High-temperature high-pressure oil way system for three-position four-way hydraulic combined valve

A hydraulic combination valve, three-position four-way technology, applied in servo motor components, fluid pressure actuating devices, servo motors, etc., can solve the problems of oil leakage, time-consuming and laborious testing, waste of medium oil consumption, etc., and achieve intuitive detection. Accurate, easy to operate, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

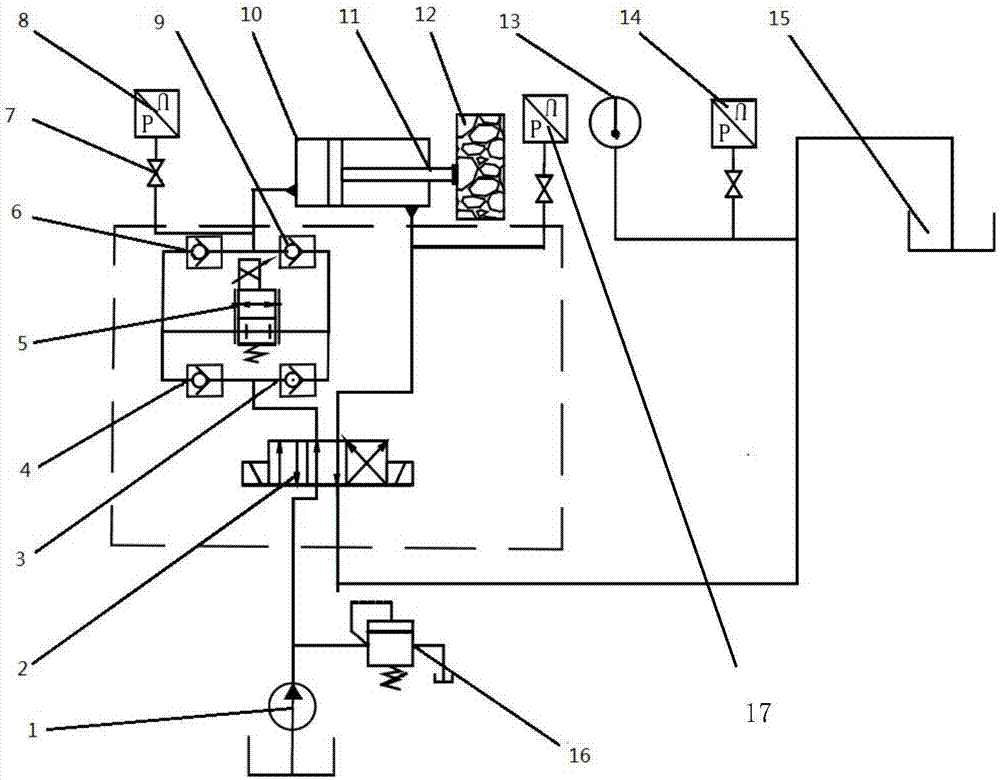

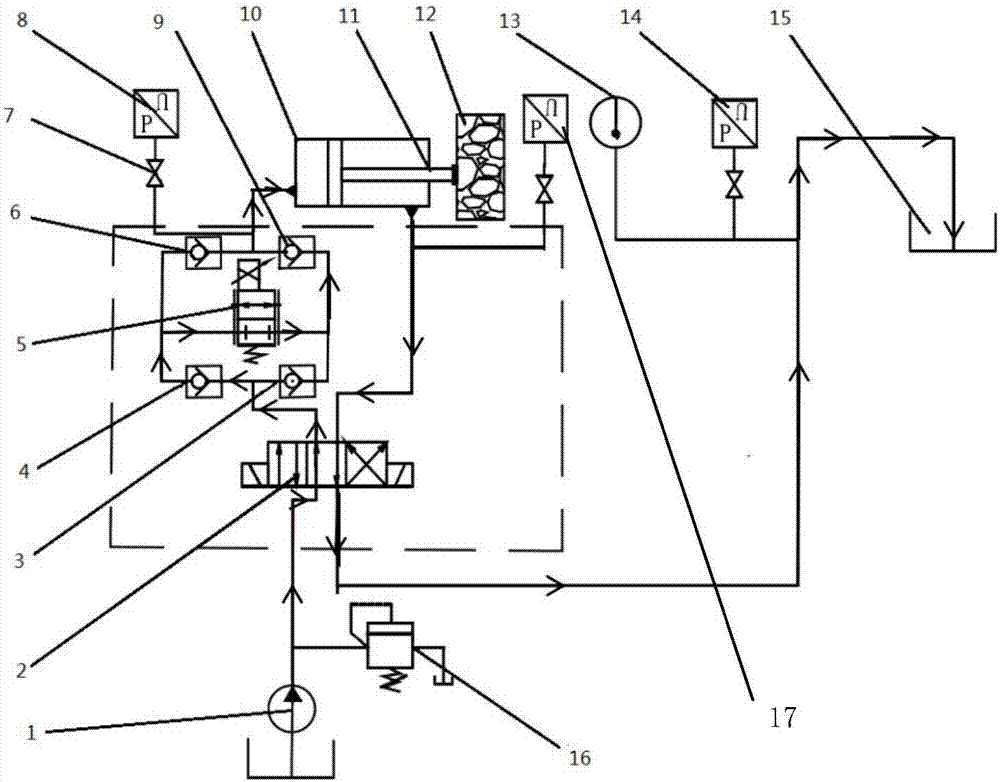

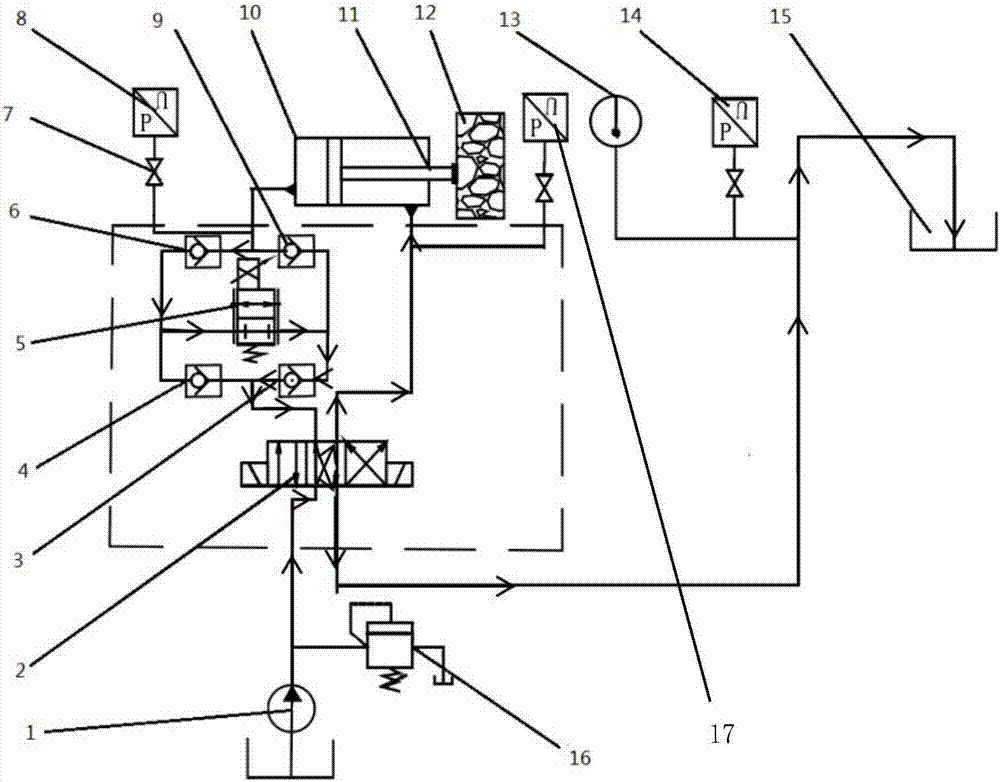

[0027] Using the high-temperature and high-pressure oil circuit system of the three-position four-way hydraulic replacement combination valve of the present invention, the technical indicators of a hydraulic system of an aircraft are tested with a working pressure of 35MPa and a medium temperature of 150°C. The specific test process is as Figure 2-3 shown.

[0028] The test results are as follows:

[0029] Working medium: HY-15 (aviation hydraulic oil);

[0030] Medium temperature: 150°C;

[0031] Working pressure: 35NPa;

[0032] Flow rate: 0~110L / min;

[0033] Flow adjustment direction: same as the oil circuit, one valve and two directions (in and out);

[0034] Work reversing: three-position four-way;

[0035] Test conclusion: All indicators meet the standard requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com