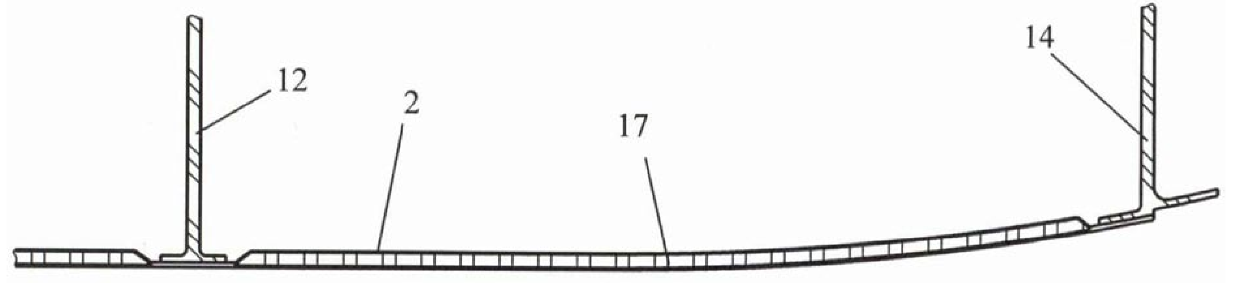

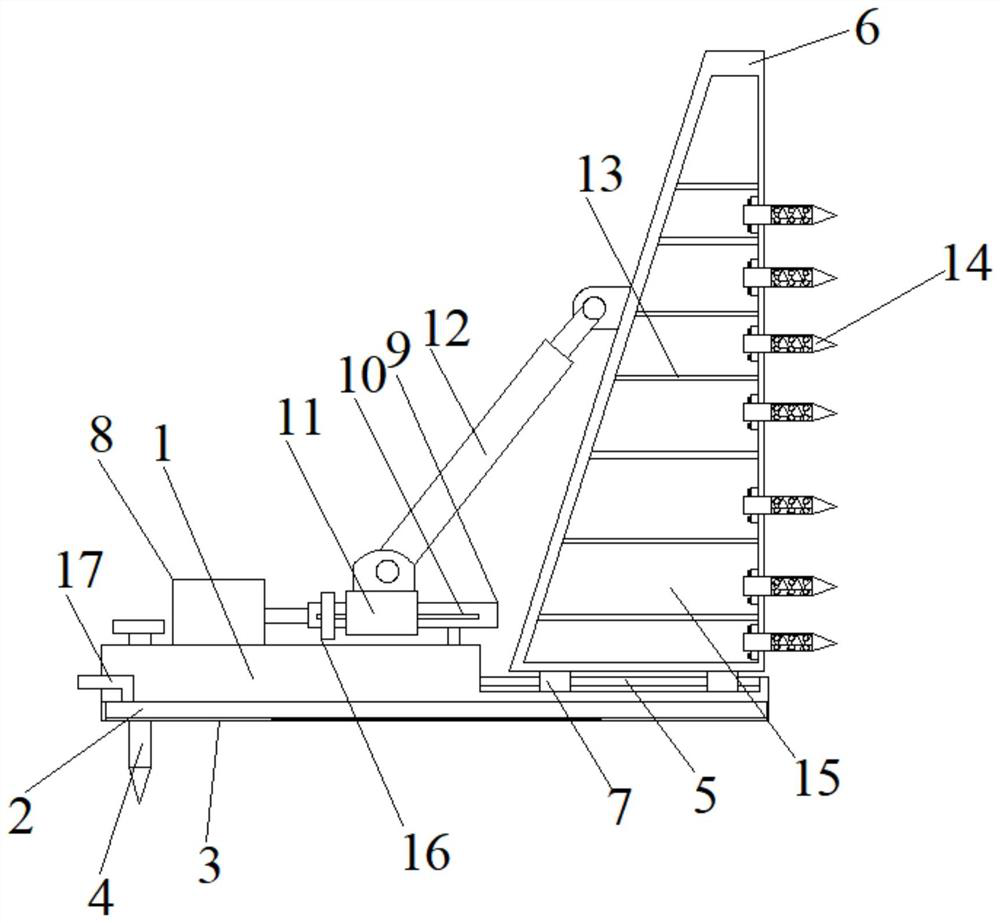

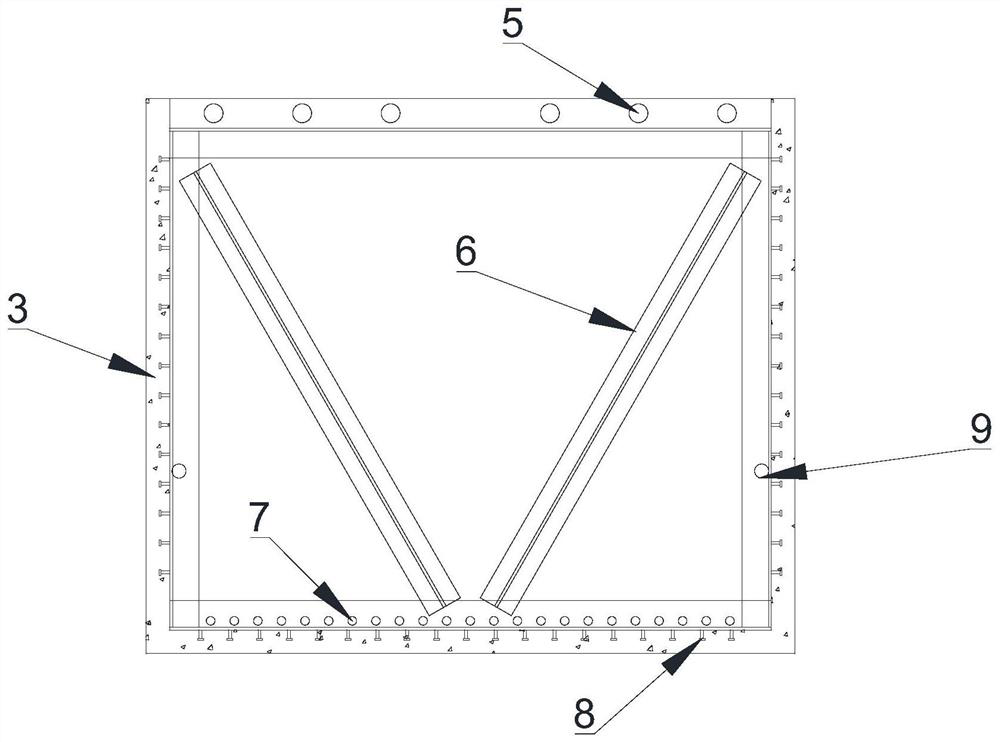

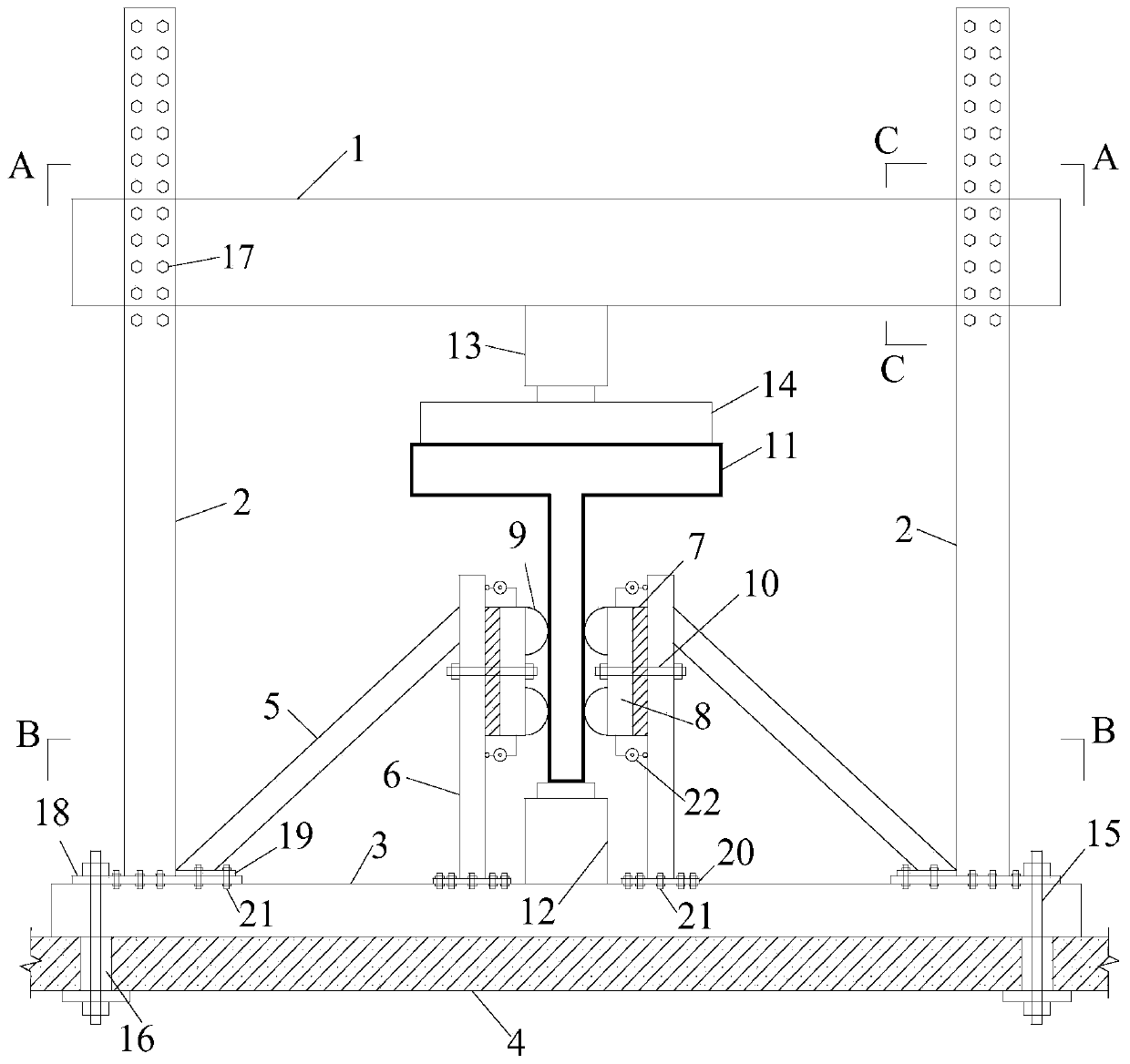

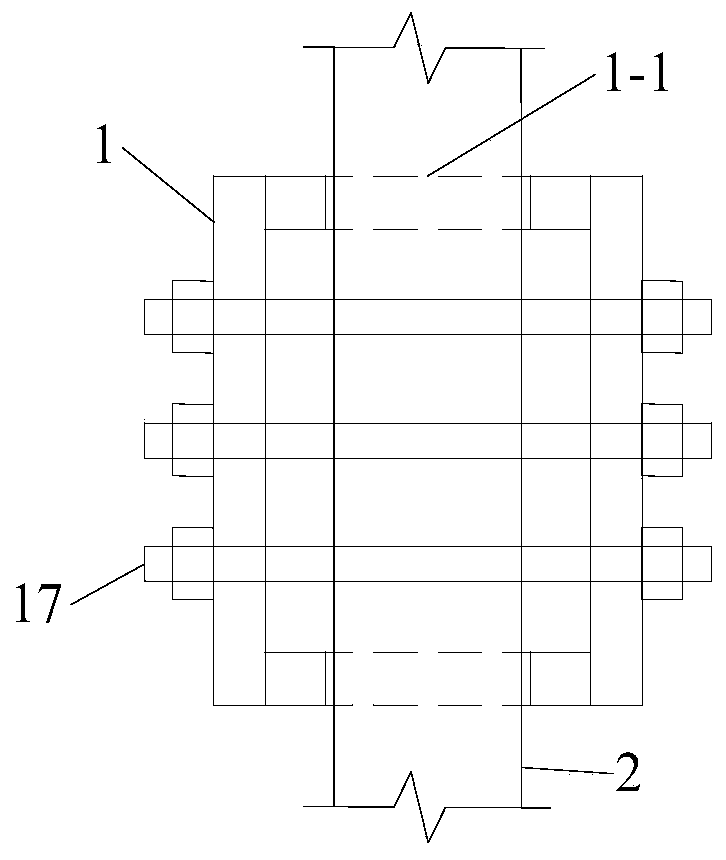

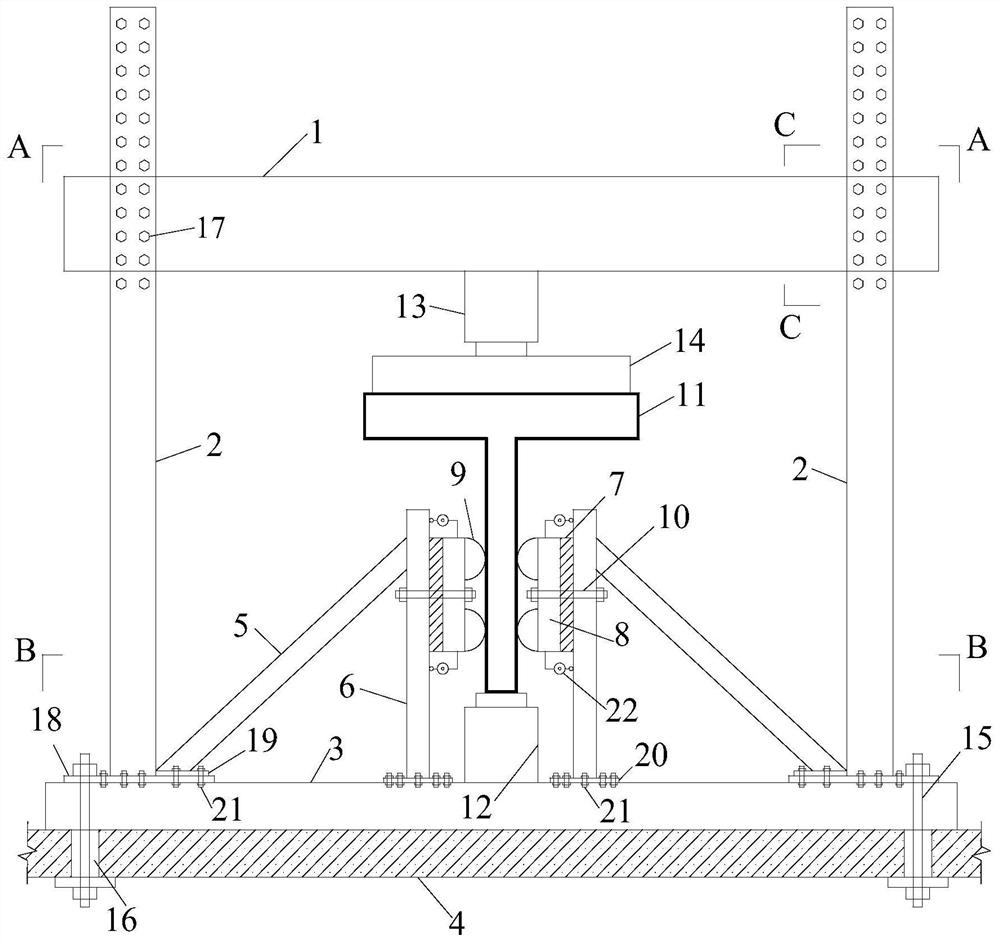

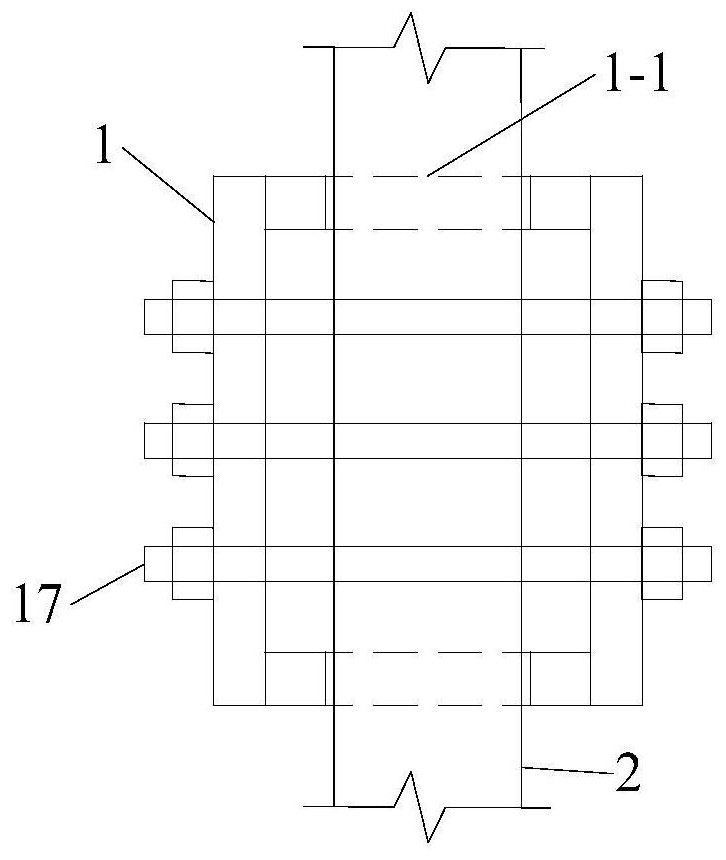

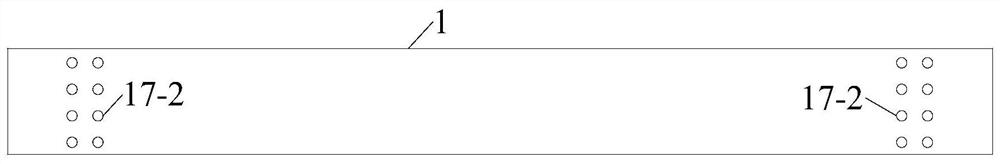

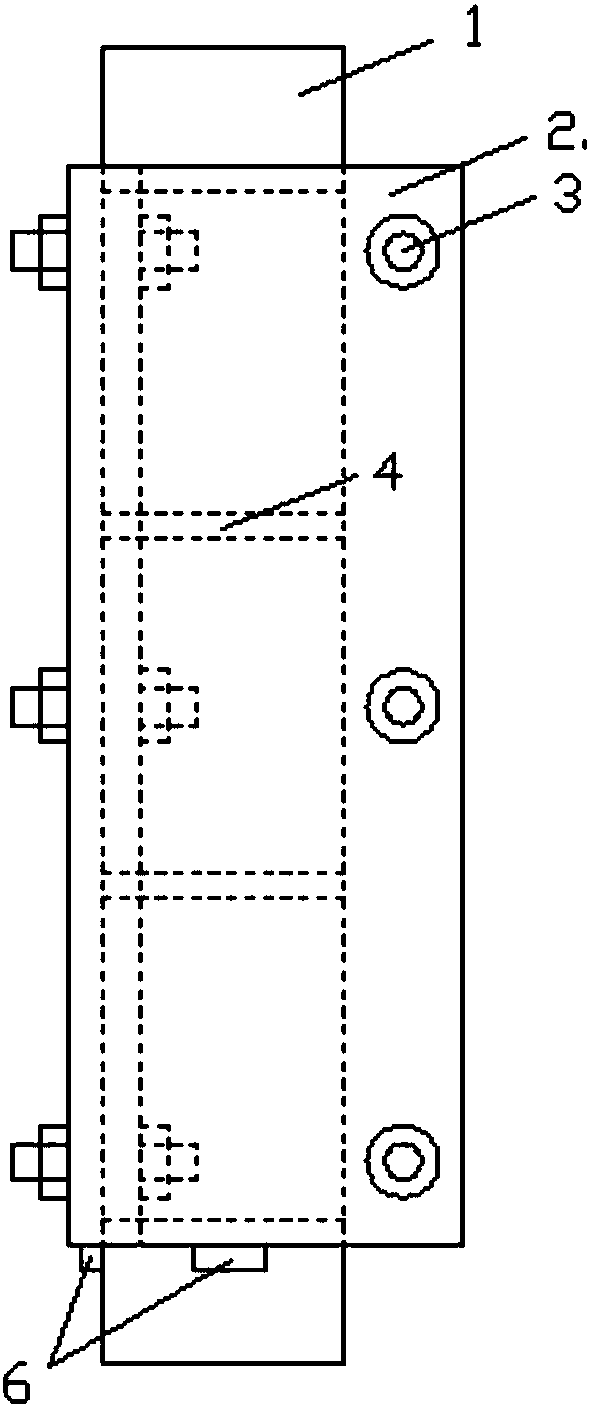

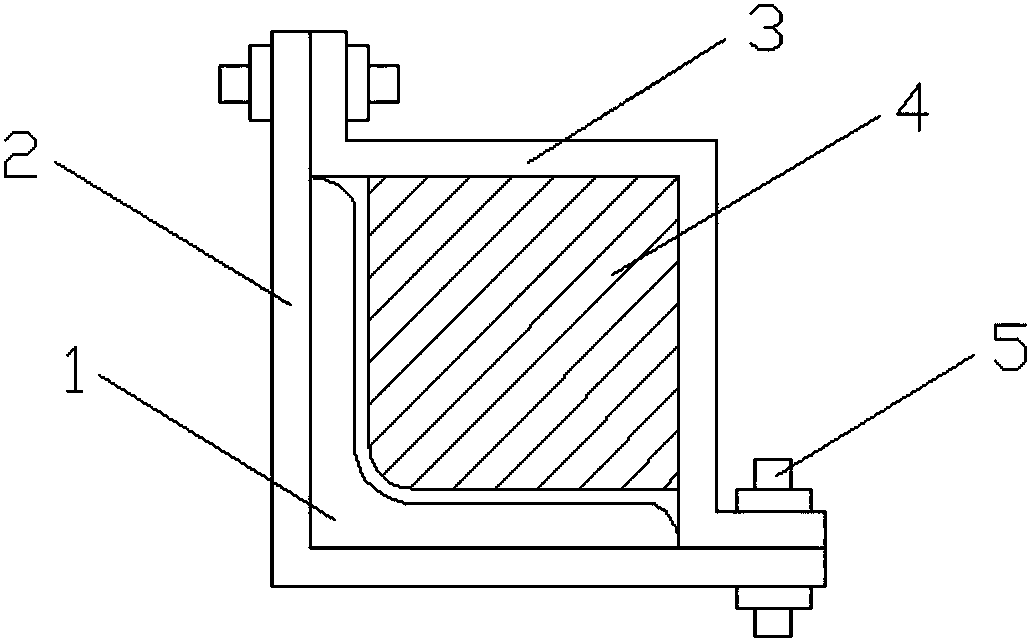

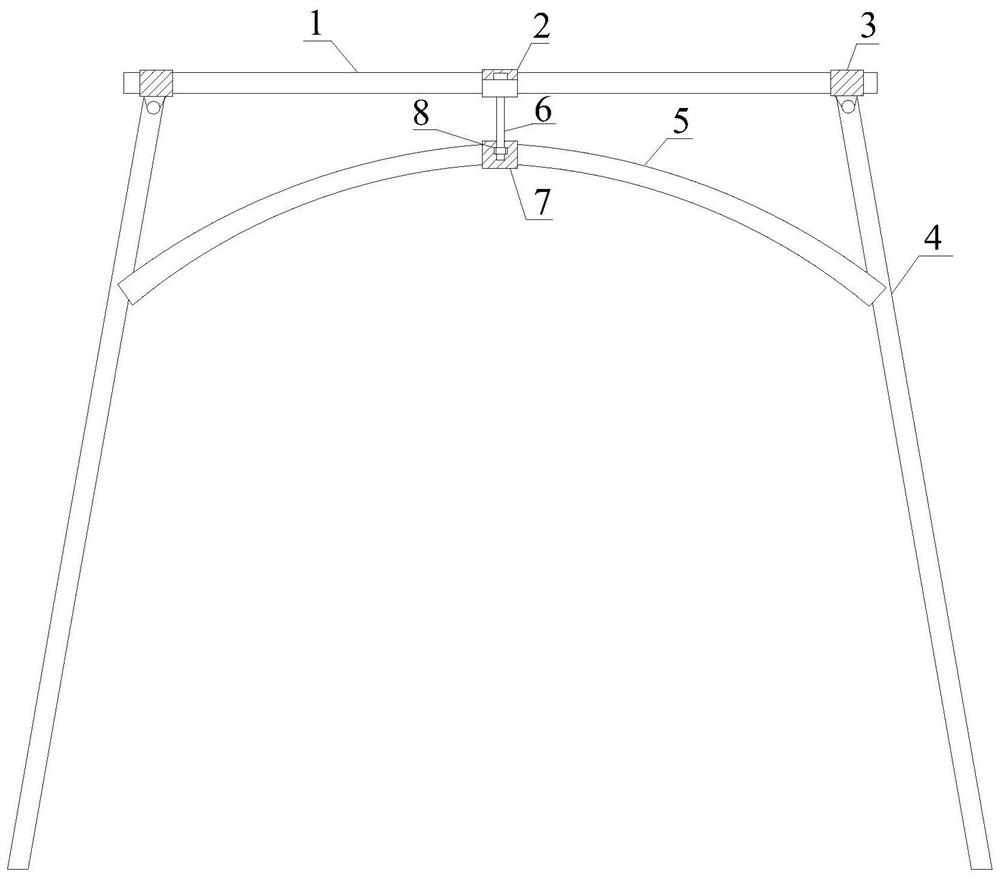

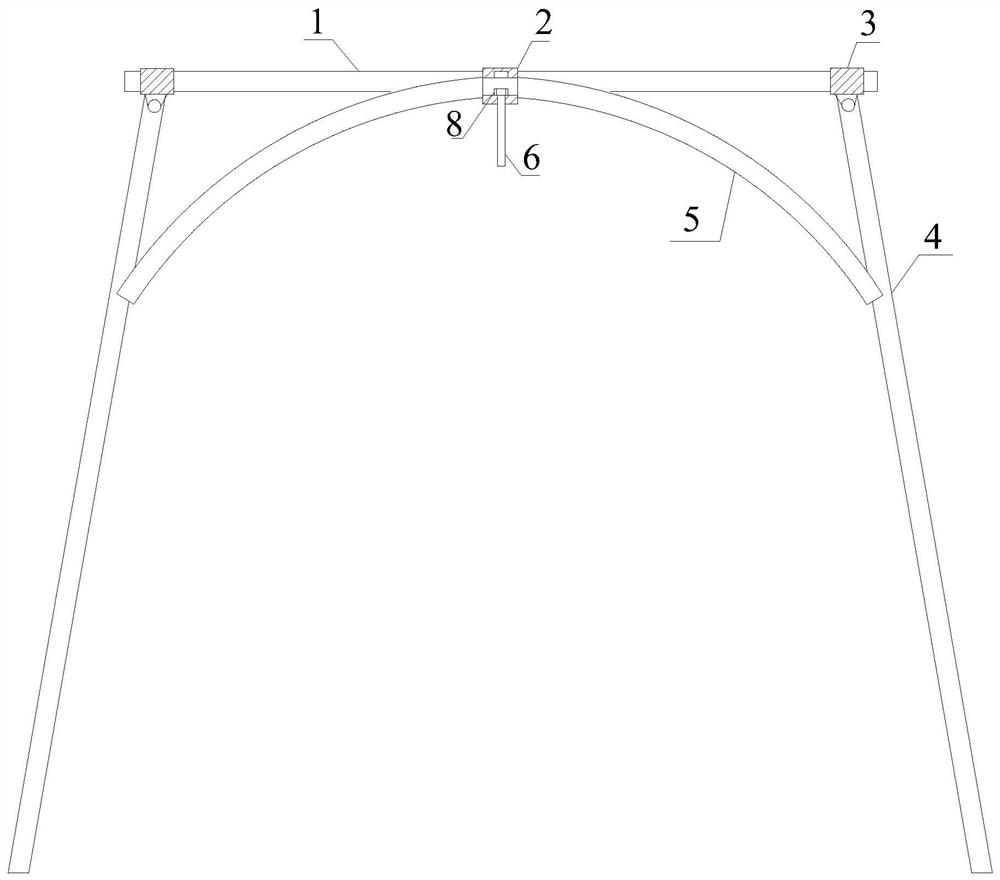

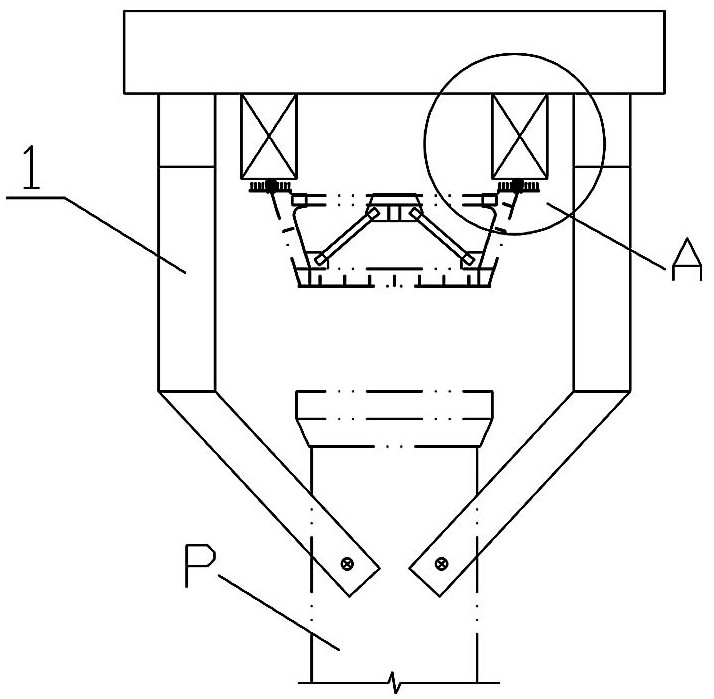

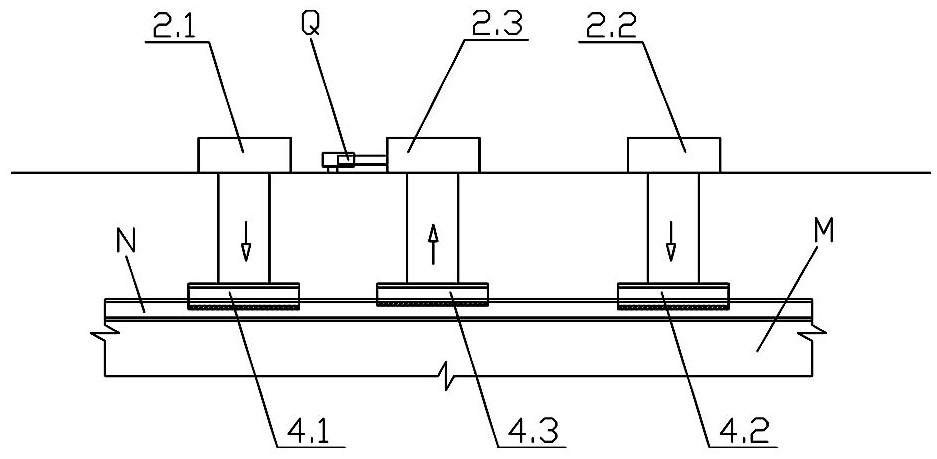

