Patents

Literature

38results about How to "Detection is accurate and intuitive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

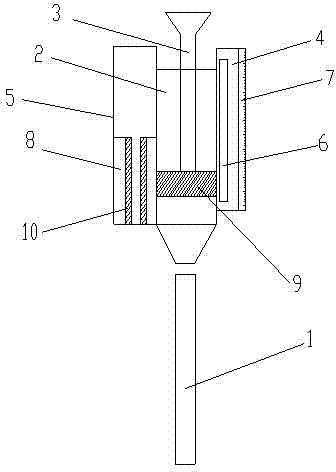

Engine fire detection method and detection device thereof

InactiveCN101907520AReasonable designSimple signal processingInternal-combustion engine testingPeak valueDischarge pressure

The invention provides an engine fire detection method and a detection device thereof, belonging to the technical field of automobile engines. The invention solves the problems of low detection precision and easy occurrence of wrong judgment of the traditional engine fire detection device. The engine fire detection device comprises a pressure sensor arranged on an engine exhaust system and used for collecting an exhaust pressure wave real-time signal, and the pressure sensor is connected with a central processing unit with a built-in exhaust pressure wave mean-value signal. The engine fire detection method comprises the following steps of: collecting the exhaust pressure wave real-time signal of the engine exhaust system by using the pressure sensor arranged on the engine exhaust system; inputting the collected exhaust pressure wave real-time signal to the central processing unit; and comparing the peak-to-peak value of the exhaust pressure wave real-time signal with the peak-to-peak value of the built-in exhaust pressure wave mean-value signal by the central processing unit. The invention has the advantages of simple signal processing process, difficult interference, high fire detection precision and the like.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

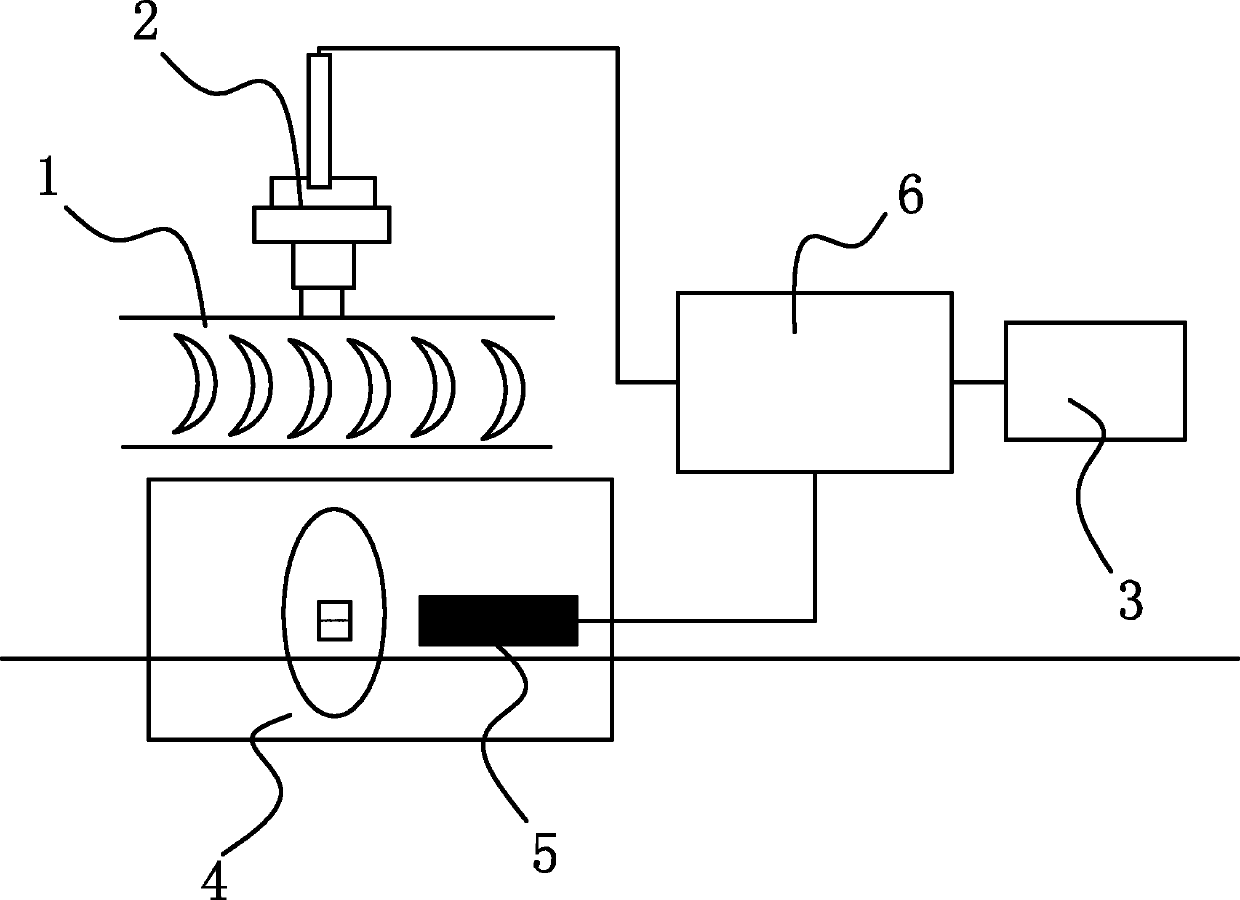

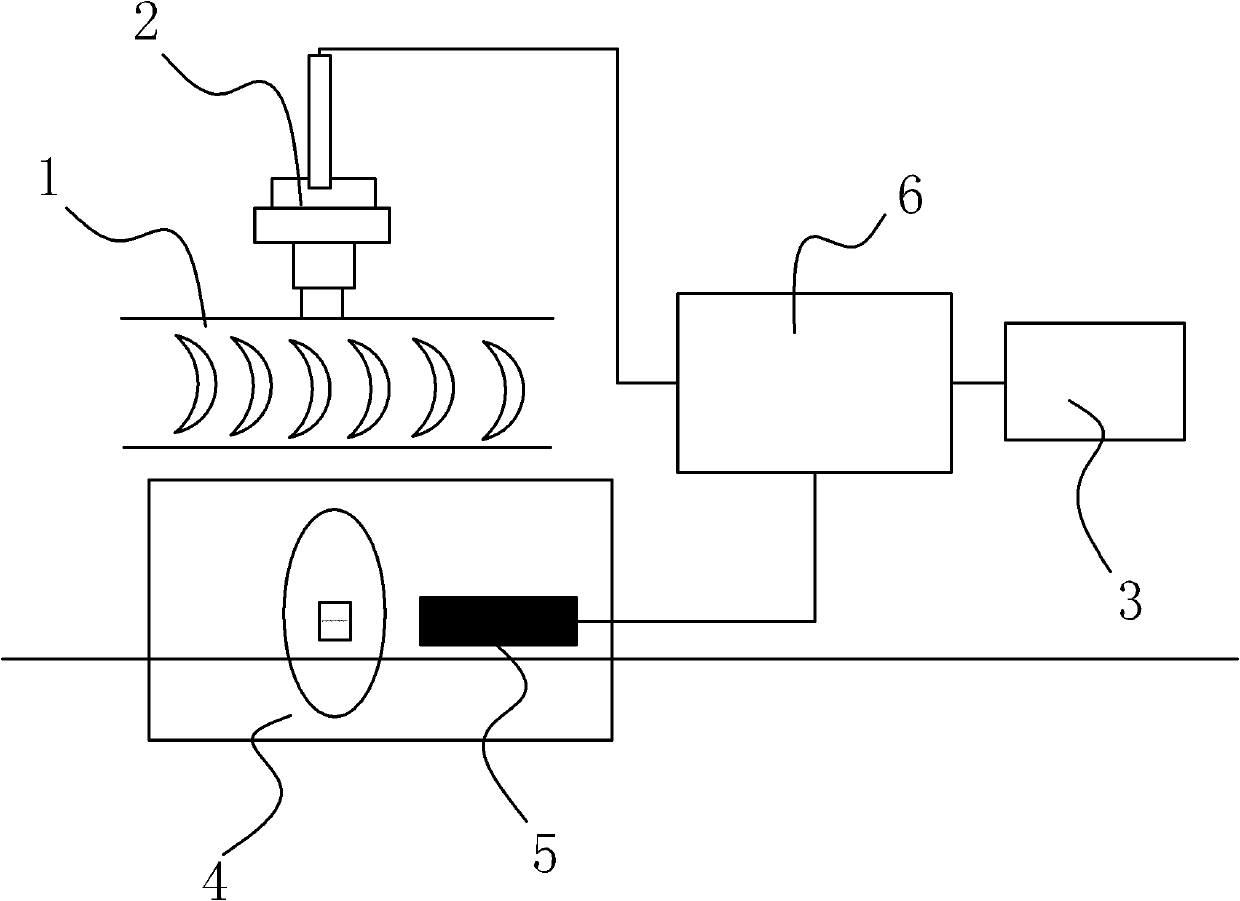

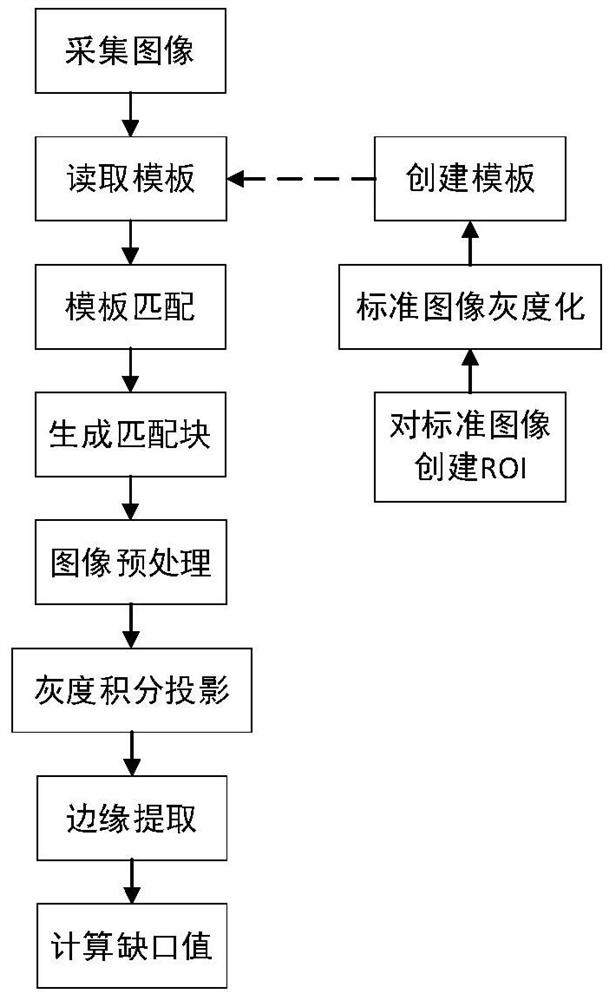

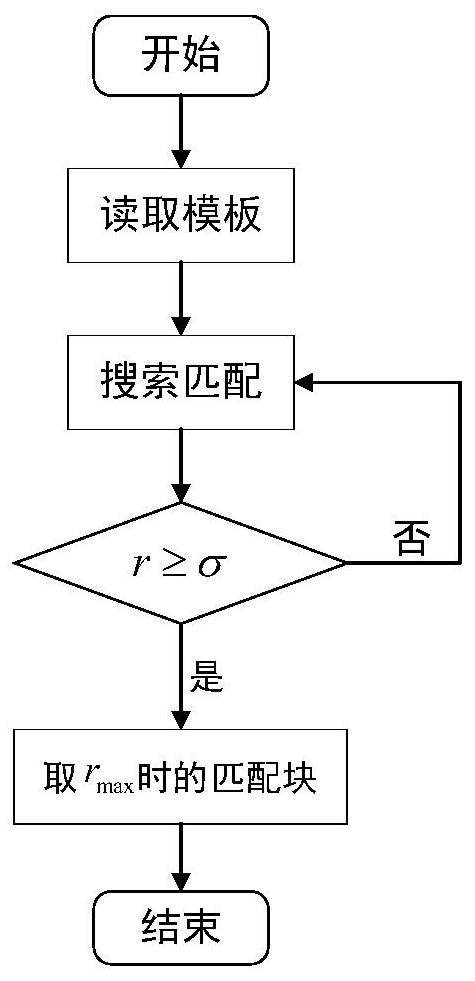

Automatic detection method for point switch notch and system and storage medium

PendingCN111754460ADetection is accurate and intuitiveImprove robustnessImage enhancementImage analysisTemplate matchingAlgorithm

The invention discloses an automatic detection method and system for a point switch notch and a storage medium, and the method enables a template matching algorithm and a gray integral projection algorithm to be applied to the real-time detection of the notch, and achieves the accurate and visual detection of a notch value through the analysis of a real-time photographed point switch notch image or a real-time photographed point switch notch video. Actual tests show that the algorithm used in the invention is suitable for point switch notch detection, the change of the illumination intensity in the image acquisition process does not influence the detection result, and the noise existing in the acquired image does not influence the extraction of the notch detection line, so the algorithm has strong robustness. Starting from the algorithm, the reference line of the gap detection adopts an automatic identification mode, and does not need to be manually delimited; according to the invention, the problem that reference lines need to be manually delimited at the notch fixing ends of a plurality of point switches respectively is solved, the calibration work which must be performed due toinaccurate manual reference line delimiting is avoided, the actual working efficiency is greatly improved, and the intelligent level of notch detection is improved.

Owner:北京驿禄轨道交通工程有限公司 +1

Apparent defect determination device for structural concrete, and detection method implemented by device

ActiveCN109164043AThe detection method is simpleSimple structureUsing mechanical meansMaterial analysisElectricityHoneycomb

The invention belongs to the technical field of road and bridge construction, and particularly relates to an apparent defect determination device for structural concrete, and a detection method implemented by the device. The apparent defect determination device for the structural concrete comprises magnetic devices and a magnetic powder filling device, and is electrically connected with a power supply in a cabinet, wherein the magnetic powder filling device is arranged on the side of a concrete component where an apparent defect is located; and the magnetic devices are arranged on the side opposite to the apparent defect, and the positions of the magnetic devices correspond to the position of the magnetic powder filling device for measurement. The invention further provides the detection method adopting the apparent defect determination device for the structural concrete. The device and the method provided by the invention have the advantages that magnetically conductive ferrous fillers sprayed by the magnetic powder filling device can be sucked into holes and cracks through the magnetic devices, and the magnetically conductive ferrous materials in irregularly shaped holes, cracksor honeycombs on the surface of the structural concrete can be quantitatively measured, so that the measurement equipment and method with high accuracy, simplicity and visualization can be provided for detection of the surface defect of the structural concrete.

Owner:NINGBO CONSTR TEST

Engineering pipeline offset detecting device based on cutting magnetic induction line principle

ActiveCN110174043AIncrease linkageImprove synchronicityUsing electrical meansMechanical measuring arrangementsElectrical conductorArchitectural engineering

The present invention discloses an engineering pipeline offset detecting device based on the cutting magnetic induction line principle, and relates to the technical field of construction engineering.The device comprises two bottom plates; the middle part of two opposite sides of the two bottom plates is movably connected with an adjusting mechanism; the front side of the adjusting mechanism is fixedly connected with a threaded sleeve; the inner part of the threaded sleeve is movably connected with a screw; and the front surface of the bottom plates is movably connected with three limiting blocks, the shape specifications of the three limiting blocks are the same, the limiting block is a curved structure, and the center of the limiting block is the same as the center of the bottom plate. According to the engineering pipeline offset detecting device based on the cutting magnetic induction line principle provided by the present invention, the change of the induced electromotive force when the conductor cuts the magnetic induction line is used to detect whether the workpiece is offset, and when the workpiece is offset, positions of the first conductor plate and the second conductor plate change; and the magnetic induction line is cut, and the induced electromotive force changes, so that by using the process and the principle, the position of the workpiece can be accurately and intuitively detected.

