Patents

Literature

97results about How to "Guaranteed not to slip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

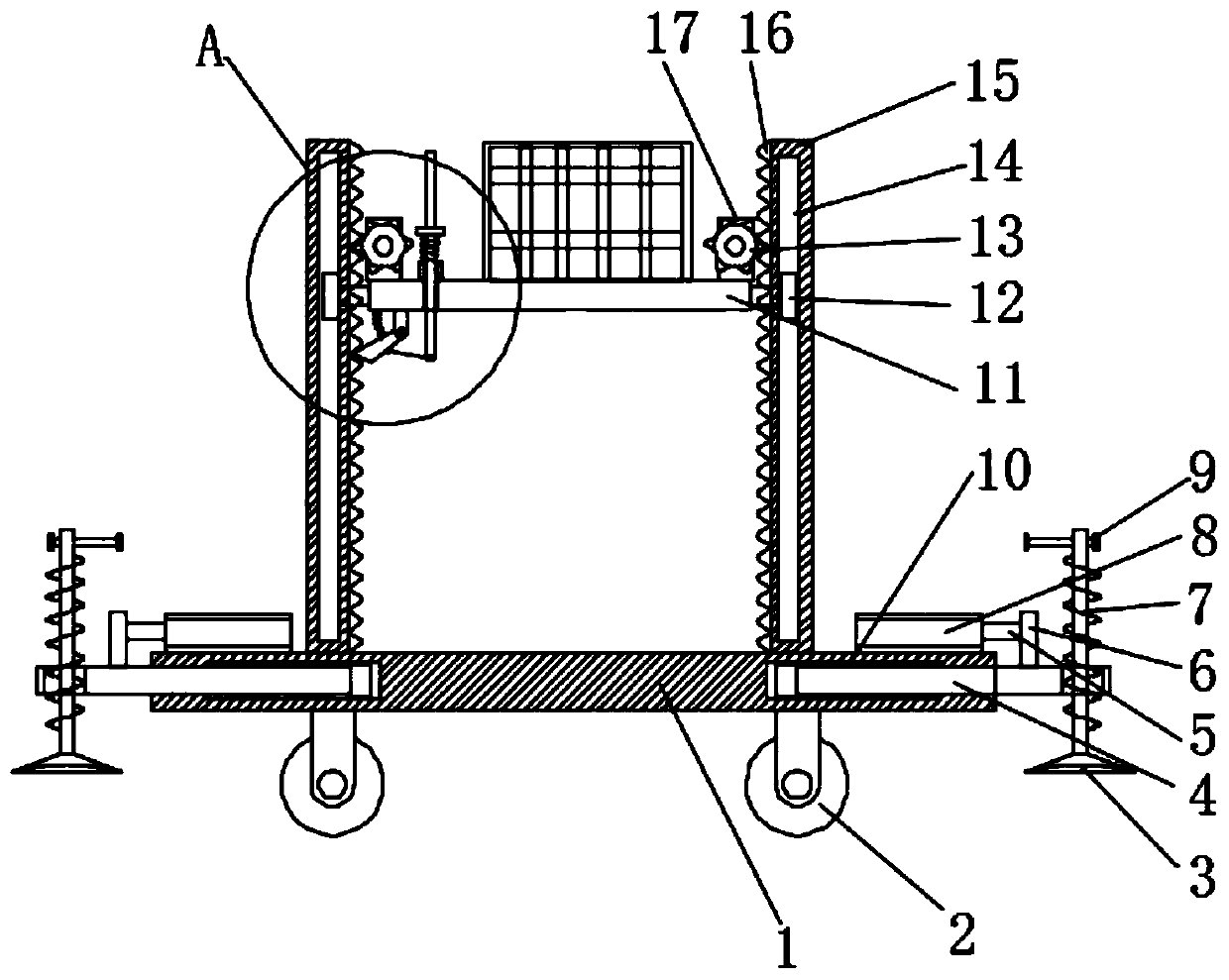

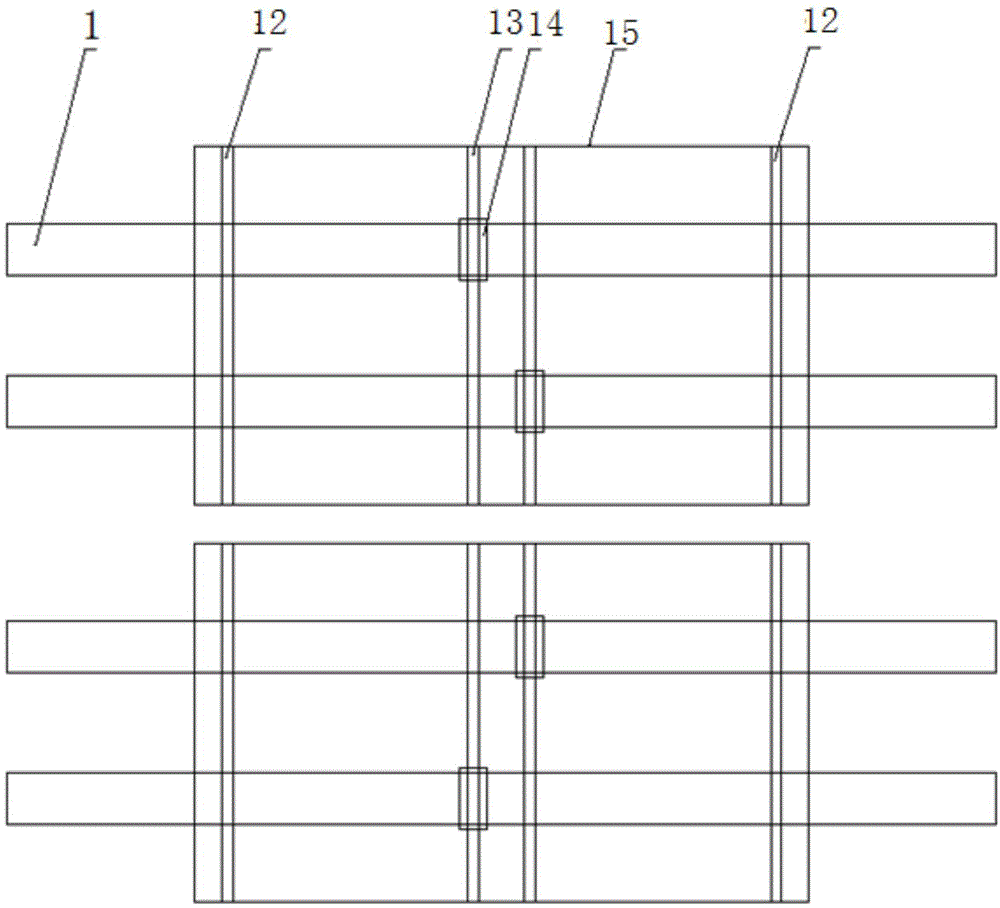

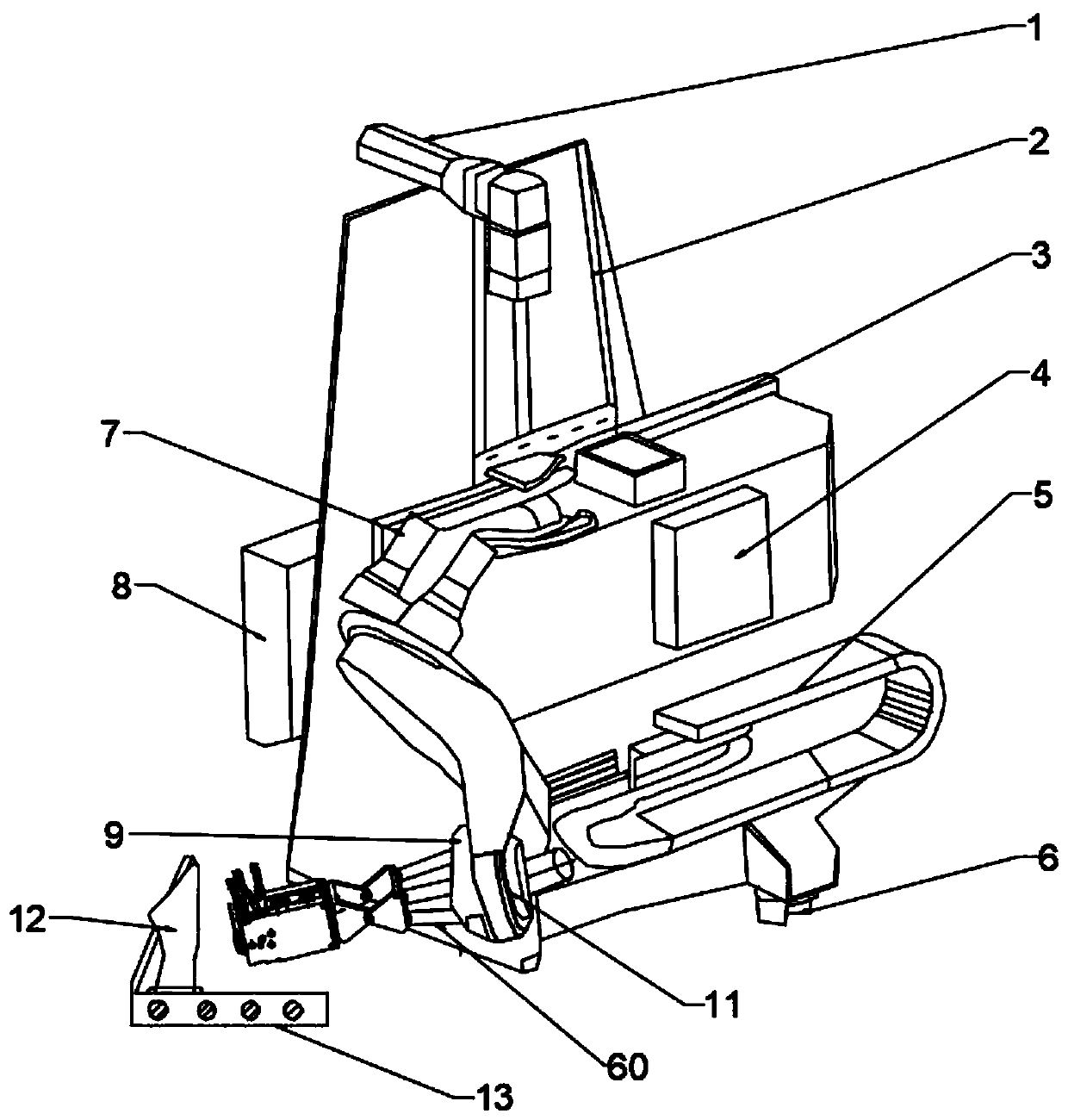

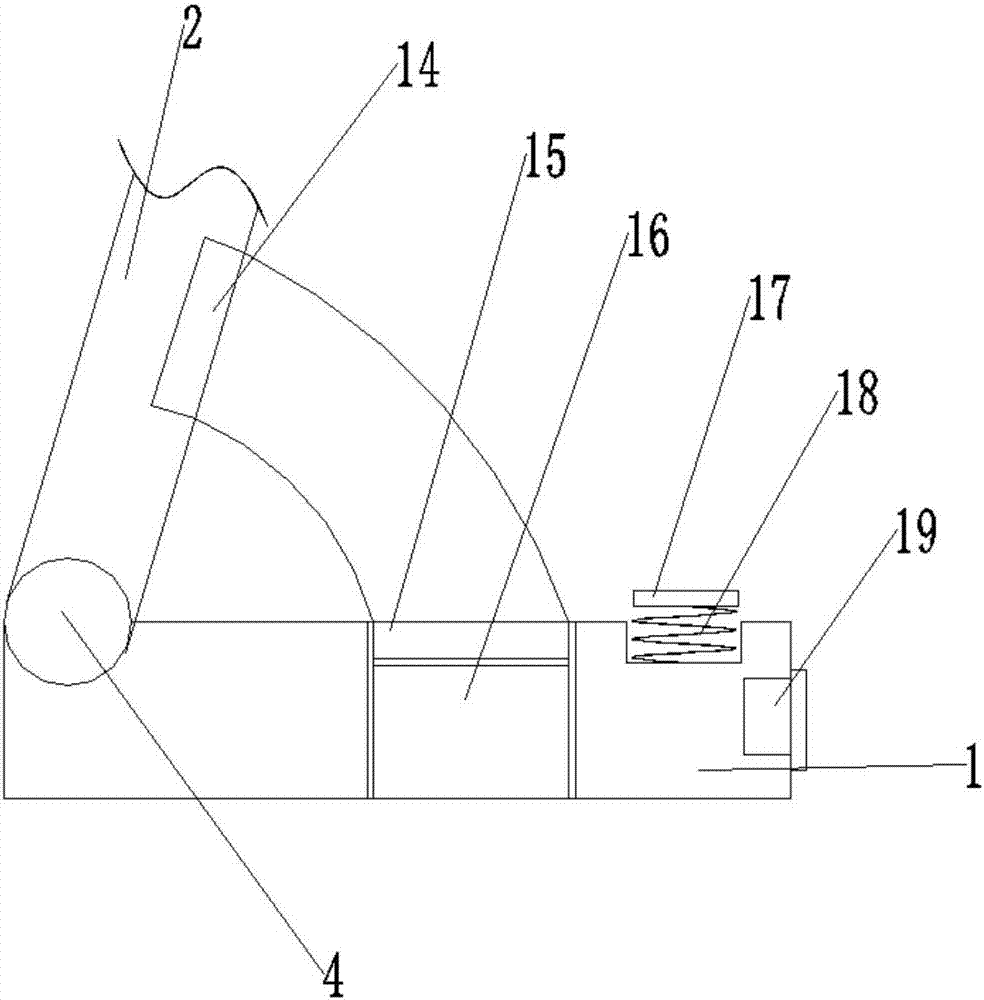

Lifting type construction platform for constructional engineering

The invention discloses a lifting type construction platform for constructional engineering. The lifting type construction platform comprises a bottom plate, wheels, a support plate, a rotating lead screw, a support plate, a sliding block, a gear, a toothed belt, a feeding assembly, a reset spring, a clamping hook, a support rod, a rotating shaft and a third motor. According to the invention, teeth are matched with the toothed belt, the vertical up-down movement of the support plate can be realized, by matching with the clamping hook, when the motor fails, the support plate does not slip, safety of constructors is guaranteed, the safety performance of the lifting platform is greatly improved, extensible sliding plates are arranged on the two sides of the bottom plate, the support range ofthe bottom side can be expanded, through the effect of the rotating lead screw, the stability of the lifting platform can be guaranteed at the non-platform operation position, the situation that the lifting platform inclines is avoided, the lifting platform can be better fixed, a feeding structure is arranged on the side edge of the lifting platform, construction materials and construction waste materials can be conveniently conveyed, and the construction efficiency can be greatly improved.