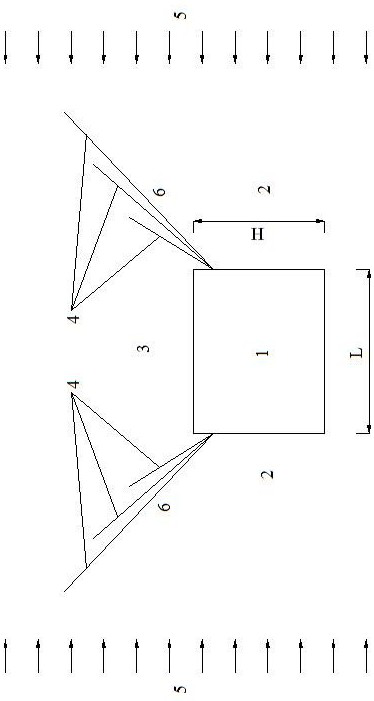

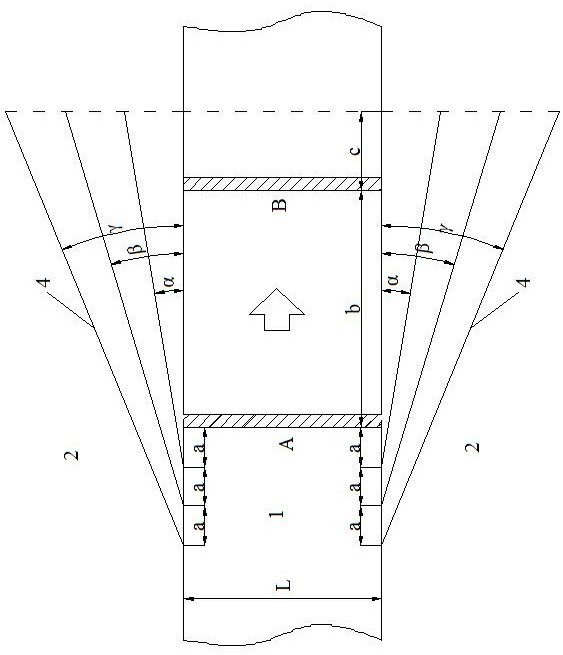

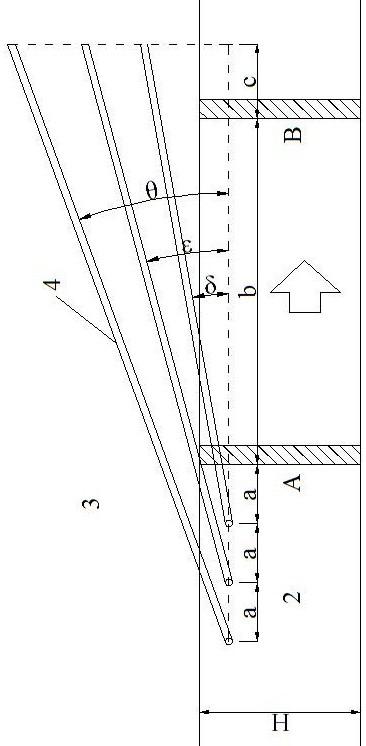

Assembly-type anti-instability test loading device for T-shaped beam and test method thereof

ActiveCN110361183AWill not affect test resultsAvoid instabilityMachine part testingShaped beamInstability

The invention discloses an assembly-type anti-instability test loading device for a T-shaped beam. The loading device comprises a loading reaction frame. The loading reaction frame is fixedly connected to a lower cross beam; and the lower cross beam is fixed to a ground anchor system. The loading