Owner:陈昱见

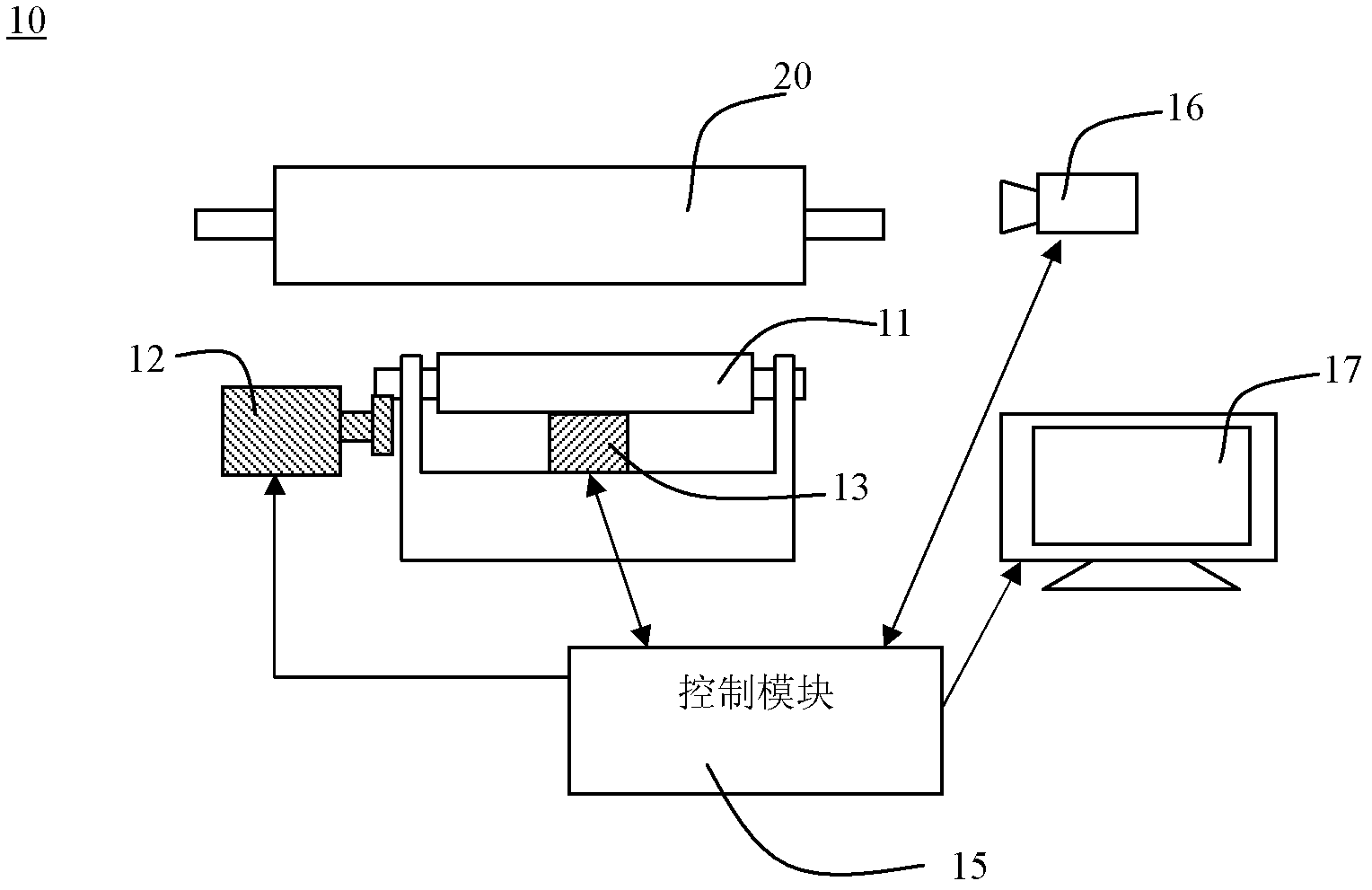

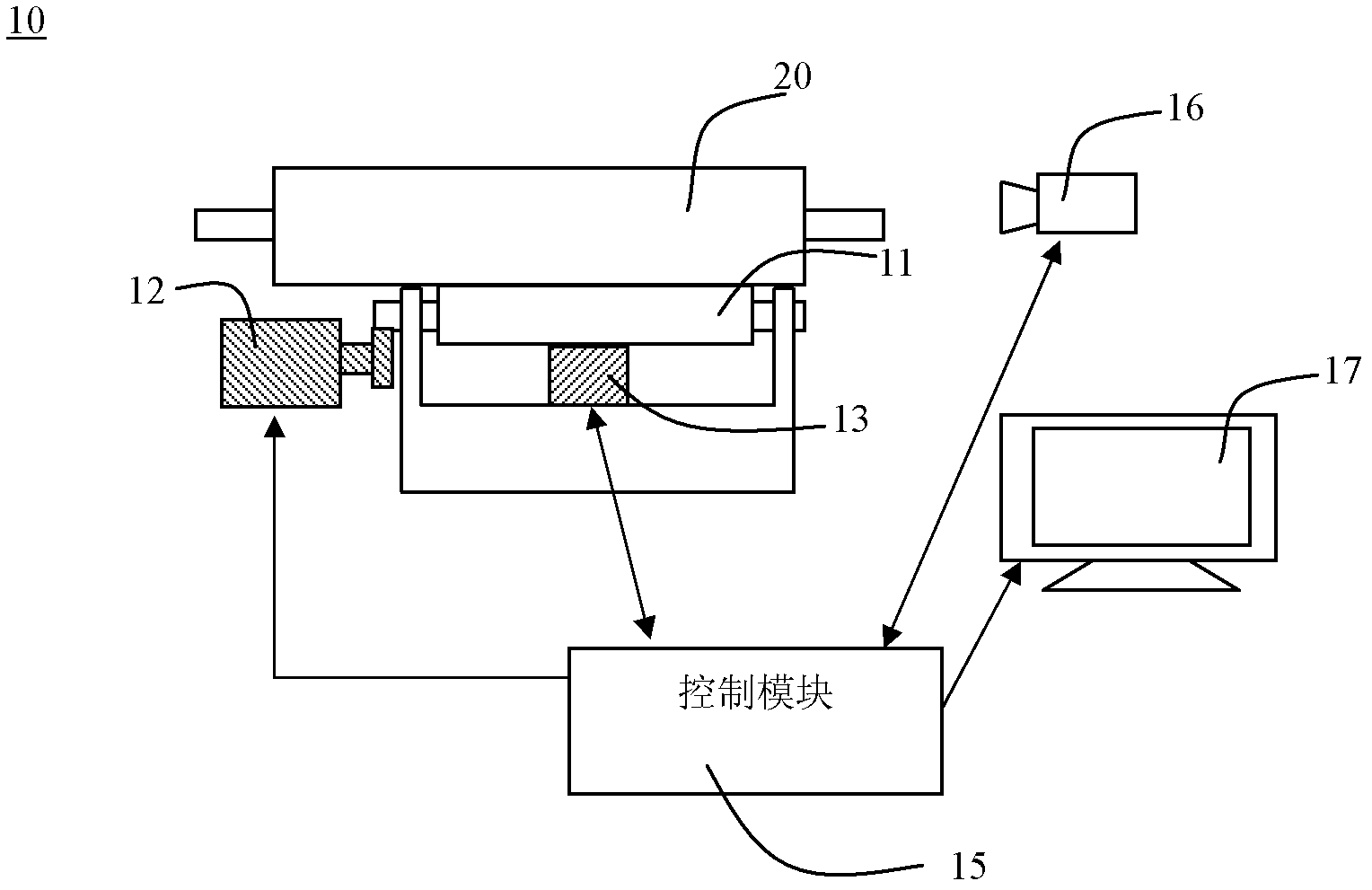

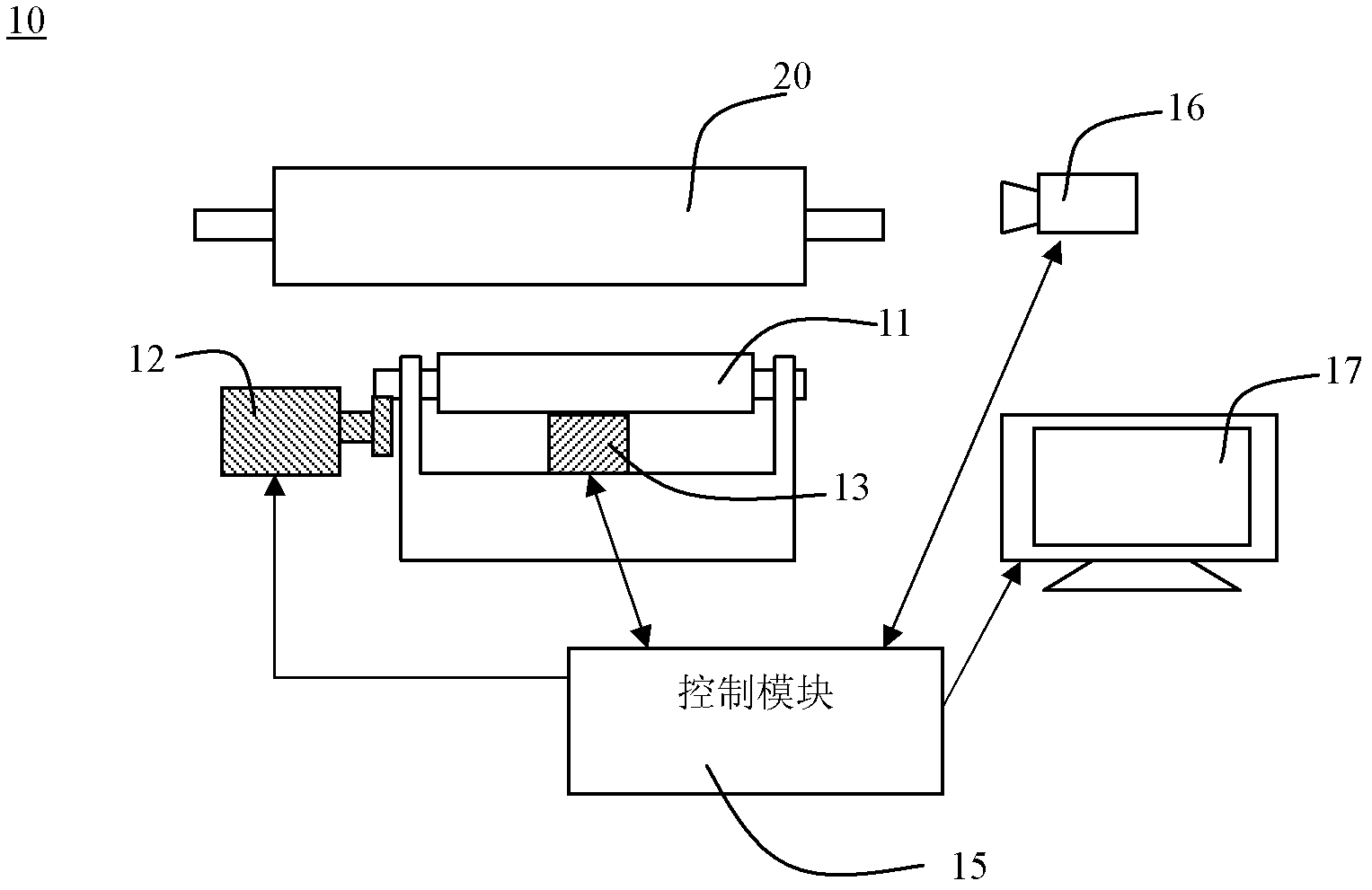

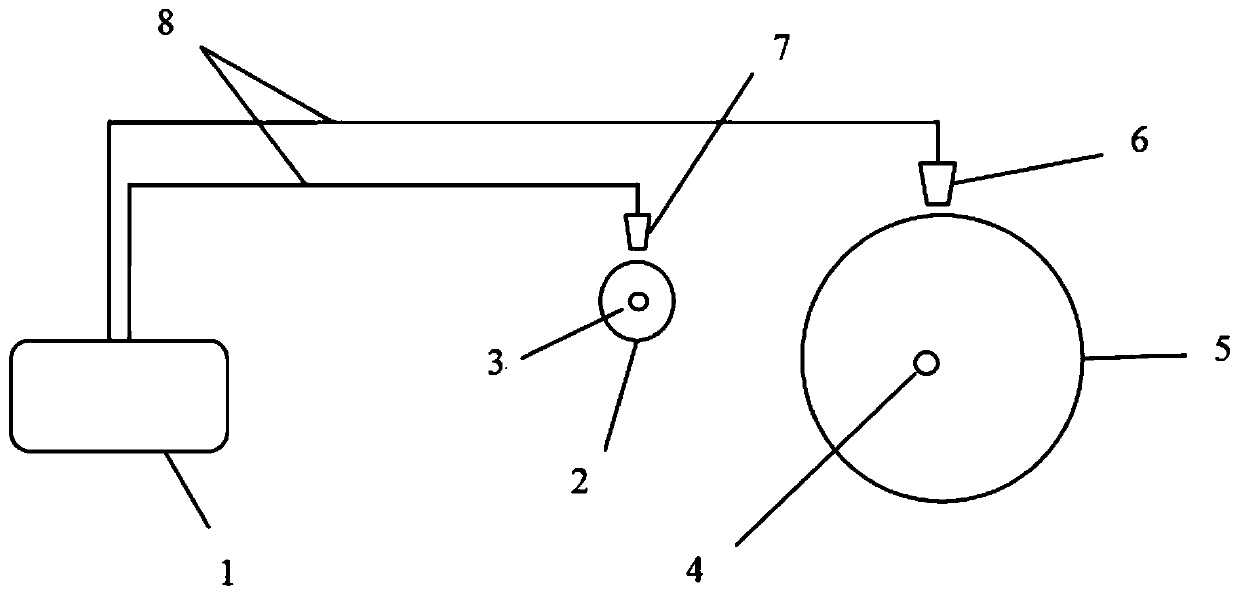

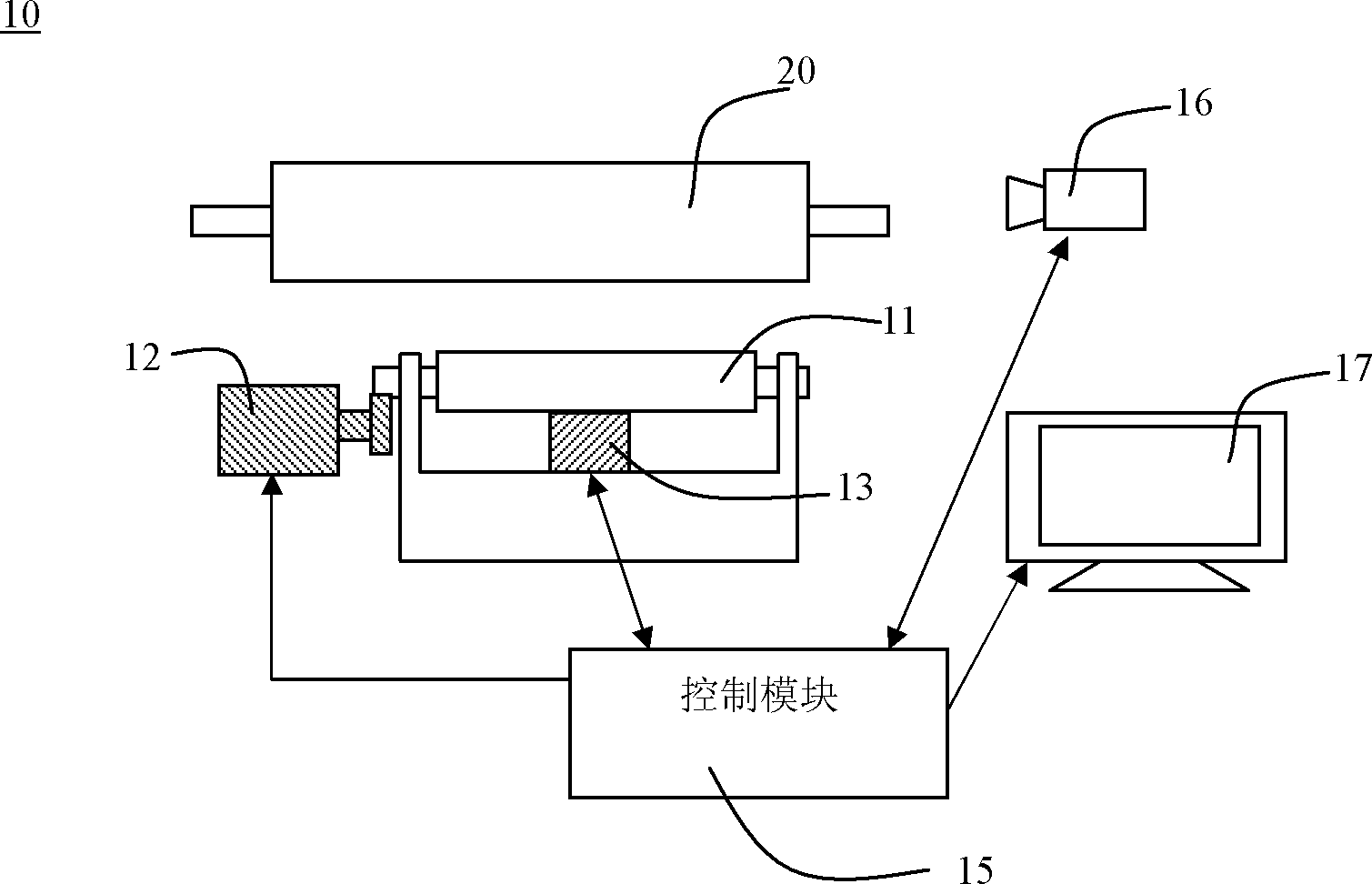

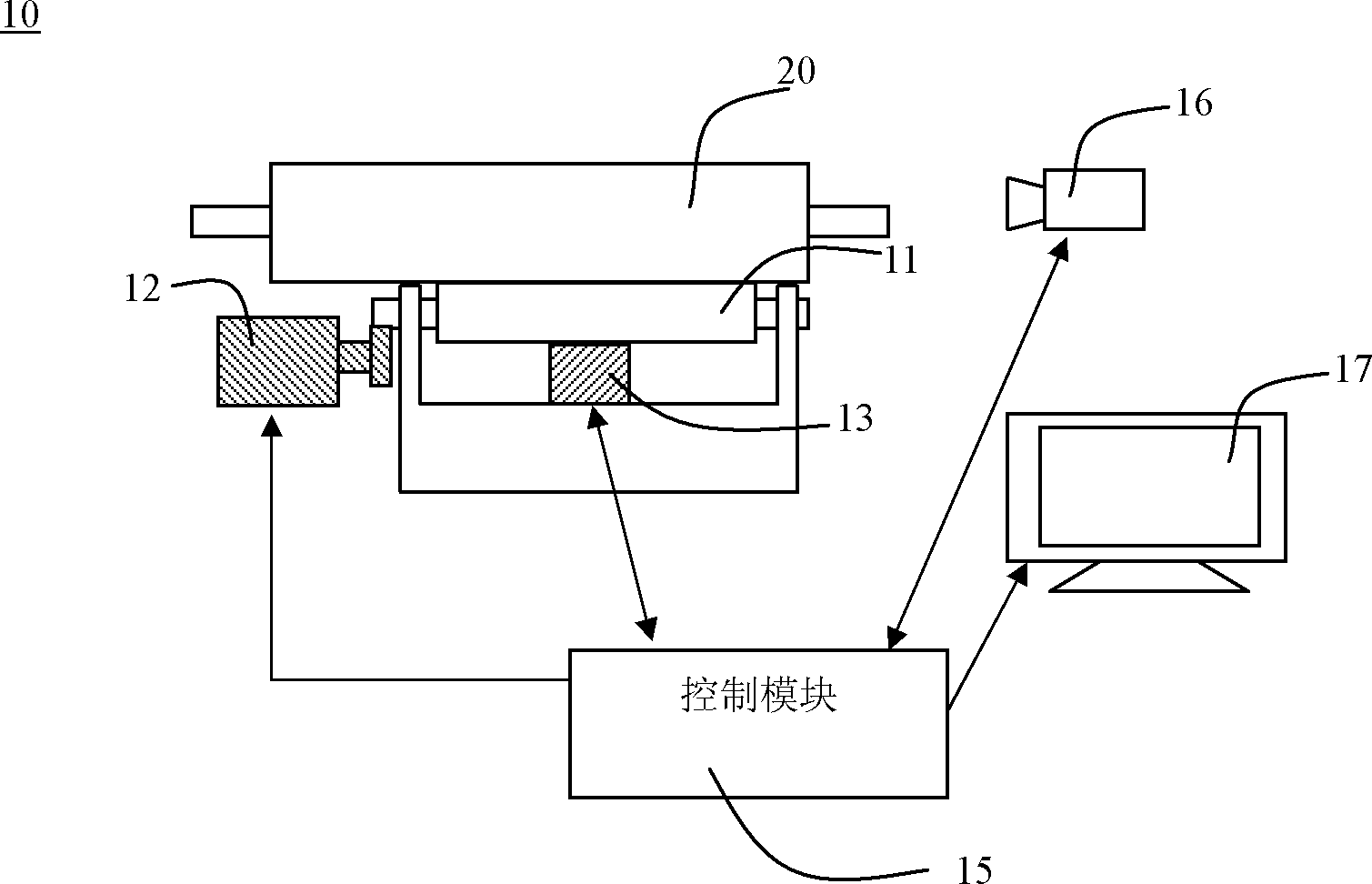

Test device for roller damping and method

InactiveCN102539138AEasy to detectGuaranteed reliabilityMachine part testingDrive motorPressure sensor

The invention relates to a test device for roller damping, which comprises a contact roller wheel, a driving motor, a pressure sensor, a control module, a sensor and a display module, wherein the contact roller wheel is provided with a translation mechanism; the driving motor is used for driving the contact roller wheel to rotate; the pressure sensor is used for detecting the pressure born by the contact roller wheel; the control module is used for receiving a signal of the pressure sensor; the rotation of the driving motor and the translation of the contact roller wheel are controlled by the control module; the sensor is used for detecting the rotation of a tested roller and transmitting a detecting result to the control module; and the display module is connected with the control module and is controlled by the control module. The test device for roller damping is used for testing the roller damping.

