Method of Constructing Variable-height Steel Beams Using Lifting and Pushing Brackets

A technology of variable height and steel girders, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of lower construction efficiency, cumbersome operation, and complicated operation procedures, and achieve improved construction safety factor, good comprehensive economic benefits, The effect of reducing the construction workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

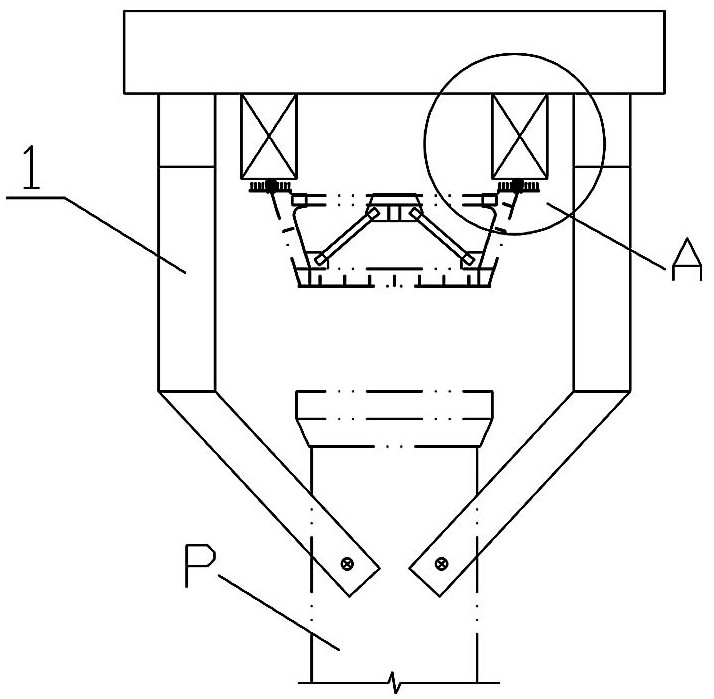

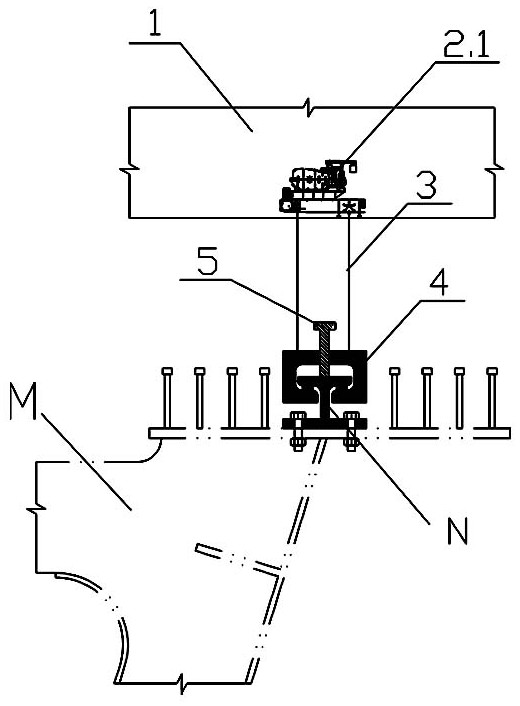

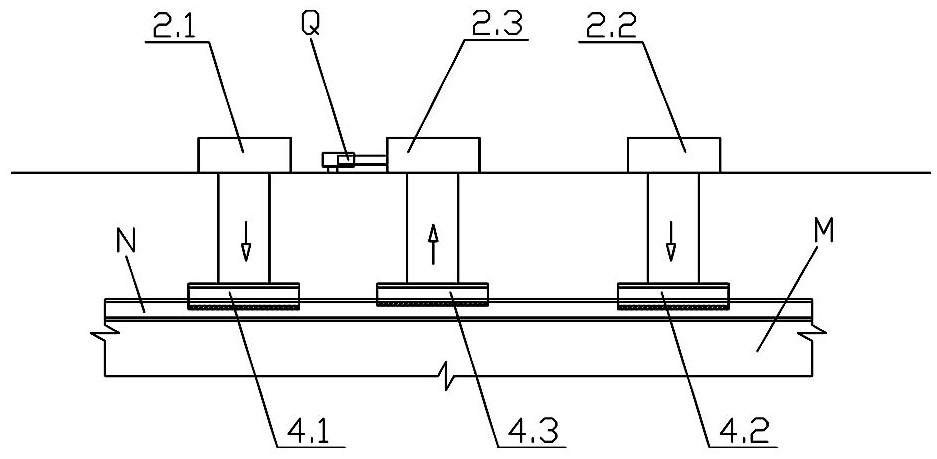

[0031] The method for constructing variable-height steel girders using lifting and pushing brackets according to the present invention needs to use such as figure 1 , 2 The shown hanging and pushing bracket includes a corner outrigger installed on the pier P, and two columns of lifting and pushing equipment are installed on the top beam 1 of the corner outrigger, and the hanging and pushing equipment is used to connect the upper wing of the steel beam M I-beam N at the top of the board. Each row of lifting equipment includes a left fixed hoist 2.1 and a right fixed hoist 2.2 located at both ends of the top beam 1, and a mobile hoist 2.3 located in the middle of the top beam 1, and the mobile hoist 2.3 slides with the top beam 1 through longitudinal slide rails Linked to each other, and linked to each other with the flat push jack installed on one side of the mobile hoist 2.2. In order to improve the lifting thrust, 1-3 sets of mobile hoists 2.3 can be installed, and each mob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com