device also comprises a pair of anti-instability supports. The each anti-instability support comprisesan inclined rod and a vertical rod. The vertical rods of the pair of anti-instability supports are arranged oppositely. The anti-instability supports are in assembly connection with long holes in thelower cross beam. The device also comprises a clamping mechanism. The clamping mechanism is mounted on the vertical rods. The clamping mechanism makes contact with a web of a T-shaped beam test piece. The device also comprises a pressure applying mechanism. The pressure applying mechanism is used for applying test pressure to the T-shaped beam test piece. The provided device can prevent overturning or local instability of the test piece without affecting the test result of the T-shaped beam test piece in the whole process, is high in assembly degree, convenient to install and reusable, can besuitable for different sizes and kinds of T-shaped beam test pieces and is wide in applicability.

Owner:SOUTHWEST JIAOTONG UNIV

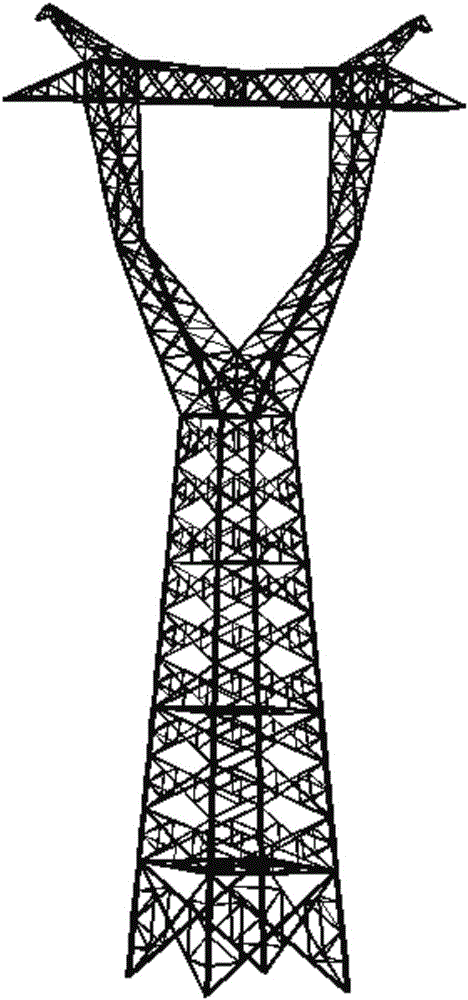

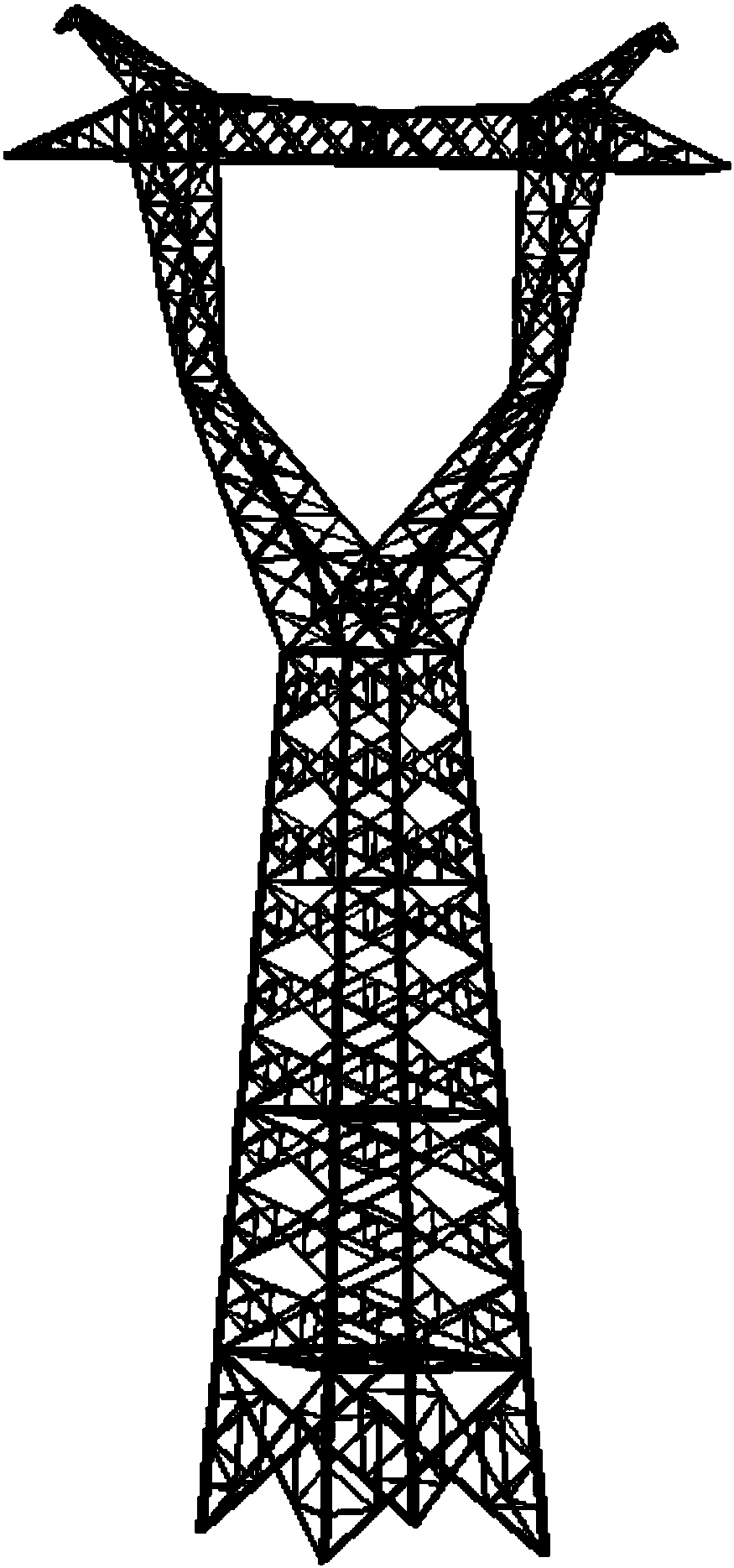

Reinforcing structure for preventing buckling based on main material of power transmission tower