Owner:BENQ MATERIALS WUHU CORP

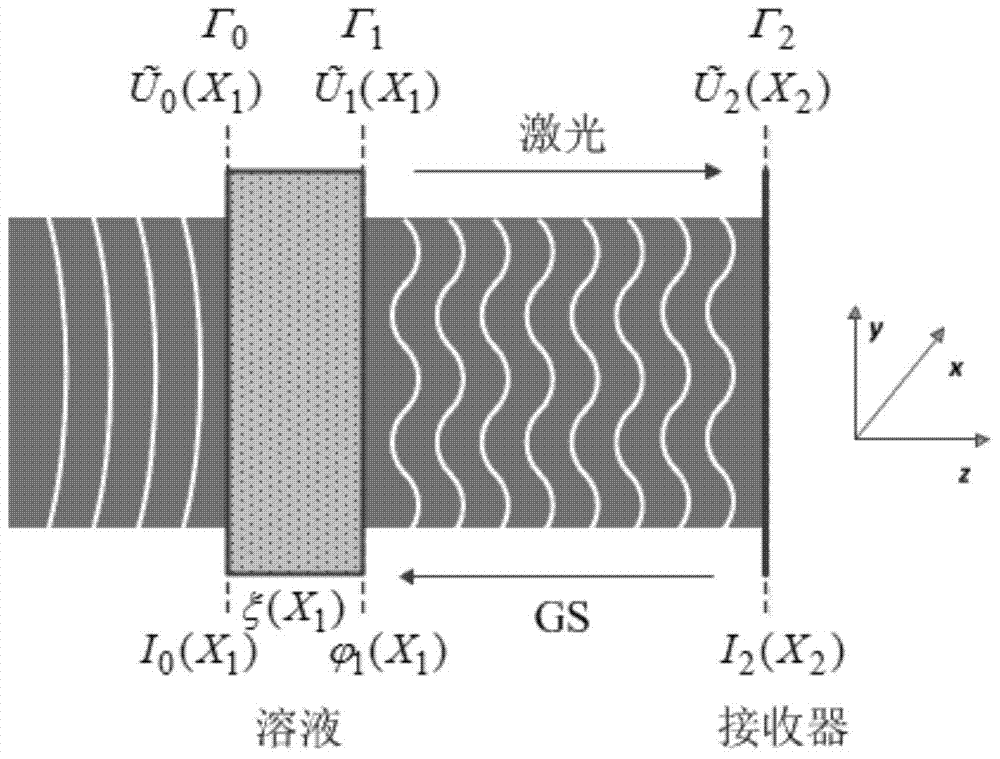

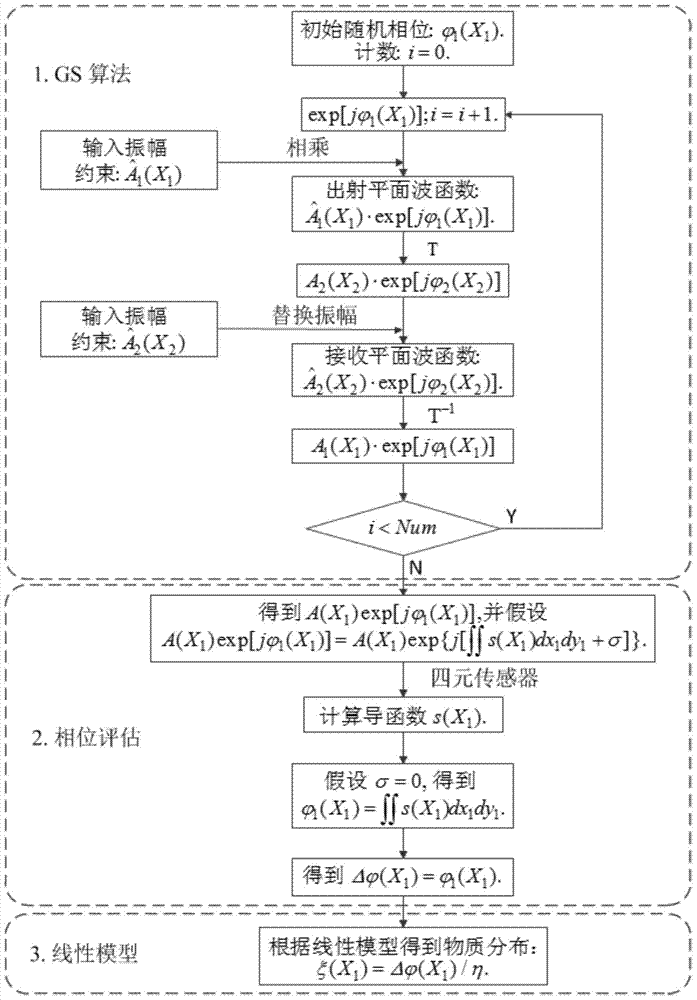

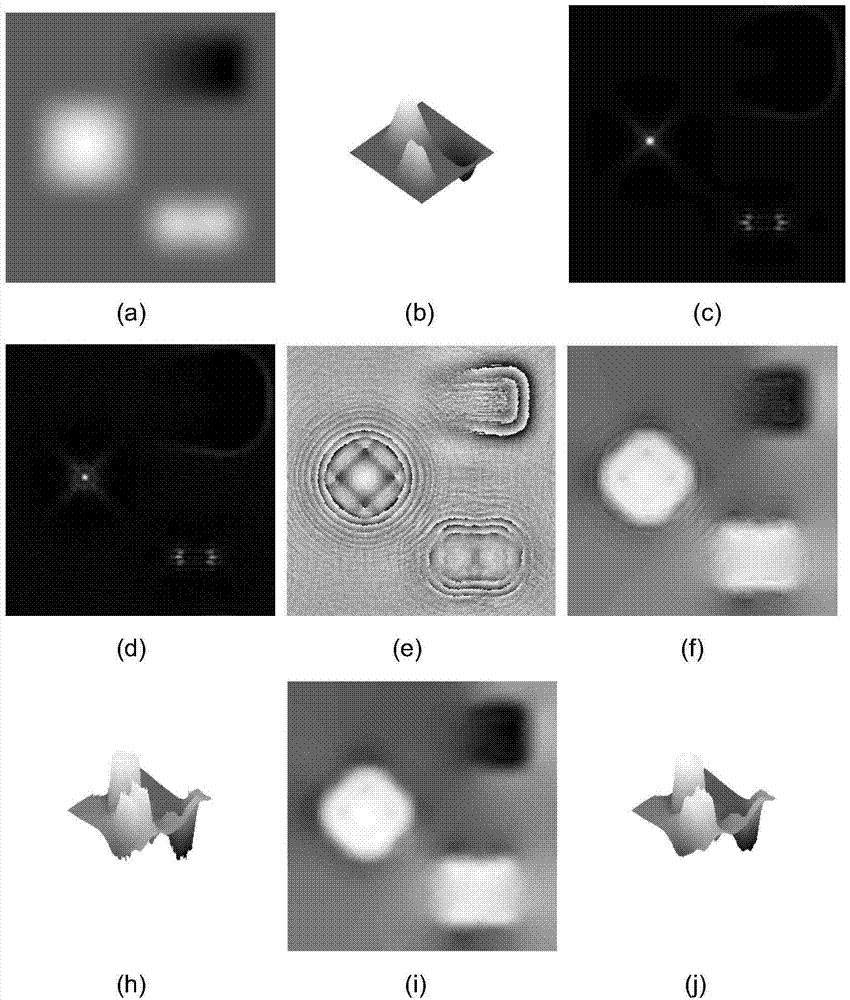

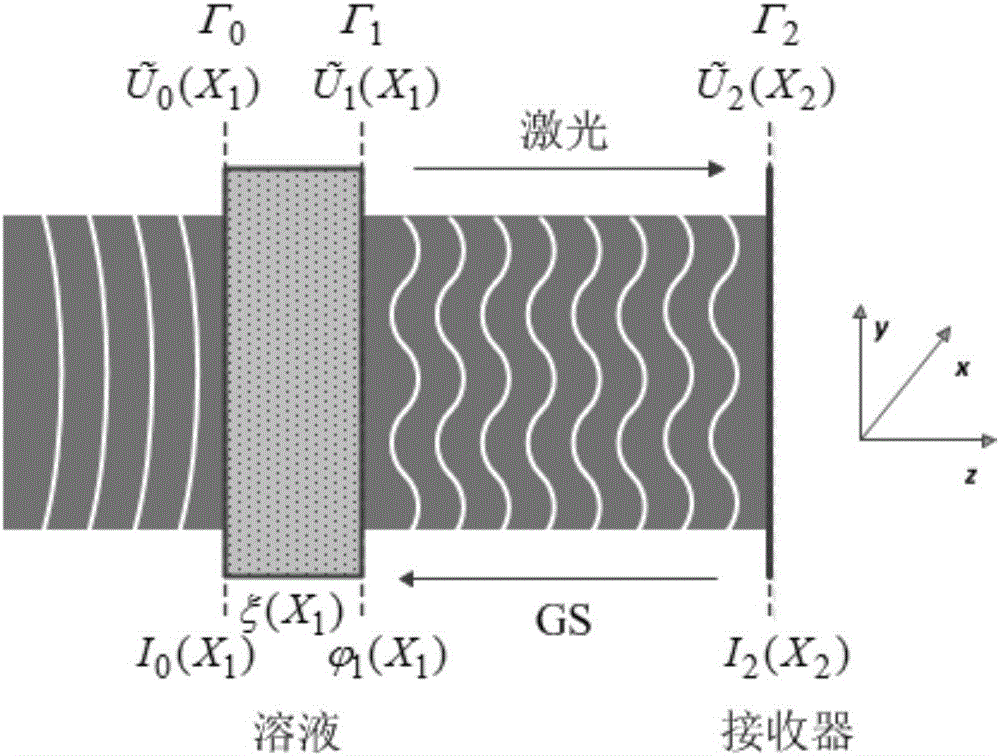

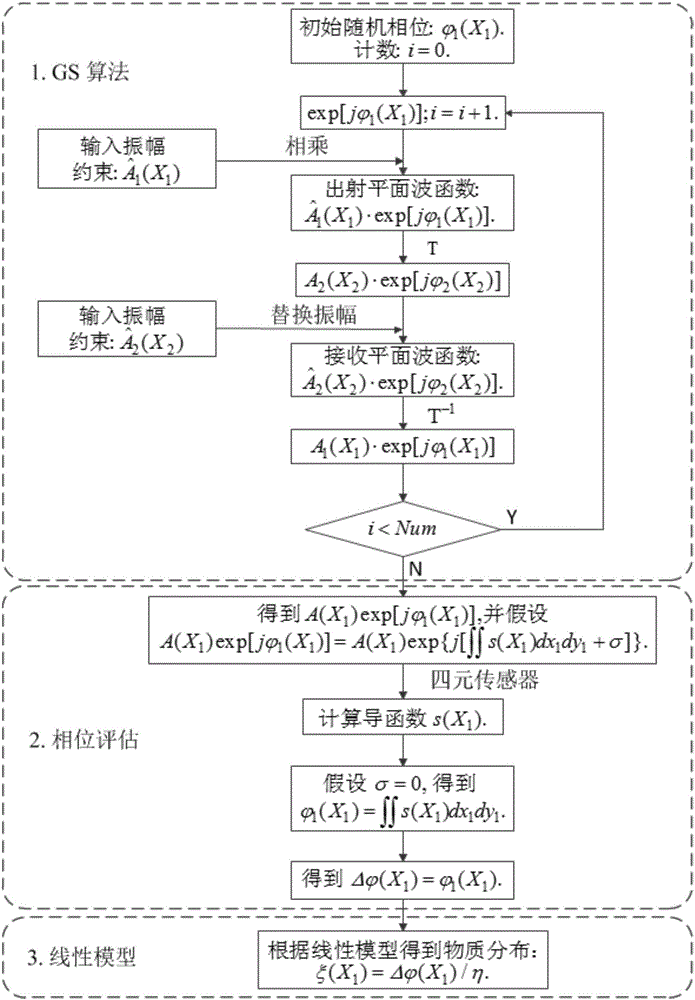

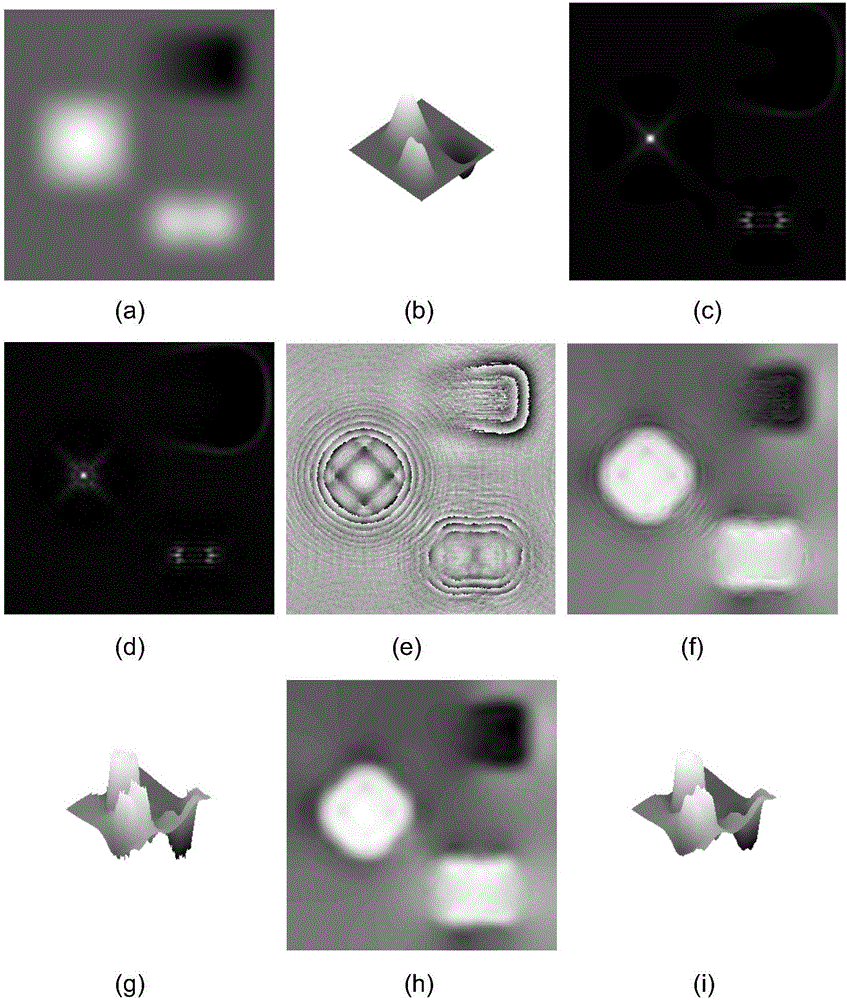

Matter distribution detection method based on phase retrieval

InactiveCN104504735ADetection is accurate and intuitiveHelp analyze qualityImage analysisImage retrievalComputational physics

The invention provides a matter distribution detection method based on phase retrieval. Firstly, a wave function that contains phase change information is retrieved by means of incident light intensity and diffraction light intensity of transparent matters according to a gerchberg-saxton (GS) algorithm; then phase change is calculated in the obtained wave function by a phase evaluation algorithm based on a gradient field in order to avoid phase folding; finally, three-dimensional distribution of matters can be obtained according to linear models of the matter three-dimensional distribution and phase change. By means of the matter distribution detection method based on the phase retrieval, morphology and distribution of the transparent matters can be visually and accurately detected, and reliability and accuracy are high.

Owner:CENT SOUTH UNIV

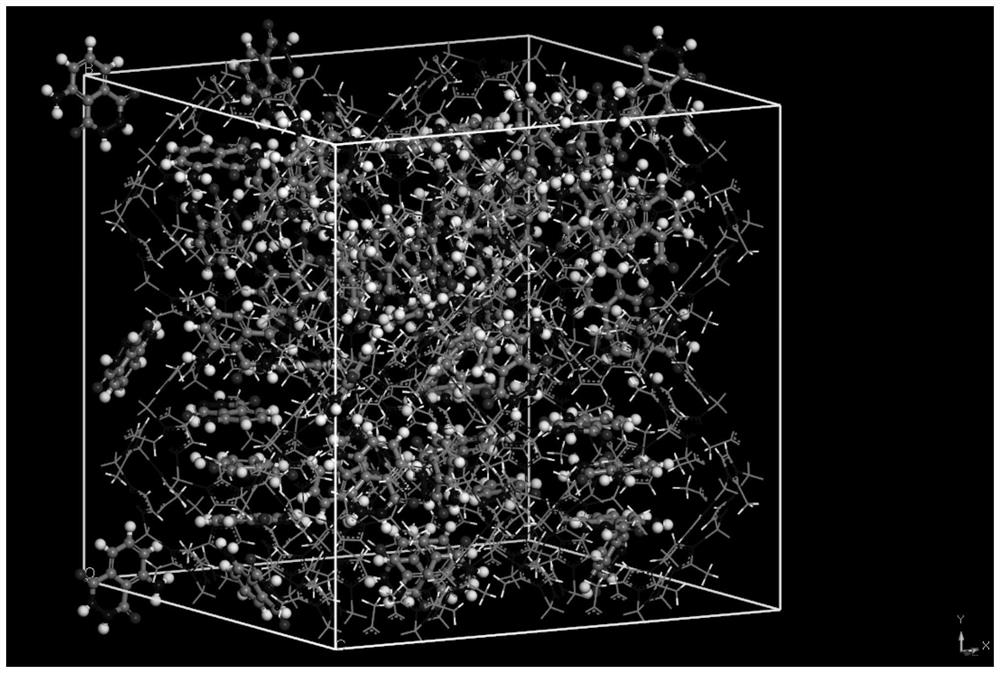

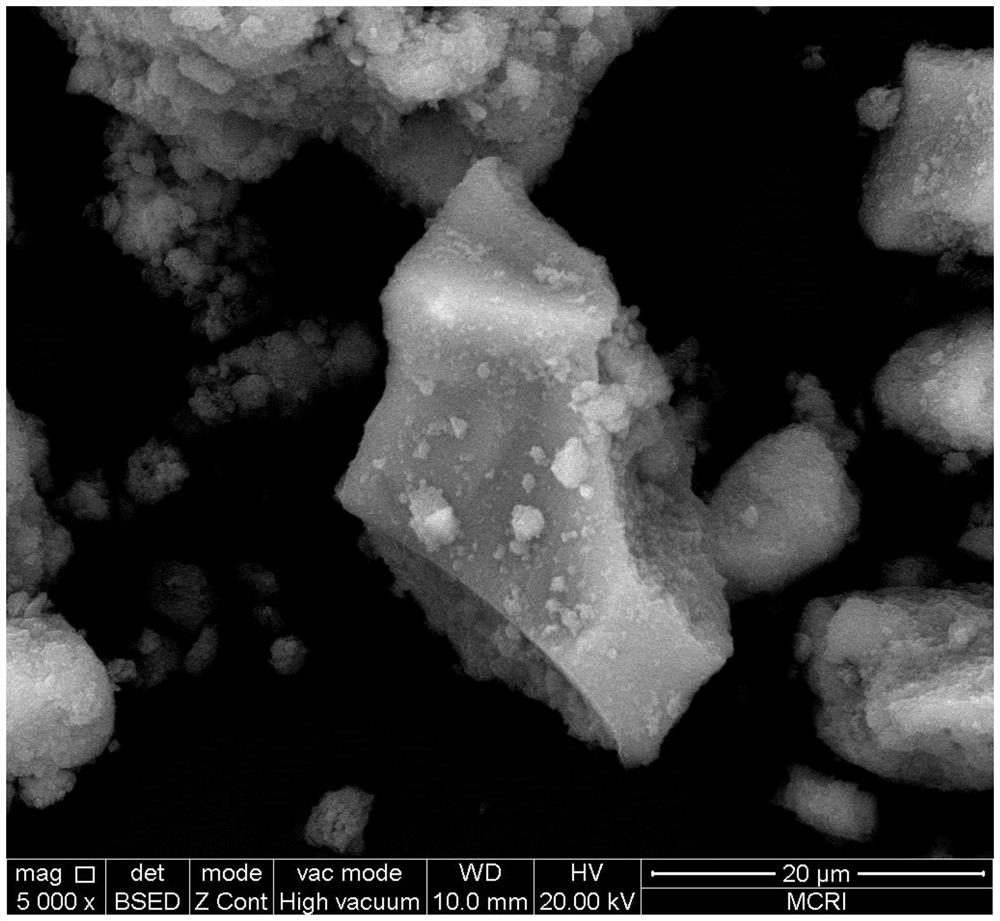

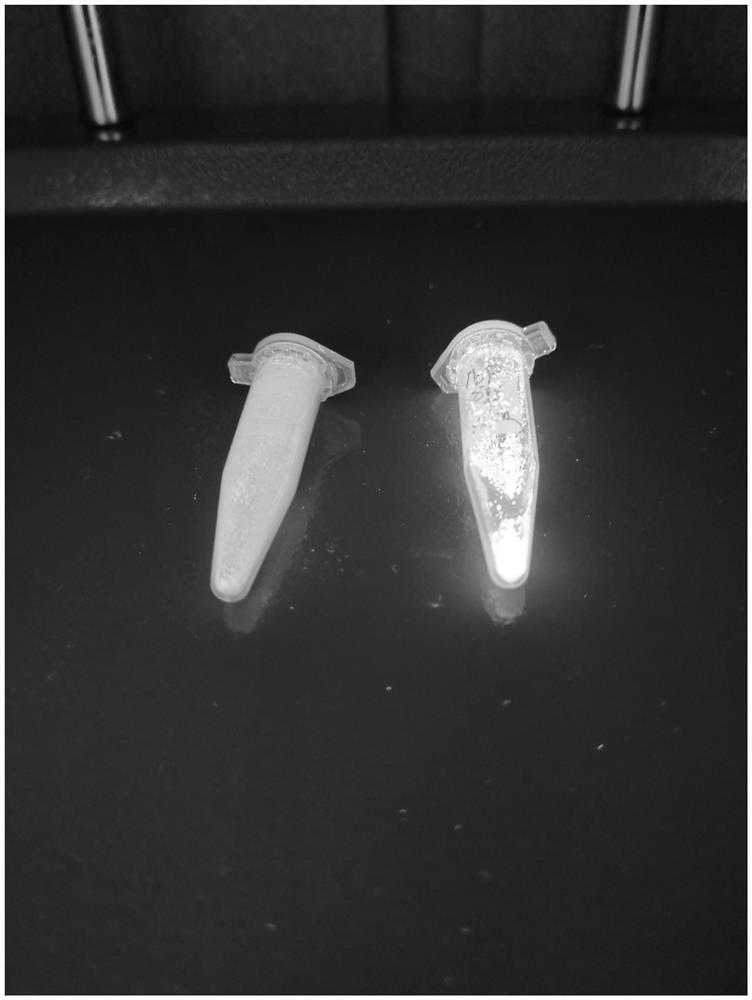

Visual detection method for CL-20 coating uniformity

PendingCN114577769AImprove the efficiency of uniformity inspectionSimplify the experimental stepsFluorescence/phosphorescenceLuminescent compositionsPtru catalystIn situ polymerization

The invention provides a visual detection method for CL-20 coating uniformity, which comprises the following steps: step 1, coating 7-hydroxyl dimethyl all-carbon spirocoumarin to obtain a coating product MOF-808-coumarin; step two, CL-20 coating: sequentially adding a melamine formaldehyde resin prepolymer, methylbenzene, CL-20 and the MOF-808 coumarin prepared in the step one, adding a citric acid catalyst, performing ultrasonic dispersion uniformly, stirring for in-situ polymerization, filtering, and naturally airing to obtain a coating product, namely a CL-20 coating product; and 3, visual detection: directly irradiating the coated product obtained in the step 2 by using an ultraviolet lamp so as to visually detect the uniformity of the coated product according to the solid-state fluorescence distribution condition. According to the visual detection method, after CL-20 coating is carried out, uniformity visual detection is carried out, the method is simple and convenient, and the efficiency of uniformity detection after CL-20 coating can be effectively improved.

Owner:XIAN MODERN CHEM RES INST

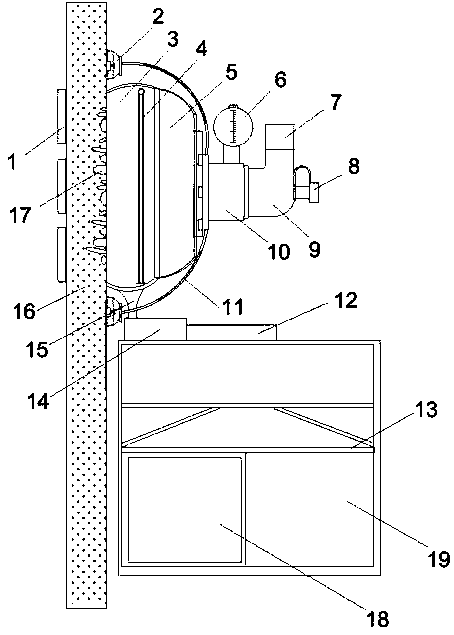

Ink probe device of printer

InactiveCN104494303ADetection is accurate and intuitiveAvoid wastingPrinting press partsVacuum pumpingVacuum extraction

The invention discloses an ink probe device of a printer. The ink probe device comprises an ink probe tube and a vacuum extraction tube. Two ends of the ink probe tube are communicated with each other. One end of the ink probe tube is in threaded connected with the vacuum extraction tube which is internally provided with a piston rod. One end of the vacuum extraction tube is provided with an observation searchlight device, and the other end of the vacuum extraction tube is provided with a probe wiping device. A searchlight tube is arranged in the observation searchlight device. A scale is arranged on the outside of the observation searchlight device. An elastic clamping cleaning wiping head is arranged in the probe tube wiping device. According to the arrangement, residual ink can be visually and clearly detected and then repressed into the printer after being taken out during detection through the vacuum extraction tube, avoiding waste; and a cleaning head of the ink probe tube wiping device is further provided.

Owner:无锡市晨阳彩印厂

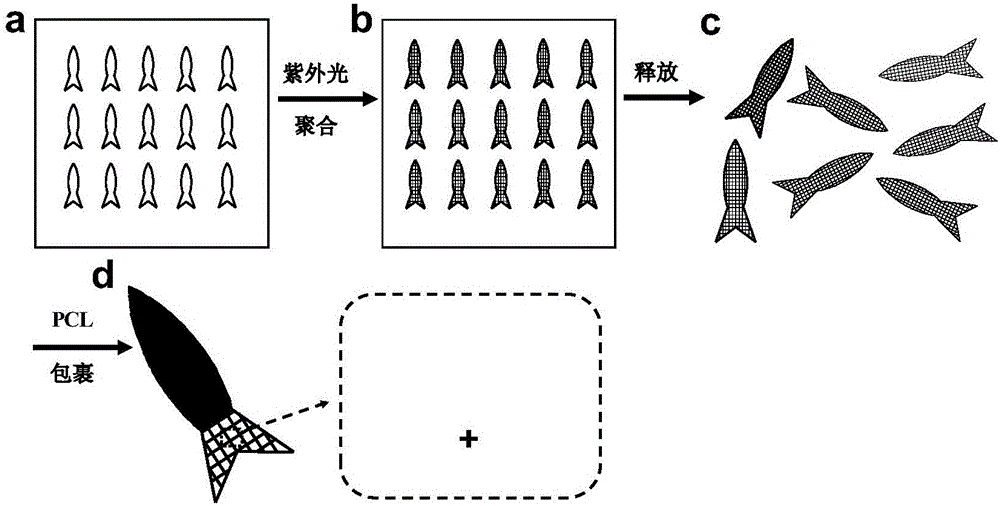

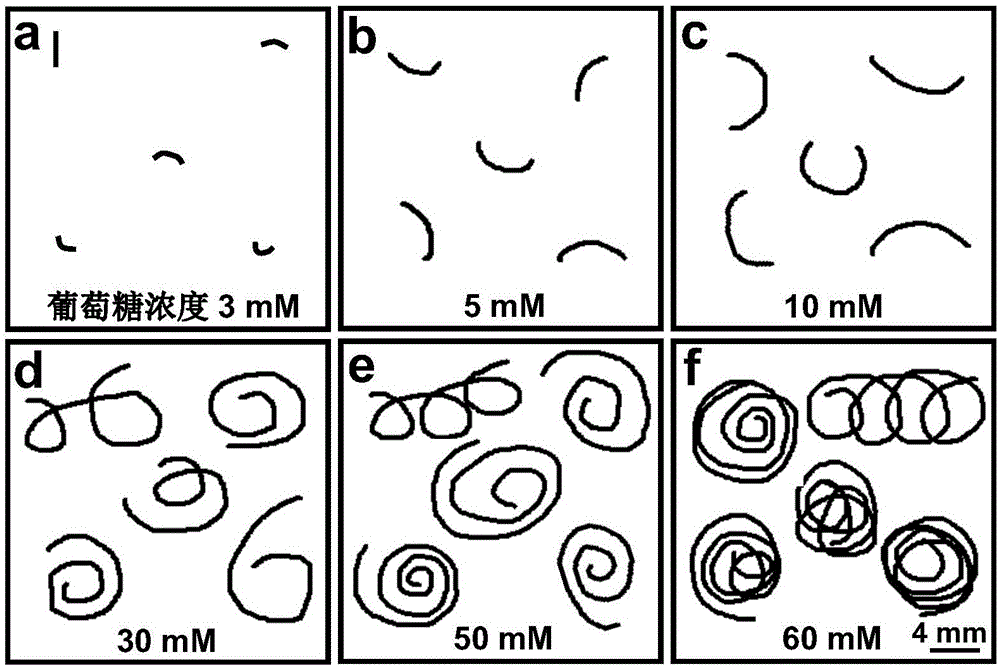

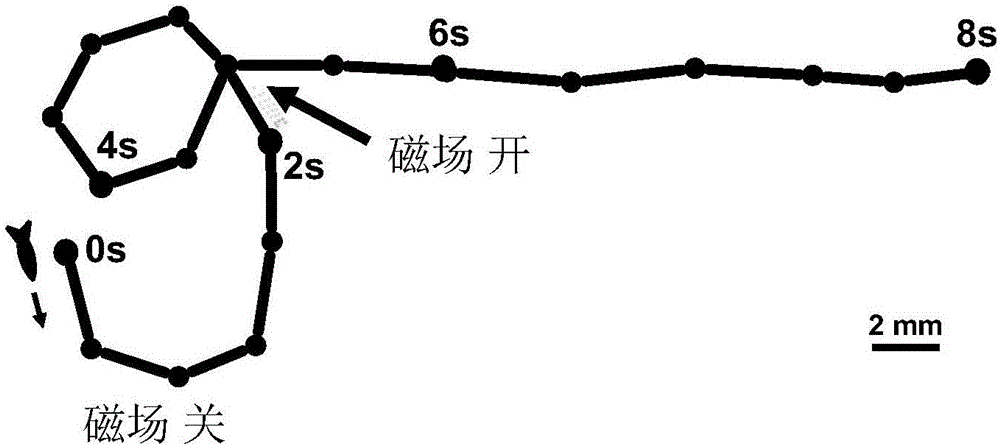

Hydrogel and preparation method and application of ampholytic hydrogel shaped body

ActiveCN106633109ALow detection limitDetection is accurate and intuitiveBiological testingGel preparationConcentrations glucoseUrine glucose

The invention provides hydrogel and application of an ampholytic hydrogel shaped body prepared from the hydrogel in medicine for detecting glucose content in urine. The ampholytic hydrogel shaped body comprises a monomer with telescopic performance and a monometer having response with glucose, a surface active agent and magnetic-induction particles are wrapped in copolymer of the two monomers, a moving route of the ampholytic hydrogel shaped body can be controlled by a magnetic field, and the moving distance and the glucose concentration of ampholytic hydrogel in the same period are calculated and analyzed to obtain a curve chart. The ampholytic hydrogel shaped body has the advantages of being low in detection limit in urine glucose detection and capable of visually and accurately detecting the glucose concentration in the urine.

