Method for detecting azimuth of damaged oilfield downhole casing

A detection method and casing technology, which is applied in the direction of earthwork drilling, wellbore/well components, etc., can solve the problem that the specific position of the damaged part cannot be detected, and achieve the effects of small error, simple operation, convenience and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

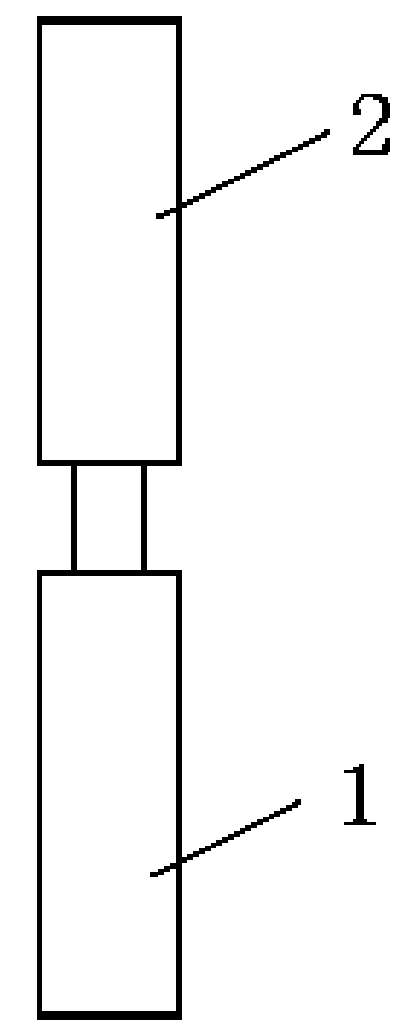

[0011] Example 1. Such as figure 1 As shown, the bushing tester 1 and the gyro inclinometer 2 are hard-connected in series. When testing, first mark on the ground to determine the position of the probe of the bushing tester 2 and the gyro inclinometer 2, and then By detecting the posture of the gyro inclinometer 2 itself, the position of the probe of the bushing detector 2 can be calculated, thereby calculating the specific orientation of the damaged part of the bushing. Gyro inclinometer 2 is an instrument used in the petroleum industry and geological exploration drilling. It is used to measure the inclination angle and azimuth angle in the strong magnetic mining area and the wellbore that has been casing. Through the measurement, it can be accurately recorded. Casing deformation caused by ground stress changes, and the instrument determines the data of inclination and azimuth angle generated in the casing.

Embodiment 2

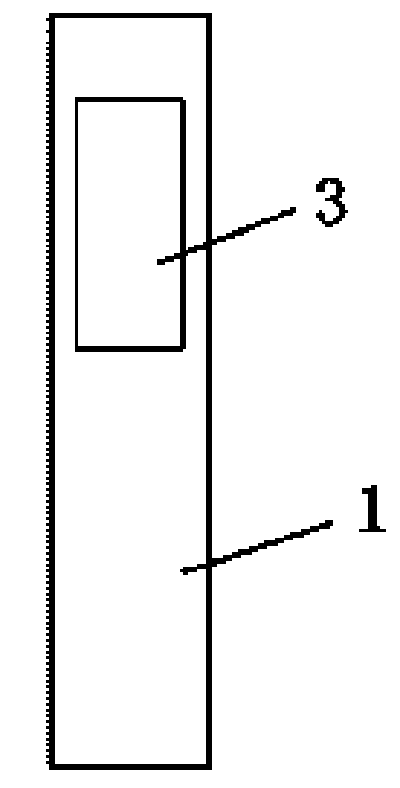

[0012] Example 2. Such as figure 2 As shown, an azimuth measuring mechanism 3 is installed in the bushing detector 1 . The position of the probe of the casing tester 1 and the position of the azimuth measuring mechanism 3 is determined in advance during the design, and kept still; during detection, the position of the probe of the casing tester 1 can be calculated by measuring the position of the position of the azimuth measuring mechanism 3 , so as to calculate the specific orientation of the casing damage site.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com