Engine fire detection method and detection device thereof

A detection method and technology of a detection device are applied in the direction of internal combustion engine testing and other directions, which can solve the problems of low detection accuracy and difficulty in achieving synchronization, and achieve the effects of simple signal processing process, high misfire detection, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

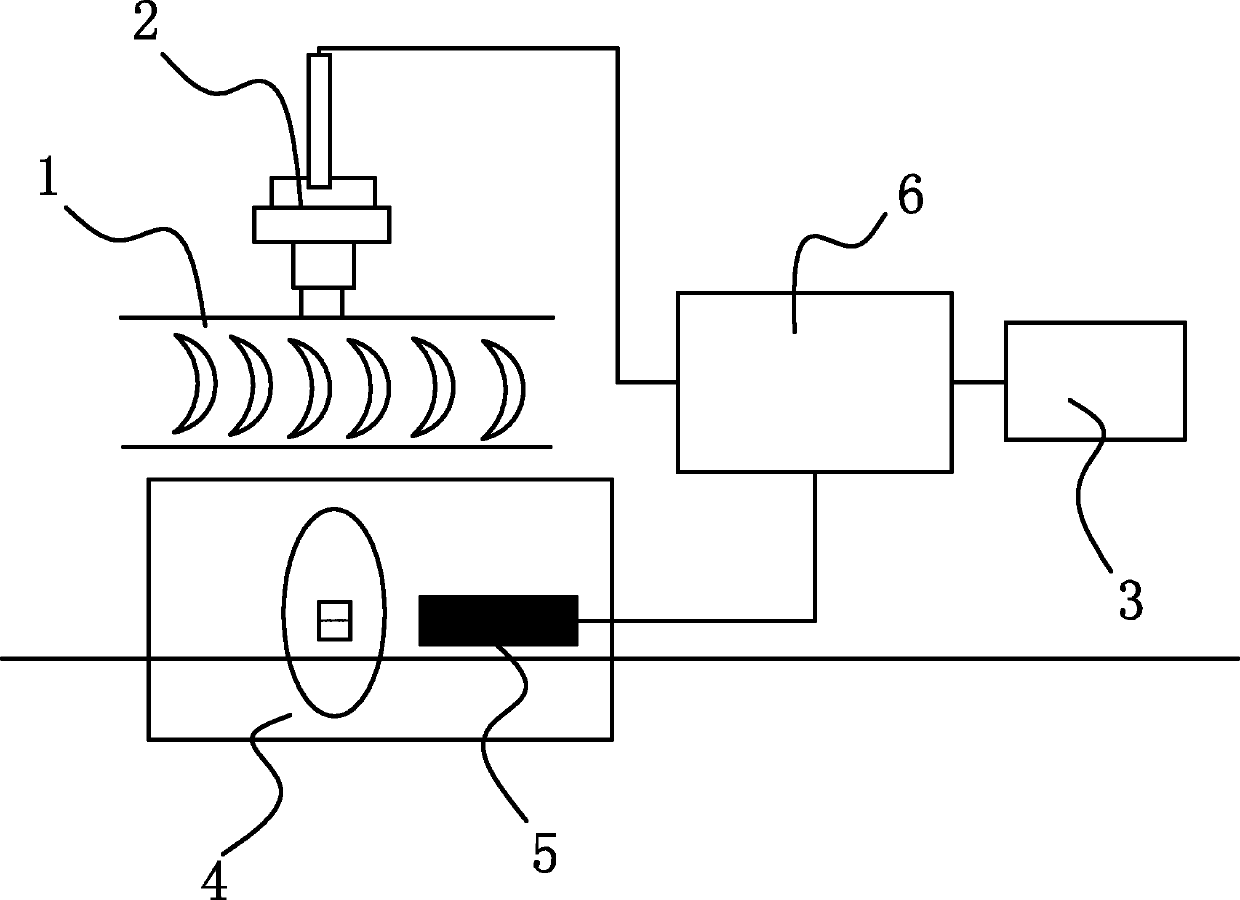

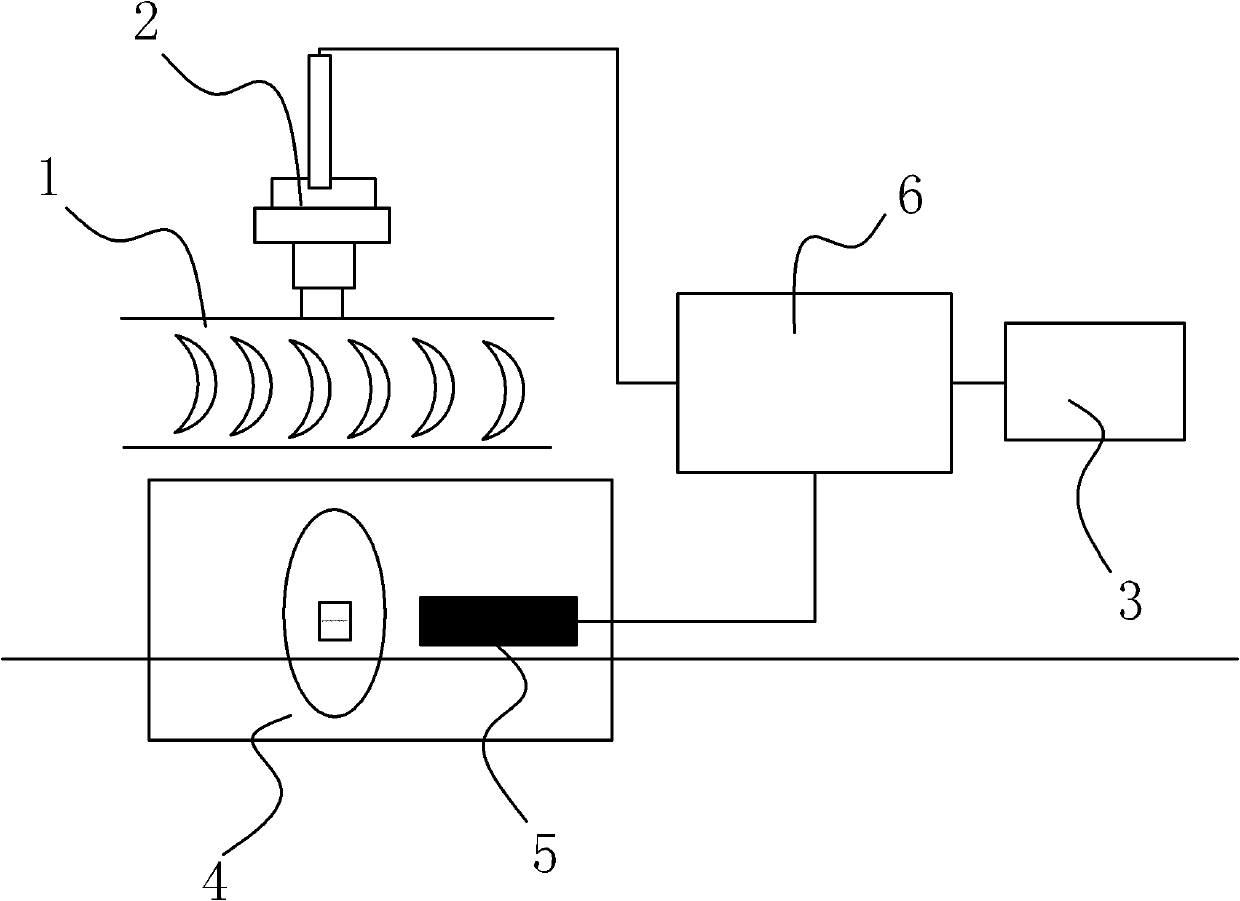

[0021] Such as figure 1 As shown, the engine misfire detection method uses the pressure sensor 2 arranged on the engine exhaust system 1 to collect the real-time exhaust pressure wave signal of the engine exhaust system 1 . More specifically, the pressure sensor 2 is provided in the front exhaust pipe of the engine exhaust system 1 . The collected real-time exhaust pressure wave signal is input to the central processing unit 3, and the central processing unit 3 compares the peak-to-peak value of the real-time exhaust pressure wave signal with the peak-to-peak value of the built-in exhaust pressure wave average signal. When the difference between the two is greater than or equal to a preset threshold, the central processing unit 3 generates an engine misfire determination signal, and when the difference is smaller than the preset threshold, it is determined that the engine is in a normal working state. The threshold here is set according to factors such as different engine mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com