Owner:SUZHOU UNIV

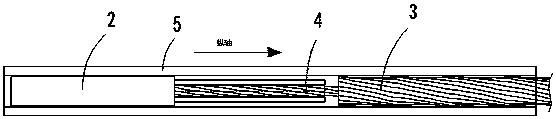

Strain clamp aluminum stranded wire press-fitting quality detection device and method

PendingCN110672724ADetection is accurate and intuitiveAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringUltrasonic testing

The invention discloses a strain clamp aluminum stranded wire press-fitting quality detection device and method. The detection device comprises a steel anchor, aluminum stranded wires, an external detection probe and a digital ultrasonic detection device, wherein the steel anchor and the aluminum stranded wires are press-fitted, the external detection probe is closely attached to press-fitting parts for detection, the digital ultrasonic detection device is electrically connected with the external detection probe, and a to-be-detected surface is uniformly coated with a coupling agent. The detection method comprises detection of the press-fitting parts between the steel anchor and steel cores of the aluminum stranded wires and detection of a press-fitting part between the steel anchor and analuminum bushing. The strain clamp aluminum stranded wire press-fitting quality detection device and method aim to detect press-fitting quality, to be specific, internal conditions of the press-fitting parts are visually displayed in the form of an image, then a press-fitting defect is discovered, and therefore the press-fitting quality is accurately judged.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

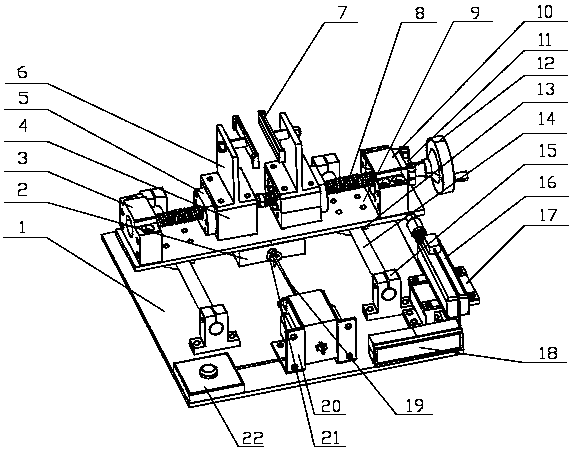

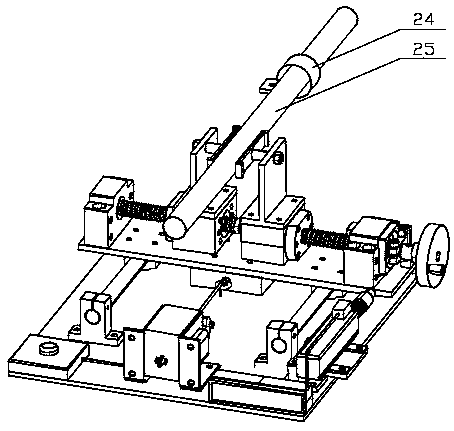

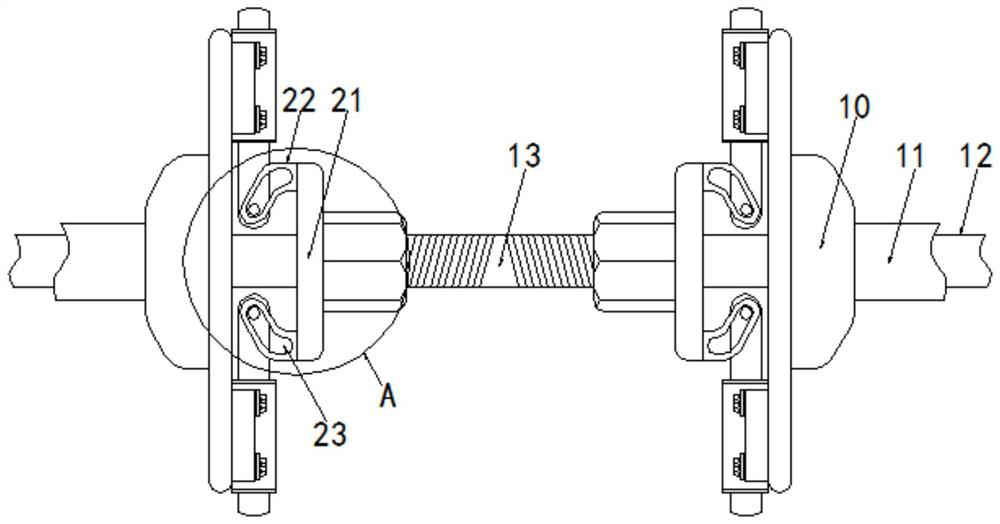

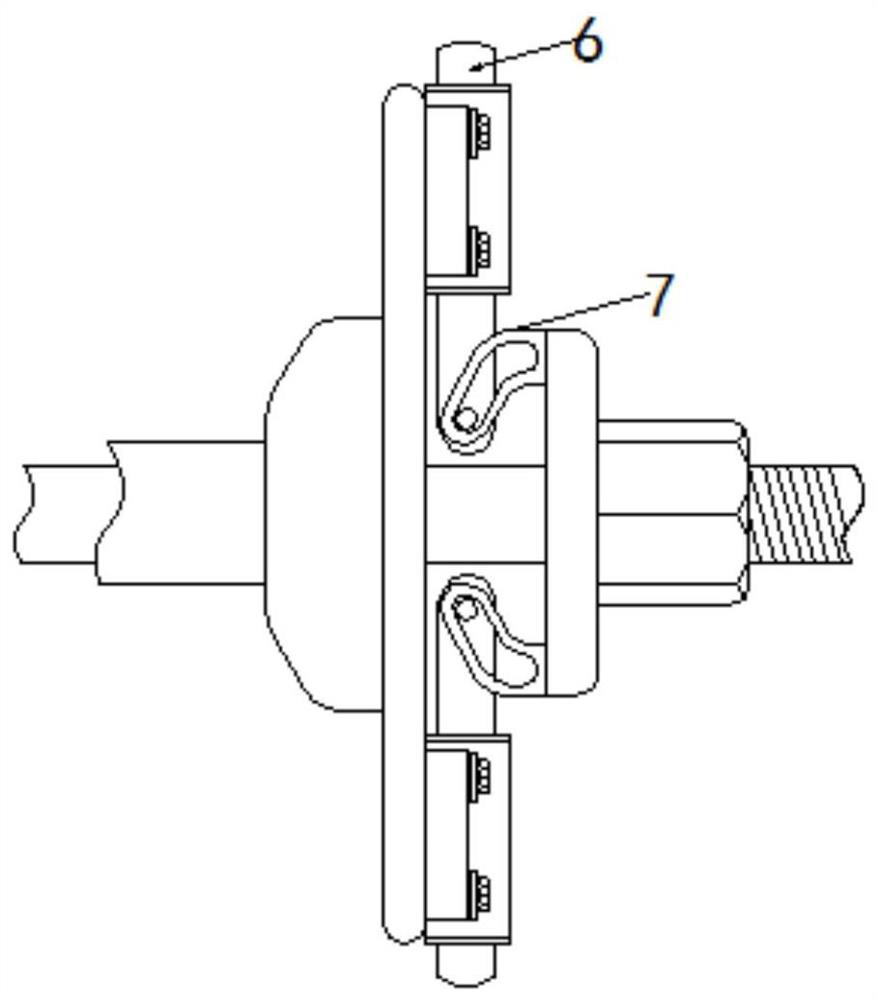

Device for detecting installation quality of wire harness

PendingCN108801330AIntuitive Assembly QualityReduce labor intensityMeasurement devicesAircraft components testingSingle chipBolt connection

The invention belonging to the field of detecting equipment discloses a device for detecting the installation quality of a wire harness so that the stable medium force can be provided. Two ends of a ball lead screw are respectively fixed to a BF10 support seat and a BK10 support base respectively; one end of the lead screw is connected with a hand wheel through a lead screw lock; and an assemblingbody is fixed to a mobile support by a bolt. A clamping mechanism consists of lead screw nut bases, lead screw nuts, T-shaped plates, straight plate clamps and a ball lead screw. A mobile support unit is fixed with a suspension ring sliding base and sliding blocks by bolt connection. A displacement sensor is fixed to a rising bench by bolt connection; a sensing head of the displacement sensor isin contact with the side of the moving support unit; and a wire is connected to a single-chip microcomputer. A traction electromagnet is fixed to a bottom plate support by bolt connection and is connected with a suspension ring nut by a connecting rod. The device is able to provide a constant medium tension and display an inspection result digitally; and thus the assembly quality of the wire harness can be detected visually and accurately.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

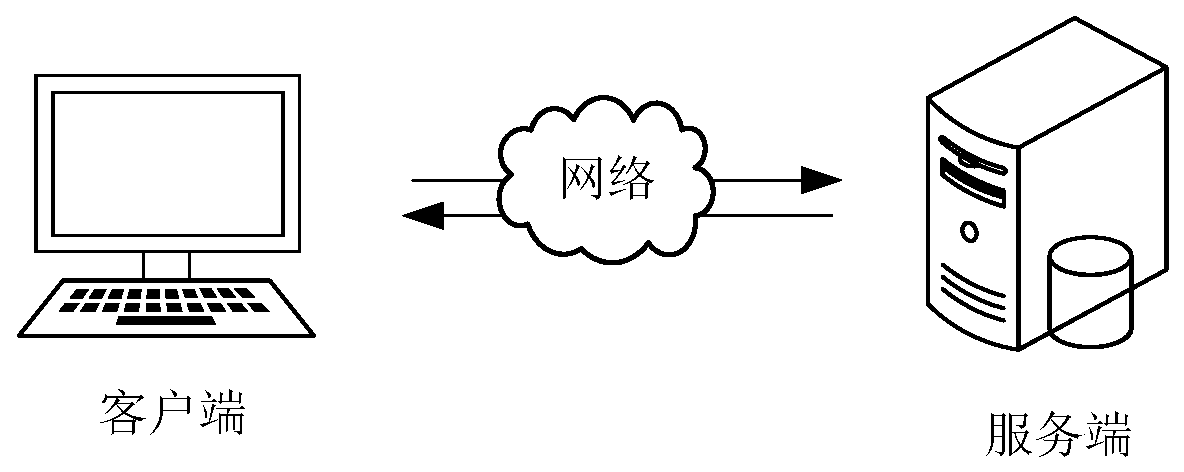

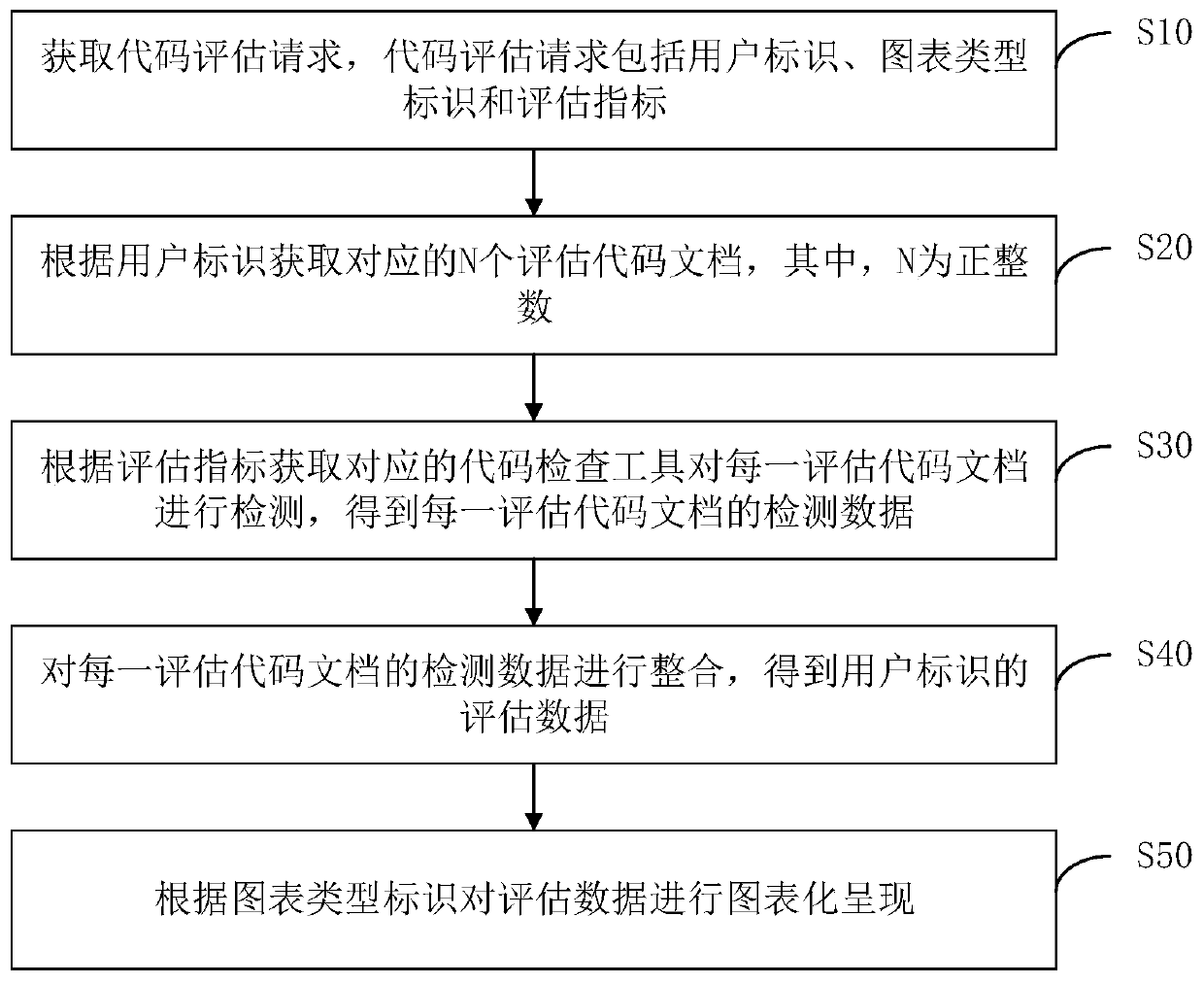

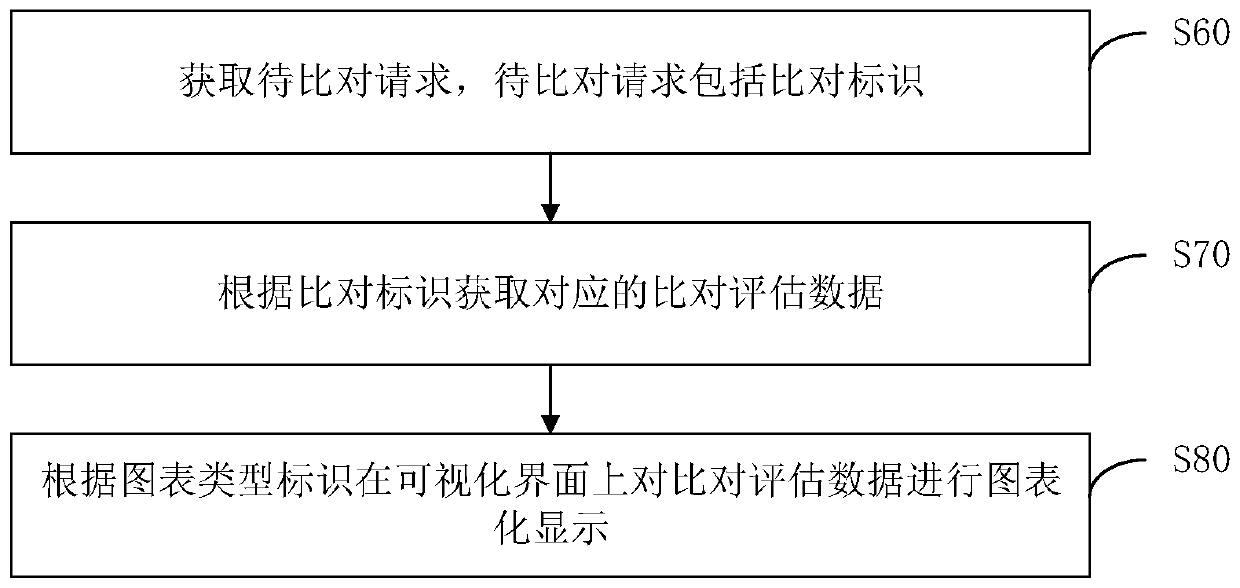

Code detection method and device, computer equipment and storage medium

PendingCN109857657ADetection is accurate and intuitiveSoftware testing/debuggingCode assessmentUser identifier

The invention discloses a code detection method. The method comprises the following steps: firstly obtaining a code evaluation request which comprises a user identification, a chart type identification and an evaluation index; N corresponding evaluation code documents are obtained according to the user identification, and N is a positive integer; obtaining a corresponding code inspection tool according to the evaluation index to detect each evaluation code document to obtain detection data of each evaluation code document; integrating the detection data of each evaluation code document to obtain evaluation data of the user identifier; and finally, performing graphical presentation on the evaluation data according to the chart type identifier. The evaluation code document corresponding to the user identifier is evaluated through different evaluation indexes, and finally the evaluation data is presented in a graphical mode according to the chart type identifier, so that code evaluation is more accurate and visual. The invention further discloses a code detection device, related computer equipment and storage medium.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

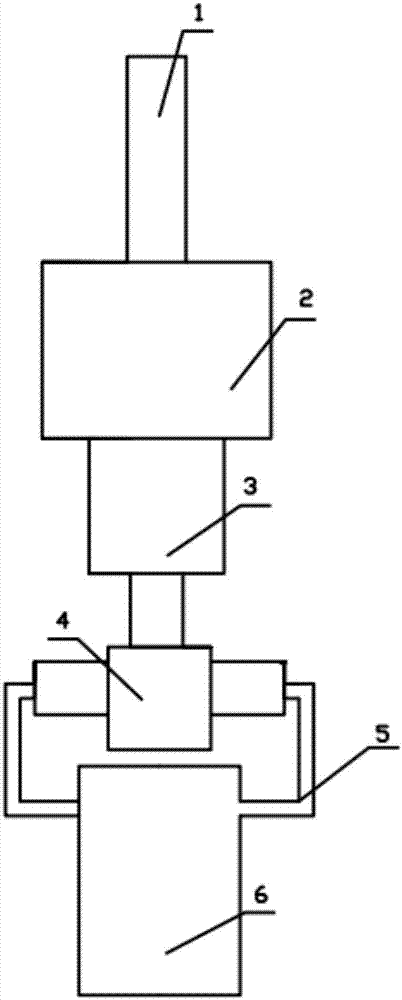

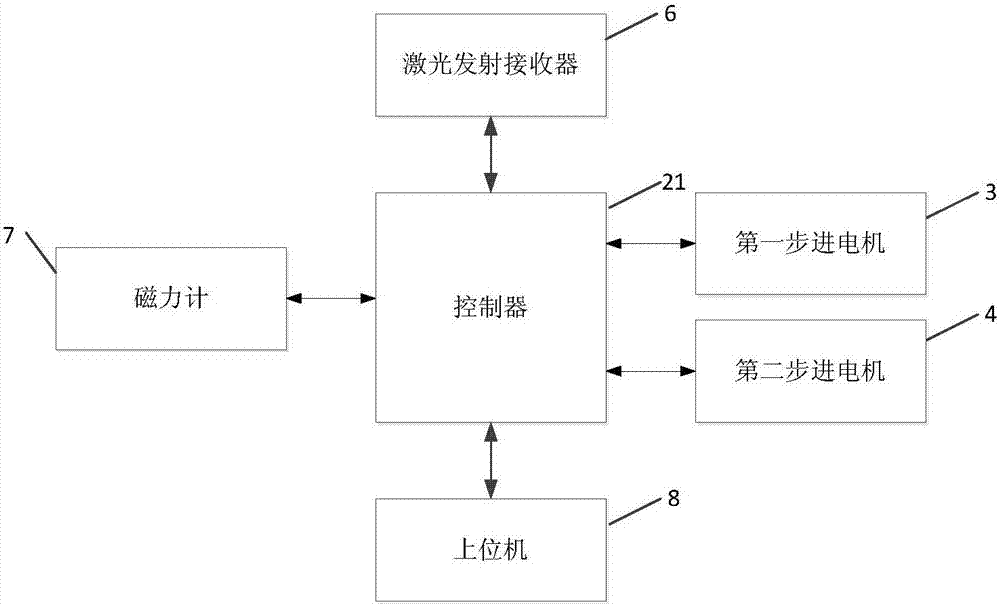

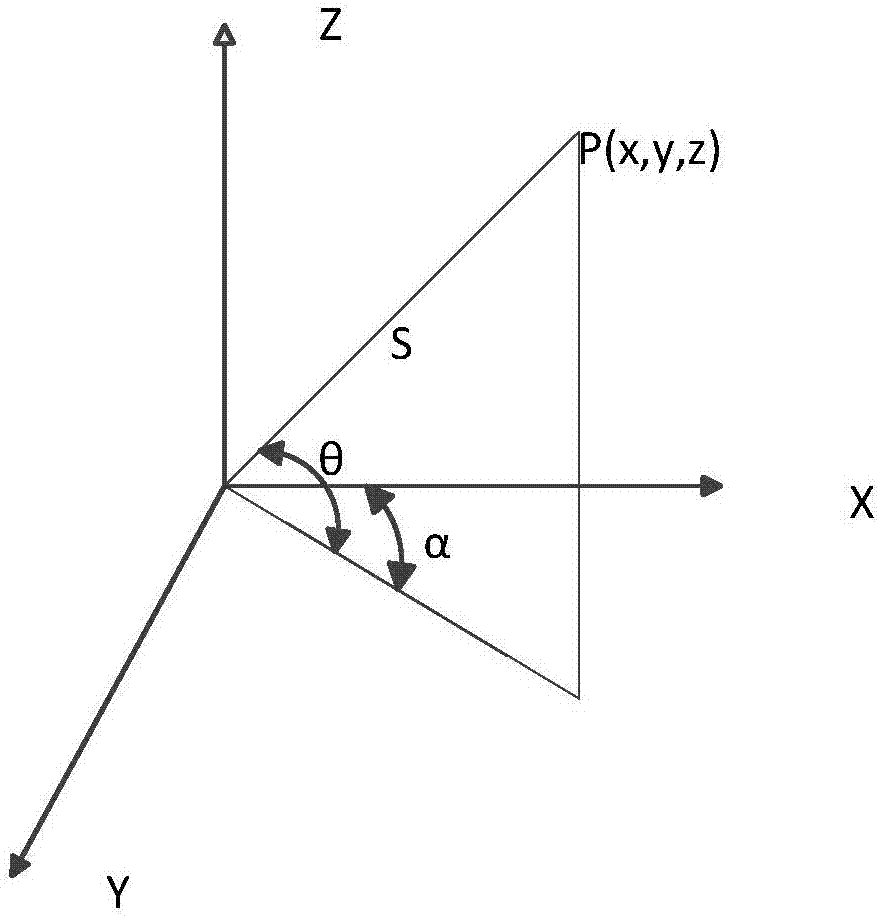

Underground space laser 3D imaging device and imaging method

PendingCN107957250AFunction increaseIntuitive and accurate detectionOptical detectionUsing optical means3d imageEngineering

The invention discloses an underground space laser 3D imaging device and an imaging method. The imaging device comprises a vertical telescopic rod, a control box, a first stepping motor, a second stepping motor, a rocking arm, a laser emission receiver, a magnetometer and an upper computer, wherein the control box is connected with the lower end of the vertical telescopic rod; the first stepping motor and the second stepping motor are arranged at the lower end of the control box; the horizontal and vertical rotation of the laser emission receiver can be achieved; the magnetometer is fixedly connected with the laser emission receiver and is used for measuring azimuth information of the laser emission receiver; the upper computer is used for receiving spherical scanning data obtained by thelaser emission receiver, and processing the data to obtain imaging information. According to the underground space laser 3D imaging device and the imaging method, the functions of other underground detection device are optimized, and the geometrical morphology and the space change of an underground space can be detected intuitively and accurately.

