Prestressed UHPC shell-concrete inner core combined cover beam structure and construction method thereof

A concrete internal and prestressed technology, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of non-conforming to green, environmental protection, large deformation of the cantilever end, and no significant improvement in stress, so as to save space and temporarily The cost of the bracket is good, the integrity is good, and the quality and reliability are good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Although the structural shape of the present application is similar to that of the traditional concrete cap beam, the composite cap beam has a lighter weight and higher bearing capacity, and realizes prefabricated hoisting, eliminating the need for construction procedures such as support and formwork.

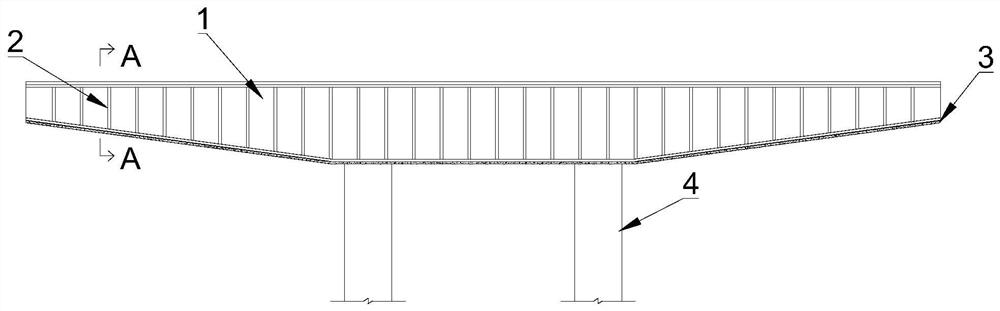

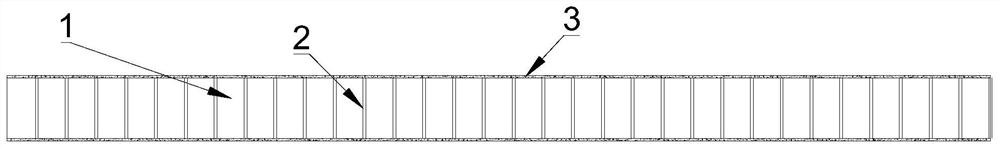

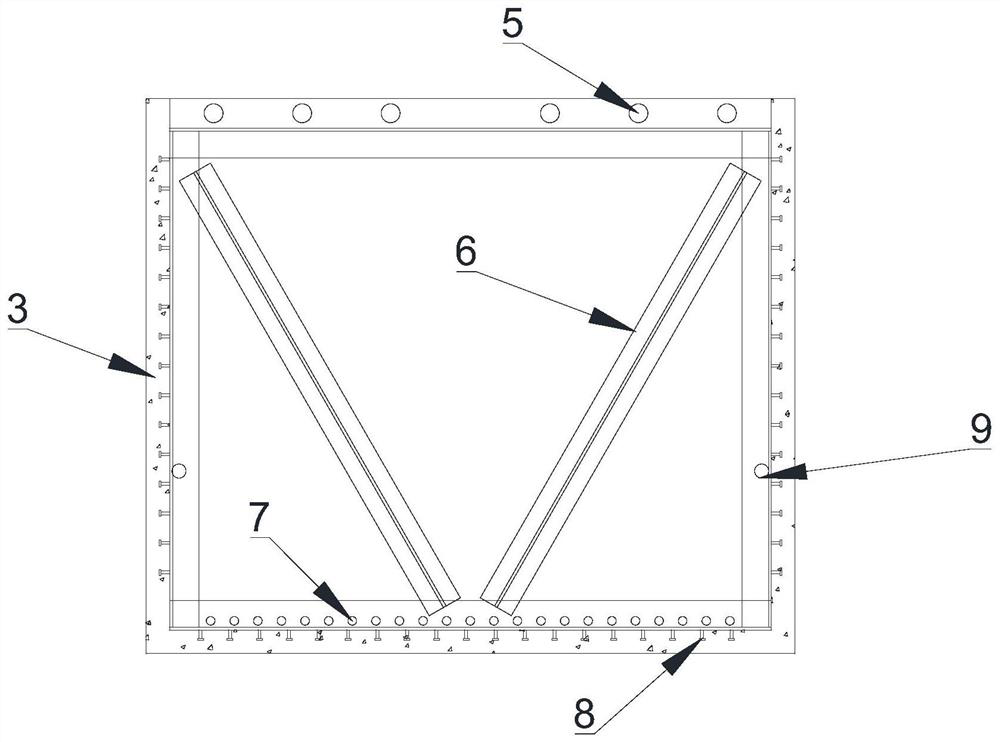

[0042] Such as Figures 1 to 9 As shown, a prestressed UHPC shell-concrete core composite cover beam structure of this embodiment includes a cover beam shell 3, and the cover beam shell 3 includes a web and a bottom plate, and a plurality of webs are connected to the bottom plate and connected to the bottom plate Enclosing an inner cavity with an upward opening, the cover beam shell 3 is a prefabricated UHPC shell, and a plurality of strengthening frames 2 are vertically arranged in the inner cavity, and the plurality of strengthening frames 2 are arranged at intervals along the length direction of the cover beam shell 3, so as to The cover beam shell 3 is a pouring temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com