Owner:湖南林森建筑有限公司

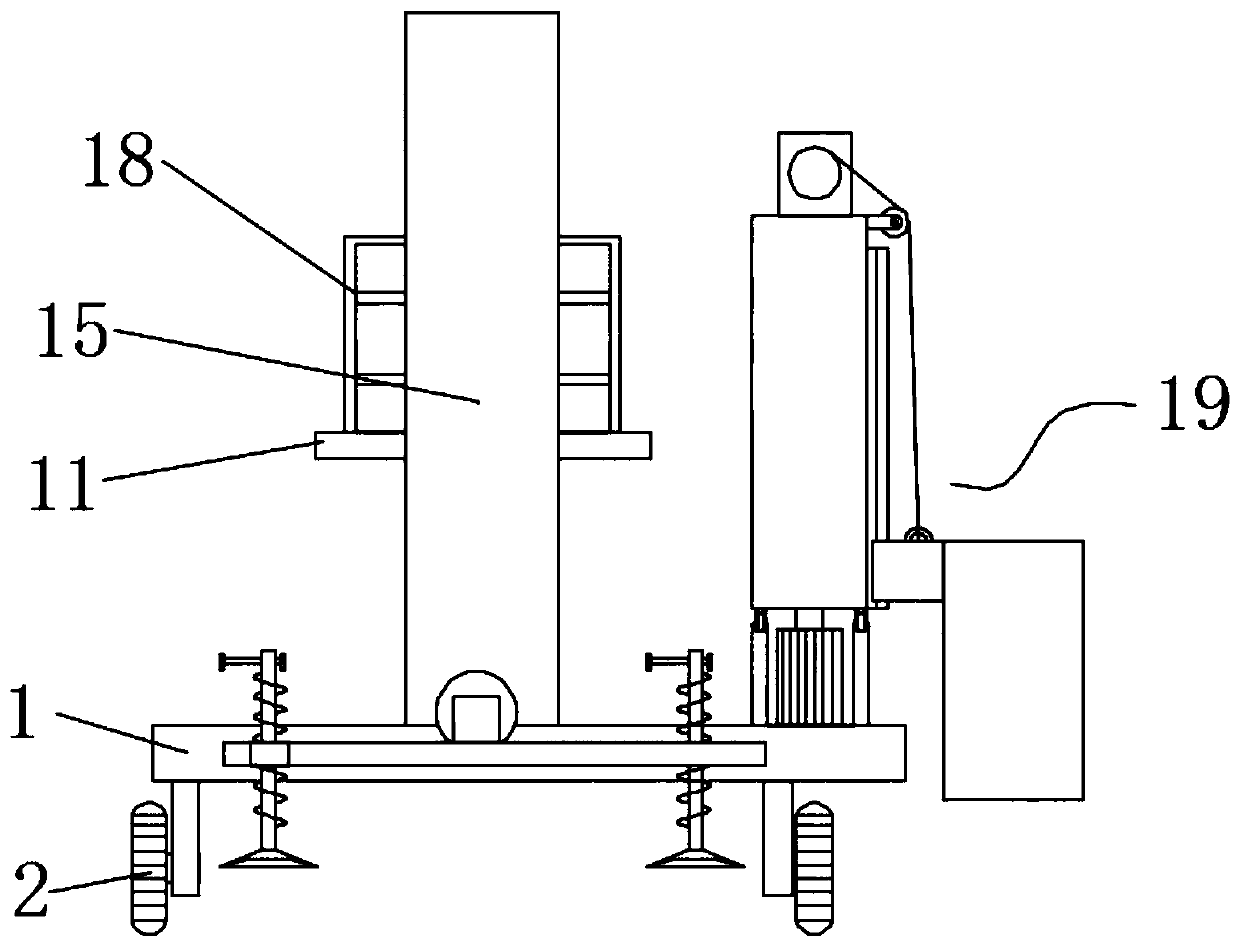

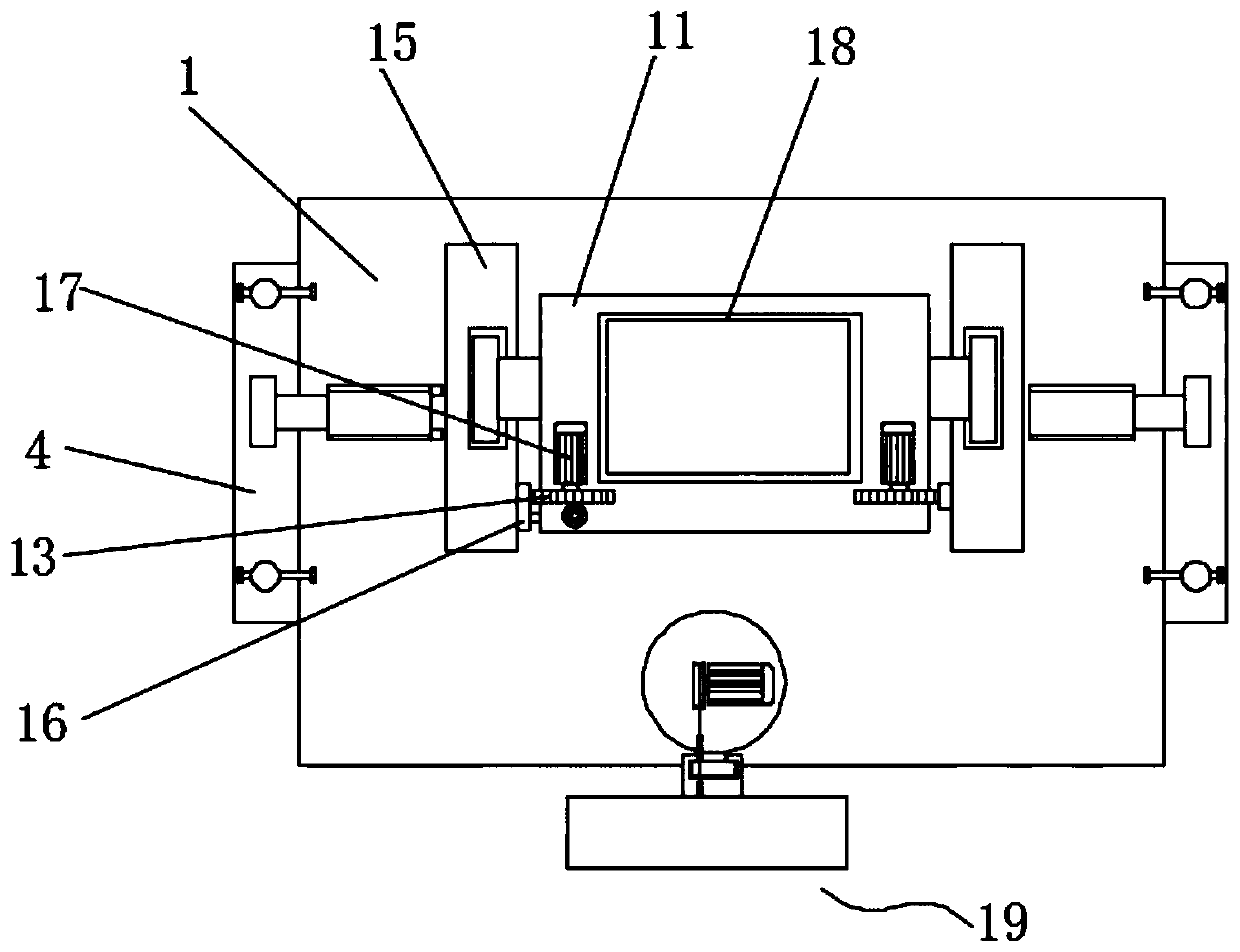

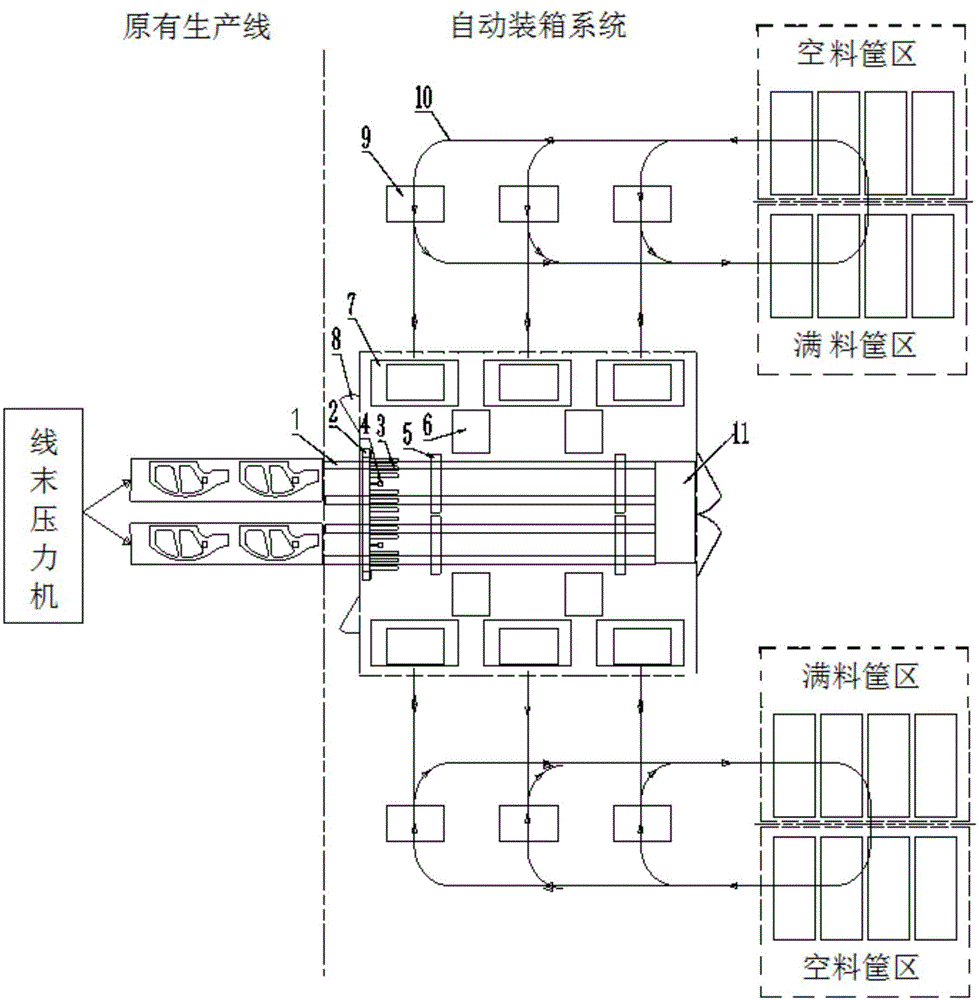

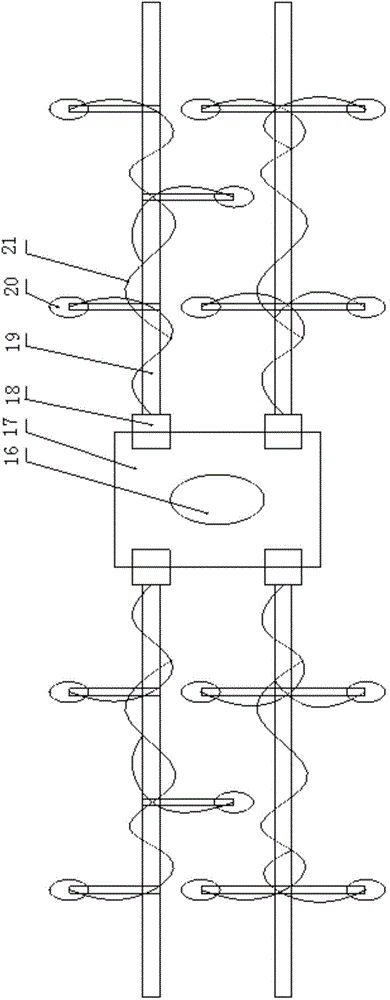

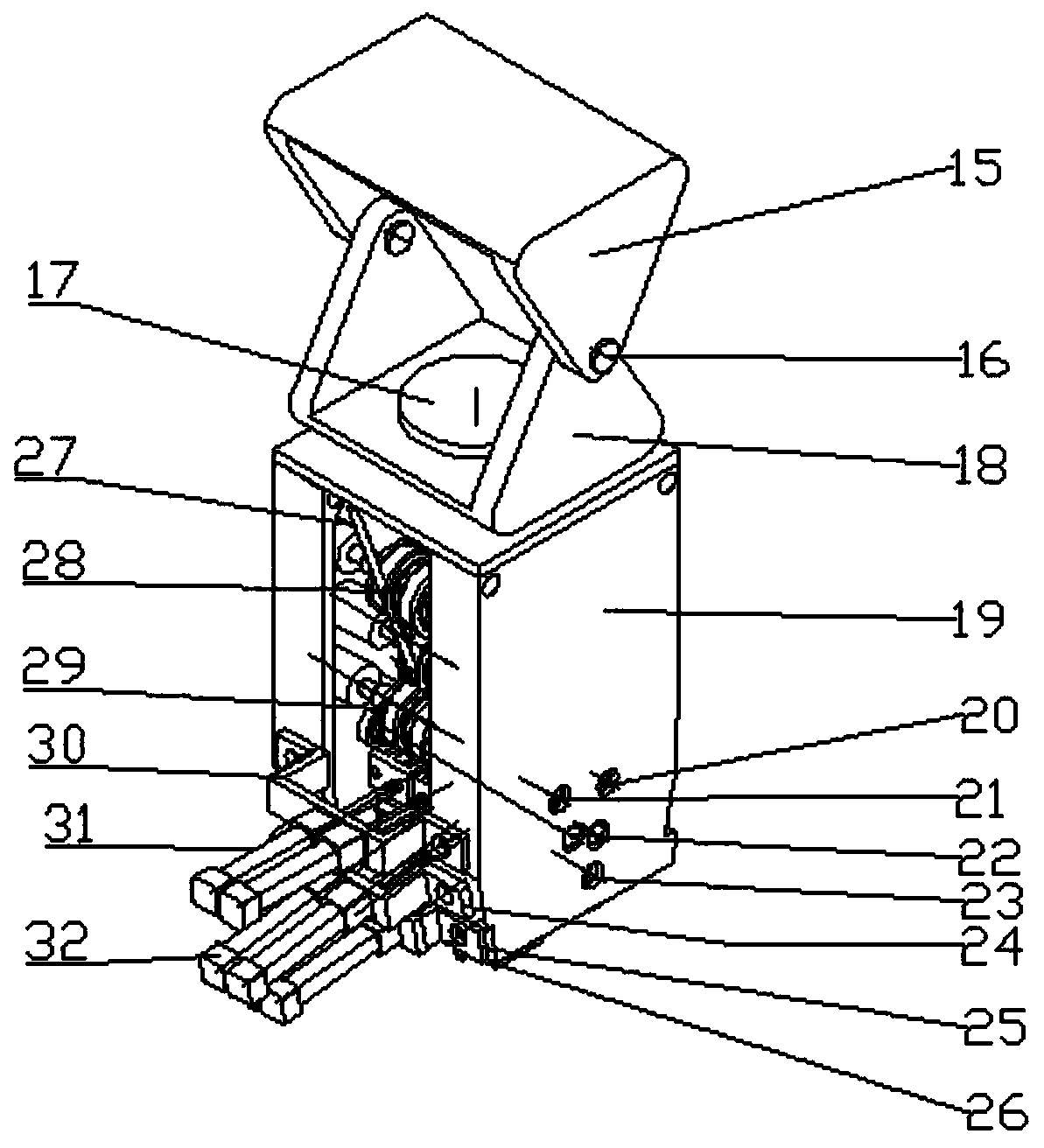

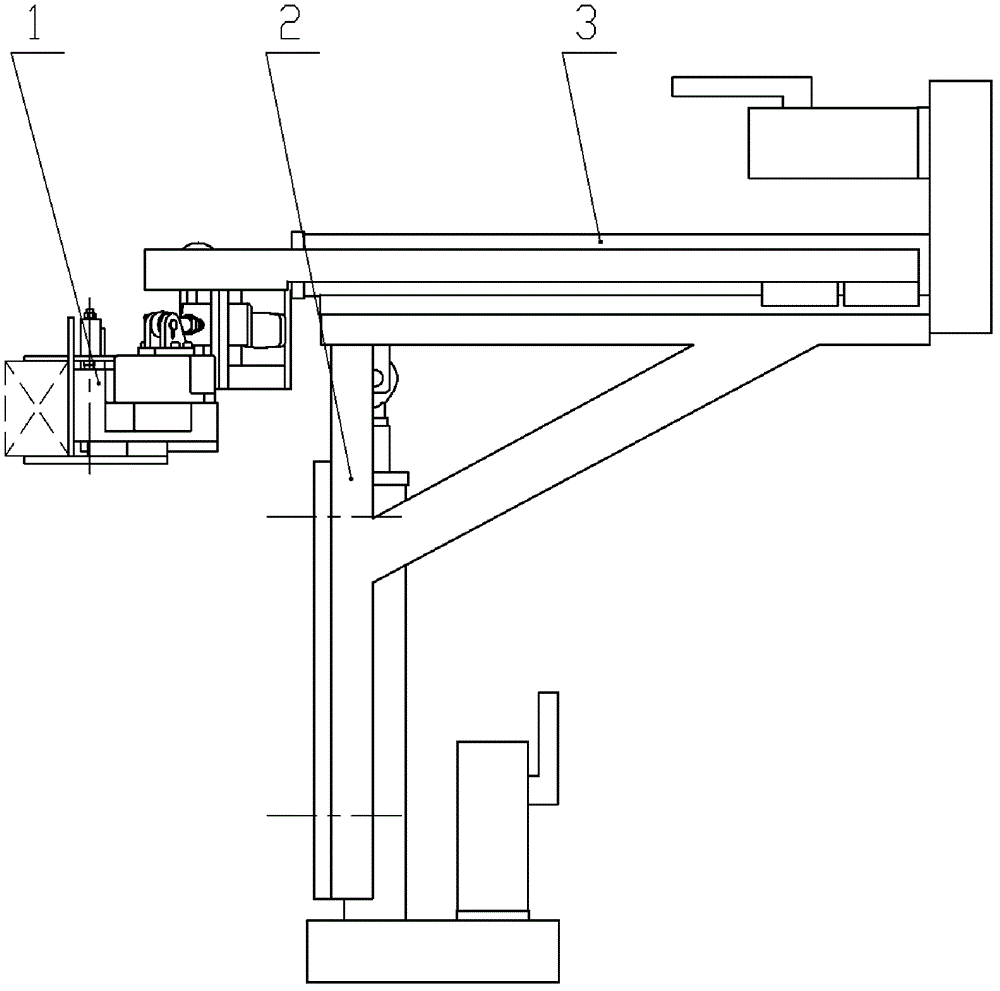

Automatic packing system in full-component press line end and method

ActiveCN104942178AAchieve precise positioningGuaranteed not to slipMetal-working feeding devicesMetal working apparatusRobotic systemsControl theory

The invention discloses an automatic packing system in full-component press line end and method. The automatic packing system in the full-component press line end and method comprise that robot systems are arranged at the two ends of the servo synchronous belt system respectively, and a visual system is connected with a PLC controller. The robot systems are connected with robot controllers. The PLC controller is connected with the robot controllers. A charging basket is connected with a charging basket changing system. Components are transmitted through the servo synchronous belt system. The visual system obtains component position information and judges positional deviations of the components. The PLC controller sends the positional deviation information to the robot controllers. The robot controllers control robots to grip the components, and the components are put into the corresponding charging basket. The automatic packing system in the full-component press line end and method has the advantages that the robots adjust the position of gripping the components according to the positional deviation information automatically, and accurate positioning of each component is achieved.