Owner:JILIN UNIV

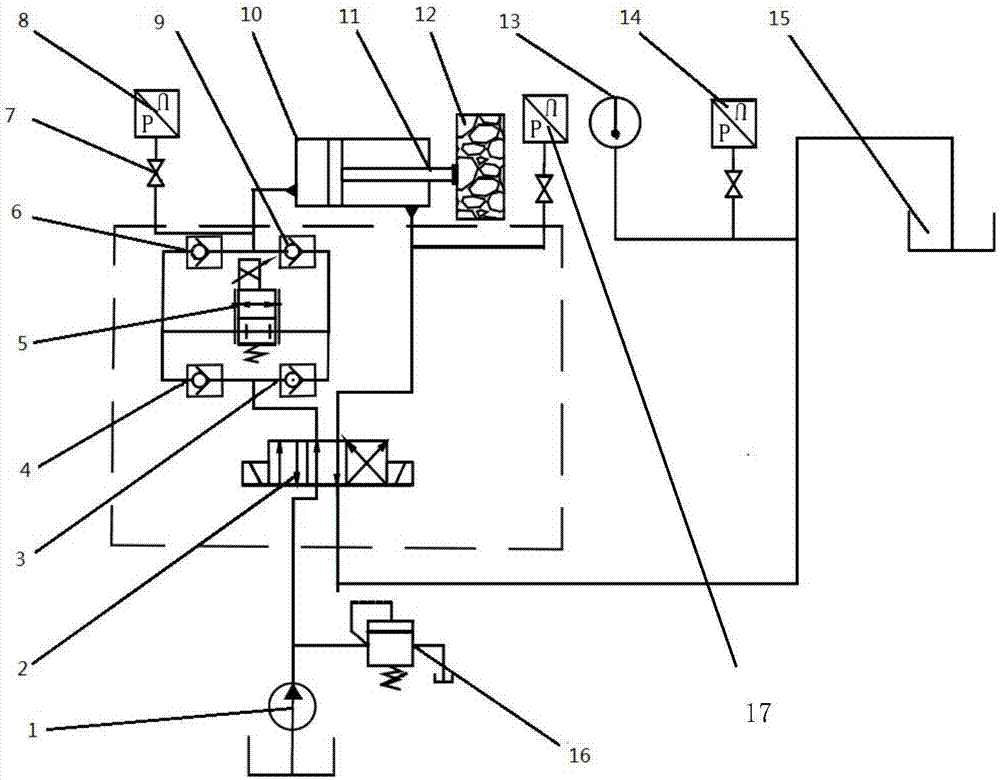

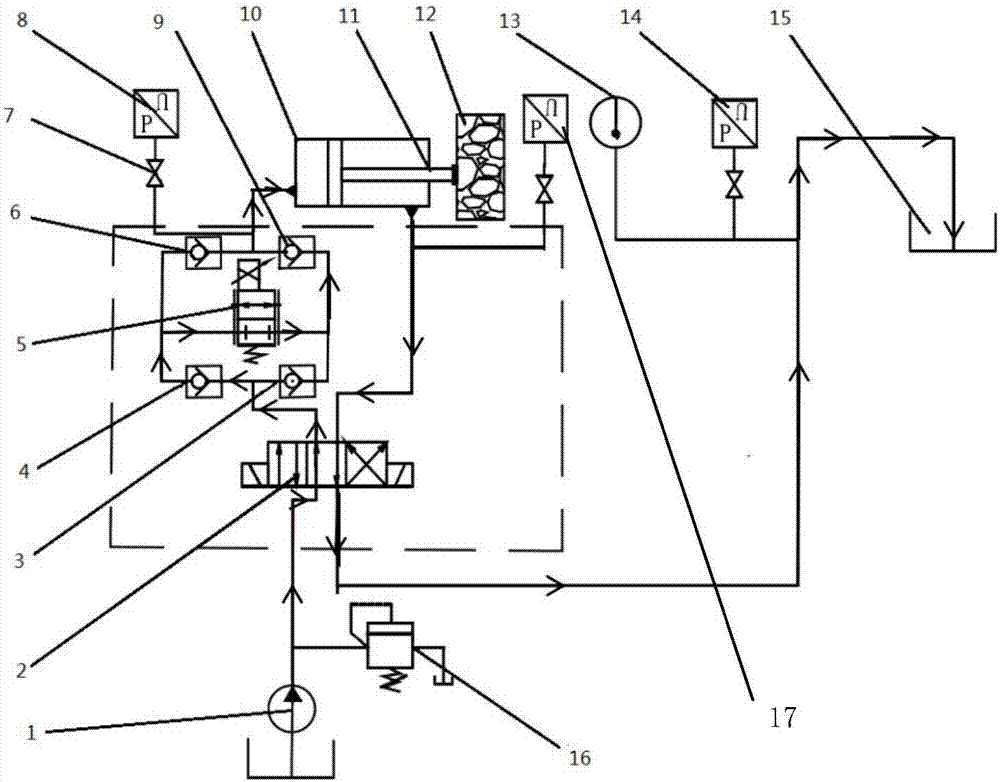

High-temperature high-pressure oil way system for three-position four-way hydraulic combined valve

InactiveCN107989847AControl the speed of left and rightReduce volumeServomotor componentsServomotorsHydraulic cylinderFuel tank

The invention discloses a high-temperature high-pressure oil way system for a three-position four-way hydraulic combined valve. The high-temperature high-pressure oil way system comprises a high-pressure plunger pump, a three-position four-way reversing valve, a proportional throttle valve and a high-pressure hydraulic cylinder. The three-position four-way reversing valve is connected with the high-pressure plunger pump, the proportional throttle valve, the high-pressure hydraulic cylinder and an oil tank. The high-pressure hydraulic cylinder is connected with a simulation load through a high-pressure piston rod. The input end of the high-pressure hydraulic cylinder is connected with the output end of the proportional throttle valve. The proportional throttle valve and four one-way valvesform a bridge type loop system. According to the high-temperature high-pressure oil way system for the three-position four-way hydraulic combined valve, the three-position four-way reversing valve where oil can enter through two oil ways is adopted to replace a plurality of function valves in two kinds of equipment, a high-temperature high-pressure bearing valve where energizing is conducted fromthe left and the right and oil enters from the left and the right is achieved, and oil pressure is adjusted through the bridge type loop system; the inlet flow and the outlet flow of a rodless cavityof the hydraulic cylinder are controlled; the left inlet speed and the right inlet speed of the oil tank are controlled; the functions of two proportional throttle valves are achieved through one proportional throttle valve; and test detection of high-temperature high-pressure oil on a hydraulic part is completed.

Owner:沈阳创新航空科技有限公司

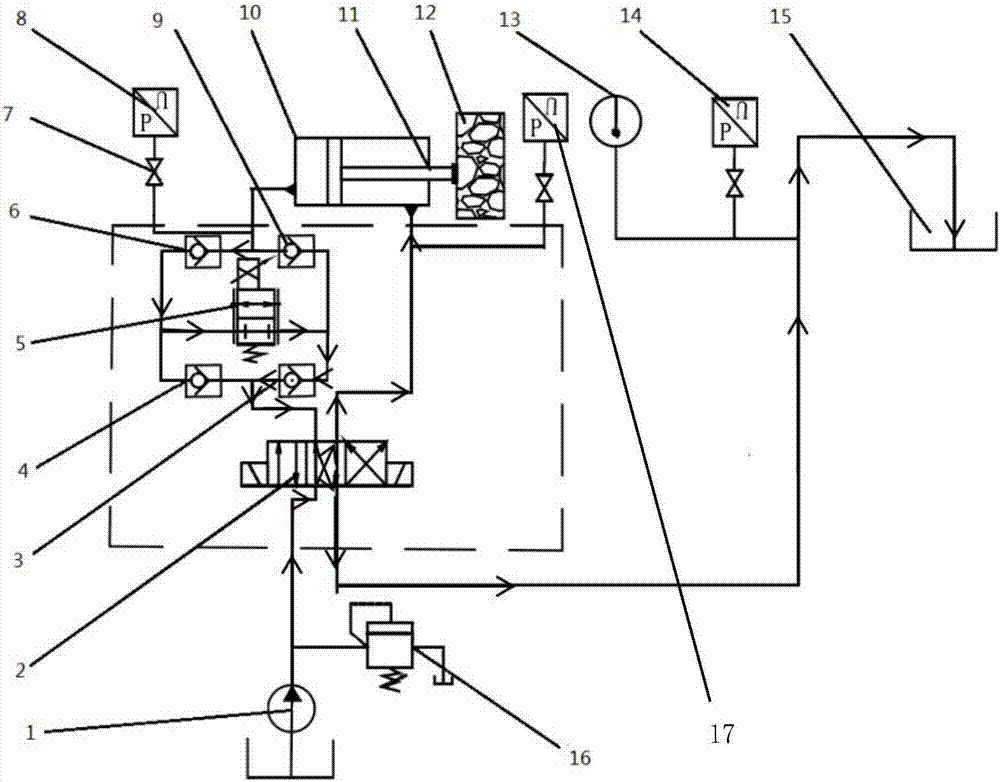

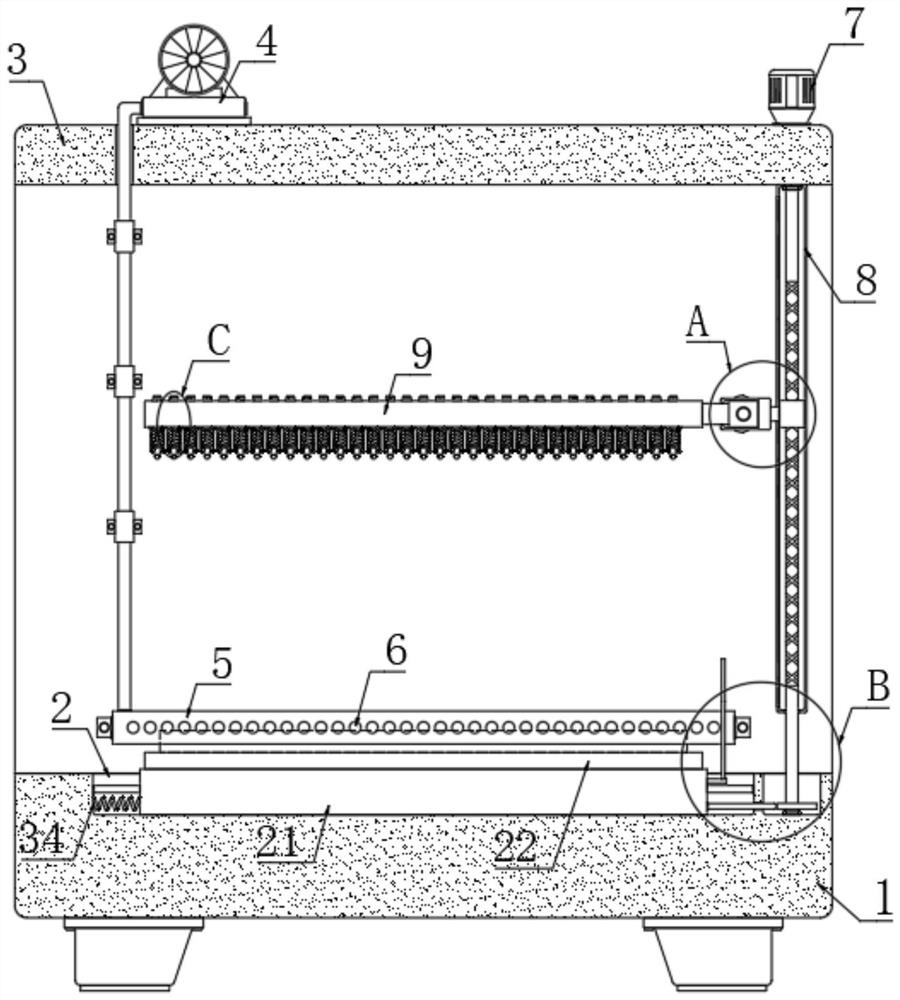

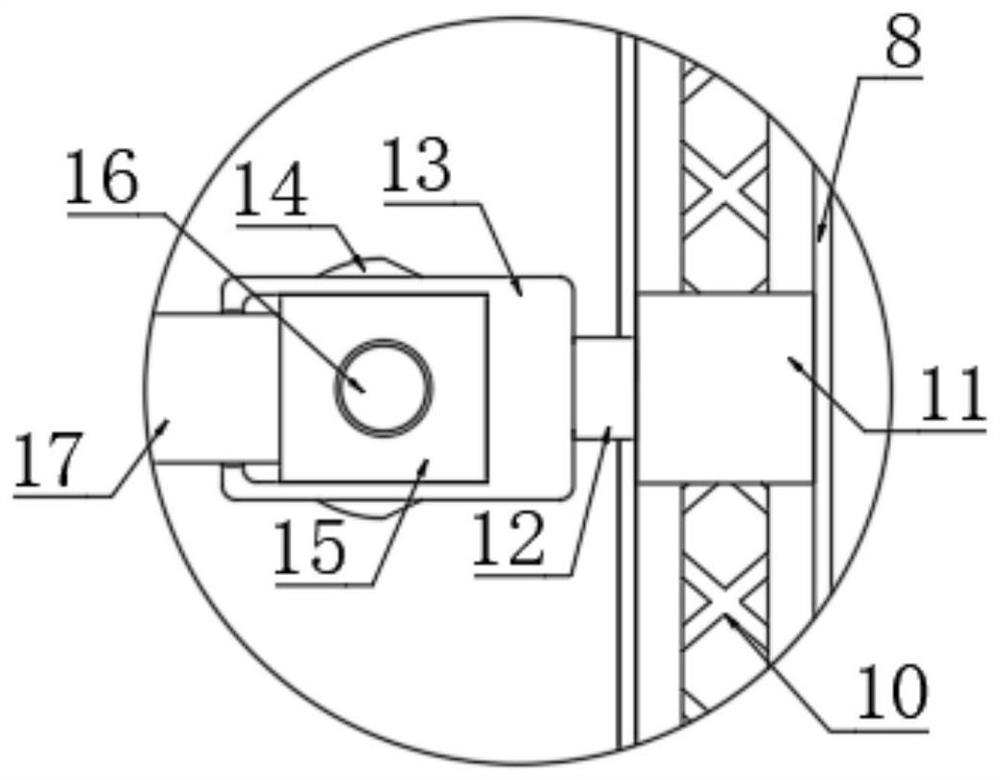

Flatness detection equipment for building wood processing and detection method thereof

PendingCN114018207AAvoid situations where flatness detection is affectedDetection is accurate and intuitiveMeasurement devicesAgricultural engineeringEngineering

The invention discloses flatness detection equipment for building wood processing. The flatness detection equipment comprises a base; an L-shaped mounting frame is mounted at the upper end of the base, and the L-shaped mounting frame is composed of a transverse plate and a vertical plate; a cleaning mechanism is mounted on the front side of the vertical plate, the cleaning mechanism comprises a hollow air outlet strip mounted on the front side of the vertical plate, a plurality of air outlets are formed in the front side of the hollow air outlet strip, and the air outlet end of the fan extends into the hollow air outlet strip; a detection mechanism is arranged between the transverse plate and the base and comprises a detection strip arranged between the transverse plate and the base. The invention further provides a detection method of the flatness detection equipment for building wood processing. Before detection, the surface of a wood board can be subjected to pre-chipping treatment and chipping removal before detection, and during detection, the wood board is moved left and right in a reciprocating manner, so that the detection structure can more comprehensively detect the wood board, and the detection accuracy is greatly improved.

Owner:魏本林

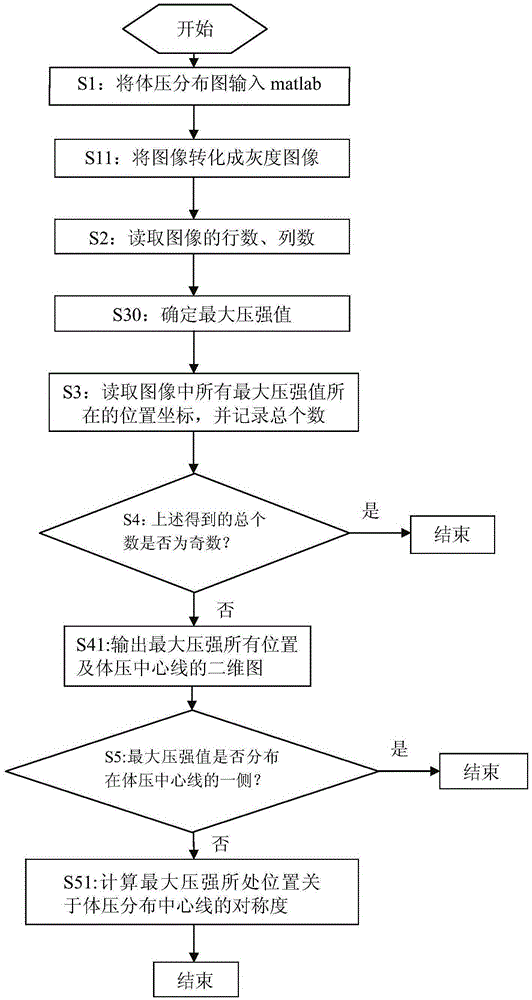

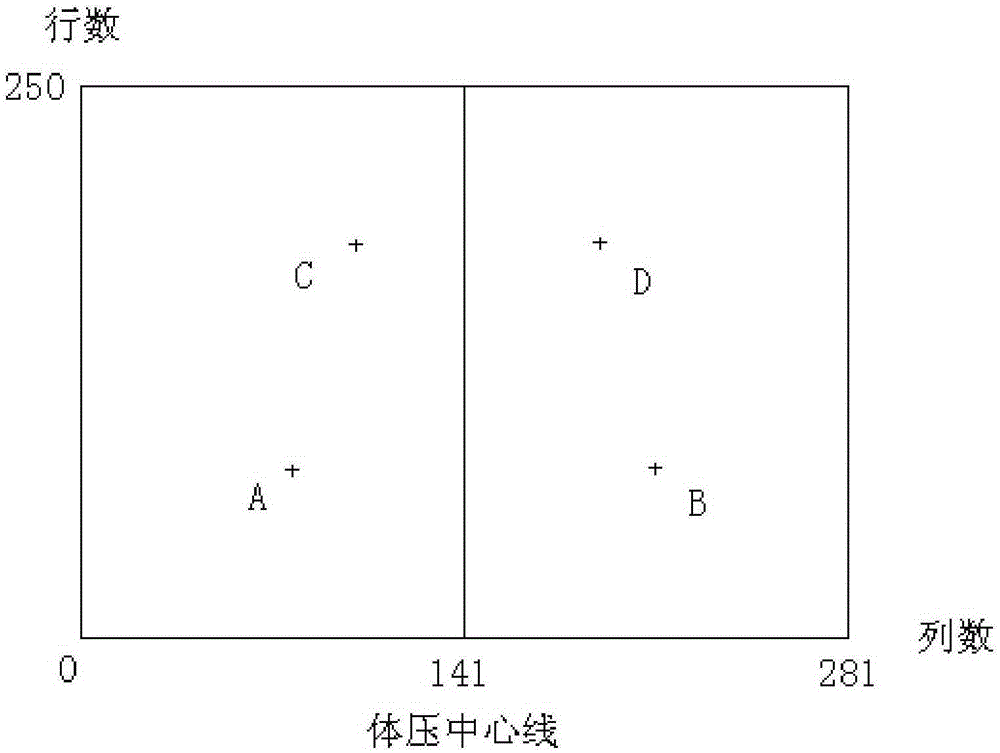

Method for detecting body pressure distribution symmetry of seat

ActiveCN105303559ADetection is accurate and intuitiveImage analysisTwo-dimensional graphImaging processing

The invention discloses a method for detecting the body pressure distribution symmetry of a seat. The method comprises the steps of 1, acquiring a body pressure distribution graph; 2, reading the row number and the column number of the body pressure distribution; 3, reading the position coordinates of maximum pressure values in the body pressure distribution graph and counting the total number of maximum pressure values; 4, on the condition that the total number is an odd number, determining the body pressure distribution of the seat to be in the asymmetrical state and stopping the process; otherwise, displaying the position coordinates of the maximum pressure values and the center line of the body pressure in a two-dimensional graph; 5, on the condition that the maximum pressure values are on one side of the center line of the body pressure or the numbers of the maximum pressure values on the two sides of the center line are not equal in the two-dimensional graph obtained in the step 4, judging the body pressure distribution of the seat to be in the asymmetrical state and stopping the process; otherwise, calculating the body pressure distribution symmetry of the seat and quantizing the determined body pressure distribution symmetry of the seat. According to the technical scheme of the invention, on the basis of the measured body pressure distribution of the seat, the body pressure distribution symmetry of the seat can be intuitively and accurately detected through the image processing process.

