Device for detecting installation quality of wire harness

A technology for detecting wire and quality, applied in the field of detection equipment, can solve the problems of signal power transmission, swing, damage to the insulation sheath of wiring harness wires, etc., to achieve intuitive and accurate assembly quality, reduce labor intensity, and reduce the effect of false detection rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing and implementation example:

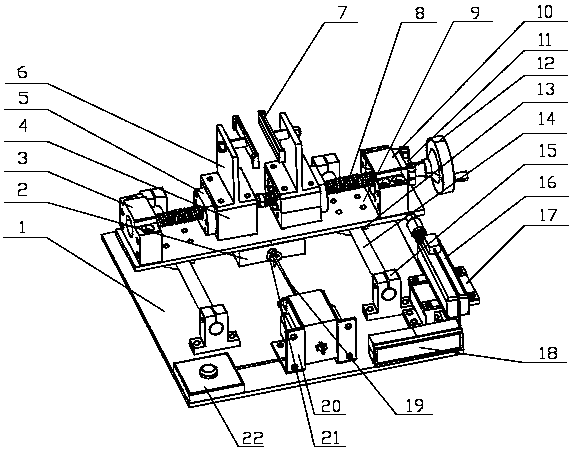

[0015] Such as figure 1 The device used to detect the installation quality of the wiring harness shown includes: base plate support 1, ring slide seat 2, centering clamping device, mobile support 9, slider 13, linear optical axis guide rail 14, guide rail support seat 15, connecting rod 19. Traction electromagnet 20, ring nut 21, displacement sensing device; two sets of opposite guide rail support seats 15 are arranged on the bottom plate support 1, and linear optical axis guide rails 14 are respectively arranged on the two sets of guide rail support seats 15, and the linear optical axis guide rails 14 pass through Through the slider 13, the movable support 9 is fixedly connected to the slider 13, and a centering clamping device is arranged on the movable support 9, and the movable support 9 is located between the two sliders 13 and fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com