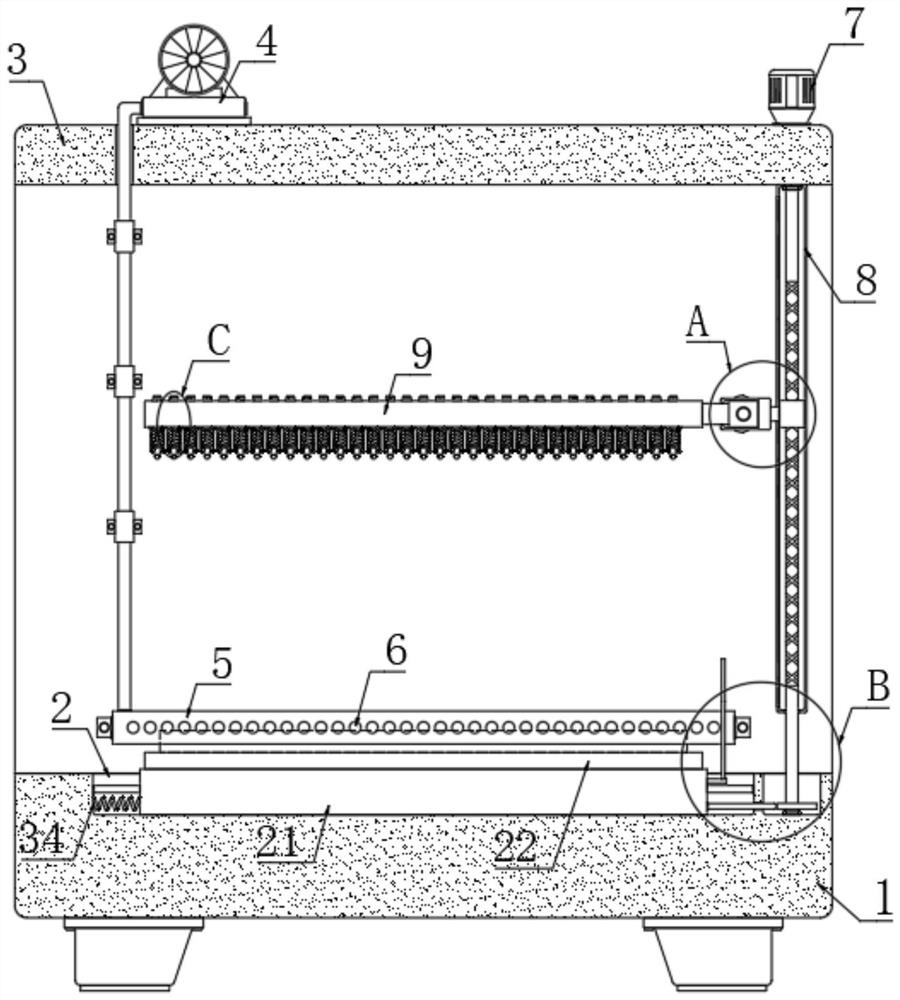

Flatness detection equipment for building wood processing and detection method thereof

A technology for testing equipment and flatness, which is applied in the field of flatness testing equipment for construction wood processing, which can solve problems such as uneven quality, influence on accuracy, difficulty in comprehensive board testing, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