Owner:BEIQI FOTON MOTOR CO LTD

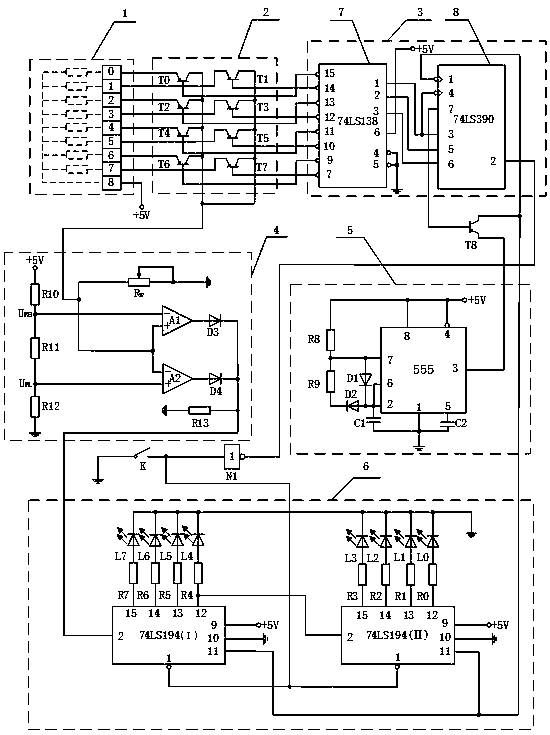

Resistor pack condition detecting device

PendingCN108254645AAutomatic detectionDetection is accurate and intuitiveElectrical testingShift registerElectrical resistance and conductance

The invention belongs to the technical field of electronics and relates to a resistor pack condition detecting device. The resistor pack condition detecting device comprises a resistor pack socket, acombined multi-way switch circuit, a combined multi-way switch control circuit, a window voltage comparator, a 555 multivibrator circuit and a resistor pack condition display circuit. The combined multi-way switch control circuit comprises a 74LS390 counter and a 74LS138 decoder. The resistor pack condition display circuit comprises a 74LS194 shifting register I, a 74LS194 shifting register II andLED indicator lights. By one-by-one comparison of voltages of pins inserted into a resistor pack, conditions of the pins of the resistor pack can be directly reflected through on-off conditions of the LED indicator lights. When resistors are damaged, the corresponding LED indicator lights emit light, and accordingly conditions of specific pin resistors in the resistor pack can be automatically, quickly, accurately and directly detected, and convenience in quick and accurate detection of resistor pack conditions is achieved.

Owner:KUNMING UNIV OF SCI & TECH

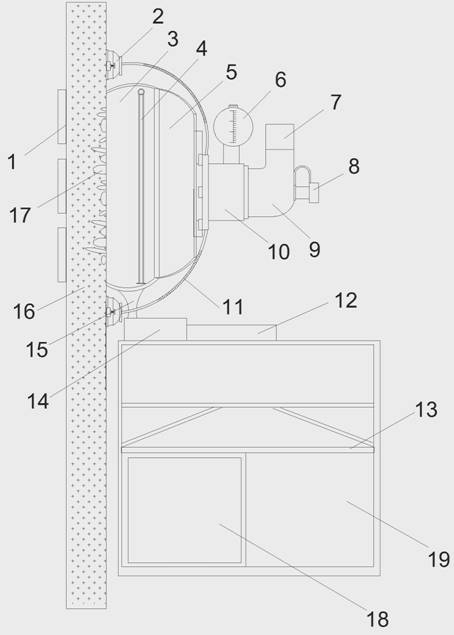

Water purifier filter element replacement grading reminding device and method

ActiveCN111196640ARealize the effect of grading reminderDetection is accurate and intuitiveWater treatment parameter controlSpecific water treatment objectivesMicrocomputerMicrocontroller

The invention discloses a water purifier filter element replacement grading reminding device, which comprises a water purifier body and a detection device, wherein the water purifier body comprises afiltering device; the filtering device comprises four stages of filter elements; the detection device comprises a color recognition module, a TDS detection module, a temperature detection module, a water flow sensor and a single chip microcomputer module; and the color recognition module, the TDS detection module, the temperature detection module and the water flow sensor are connected with the single chip microcomputer module. The invention also discloses a water purifier filter element replacement grading reminding method. The method comprises the following steps of: reminding a user to replace a first grade of pp cotton filter element by utilizing the color recognition module, and reminding the user to replace the three-stage RO membrane filter element by using the TDS value after temperature compensation and the desalination rate, or reminding the user to replace the three-stage RO membrane filter element by using the water flow after temperature compensation. Different indexes ofdifferent filter elements are detected, and the effects of self-inspection at each stage, judgment at each stage and graded reminding are realized.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