PendingCN111270868AReduce eccentricityEasy constructionBuilding repairsTowersTransmission towerBuckling instability

The invention discloses a reinforcing structure for preventing buckling based on a main material of a power transmission tower. The reinforcing structure is characterized by comprising reinforcing angle steel, end fixing components and a middle fixing component, wherein the reinforcing angle steel is arranged on the outer side of a to-be-reinforced main material of the power transmission tower andis arranged diagonally relative to the to-be-reinforced main material; the end fixing components are arranged at the upper end and the lower end of the reinforcing angle steel respectively; the middle fixing component is arranged between the two end fixing components; and the reinforcing angle steel and the main material of the power transmission tower are fixedly connected into a whole body by the two end fixing components and the middle fixing component. Except for connecting ends, at other connecting positions in a reinforcing section, the main material does not need to be perforated, so that buckling instability of the main material can be prevented; eccentricity of an auxiliary main material can be reduced; end connecting bolts can ensure that the reinforcing angle steel does not slip and meanwhile can ensure that components work together when being pulled; and second connecting angle steel and rib plates in the reinforcing angle steel can effectively prevent local instability ofmain material angle steel. The reinforcing structure has the advantages of simplicity in construction, safety and reliability, low cost and remarkable effects.

Owner:NORTHEAST DIANLI UNIVERSITY

Assembled anti-instability test loading device for T-beam and its experimental method

ActiveCN110361183BWill not affect test resultsAvoid instabilityMachine part testingShaped beamEngineering

The invention discloses an assembled anti-instability test loading device for a T-shaped beam, which includes a loading reaction frame fixedly connected to a lower beam; the lower beam is fixed on a ground anchor system; and a pair of The anti-instability bracket, the anti-instability bracket includes a diagonal bar and a vertical bar, and the vertical bars of a pair of anti-instability brackets are arranged oppositely, and the anti-instability bracket is assembled and connected with the long hole of the lower beam; it also includes a clamping mechanism, The clamping mechanism is installed on the vertical bar; the clamping mechanism is in contact with the web of the T-beam test piece; it also includes a pressure applying mechanism, and the pressure applying mechanism is applied to the T-beam test piece. parts to apply test pressure. The invention prevents the test piece from overturning or local instability, and will not affect the test results of the T-shaped beam test piece in the whole process, has a high degree of assembly, is easy to install, and can be reused; it can be applied to different sizes and different types T-beam specimens with wide applicability.

Owner:SOUTHWEST JIAOTONG UNIV

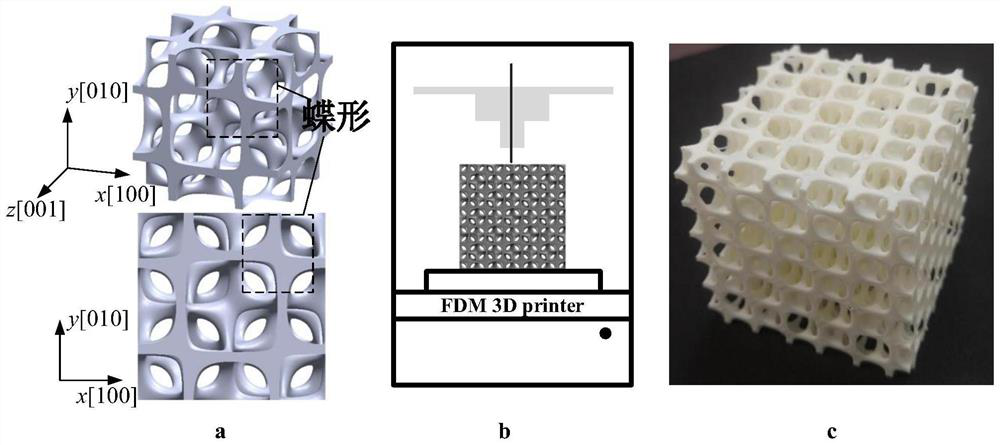

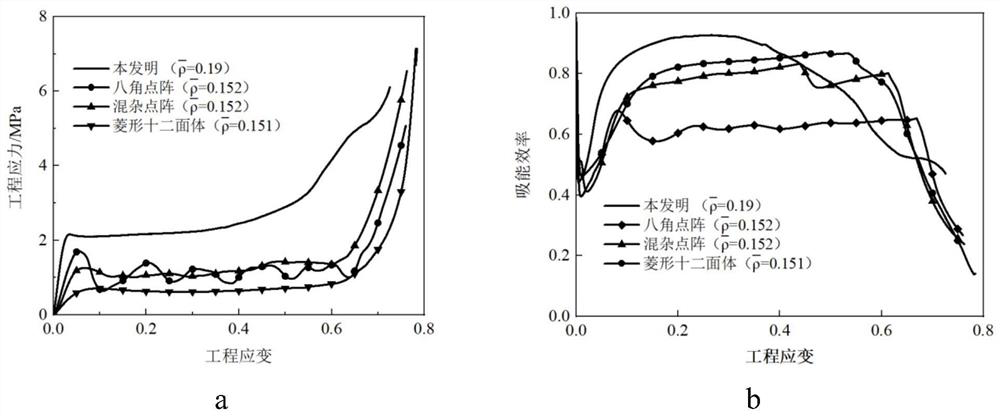

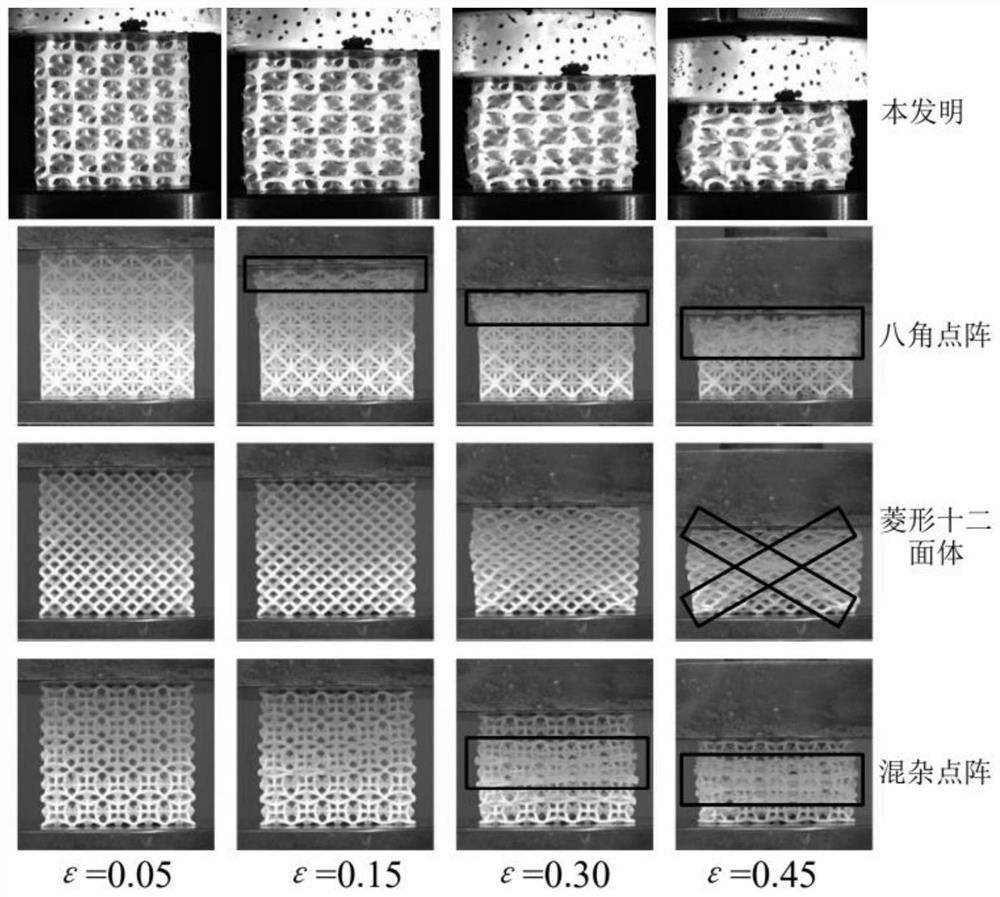

High-strength light protective lattice structure material with stable deformation

PendingCN114239145AHigh specific modulusHigh strengthGeometric CADSpecial data processing applicationsEnergy absorptionEngineering

The invention relates to a high-strength lightweight protective lattice structure material with stable deformation, in particular to a lightweight impact-resistant lattice structure material capable of being used as a lightweight protective structure core layer, and belongs to the technical field of material / structure lightweight design and protection. The non-constant-section rod pieces are adopted as the cell element rod pieces of the lattice structure material, butterfly-shaped transition is adopted at the joints between the rod pieces, and axial deformation of the rod pieces can be converted into shear torsion deformation at the joints; the whole cell structure is cubic asymmetry, so that the material deflects integrally when subjected to external compression load, local damage and collapse in the material are effectively limited, the deformation stability and energy absorption capacity of the material are improved, and a protected object is effectively protected.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

