Assembled anti-instability test loading device for T-beam and its experimental method

A technology of loading device and T-shaped beam, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc. The effect of instability and high degree of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and actual test cases, rather than limiting the protection scope of the present invention.

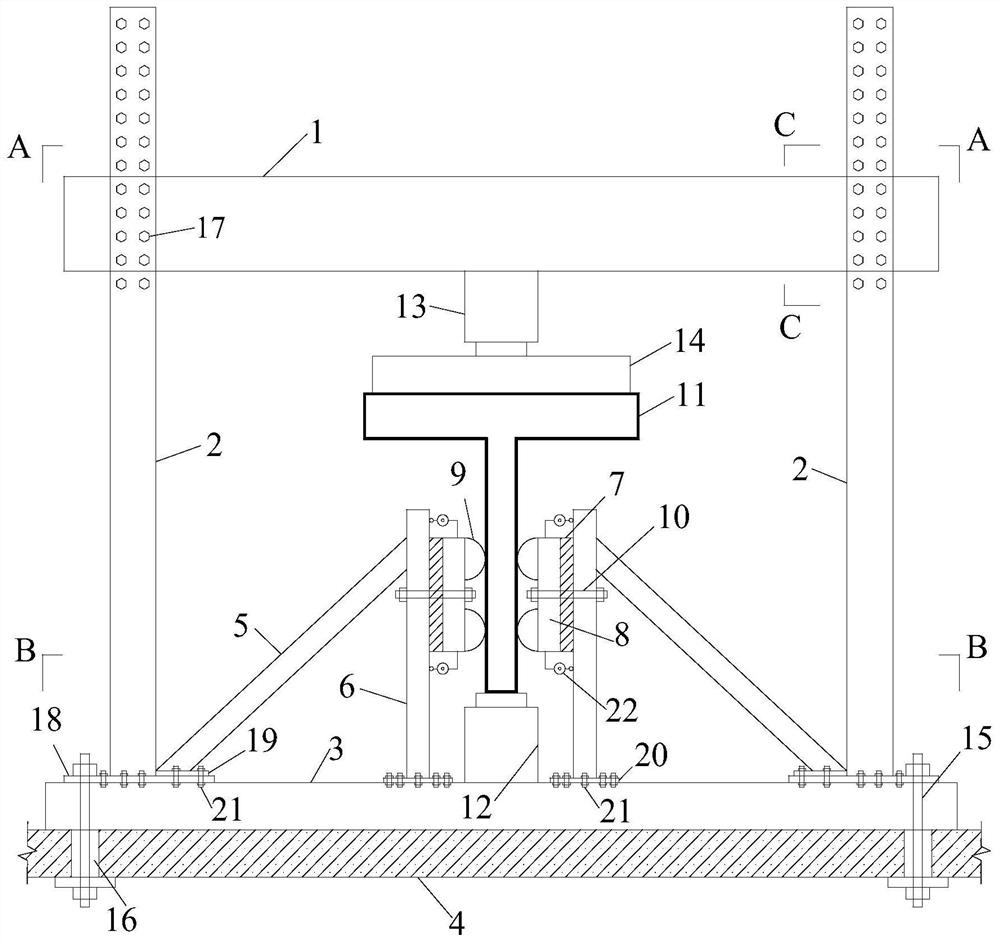

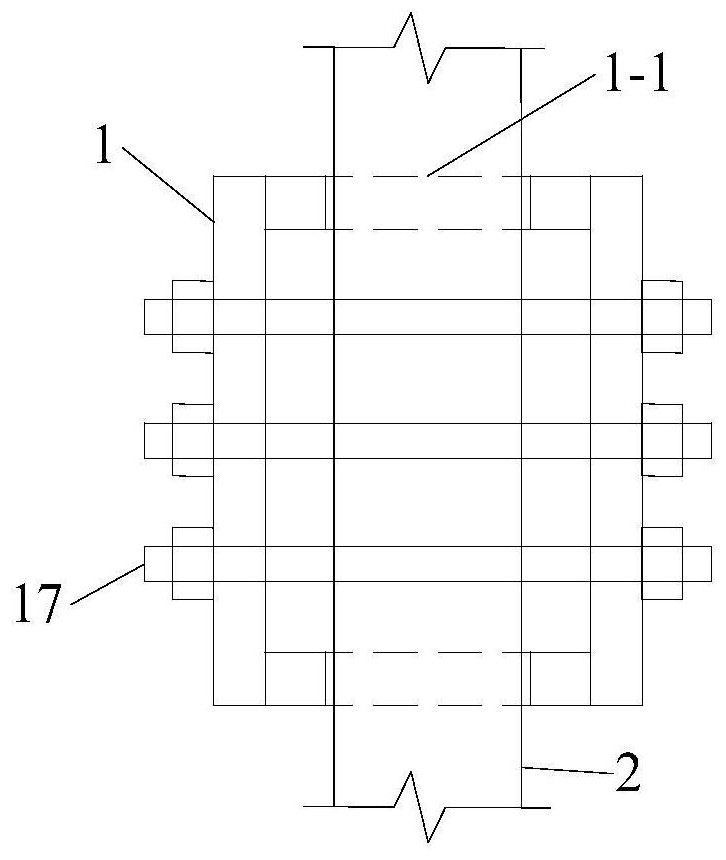

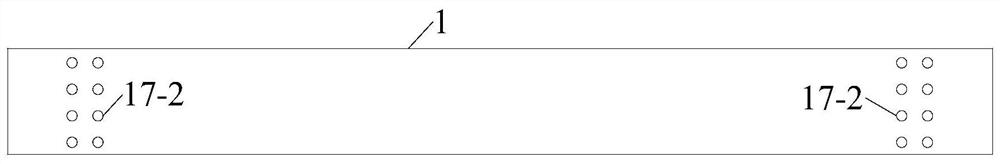

[0044] Such as figure 1As shown, for the prefabricated anti-instability test loading device for T-shaped beams, the horizontal upper beam 1, the vertical vertical beam 2 and the horizontal lower beam 3 form a loading reaction frame, and the upper beam 1 and the vertical Beam 2 is connected by position-adjustable shear bolts 17, the bottom of vertical beam 2 is welded to first hole gusset plate 18, and first hole gusset plate 18 is connected to lower beam 3 by bolt group 21; said lower The beam 3 is anchored on the ground anchor system 4 through the ground anchor bolt 15; the center of the ground anchor bolt 15 corresponds to the center of the channel 16 of the ground anchor system 4;

[0045] It also includes a pair of anti-instability brackets. The anti-instability brackets incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com