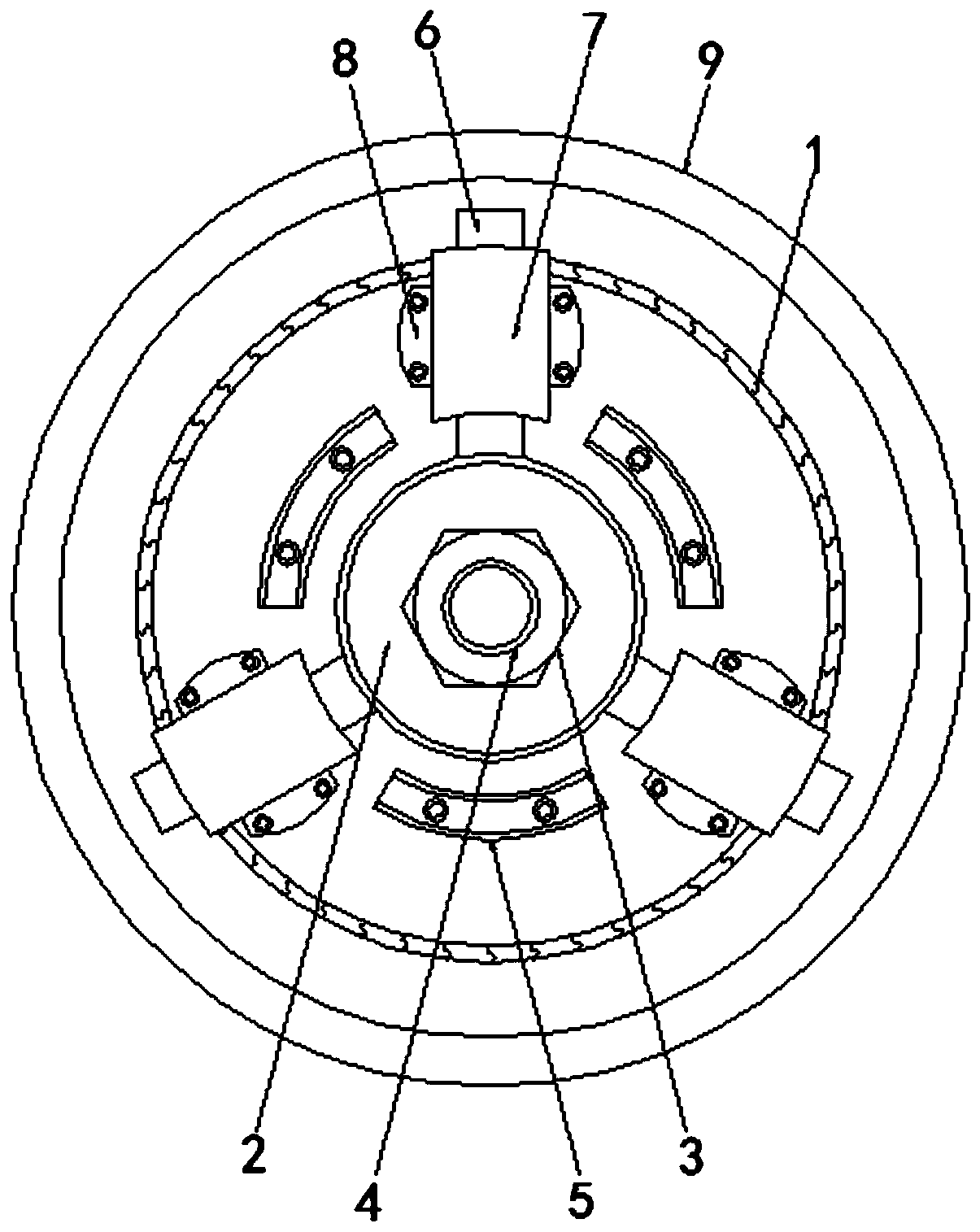

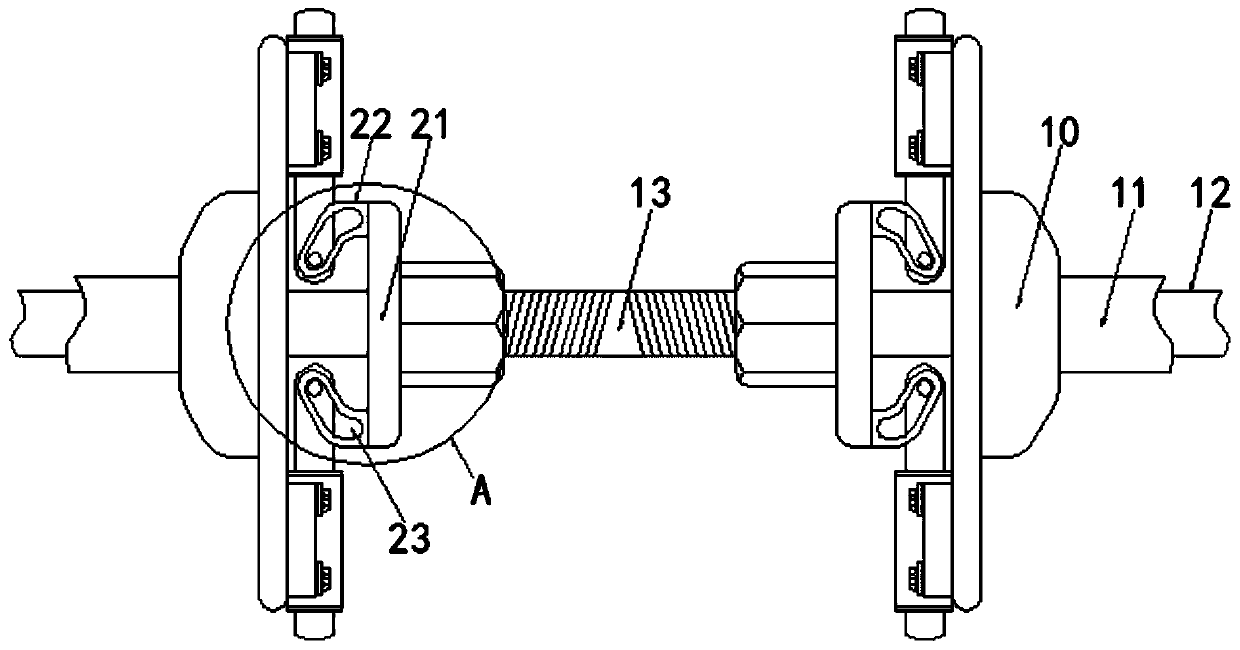

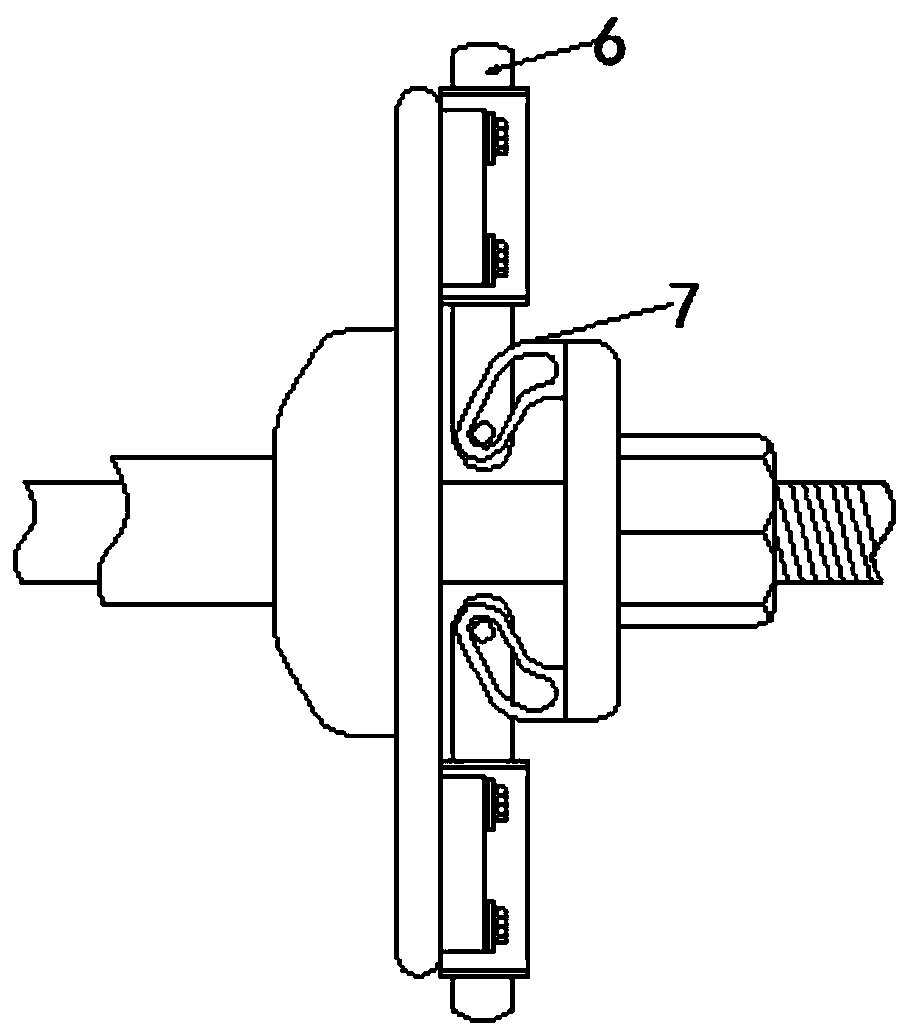

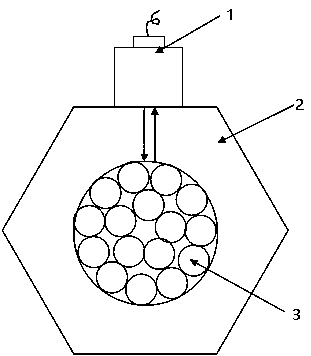

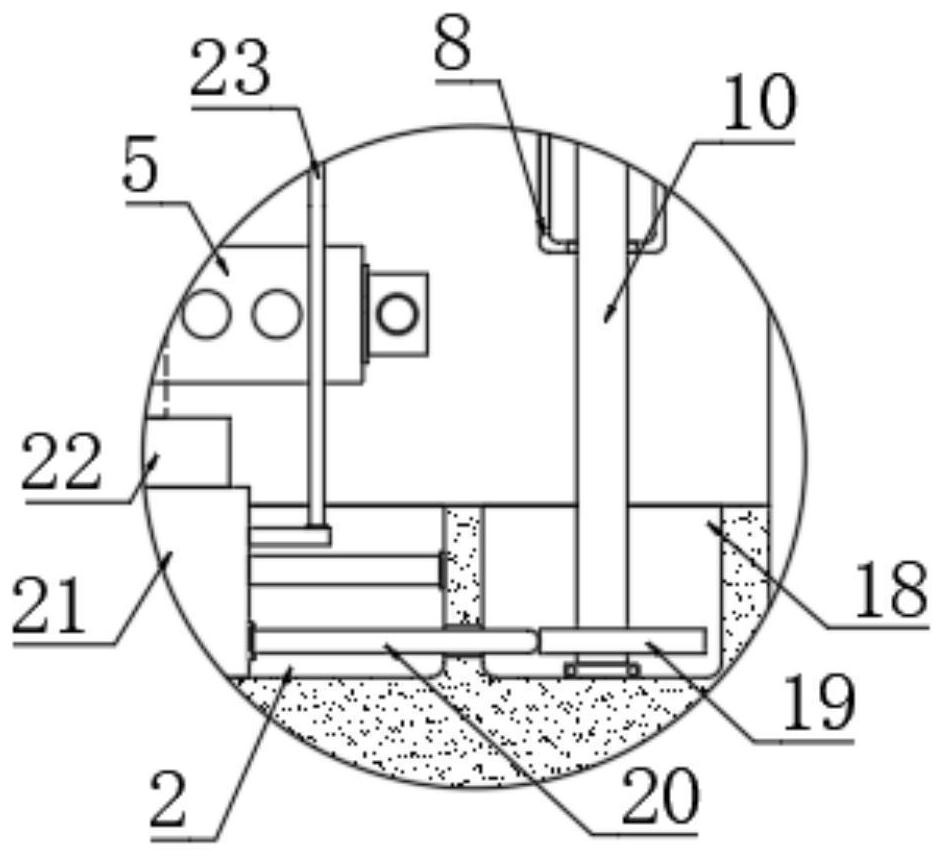

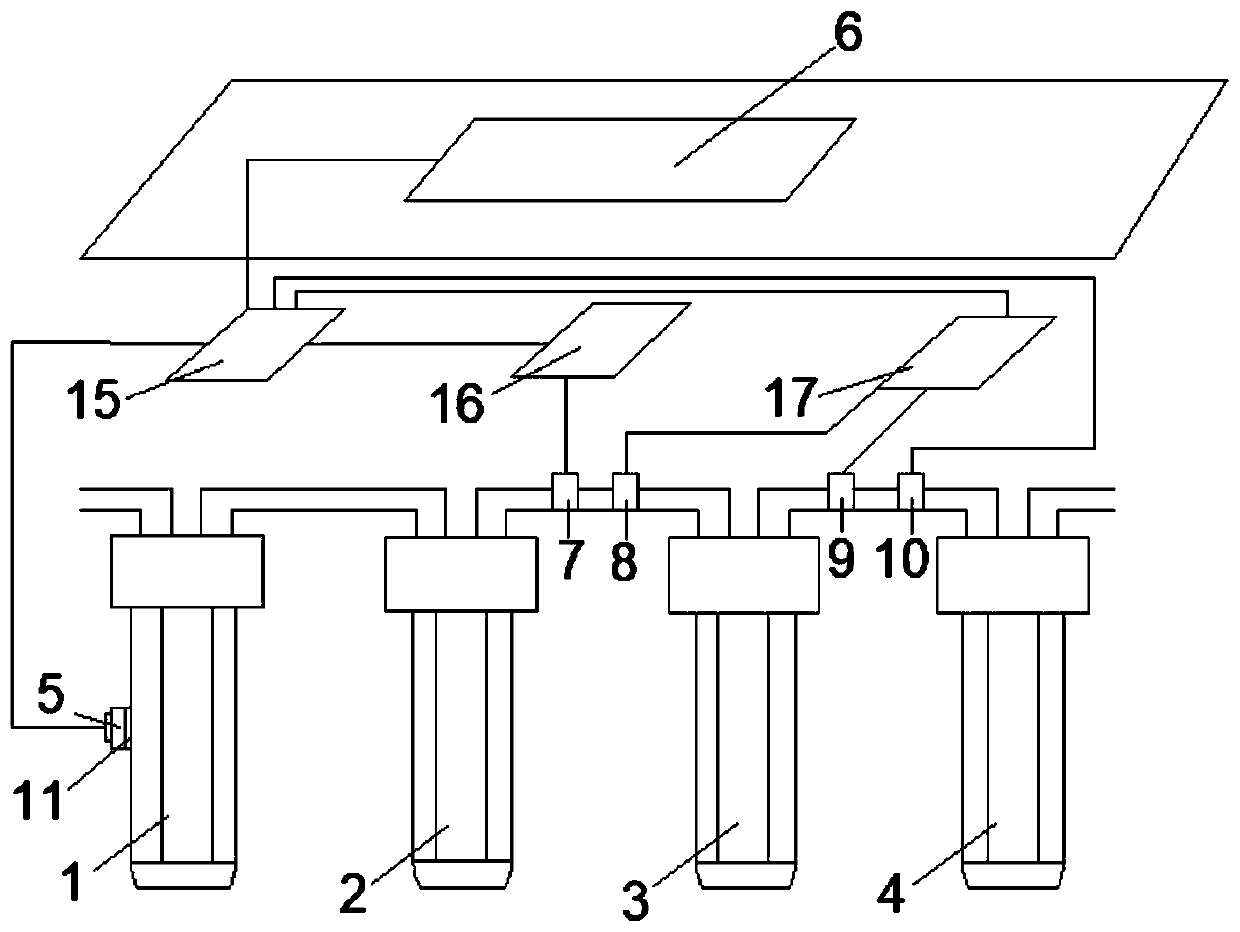

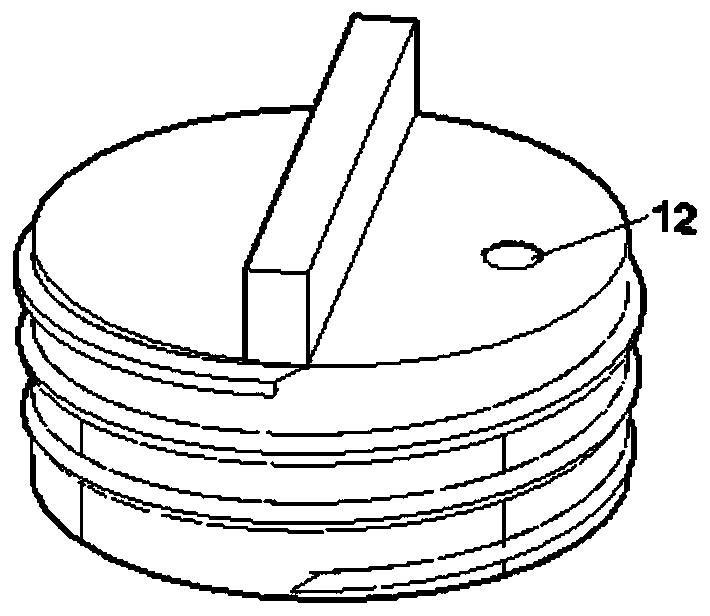

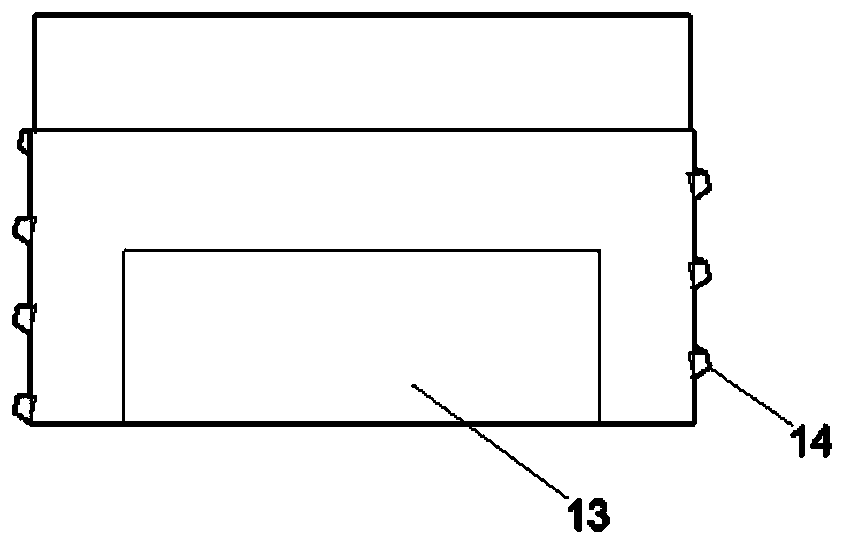

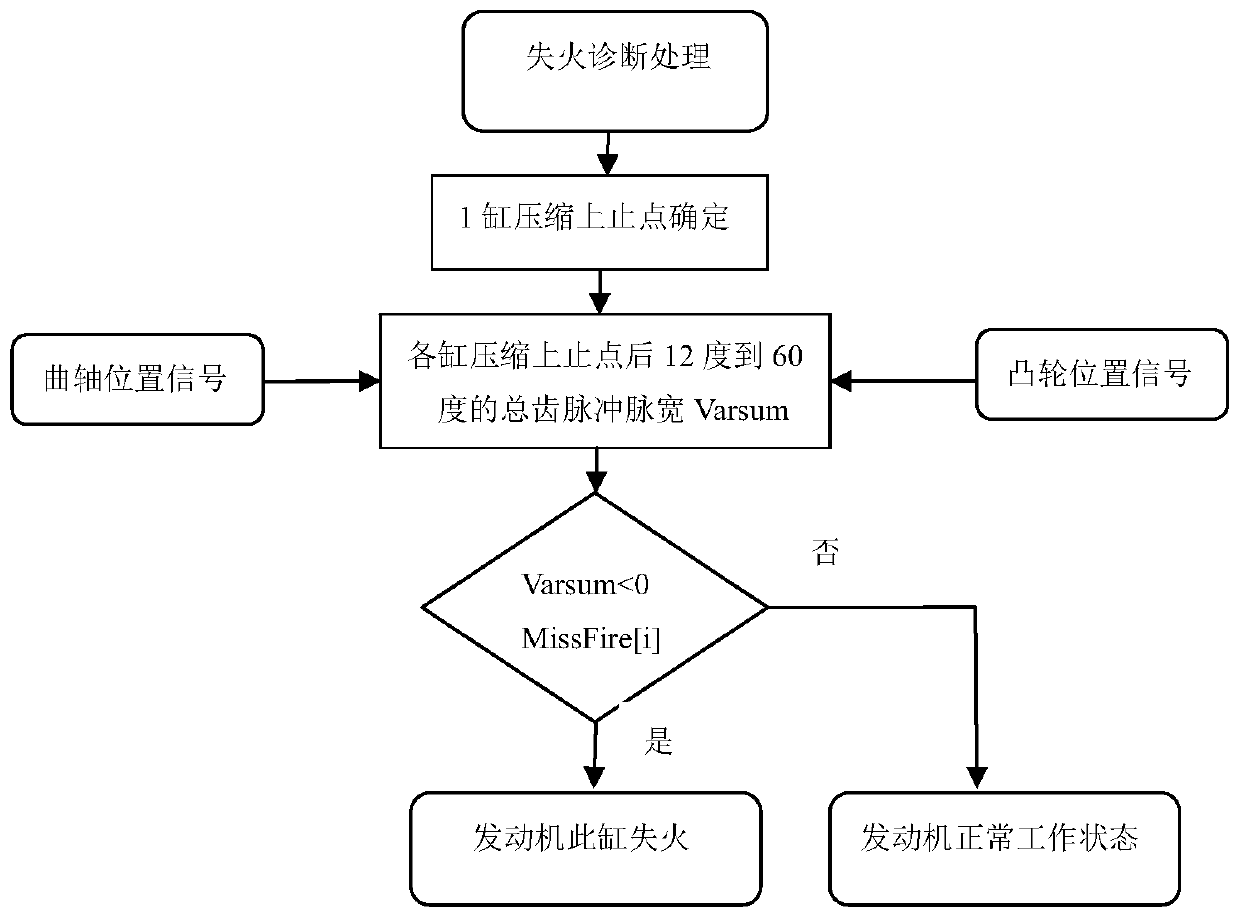

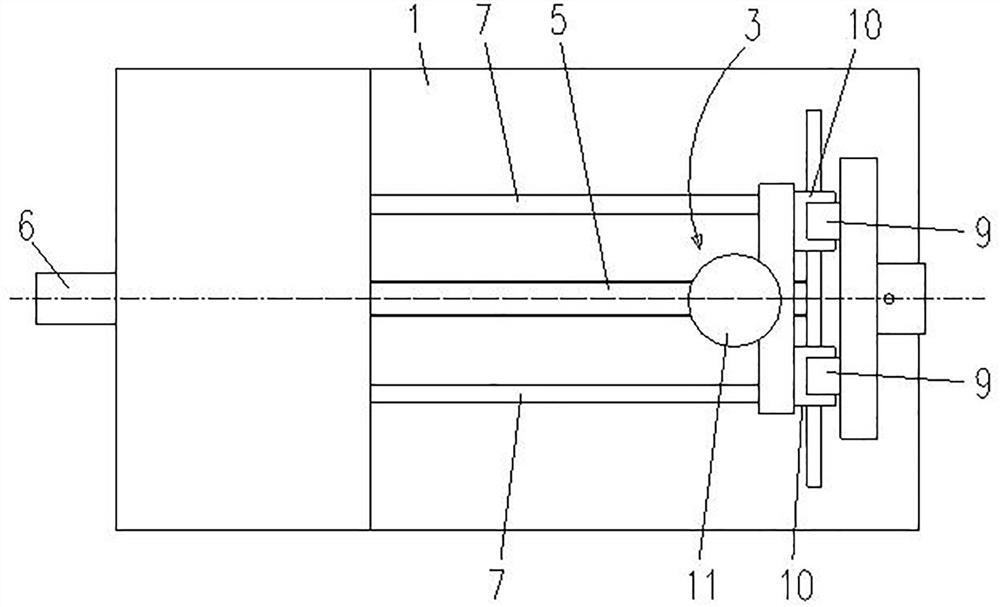

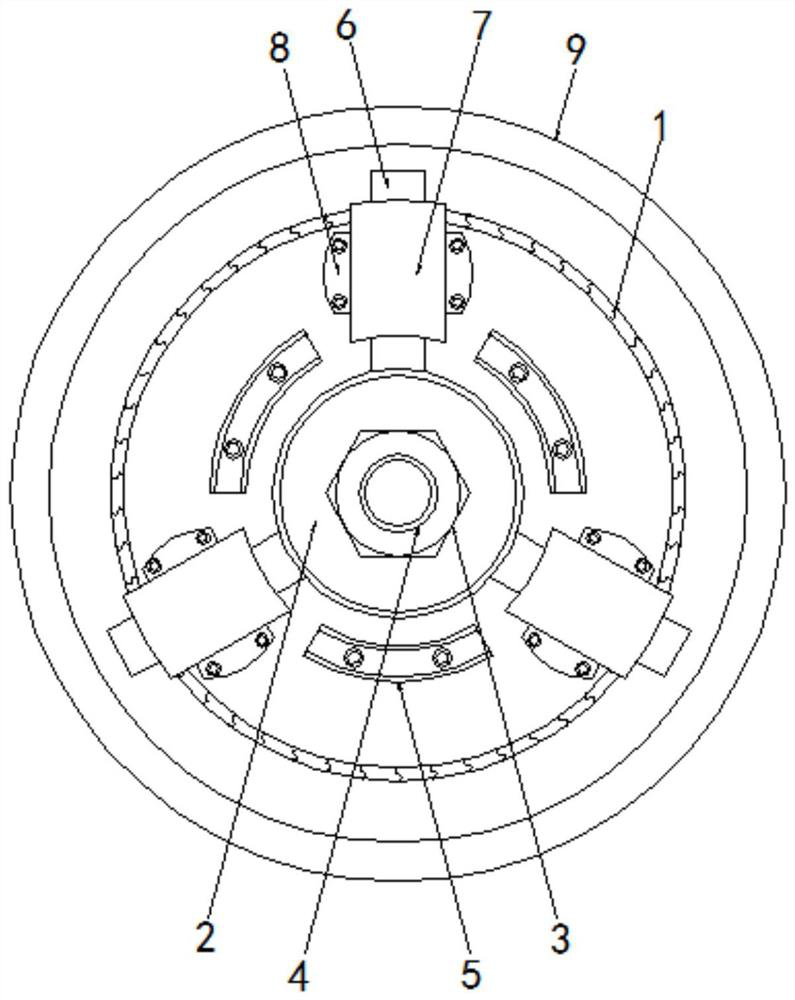

A high-power multi-point EFI gas engine misfire detection method and detection device

ActiveCN107237699BReasonable designCompact structureInternal-combustion engine testingInternal combustion piston enginesTop dead centerEngineering

Owner:SHANGHAI UNIV OF ENG SCI

Apparatus for measuring structural concrete defects and its method

ActiveCN109164043BThe detection method is simpleSimple structureUsing mechanical meansMaterial analysisClassical mechanicsElectrical connection

The invention belongs to the technical field of road and bridge construction, and particularly relates to an apparent defect determination device for structural concrete, and a detection method implemented by the device. The apparent defect determination device for the structural concrete comprises magnetic devices and a magnetic powder filling device, and is electrically connected with a power supply in a cabinet, wherein the magnetic powder filling device is arranged on the side of a concrete component where an apparent defect is located; and the magnetic devices are arranged on the side opposite to the apparent defect, and the positions of the magnetic devices correspond to the position of the magnetic powder filling device for measurement. The invention further provides the detection method adopting the apparent defect determination device for the structural concrete. The device and the method provided by the invention have the advantages that magnetically conductive ferrous fillers sprayed by the magnetic powder filling device can be sucked into holes and cracks through the magnetic devices, and the magnetically conductive ferrous materials in irregularly shaped holes, cracksor honeycombs on the surface of the structural concrete can be quantitatively measured, so that the measurement equipment and method with high accuracy, simplicity and visualization can be provided for detection of the surface defect of the structural concrete.

Owner:NINGBO CONSTR TEST

A detection method of material distribution based on phase recovery

InactiveCN104504735BDetection is accurate and intuitiveHelp analyze qualityImage analysisComputational physicsPhase retrieval

The invention provides a matter distribution detection method based on phase retrieval. Firstly, a wave function that contains phase change information is retrieved by means of incident light intensity and diffraction light intensity of transparent matters according to a gerchberg-saxton (GS) algorithm; then phase change is calculated in the obtained wave function by a phase evaluation algorithm based on a gradient field in order to avoid phase folding; finally, three-dimensional distribution of matters can be obtained according to linear models of the matter three-dimensional distribution and phase change. By means of the matter distribution detection method based on the phase retrieval, morphology and distribution of the transparent matters can be visually and accurately detected, and reliability and accuracy are high.

Owner:CENT SOUTH UNIV

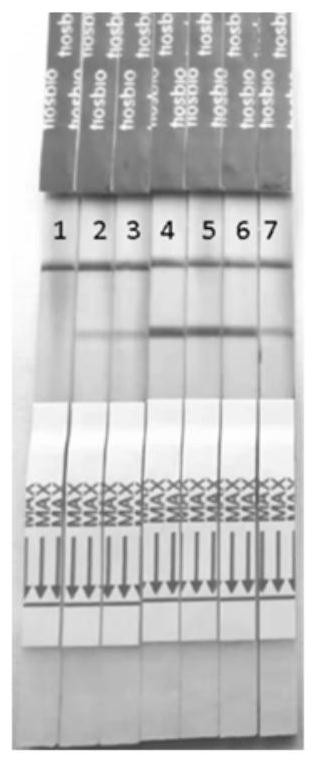

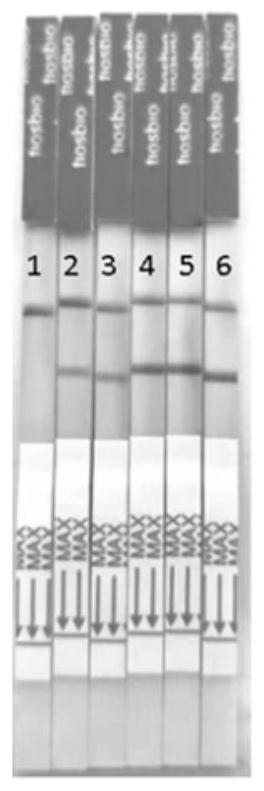

Nucleic acid detection kit for rapidly detecting plasmodium and application of nucleic acid detection kit

PendingCN114807404ASimple and fast operationAccurate detectionMicrobiological testing/measurementMicroorganism based processesNucleic acid detectionNucleotide

The invention discloses a nucleic acid detection kit for rapidly detecting plasmodium and application of the nucleic acid detection kit. The kit comprises a plasmodium upstream primer, a plasmodium downstream primer and a probe, and nucleotide sequences of the upstream primer and the downstream primer are respectively shown as SEQ ID No.2 and SEQ ID No.3 in a sequence table; the nucleotide sequence of the probe is shown as SEQ ID No.4 in a modified sequence table. The kit can rapidly and sensitively detect plasmodium, does not need expensive instruments and equipment, is simple to operate, easy in observation of reaction results and good in specificity, is very suitable for field screening of high-risk population and plasmodium prevalence areas with underdeveloped economic conditions, and is easy to popularize and use in a large range.

Owner:江苏省血液中心(江苏省医学生物制品研究所)

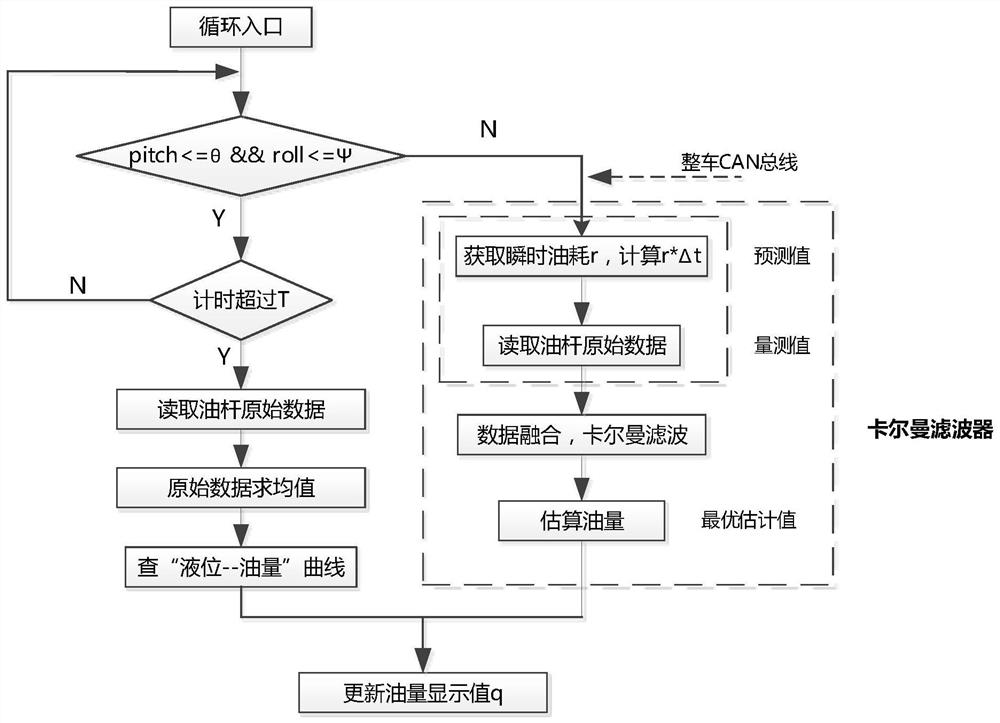

System and method for estimating fuel quantity of fuel tank of automobile

PendingCN114659593AImprove anti-interference abilityDetection is accurate and intuitiveMachines/enginesLevel indicatorsAutomotive engineeringFuel tank

The invention discloses an automobile fuel tank fuel quantity estimation method and system. The method comprises the steps that firstly, the system detects the pitch angle and the roll angle of the current whole automobile and conducts timing or timing zero clearing; 2, reading a measured value Vi of a sucker rod sensor, continuously measuring for N times, and solving a mean value or a smooth filtering value of V1-VN to obtain a current liquid level L; 3, implementing a Kalman filter; fourthly, the optimal value, estimated in the third step, of the current oil mass is sent to an oil mass display module; 5, the process is executed circularly, and the fuel quantity of the fuel tank is updated continuously. The invention further provides a system for estimating the fuel quantity of the automobile fuel tank. According to the method, an oil tank and an oil rod sensor are calibrated to obtain a liquid level-oil quantity curve, then the oil quantity value is continuously iterated and updated through the method, and the estimation precision problem is solved through steady-state continuous correction and unsteady-state continuous data fusion.

Owner:SHAANXI CCCC TIANJIAN CAR NETWORKING INFORMATION TECH CO LTD

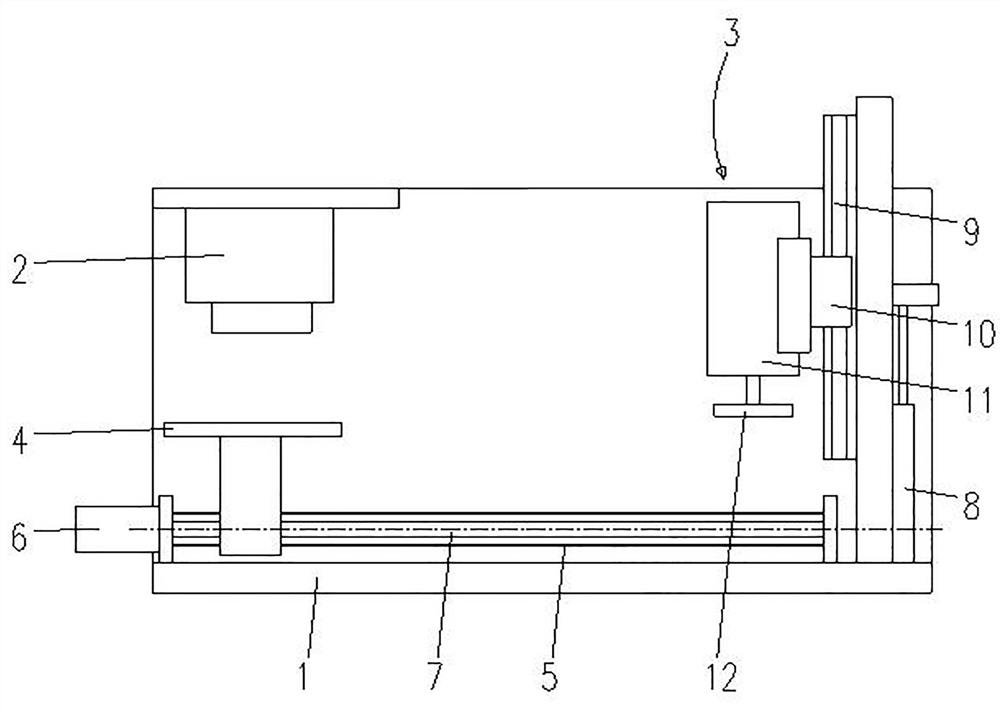

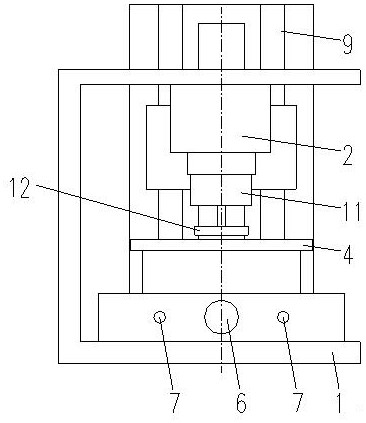

Device and method for detecting porosity of aluminum alloy welding seam

InactiveCN113607746ADetermine the level of weld defectsAccurate detectionPreparing sample for investigationOptically investigating flaws/contaminationStructural engineeringWeld seam

The invention relates to the technical field of welding wire detection, and especially relates to a device and a method for detecting the porosity of an aluminum alloy welding seam. The device comprises a base, an image shooting module and a computer, and the base is provided with a plane milling mechanism used for milling an aluminum alloy welding seam and a moving platform used for fixing the aluminum alloy welding seam; and the base is provided with a displacement mechanism used for controlling transverse displacement of the movable platform and a control mechanism used for controlling the plane milling mechanism to be close to or away from the movable platform, the image shooting module is located above the movable platform, and the image shooting module is connected with the computer. During use, plane milling is carried out on the aluminum alloy welding seam, the image shooting module is used for shooting the image of the aluminum alloy welding seam when one layer of plane is milled, the shot images are synthesized into one image, air hole data in the image are measured, and the measured data are compared with the standard, so that the defect grade of the aluminum alloy welding seam is judged, and detection is more visual and accurate.

Owner:哈焊所华通(常州)焊业股份有限公司

Engineering pipeline offset detection device based on the principle of cutting magnetic induction lines

ActiveCN110174043BIncrease linkageImprove synchronicityUsing electrical meansMechanical measuring arrangementsElectrical conductorEngineering

The present invention discloses an engineering pipeline offset detecting device based on the cutting magnetic induction line principle, and relates to the technical field of construction engineering.The device comprises two bottom plates; the middle part of two opposite sides of the two bottom plates is movably connected with an adjusting mechanism; the front side of the adjusting mechanism is fixedly connected with a threaded sleeve; the inner part of the threaded sleeve is movably connected with a screw; and the front surface of the bottom plates is movably connected with three limiting blocks, the shape specifications of the three limiting blocks are the same, the limiting block is a curved structure, and the center of the limiting block is the same as the center of the bottom plate. According to the engineering pipeline offset detecting device based on the cutting magnetic induction line principle provided by the present invention, the change of the induced electromotive force when the conductor cuts the magnetic induction line is used to detect whether the workpiece is offset, and when the workpiece is offset, positions of the first conductor plate and the second conductor plate change; and the magnetic induction line is cut, and the induced electromotive force changes, so that by using the process and the principle, the position of the workpiece can be accurately and intuitively detected.

Owner:陈昱见

Method for detecting azimuth of damaged oilfield downhole casing

ActiveCN102022111BRich detection methodsDetection is accurate and intuitiveBorehole/well accessoriesPhysicsAzimuth

The invention discloses a method for detecting the azimuth of a damaged oilfield downhole casing. In the method, a casing detector (1) for detecting a casing is connected with a gyroscopic clinometer (2), or an azimuth measuring mechanism (3) is mounted in the casing detector (1); the position of a probe of the casing detector (1) can be calculated by measuring the inclination of the gyroscopic clinometer (2) or the position of the azimuth measuring mechanism (3), and thus, the specific azimuth of the damaged position of the casing can be calculated. In the invention, the specific azimuth of the damaged position of the casing can be visually and precisely detected, and the method has the characteristics of high detection accuracy and less detection error and is simple and convenient to operate. The invention perfects the detection means of the downhole casing and provides important foundations for oilfield downhole analyses. The invention is applicable to the azimuth test of all downhole detection parameters.

