Test device for roller damping and method

A testing device and roller technology, which is used in measuring devices, testing of mechanical parts, testing of machine/structural parts, etc., can solve problems such as difficult detection, ensure reliability, improve yield and production efficiency, and facilitate testing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

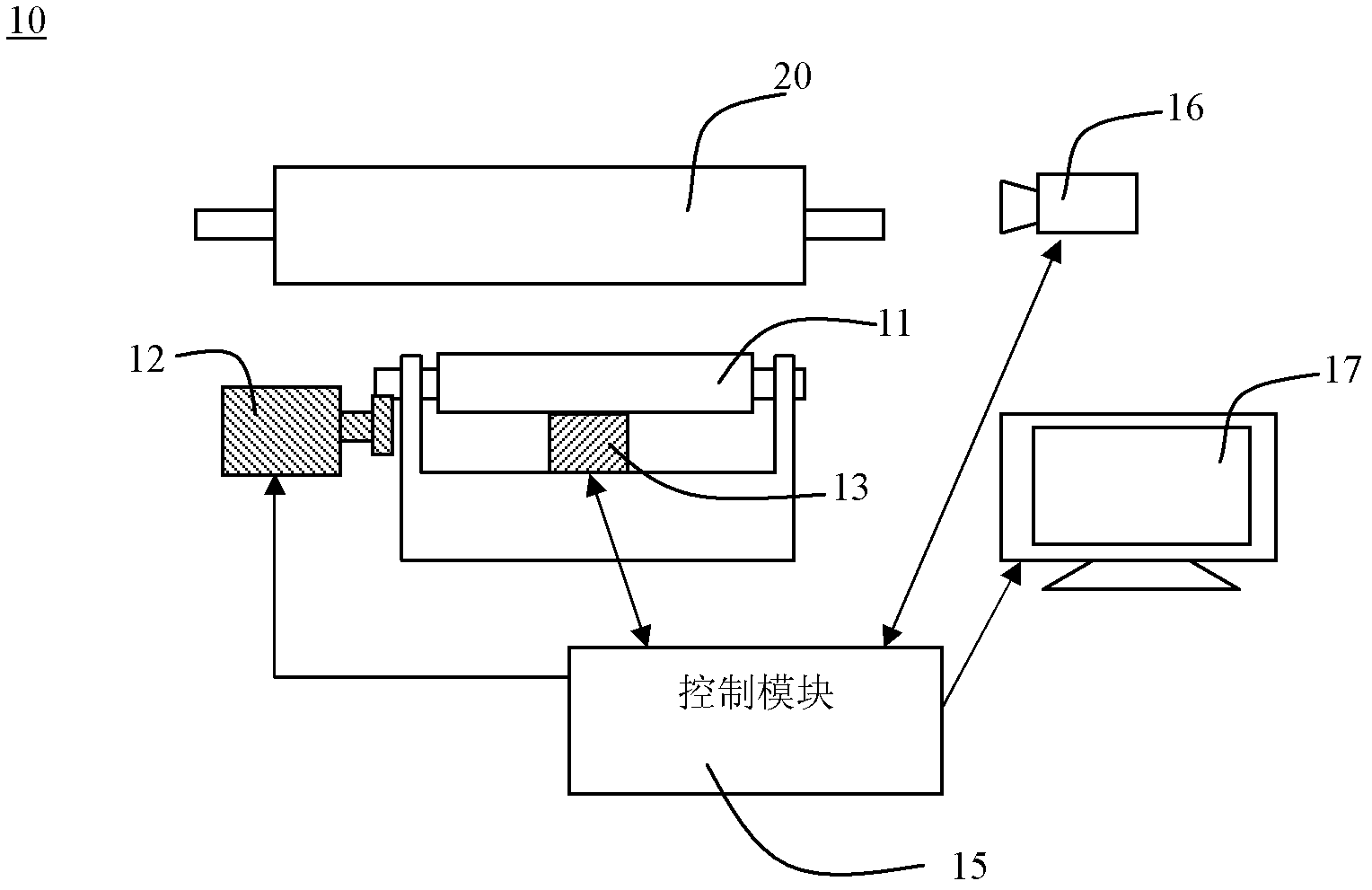

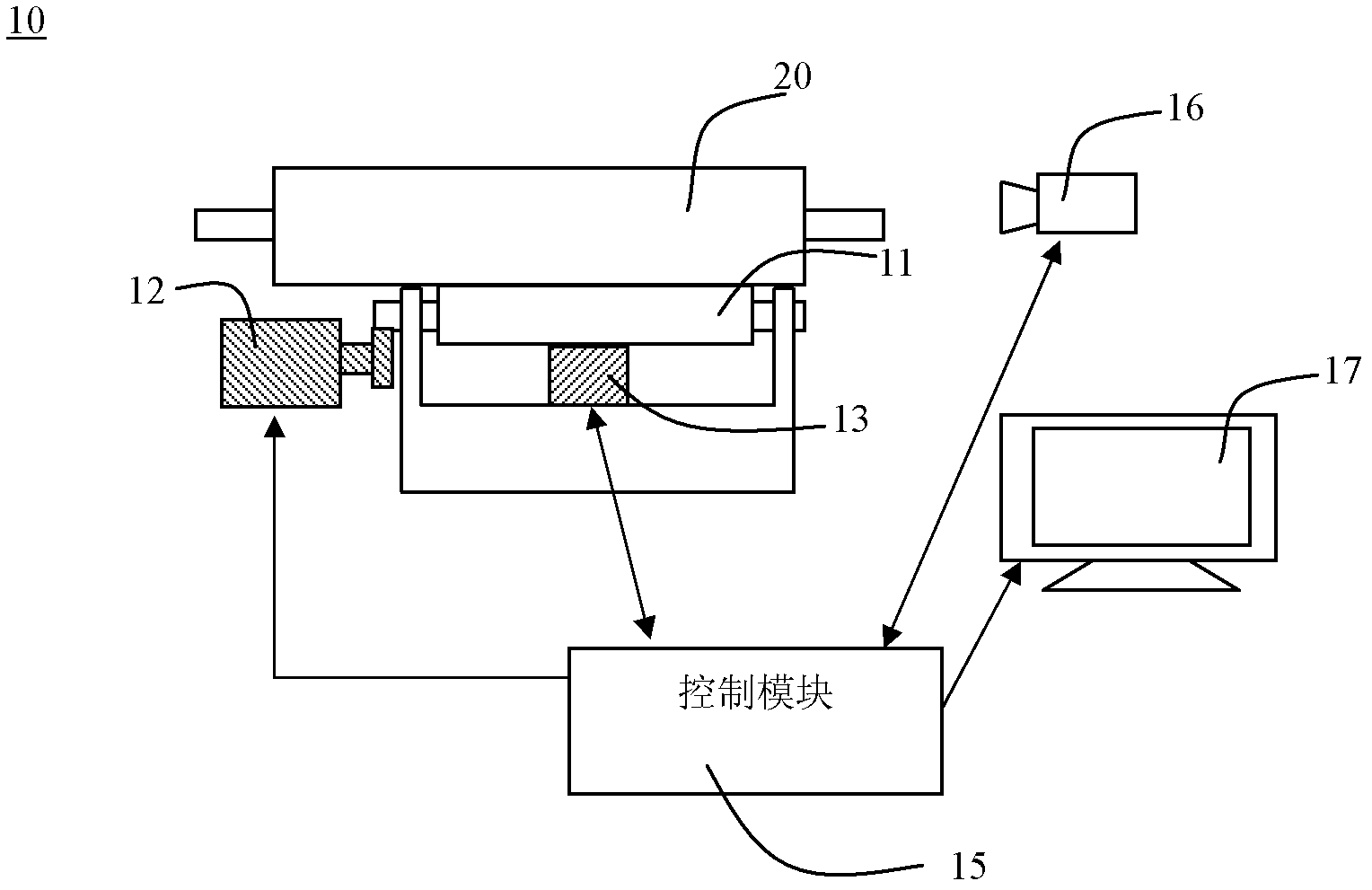

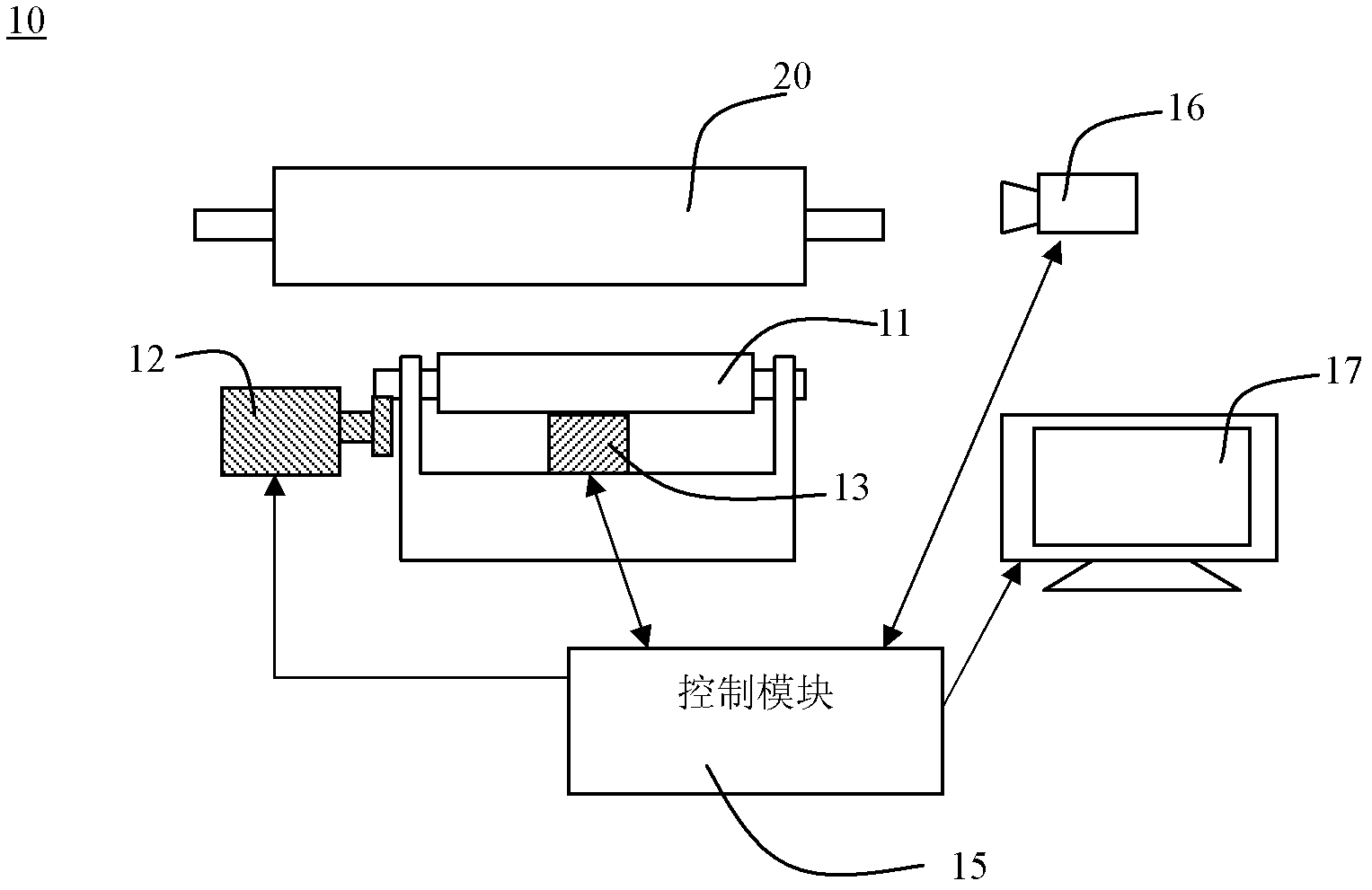

[0018] Please refer to figure 1 , figure 1 It is a schematic diagram of a testing device according to an embodiment of the present invention. The idler damping test device 10 of this embodiment includes: a contact roller 11 with a translation mechanism (not shown, not the key content of this technology, and any translation mechanism in the prior art can be referred to); drive the contact roller The drive motor 12 that wheel rotates; The pressure sensor 13 that detects the pressure that the contact roller 11 is subjected to; The control module 15 that receives the signal of the pressure sensor 13, the control module 15 controls the rotation of the drive motor 12 and the The translation of the contact roller 11; the sensor 16 that detects the rotation of the measured idler roller, the sensor 16 transmits the sensing result to the control module 15; the display module 17, the control module 15 is connected and The display module 17 is controlled.

[0019] Please also refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com