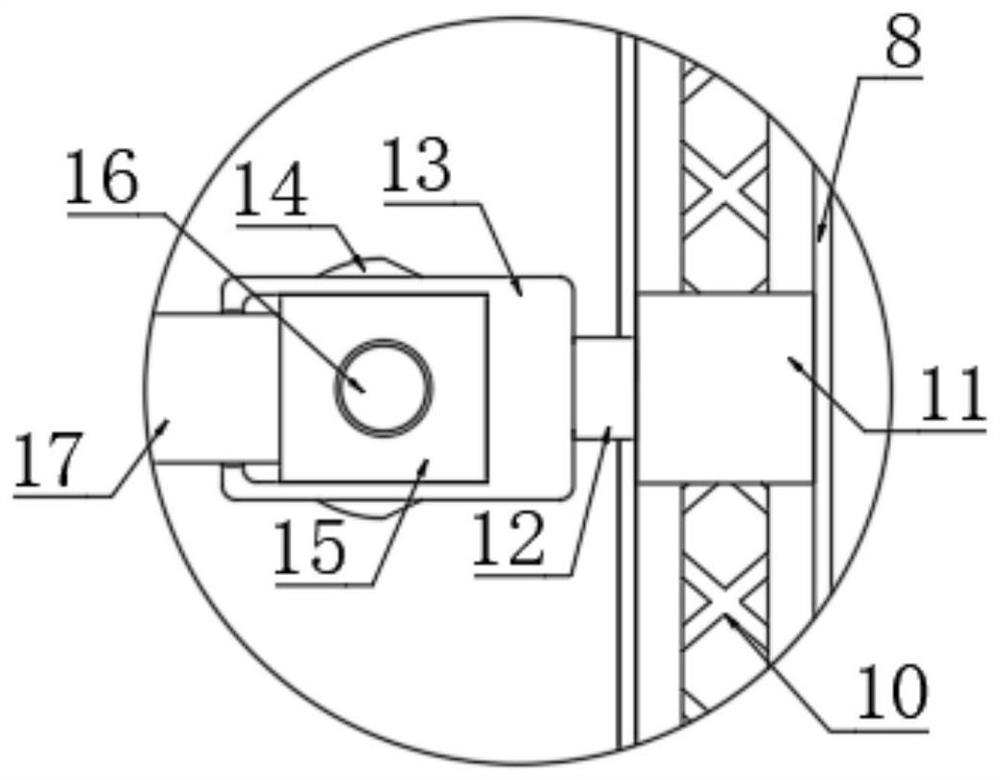

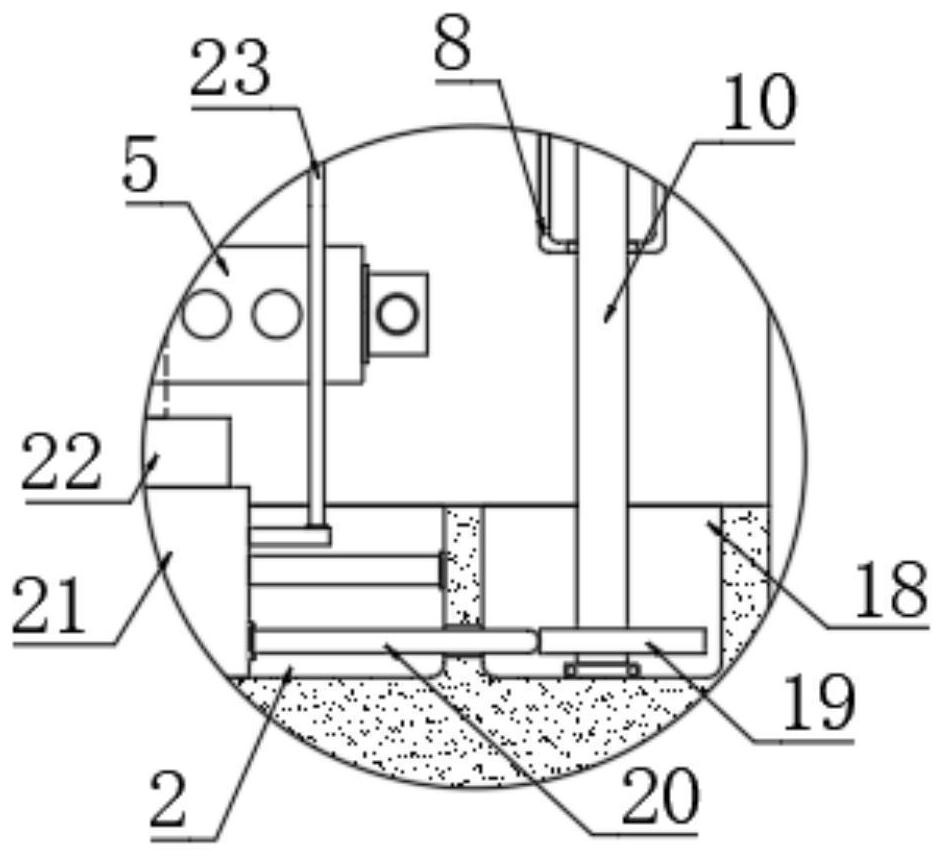

[0036] As an embodiment of the present invention, it also includes an up and down movement mechanism. The up and down movement mechanism includes a first hollow bar 8 installed at the lower end of the horizontal plate. The left side wall of the first hollow bar 8 is provided with a first bar-shaped opening. A first reciprocating screw rod 10 is rotatably connected between the upper and lower inner walls of a hollow bar 8, and the first reciprocating screw mandrel 10 is threadedly connected with a first slider 11, and the first slider 11 is slidably connected with the inner wall of the first hollow bar 8, The upper end of the horizontal plate is equipped with a first motor 7, the end of the output shaft of the first motor 7 extends to the inside of the first hollow bar 8, and is fixedly connected with the upper end of the first reciprocating screw mandrel 10, and the lower end of the first reciprocating screw mandrel 10 extends Into the driving groove 18, and is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com