A high-power multi-point EFI gas engine misfire detection method and detection device

A technology of gas engine and detection method, which is applied in the direction of combustion engine, engine control, engine components, etc., can solve the problems of large amount of calculation of instantaneous acceleration, difficulty in satisfying real-time performance, complex algorithm, etc., and achieve reduction of calculation amount and calculation steps, misfire High detection accuracy, intuitive and accurate detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

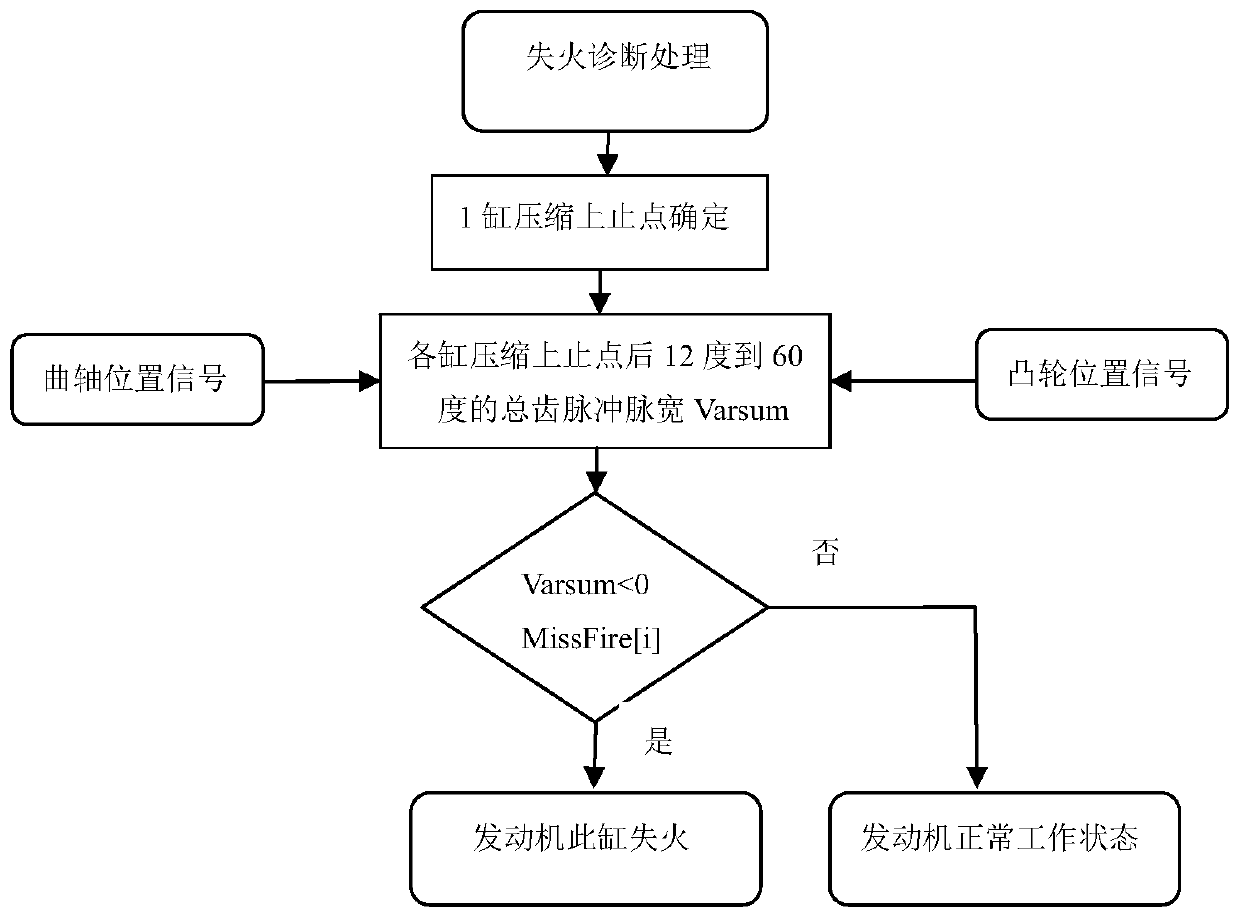

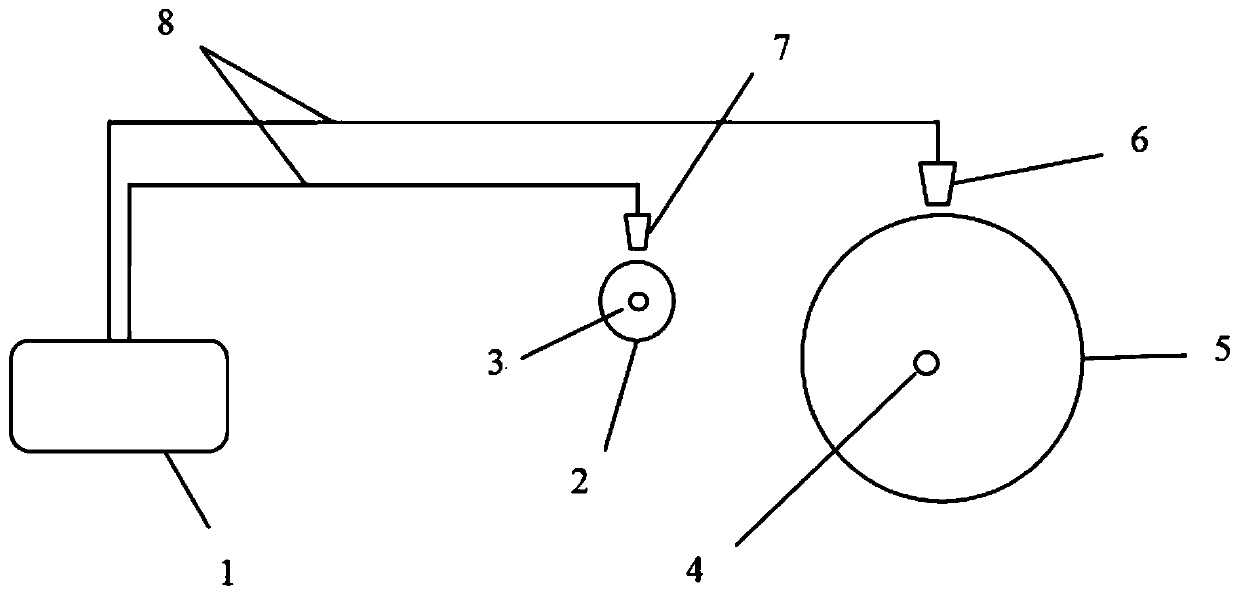

[0028] The present invention provides an engine misfire detection method capable of accurately diagnosing the engine, with simple signal processing, small amount of calculation, easy handling, less interference, and no misjudgment. Another purpose of the present invention is to provide a The invention provides an engine misfire detection device with simple and compact structure, low manufacturing cost, less interference, high misfire detection accuracy, intuitive detection process and accuracy.

[0029] In this engine misfire detection method, the crankshaft position sensor installed on the crankshaft signal plate at the flywheel end and the cam position sensor installed on the camshaft signal plate are used to determine the signal phase, and then the crankshaft position sensor is used to collect the compression top stop of each cylinder cylinder by cylinder. At the time of 8 teeth between 12 degrees and 60 degrees after the point, the collected signal is sent to the central pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com