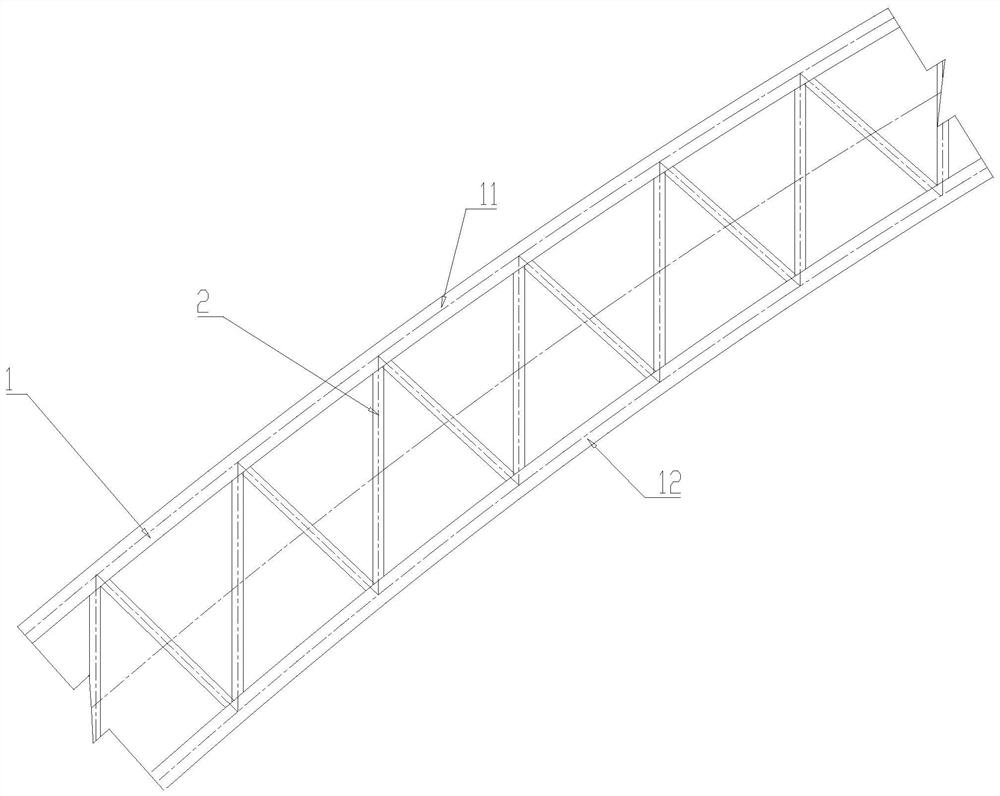

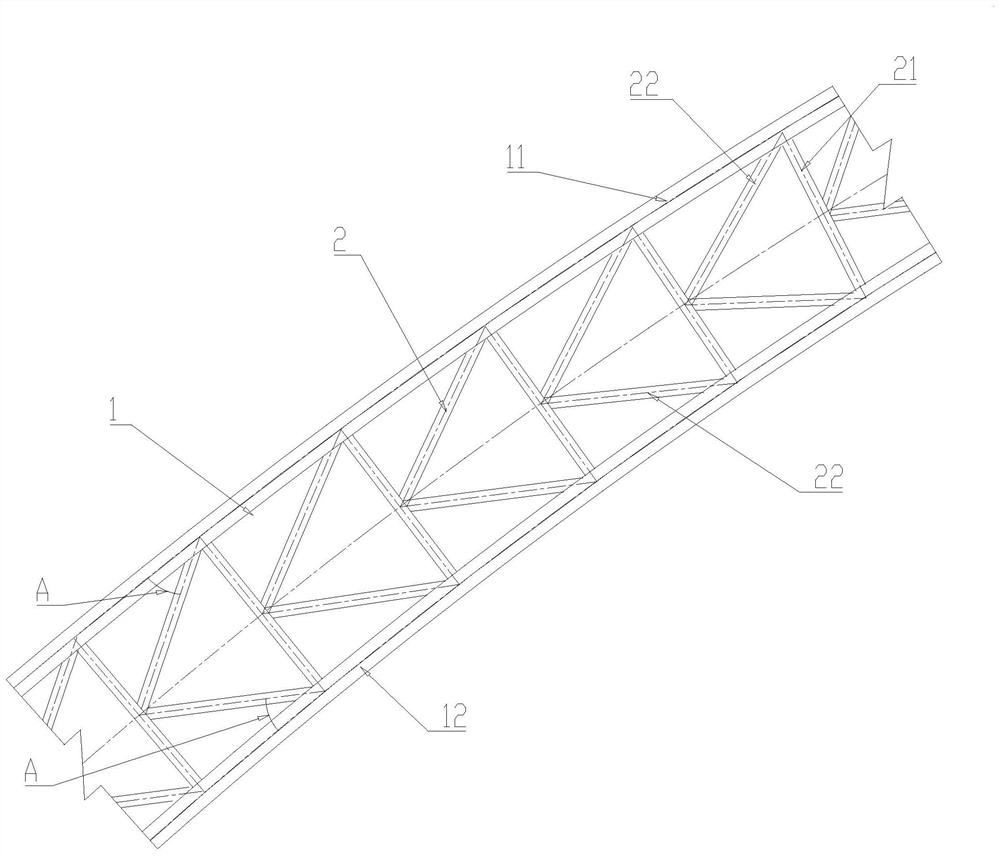

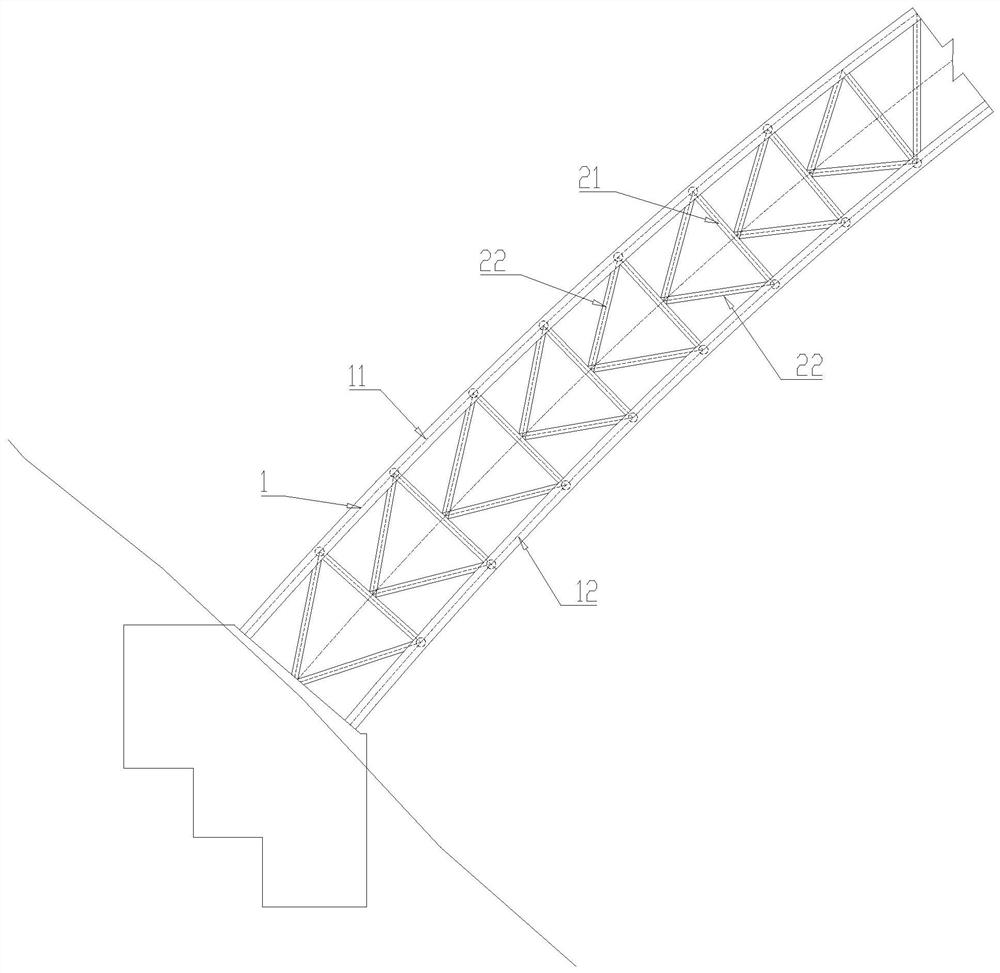

Web member structure of concrete-filled steel tube truss type main arch and bridge

PendingCN112482189AShorten the lengthReduce aspect ratioArch-type bridgeBridge materialsMechanical engineeringIndustrial engineering

The invention discloses a web member structure of a concrete-filled steel tube truss type main arch and a bridge. The web member structure comprises a plurality of sets of web member assemblies. Eachweb member assembly comprises a transverse web member and two inclined web members, the transverse web member and the two inclined web members form a triangular unit, the two ends of the transverse web member are used for being connected with the upper chord and the lower chord of the main arch on the same side respectively, one end of one inclined web member is used for being connected with the upper chord, and the other side of the inclined web member is connected with the middle of the transverse web member in the adjacent web member assembly; one end of the other inclined web member is used for being connected with the lower chord, and the other side of the inclined web member is connected with the middle of the transverse web member in the adjacent web member assembly. The free lengths of the inclined web members and the transverse web members are smaller than or equal to the height of the section of the main arch, the free lengths and slenderness ratios of the web members are reduced, if cutting is conducted in the direction of the cross section of the main arch, at least two intersection points exist between the tangential direction and the web member assemblies, compressiverigidity and shear rigidity of the web members are improved, and local instability of the main arch web members is effectively avoided.

