Reinforcing structure for preventing buckling based on main material of power transmission tower

A technology for strengthening structures and transmission towers, applied in towers, building structures, building maintenance, etc., can solve problems such as difficult construction, reduced slenderness ratio, cumbersome construction, etc., and achieve simple construction, significant effect, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1, this implementation is a comparative example of Example 2, the length of the angle steel is 1.8m, the material is Q345 steel, and the unreinforced angle steel is subjected to one-time axial compression loading.

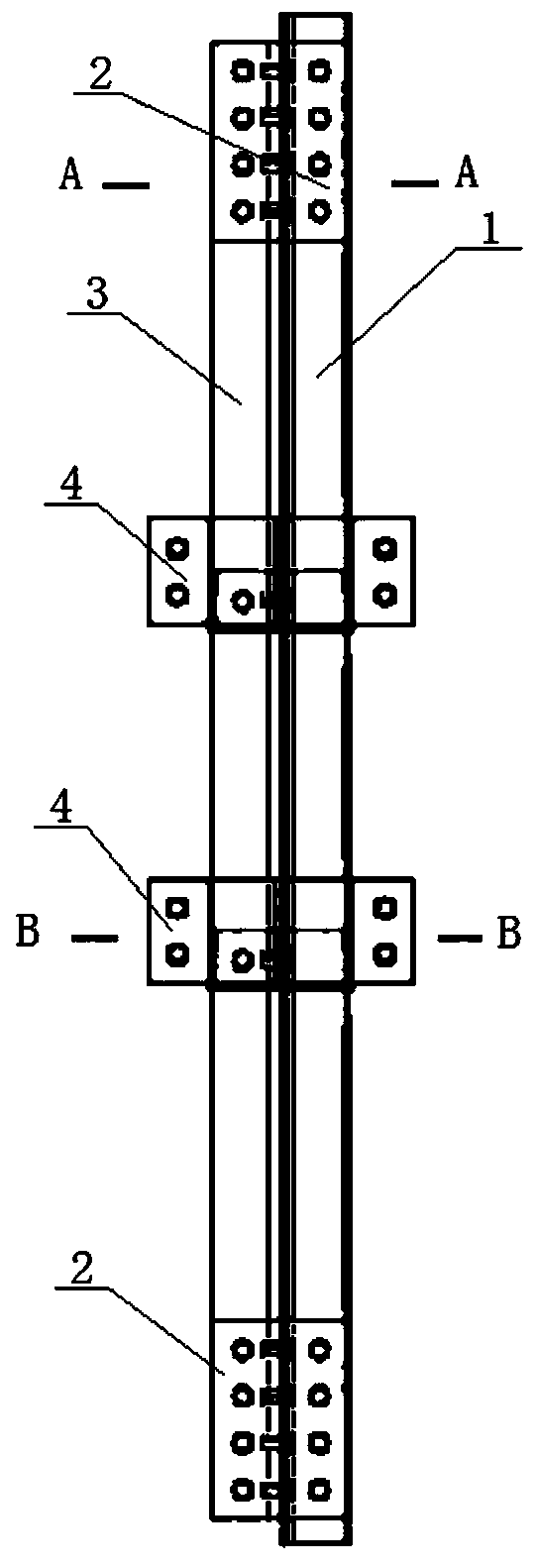

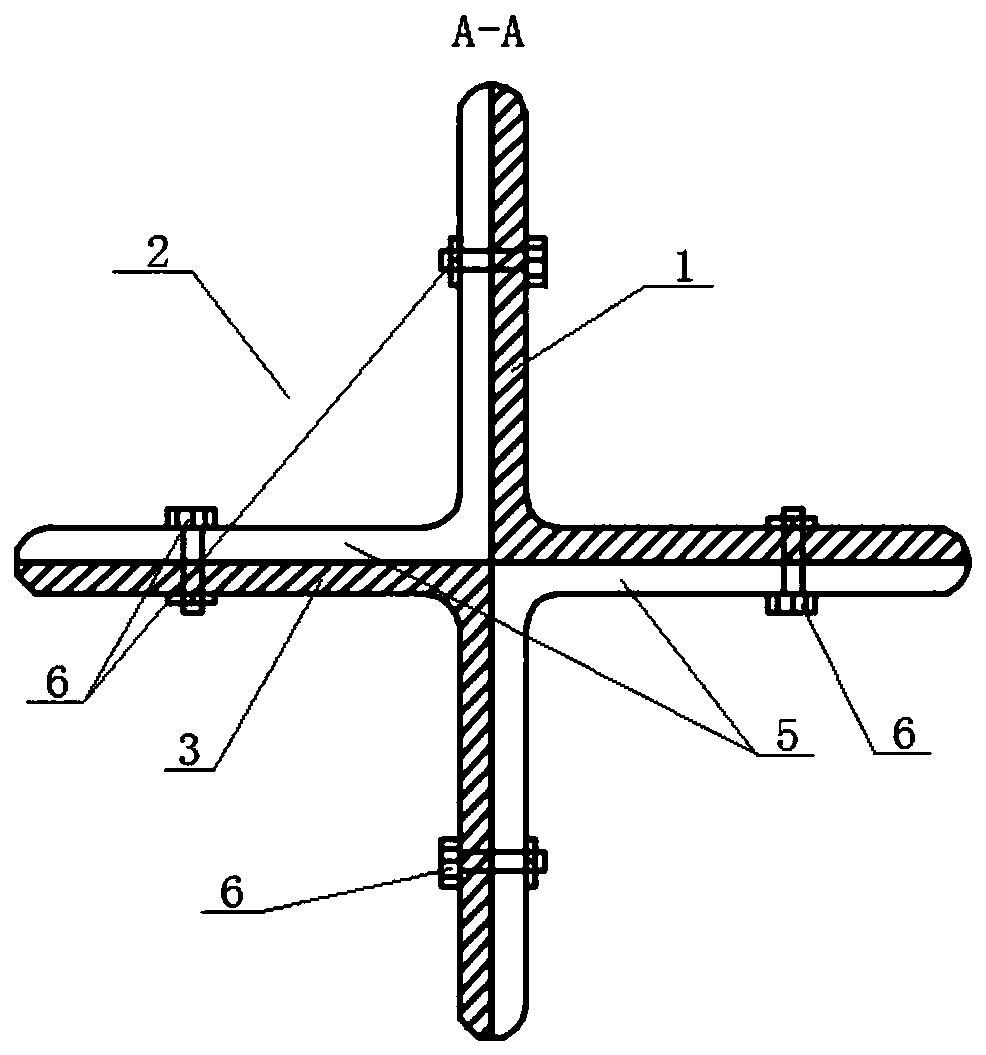

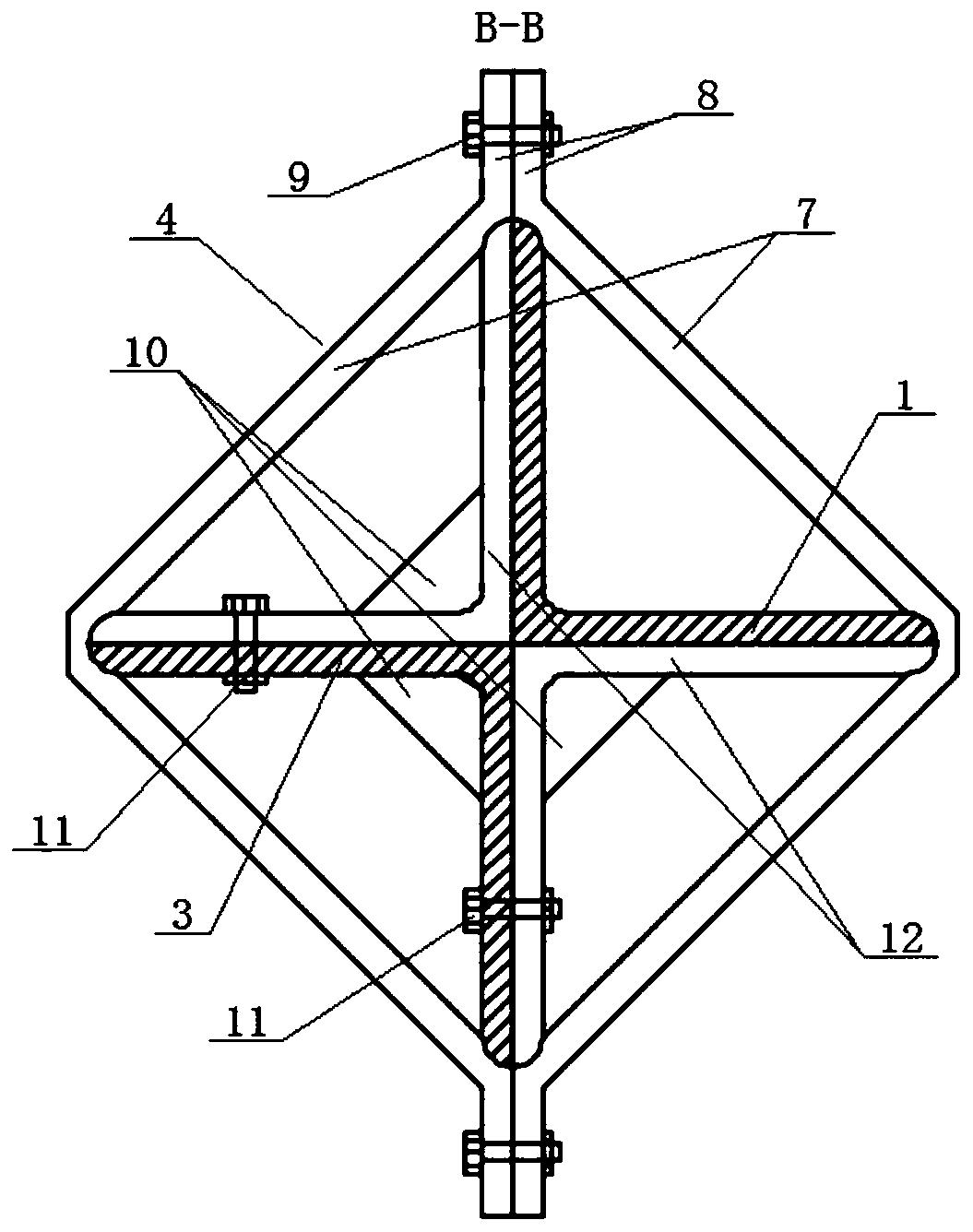

[0029] see Figure 1~6 , Embodiment 2, this embodiment is based on a reinforcement structure for preventing buckling of the main material of the transmission tower, which includes a reinforcement angle steel 3, an end fixing part 2 and an intermediate fixing part 4, and the reinforcement angle steel 3 is placed on the transmission tower to be reinforced. The outer side of the material 1 is arranged diagonally to the main material 1 to be reinforced, and the upper and lower ends of the reinforced angle steel 3 are respectively provided with end fixing parts 2, and two intermediate fixing parts 4 are arranged between the two end fixing parts 2 , the two end fixing parts 2 and the two middle fixing parts 4 connect the reinforced angle steel 3 with the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com