Self-piercing riveting quality online detection system and method

A technology of self-piercing riveting and detection method, which is applied in measuring devices, using repetitive force/pulsation force to test the strength of materials, instruments, etc., can solve the problems of limited detection range, improvement, and inability to guide the production process, so as to avoid blindness. , Fast, intuitive and accurate detection of defect types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

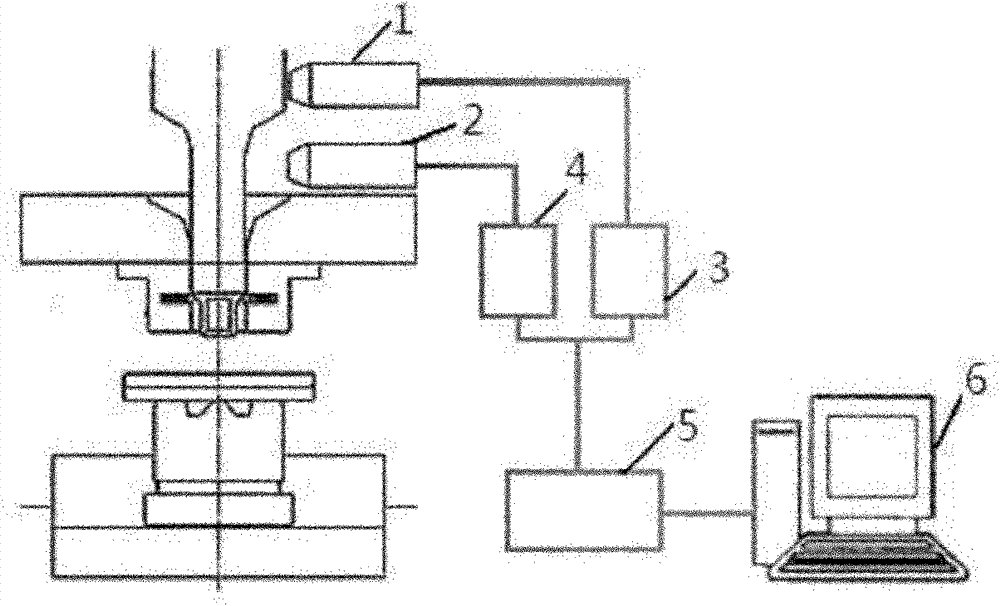

[0036] Such as figure 1 As shown, this embodiment includes: a load cell 1, a displacement sensor 2, a load cell amplifier 3, a displacement sensor amplifier 4, a data acquisition card 5 and a computing module 6, wherein: the input and output ends of the load cell 1 are respectively It is connected with the rivet driving rod of the self-piercing riveting equipment and the input end of the load cell amplifier 3, and the input end and the output end of the displacement sensor 2 are respectively connected with the rivet driving rod of the self-piercing riveting equipment and the input end of the displacement sensor amp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com