Owner:贵州航天凯山石油仪器有限公司

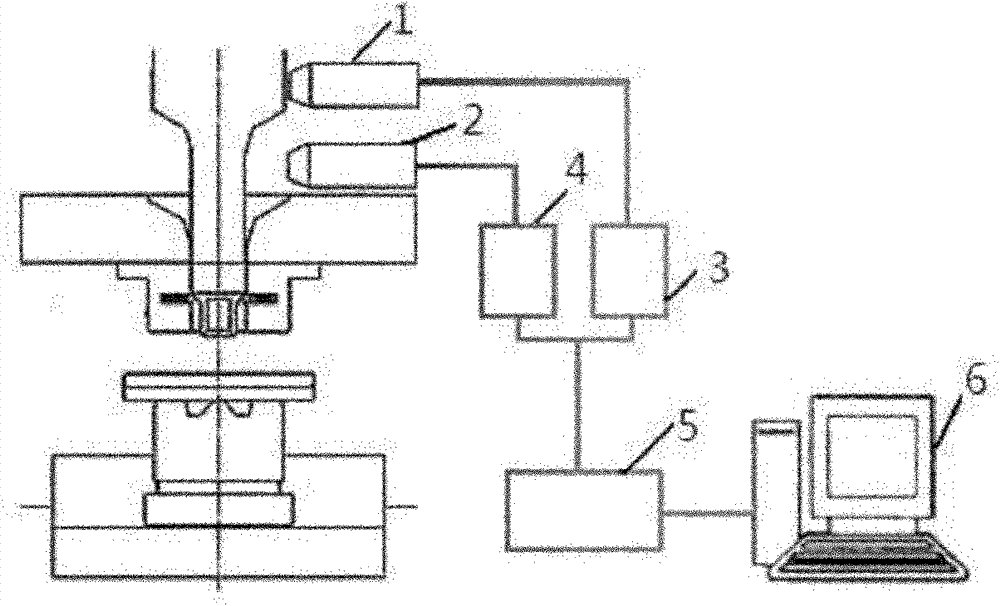

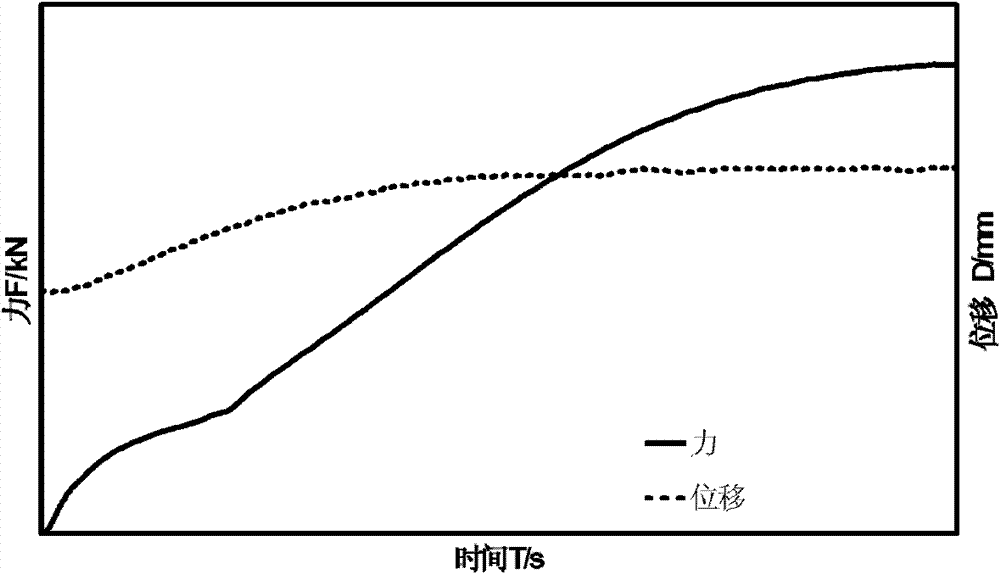

Self-piercing riveting quality online detection system and method

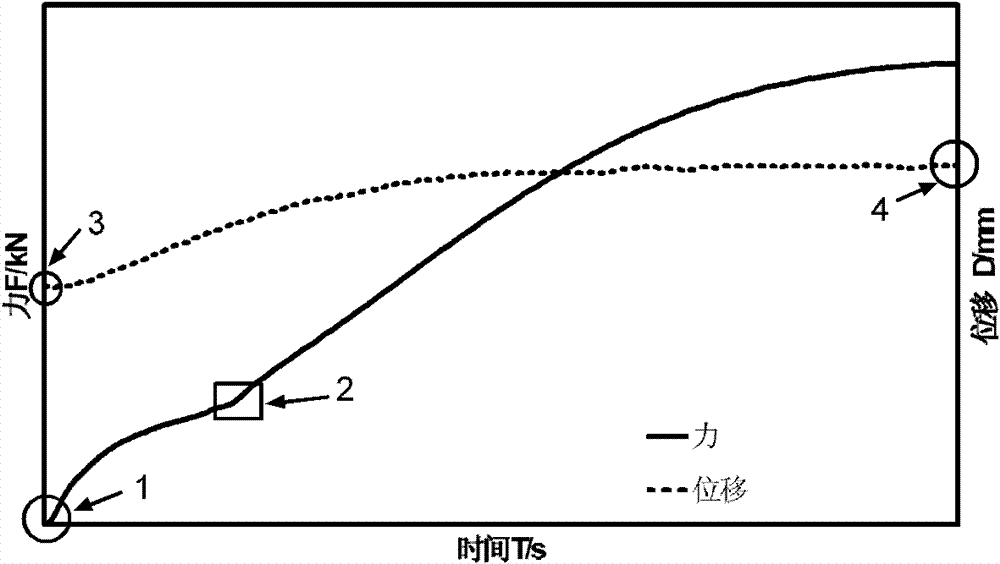

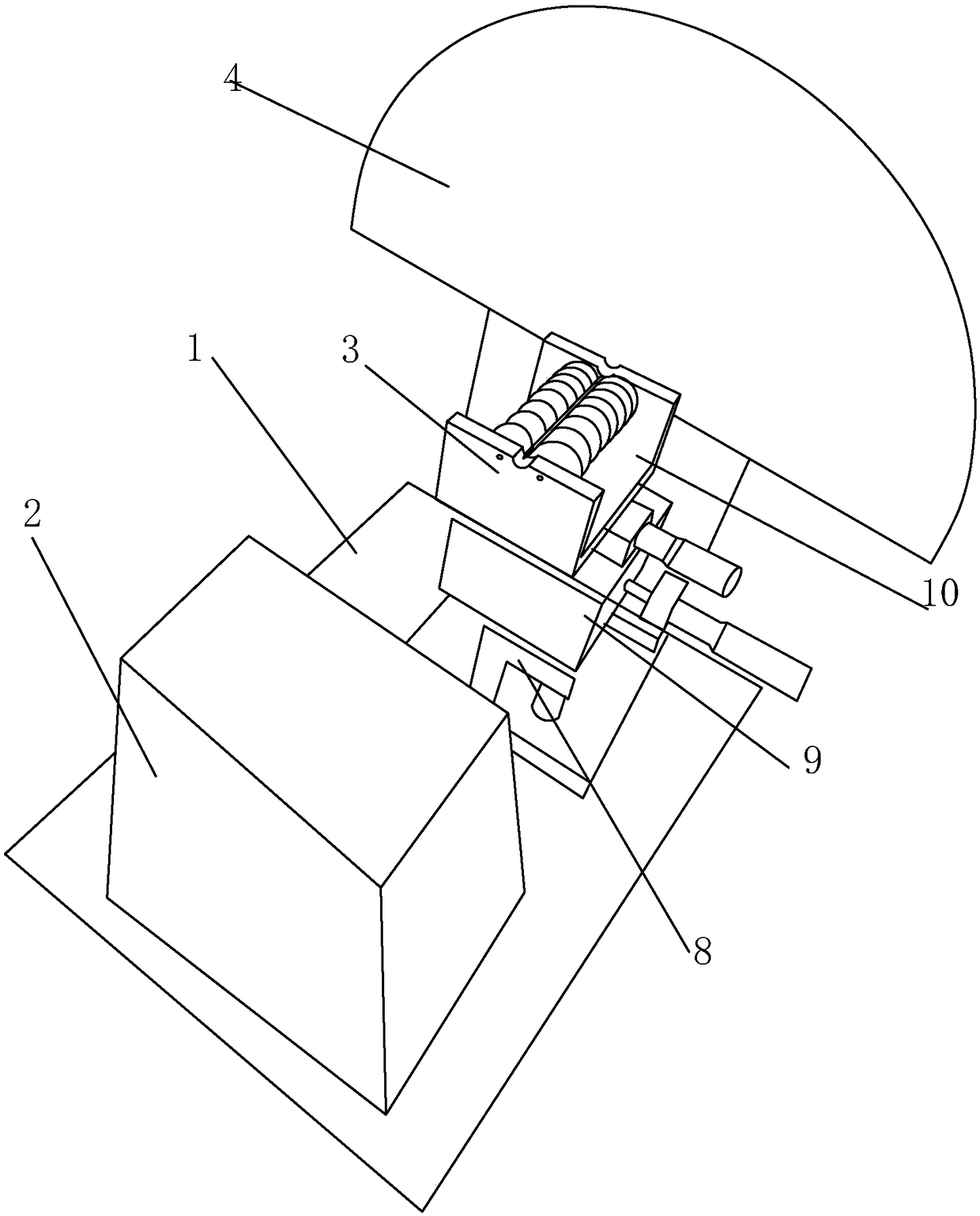

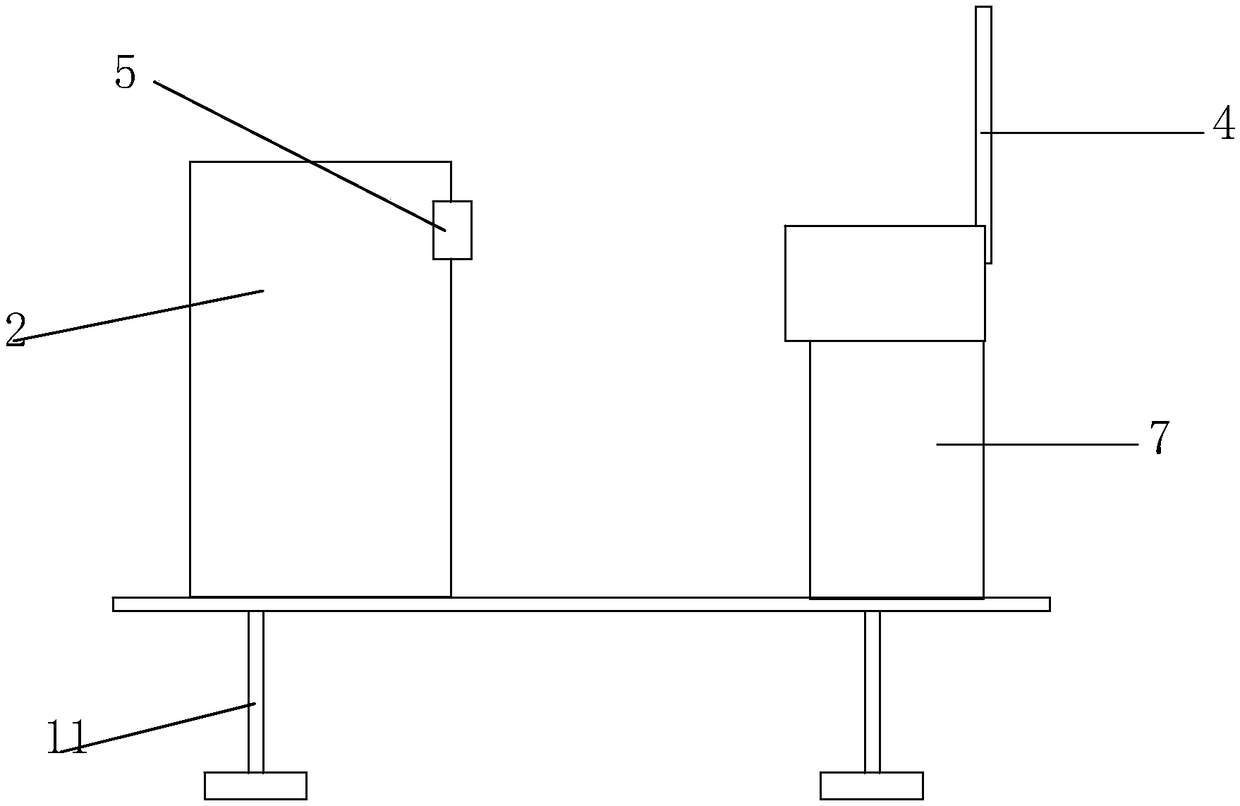

ActiveCN102004056BDetection is accurate and intuitiveAvoid blindnessMaterial strength using repeated/pulsating forcesData acquisitionLoad cell

The invention relates to self-piercing riveting quality online detection system and method in the technical field of machining. The system comprises a weighing sensor, a displacement sensor, a weighing sensor amplifier, a displacement sensor amplifier, a data acquisition card and a calculation module. According to the invention, whether the joint quality is qualified or not is judged through acquiring the force-time and displacement-time curves in the self-piercing riveting process according to one feature window and three feature tolerance ranges on the acquired curves and the defect type towhich qualified joints belong is also judged. The method gives consideration to the changes of the displacement and the force in the riveting process, has the characteristics of sensitivity to defects like plate gaps and the like, high defect detection speed and the like and can specifically detect various defects.

Owner:SHANGHAI JIAOTONG UNIV

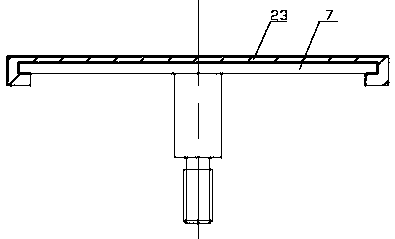

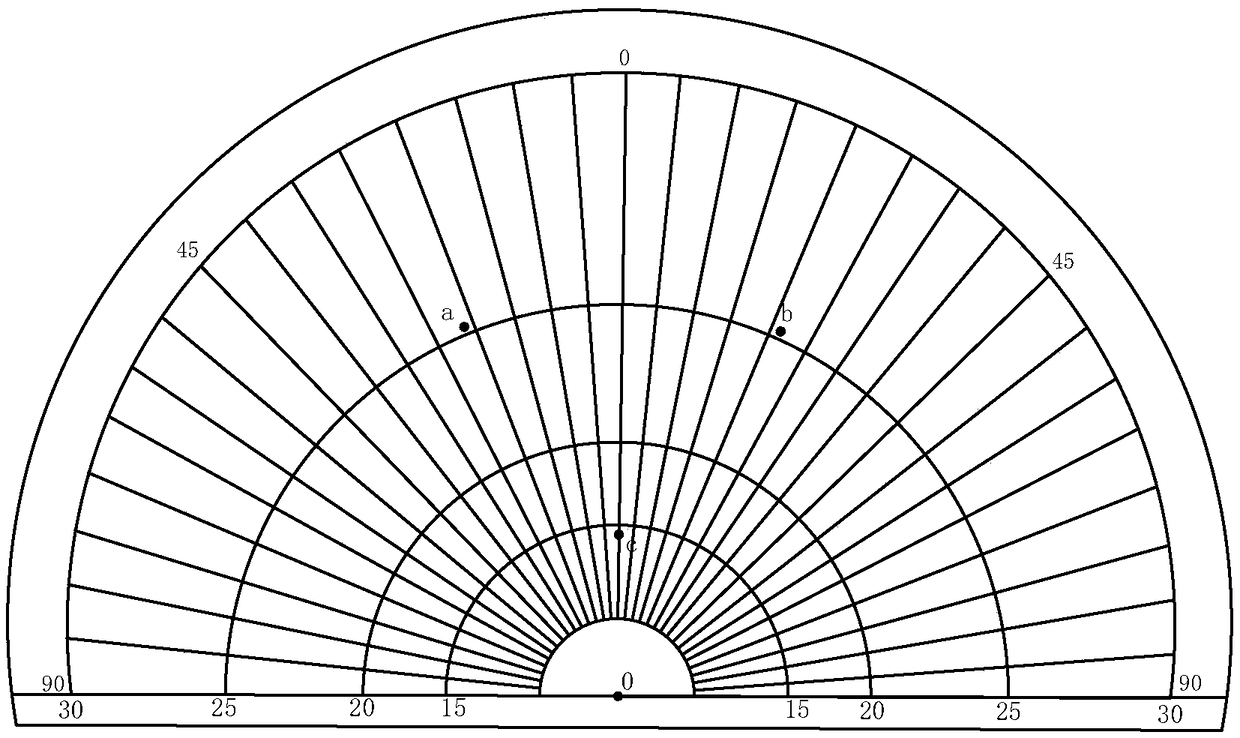

Needle tip angle detector and detection method

PendingCN109357641AAccurate measurementDetection is accurate and intuitiveUsing optical meansWorking environmentMiddle line

The invention discloses a needle tip angle detector and a detection method. The needle tip angle detector comprises a base, a laser generator, a needle seat, and an angle projection plate. The laser generator, the needle seat, and the angle projection plate are sequentially arranged on the base in a straight line. The laser generator is provided with a laser outlet near the needle seat side. The laser outlet is flush with the top of the needle seat. The needle seat has a position adjuster at its base and two supporting rods at its top. The supporting rod is arranged perpendicular to the laseroutlet. Wafers perpendicular to the supporting rod are arranged on the surface of the two supporting rods in a staggered manner. The two supporting rods are rotationally fixed on the needle base. Thesemi-circular angle projection plate is provided with a scale. The scale zero of the scale of the angle projection plate is at the center of the semi-circular. The middle of the scale zero, the central line of the supporting rod of the needle seat, and the laser outlet are arranged on the same horizontal line. According to the needle tip angle detector and the detection method, the detector measures quickly and accurately, can visually and accurately detect the angle of the needle tip, and does not need to be limited by the working environment of the production workshop.

Owner:威海富山尼德欧医疗科技有限公司

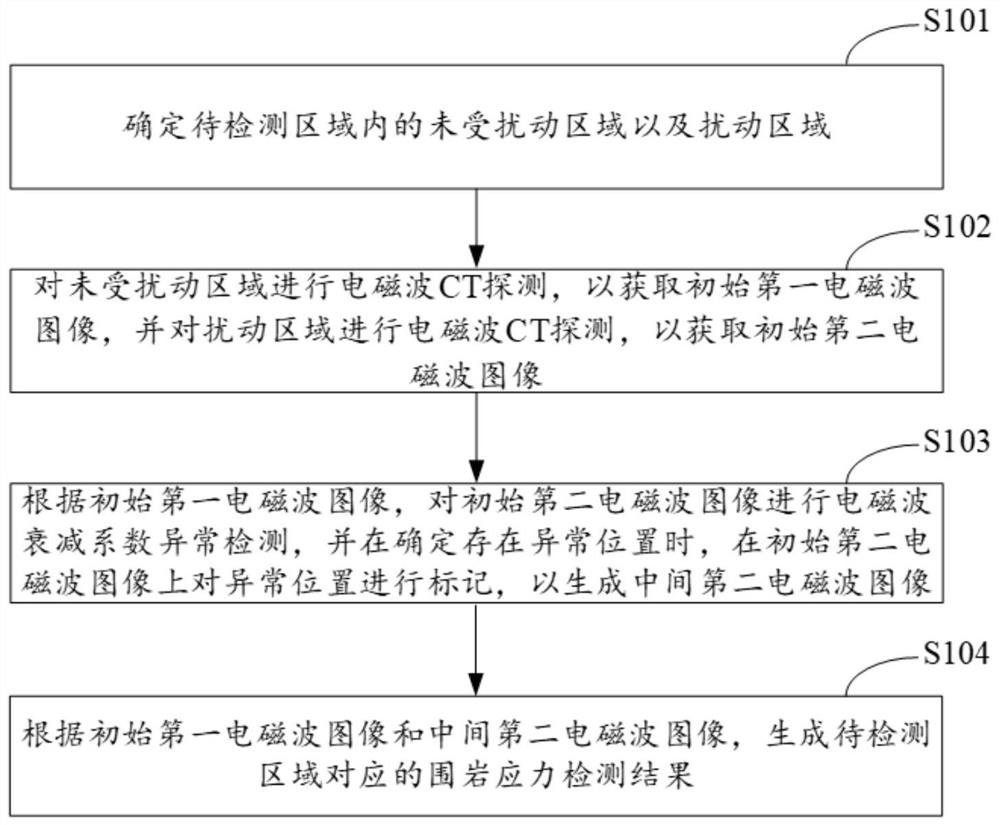

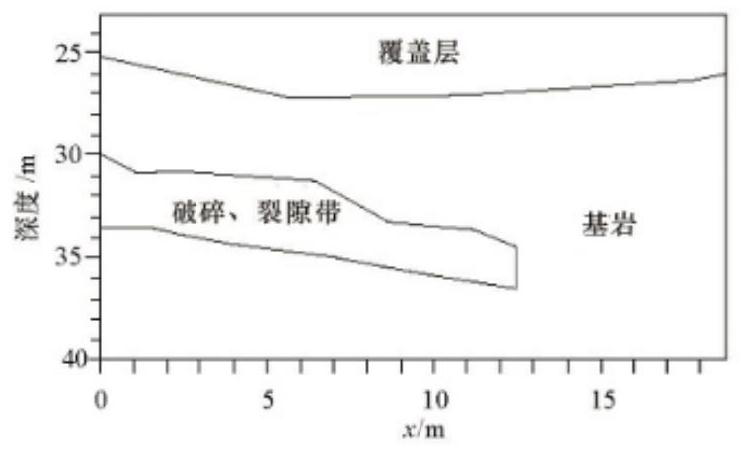

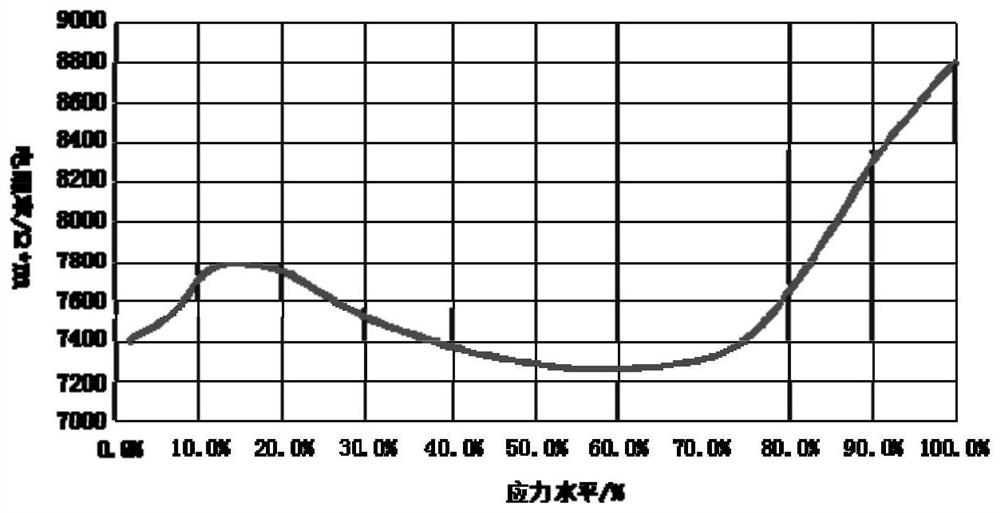

Surrounding rock stress detection method and device and electronic equipment

ActiveCN114046914AQuick checkDetection is accurate and intuitiveMining devicesForce measurement by measuring optical property variationAnomaly detectionEngineering

The invention provides a surrounding rock stress detection method and device and electronic equipment. The method comprises the steps of determining an undisturbed region and a disturbed region in a to-be-detected region; performing electromagnetic wave CT detection on the undisturbed region to obtain an initial first electromagnetic wave image, and performing electromagnetic wave CT detection on the disturbed region to obtain an initial second electromagnetic wave image; performing electromagnetic wave attenuation coefficient anomaly detection on the initial second electromagnetic wave image according to the initial first electromagnetic wave image, and marking an abnormal position on the initial second electromagnetic wave image when determining that the abnormal position exists so as to generate a middle second electromagnetic wave image; and generating a surrounding rock stress detection result corresponding to the to-be-detected area according to the initial first electromagnetic wave image and the middle second electromagnetic wave image. The surrounding rock stress is detected based on the electromagnetic waves, so that the detection process is simpler and quicker, and meanwhile, the detection precision is ensured.

Owner:CHINA COAL RES INST +1

Test device for roller damping and method

InactiveCN102539138BDetection is accurate and intuitiveGuaranteed reliabilityMachine part testingDrive motorEngineering

Owner:BENQ MATERIALS WUHU CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com