Owner:SICHUAN VOCATIONAL & TECHN COLLEGE OF COMM

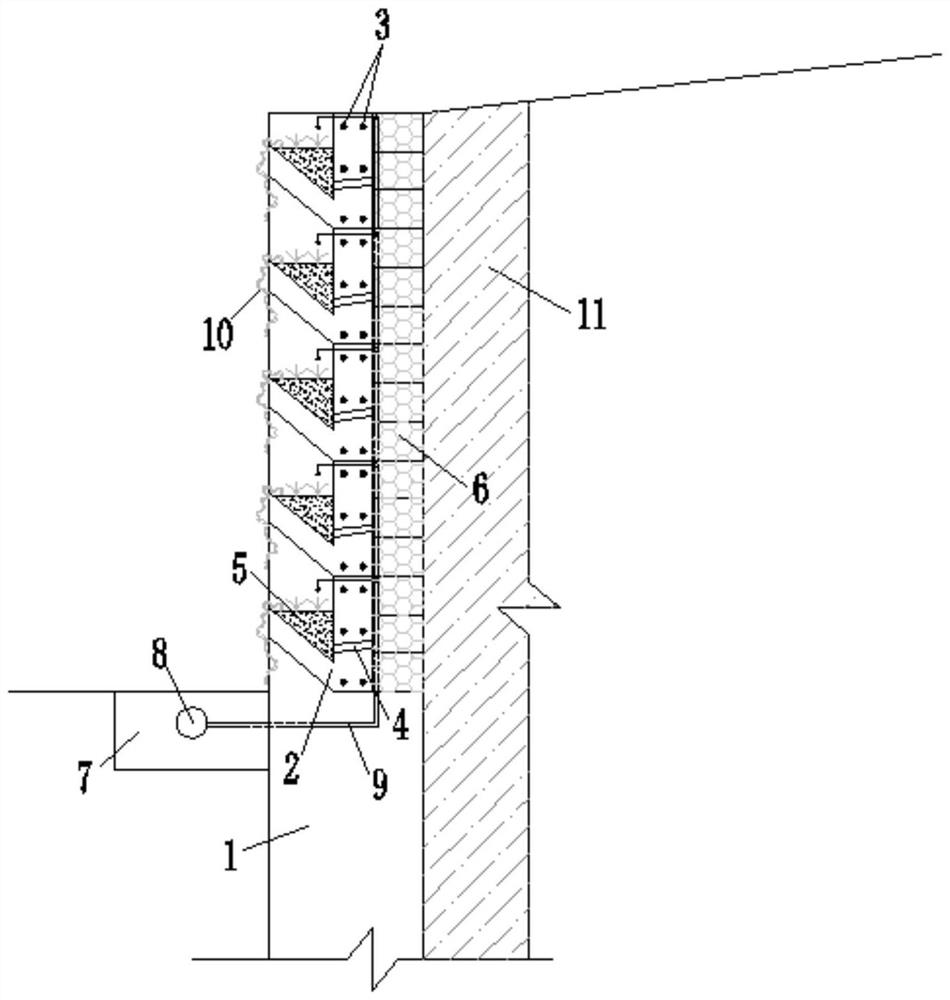

Assembled ecological retaining wall with rainwater purification and irrigation system

InactiveCN111656999AAvoid local instabilityPrevent falling blocksGeneral water supply conservationSelf-acting watering devicesEnvironmental resource managementEcological environment

The present invention provides an assembled ecological retaining wall with a rainwater purification and irrigation system. The assembled ecological retaining wall includes antiskid piles, prefabricated blocks among the piles and backfill soil layers behind the piles; the plurality of prefabricated blocks among the piles are provided and are respectively and periodically mounted on the antiskid piles from top to bottom by a connecting reinforcement and are combined from top to bottom to form a soil retaining structure; the prefabricated blocks among the piles are filled with planting soil for planting plants so as to fix the soil and improve the landscape effect; water filtration and purification layers are disposed between each of the prefabricated blocks among the piles and each of the backfill soil layers behind the piles; transverse drainage openings are formed in the prefabricated blocks among the piles; and the assembled ecological retaining wall is further provided with an irrigation system for replenishing water for the growth of the plants. By using the assembled ecological retaining wall with the rainwater purification and irrigation system, phenomena such as high construction difficulty, long construction period, incapability of realizing plant growth during rainstorm or drought, poor retaining wall landscape effect and ecological environmental pollution caused by rainfall runoff are overcome.

Owner:CHONGQING UNIV

Reinforcement piles for building foundations in collapsible loess areas and their construction methods

ActiveCN105220720BEliminate the effects ofReduce the total pile lengthFoundation repairBulkheads/pilesEngineeringSelf weight

The invention discloses a collapsible loess area building foundation reinforcing pile. The collapsible loess area building foundation reinforcing pile comprises an upper pile foundation, a lower pile foundation, an underpinning steel pipe and an operating pit. The lower end of the upper pile foundation is connected with the upper end of the lower pile foundation. The upper end of the upper pile foundation sequentially penetrates a self-weight collapsible loess layer and a lower backfill soil layer and stretches into a concrete bearing platform. The lower end of the underpinning steel pipe is connected with the upper pile foundation, the upper end of the underpinning steel pipe is connected with a building foundation, a pile foundation channel is formed in the self-weight collapsible loess layer, and a gap is formed between the upper pile foundation and the side wall of the pile foundation channel. According to the reinforcing pile, the influences of negative friction of the self-weight collapsible loess layer on the upper pile foundation can be effectively eliminated, and it is guaranteed that loads transmitted by the reinforcing pile are borne by friction between the lower pile foundation and a non-collapsible loess layer. The invention further discloses a pile pressing construction method. The method includes the steps of excavation of the operating pit; construction of the lower pile foundation; construction of the upper pile foundation; connection of the upper pile foundation and the building foundation; and construction of the concrete bearing platform. The pile pressing construction efficiency is improved through the pile pressing construction method.

Owner:XIAN UNIV OF SCI & TECH

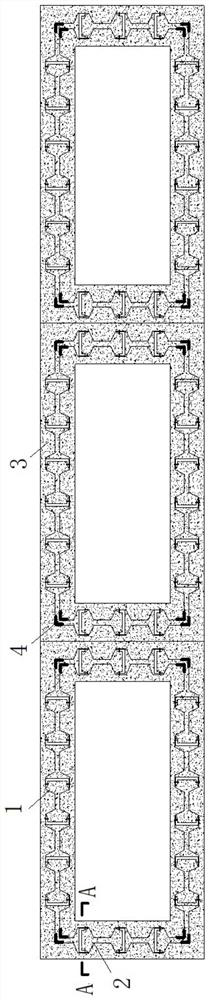

A prefabricated corrugated steel plate lattice enclosure structure and construction method thereof

ActiveCN112983116BPlay the role of tension reinforcementIncrease contact surfaceFencingClassical mechanicsAxial force

The invention discloses a prefabricated corrugated steel plate lattice-type enclosure structure and a construction method thereof. The structure includes a number of frame-structured enclosure units, each enclosure unit includes a transverse enclosure portion and a longitudinal enclosure portion filled with concrete, and a truss as a bending component is arranged inside the transverse enclosure portion. The interior of the enclosure is provided with a lattice column as an axial force-bearing member. The truss and the lattice column are connected to each other and bonded with the concrete to form a whole. It is composed of channel steel, a channel steel is arranged in the cavity formed by each peak-to-peak part, the flange of the channel steel is connected with the wave crest in the cavity, and the opening direction of the channel steel in the adjacent cavity is opposite. The invention solves the problem that the envelope structure is only regarded as a non-structure in the traditional building form, is convenient for timely replacement when damaged, and ensures that the structure has good mechanical properties.

