Non-compensation cold mounting method for large diameter heat supply pipeline

A technology for heating pipelines and installation methods, which is applied in the directions of thermal insulation protection of pipelines, pipeline protection, pipeline laying and maintenance, etc., can solve the problems that uncompensated cold installation technology cannot meet actual needs and other problems, and achieves low maintenance costs and simple installation. , the effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

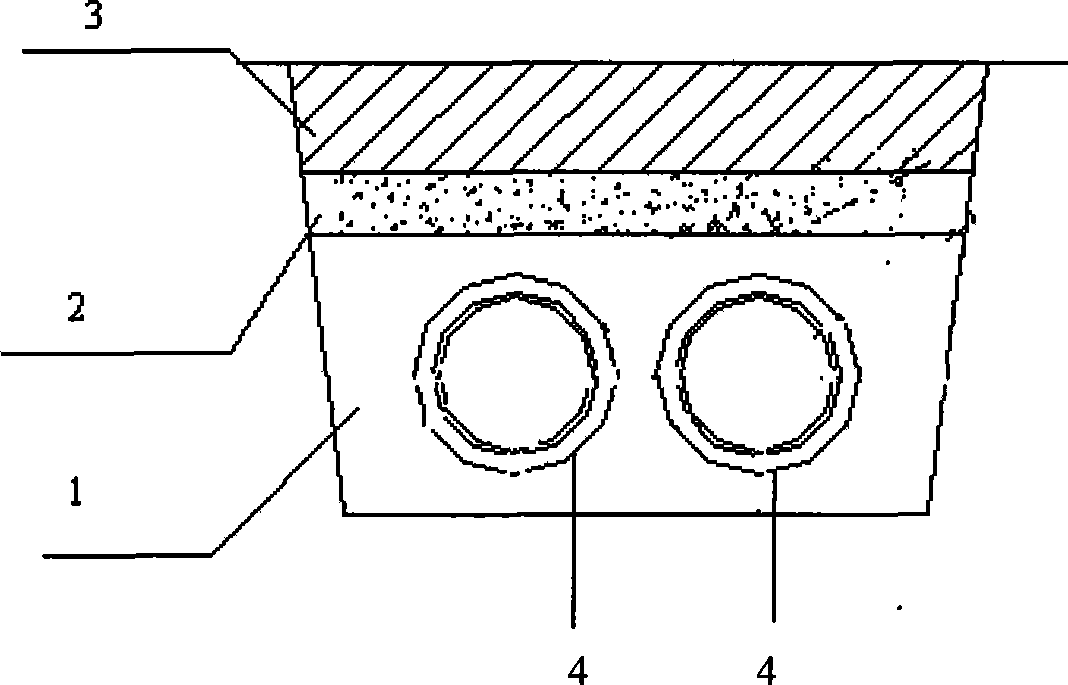

[0026] For heating pipes with a diameter of DN1100, the following installation methods can generally be used:

[0027] Before the excavation of the earthwork, you should first measure the setting-out line and measure the elevation→excavate the groove, and make the groove about -3.2m→level it up and clean up the sundries→organize the supervision and design unit to inspect the groove→fill sand after the groove inspection is qualified (tamping )→Put the directly buried prefabricated insulation pipe and pipe accessories into the groove, and calibrate the butt joint of the insulation pipe and weld it→Carry out visual inspection and non-destructive flaw detection of the welding quality→Pipeline strength test and tightness test after passing the test→Test After passing the test, the interface of the direct-buried prefabricated thermal insulation pipe shall be insulated and repaired → the groove shall be backfilled (tamped).

[0028] In particular, the depth of the trench should be in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com