Side wall vertical pillar structure of variable-cross-section passenger car

A technology of variable cross-section and column, applied in the superstructure, sub-assembly of the superstructure, vehicle components, etc., can solve the problems of affecting the rollover safety performance of the whole vehicle, uneven deformation of the side wall column, and large intrusion of the side wall structure. , to improve the safety performance of rollover, improve the energy absorption effect, and avoid the effect of local instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with the embodiment given with accompanying drawing.

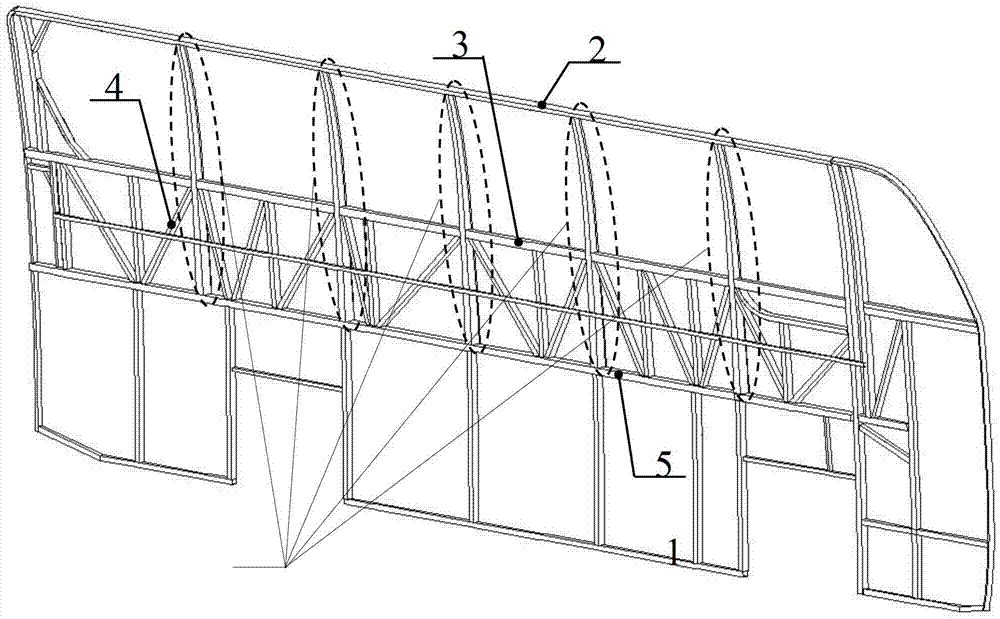

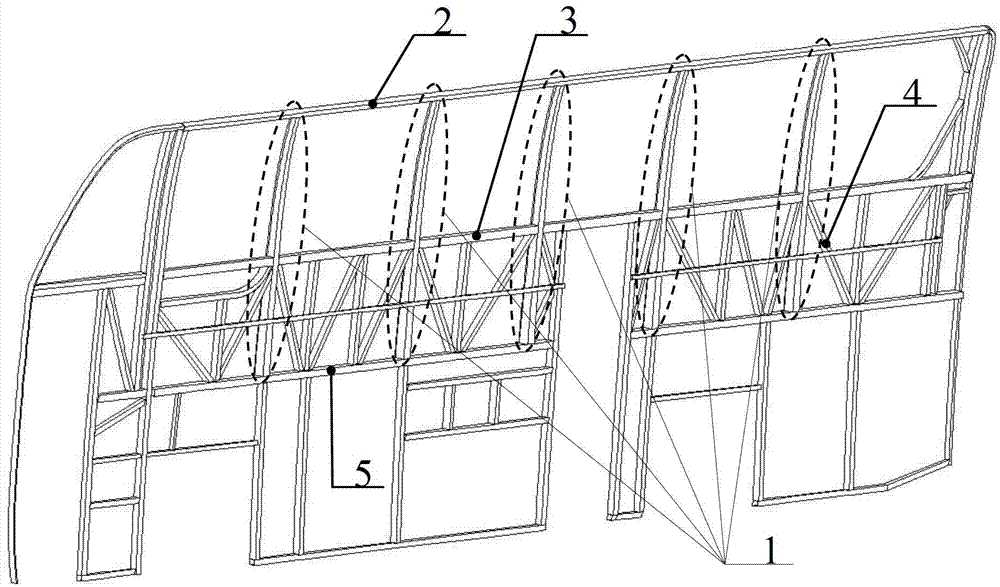

[0023] The variable cross-section stamping and welding passenger car side wall column structure 1 is composed of two parts, the outer plate structure 6 and the U-shaped inner plate structure 7, and the two parts are connected by welding process.

[0024] The outer panel structure is punched out of sheet metal, and its structural features are: the width of the outer panel structure between the top longitudinal beam 2 and the window waist beam 3 is the same, and the value range is 50-60mm to ensure sufficient side window vision It is convenient to bond with glass; the width of the outer plate structure 6 between the window waist beam 3 and the lower waist beam 5 gradually increases from top to bottom, and the maximum width is 80-100mm, which ensures that it is compatible with the U-shaped inner plate structure 7. A certain welding overlap area i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com