Owner:CHANGZHOU INST OF TECH

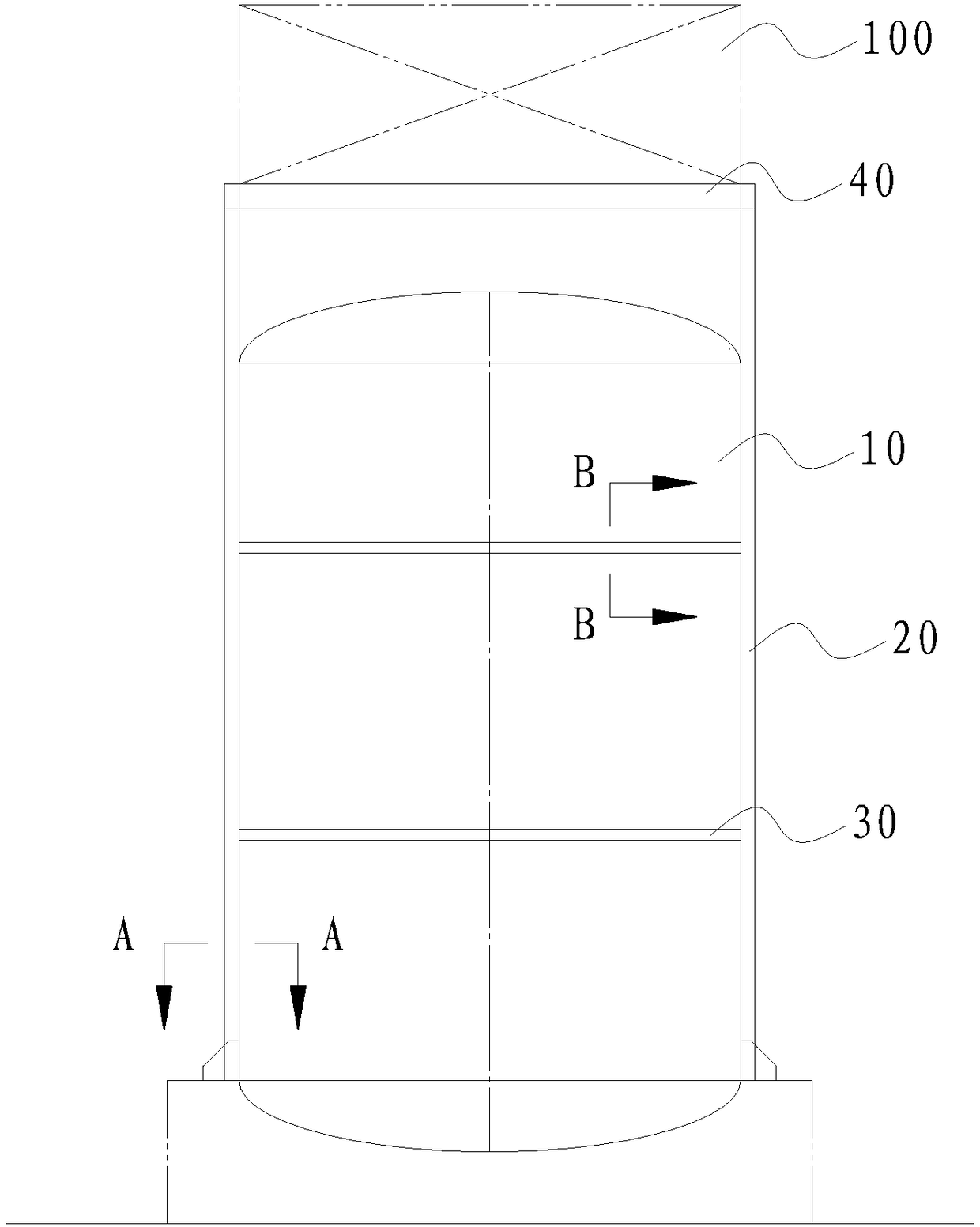

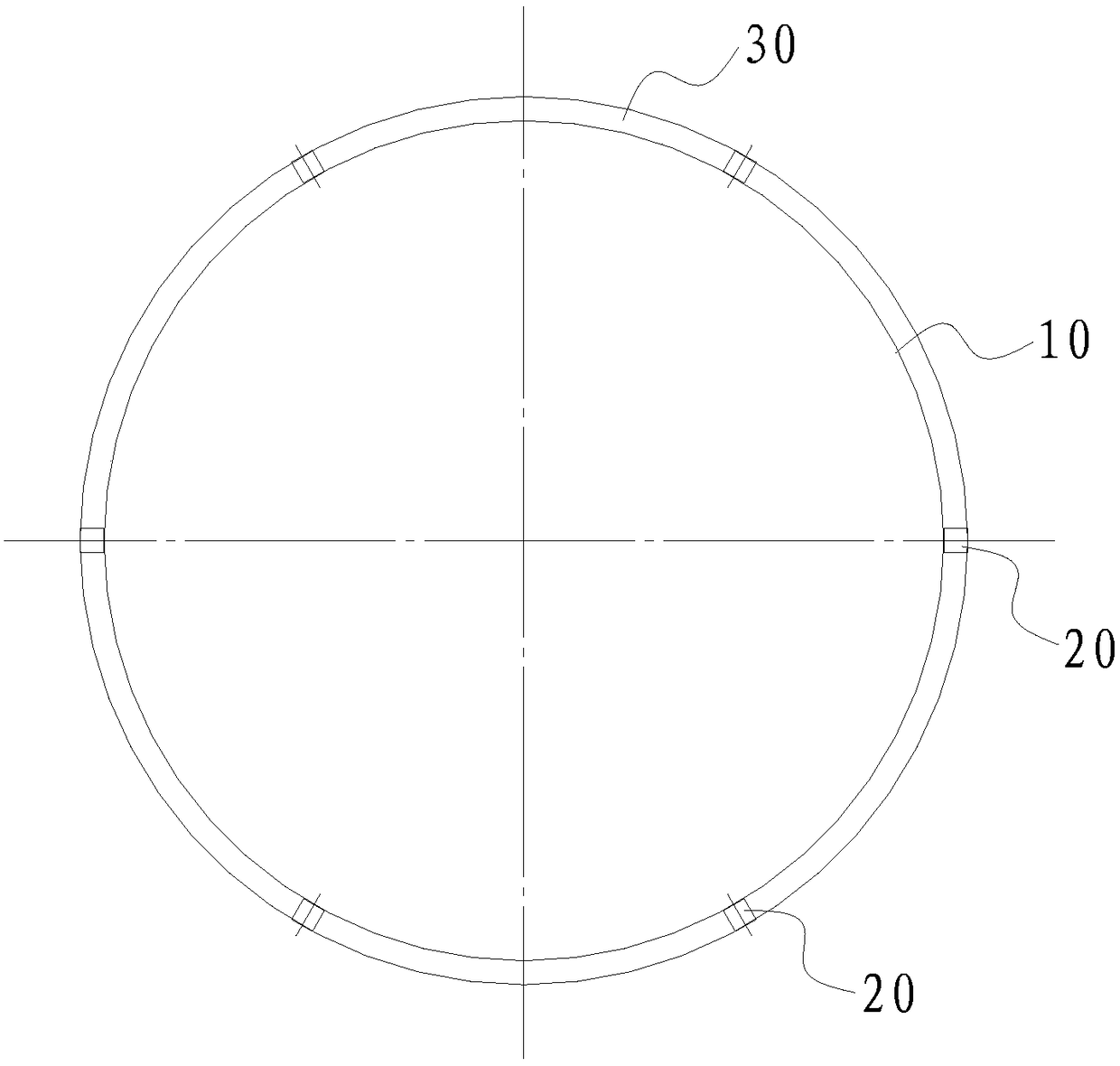

reaction tower

ActiveCN105817192BAvoid local instabilityIncrease stiffnessChemical/physical/physico-chemical stationary reactorsEngineeringVertical load

The invention discloses a reaction tower .The reaction tower comprises a tower body, one or more bearing columns and one or more annular structural beams, the bearing columns are arranged on the outer wall of the tower body in the axial direction of the tower body, the annular structural beams are arranged on the outer wall of the tower body in the circumferential direction of the tower body, and the bearing columns, the annular structural beams and the tower body are linked to be an integral structure .The bearing columns can bear most vertical load, local buckling of the tower body is avoided, and the annular structural beams can play a role in transverse linkage and reinforce integral rigidity of the tower body, so that the tower body has the capability of bearing large vertical load and transverse load .The bearing columns, the annular structural beams and the tower body are linked to be the integral structure, so that wall plates of the tower body, the bearing columns and the annular structural beams are integrated into a whole, the stable integral structure is formed, the reaction tower can form a rigid barrel body, good structural stability can be achieved without making the wall thickness be high, the structure is stable and firm, and manufacturing cost is saved.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Steel Tower Angle Steel Anti-Bending and Torsional Instability Reinforcing Device

Owner:SHANDONG UNIV

A U-shaped steel support and a method for controlling roadway surrounding rock by graded active loading

ActiveCN110847937BReasonable adjustmentExtended service lifeUnderground chambersMine roof capsStructural engineeringMechanical engineering

Owner:CHINA UNIV OF MINING & TECH

Connecting joint of prefabricated steel reinforced concrete column and reinforced concrete beam and construction process thereof

PendingCN112267576AImproves strength and ductilityStrong deformation abilityBuilding constructionsRebarSteel tube

The invention discloses a connecting joint of a prefabricated steel reinforced concrete column and a reinforced concrete beam and a construction process thereof, and belongs to the technical field ofconstructional engineering. The connecting joint comprises the prefabricated steel reinforced concrete column and a prefabricated reinforced concrete beam. Longitudinal profile steel and transverse profile steel are arranged in the prefabricated steel reinforced concrete column. One end of the transverse profile steel is connected with the longitudinal profile steel, and the other end of the transverse profile steel is fixedly connected with a first connecting piece. An embedded piece is arranged at one end of the prefabricated reinforced concrete beam. The embedded piece is an embedded steelpipe, embedded profile steel or an embedded anchor bar. A second connecting piece is fixedly connected to the end, close to the prefabricated steel reinforced concrete column, of the embedded piece. The first connecting piece is connected with the second connecting piece through a bolt so that the prefabricated steel reinforced concrete column can be connected with the prefabricated reinforced concrete beam. According to the connecting joint of the prefabricated steel reinforced concrete column and reinforced concrete beam and the construction process thereof, the structural strength and ductility are improved, the construction speed is high, and environmental protection and economy are achieved.

Owner:吉林建筑科技学院

Method of Constructing Variable-height Steel Beams Using Lifting and Pushing Brackets

ActiveCN110258358BHigh positioning accuracyImprove construction safetyBridge erection/assemblyBridge materialsArchitectural engineeringPier

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD +2

A control method for roadway roof deformation under high level stress

ActiveCN109026024BImprove deformation resistanceImprove stress environmentUnderground chambersTunnel liningStructural engineeringDeformation control

The invention discloses a control method for high-level stress effect roadway top plate deformation. The method comprises the following steps that (1) reasonable roadway width and height are determined; (2) a set of look-head pressure relief drill holes obliquely facing upward are drilled in the two sides of a roadway top plate at the surrounding rock portions of the shoulder angles on the upper portions of the two sides of a roadway; (3) high-strength high pretightening force cooperative support control is conducted on 'the roadway top plate, the roadway two sides and the shoulder angle surrounding rock'; (4) grouting holes are drilled in the surrounding rock of the shoulder angles on the two sides of the roadway top plate for grouting reinforcement. According to the control method, high-level stress on the two sides of the roadway of the top plate can be unloaded, the high-level stress is transferred to the deep portion of the roadway top plate, and compensating space is provided fordeformation of the surrounding rock of the shoulder angle of the roadway; the integral capacity of deformation resistance of the surrounding rock of the roadway can be significantly improved, and itis effectively avoided that due to the fact that an existing support mode attends to one thing and loses another, local buckling and buckling of a full cross-section are caused; the bearing capacity of the surrounding rock of the shoulder angle is enhanced, the capacity of deformation resistance of the surrounding rock is improved, and finally the stability of the roadway top plate under the effect of high-level stress is ensured.

Owner:HENAN POLYTECHNIC UNIV

Side wall vertical pillar structure of variable-cross-section passenger car

InactiveCN103085887BImprove rollover safety performanceUniform denaturationSuperstructure subunitsRollover

The invention relates to the technical field of passenger car security protection, in particular to a side wall vertical pillar structure which is capable of remarkably improving rollover security performance of a variable-cross-section passenger car. The side wall vertical pillar structure of the variable-cross-section passenger car is formed by an outside plate structure (6) and a U-shaped inner plate structure (7) in a welding mode, the width of the outside plate structure (6) from a top longitudinal beam (2) to a window waist beam (3) is the same, and from the window waist beam (3) to a lower waist beam (5), the width increases gradually from top to down. The cross-section size of the U-shaped inner plate structure (7) increases gradually along the vertical pillar length direction from top to bottom, the width of each cross-section of the U-shaped inner plate structure is (7) smaller than the cross-section width of the outside plate structure (6) at the same cross-section portion, a welding lap joint area with equal width is arranged on a joint of the U-shaped inner plate structure (7) and the outside plate structure (6). The side wall vertical pillar structure of the variable-cross-section passenger car is capable of guaranteeing that in the rollover process, the collision moment of the side wall vertical pillar of the passenger car body is matched with the pillar cross-section size, the degeneration of the side wall vertical pillar is enabled to become even, and the rollover security performance of the passenger car is improved. .

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com