Apparatus for measuring structural concrete defects and its method

A measuring device and concrete appearance technology, which is applied in the field of measuring devices for structural concrete appearance defects, can solve the problems that the results cannot be expressed in digital form, the defects cannot be accurately measured, and the accuracy is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

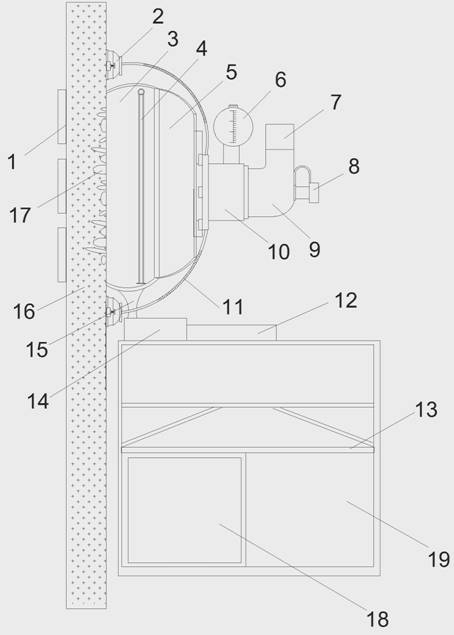

[0038] Such as Figures 3 to 5 As shown, a device for measuring apparent defects of structural concrete provided by the present invention includes a magnetic device 1 and a magnetic powder filling device 13, and both the magnetic device 1 and the magnetic powder filling device 13 are electrically connected to a power supply 18 located inside a cabinet 19 of. In this embodiment, the power supply 18 is a storage battery for the purpose of being convenient to move, and is used to continuously and more conveniently change the location of on-site detection. Wherein, the magnetic powder filling device 13 is arranged on the side of the apparent defect 17 on the concrete member 16, and the magnetic device 1 is arranged on the opposite side of the apparent defect 17 and corresponds to the position of the magnetic powder filling device 13;

[0039] Among them, the magnetic powder filling device 13 specifically includes a transparent air bag 3 arranged within the measurement area of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com