Owner:张三义

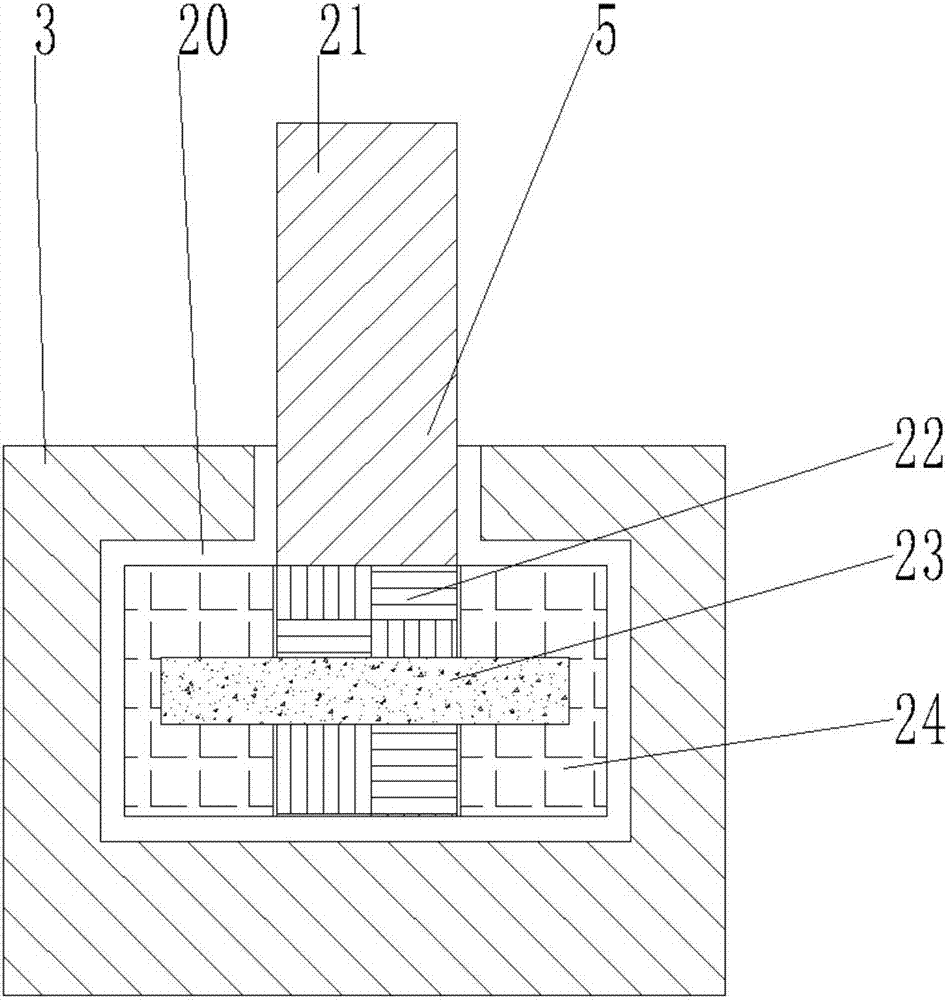

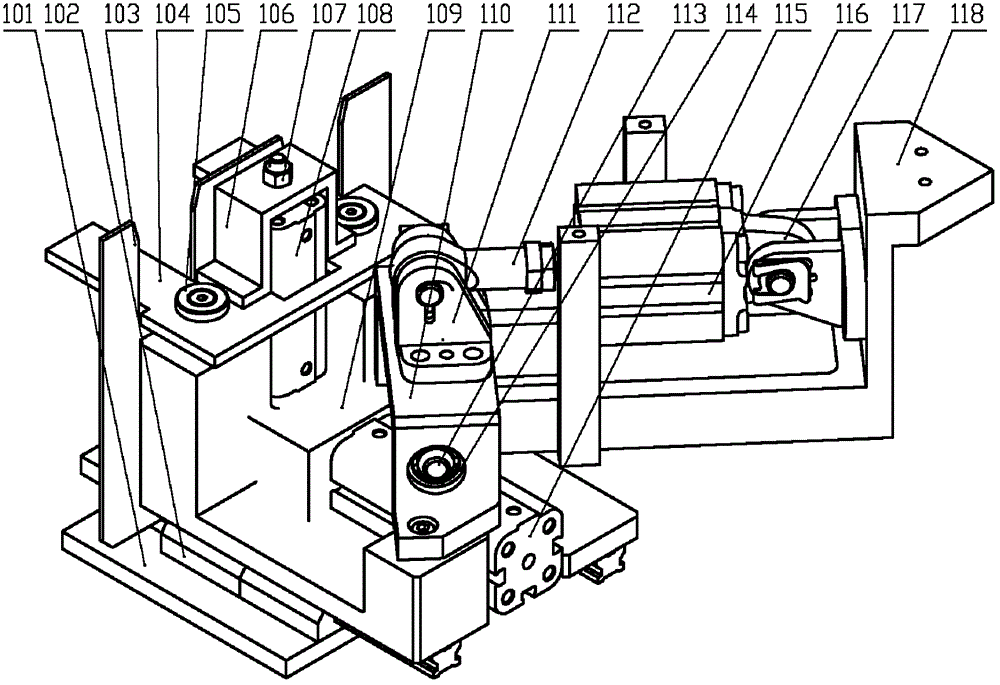

Clamping devices used for carving machining

The invention discloses clamping devices used for carving machining. The clamping devices each comprise a supporting seat. The supporting seats are mounted on a worktable. Fixed bottom plates and vertical plates are arranged on the upper end faces of the supporting seats. Adjusting sliding plates are connected with the vertical plates and slidably connected with movable caliper bodies. The movable caliper bodies are fixedly connected with adjusting pressing plates. Pushing plates are arranged above the adjusting pressing plates. Elastic elements are arranged between the adjusting pressing plates and the pushing plates. Pneumatic devices are fixedly mounted on the upper portions of the vertical plates and fixedly connected with the pushing plates. Electromagnets and gasket sucking discs are arranged on the fixed bottom plates and the adjusting pressing plates correspondingly. According to the clamping devices used for carving machining, by arranging the pneumatic devices, workpieces can be automatically clamped, the clamping force is large, and the labor intensity is large. By arranging the electromagnets and gasket sucking discs, the situation that the workpieces do not slide is guaranteed, the clamping force is further increased, and fixity is better. The elastic elements are arranged between the fixed bottom plates and the adjusting pressing plates, so that adjusting of the clamping force is facilitated, and damage to the workpieces is avoided.

Owner:HEFEI SIWEI CNC MACHINERY

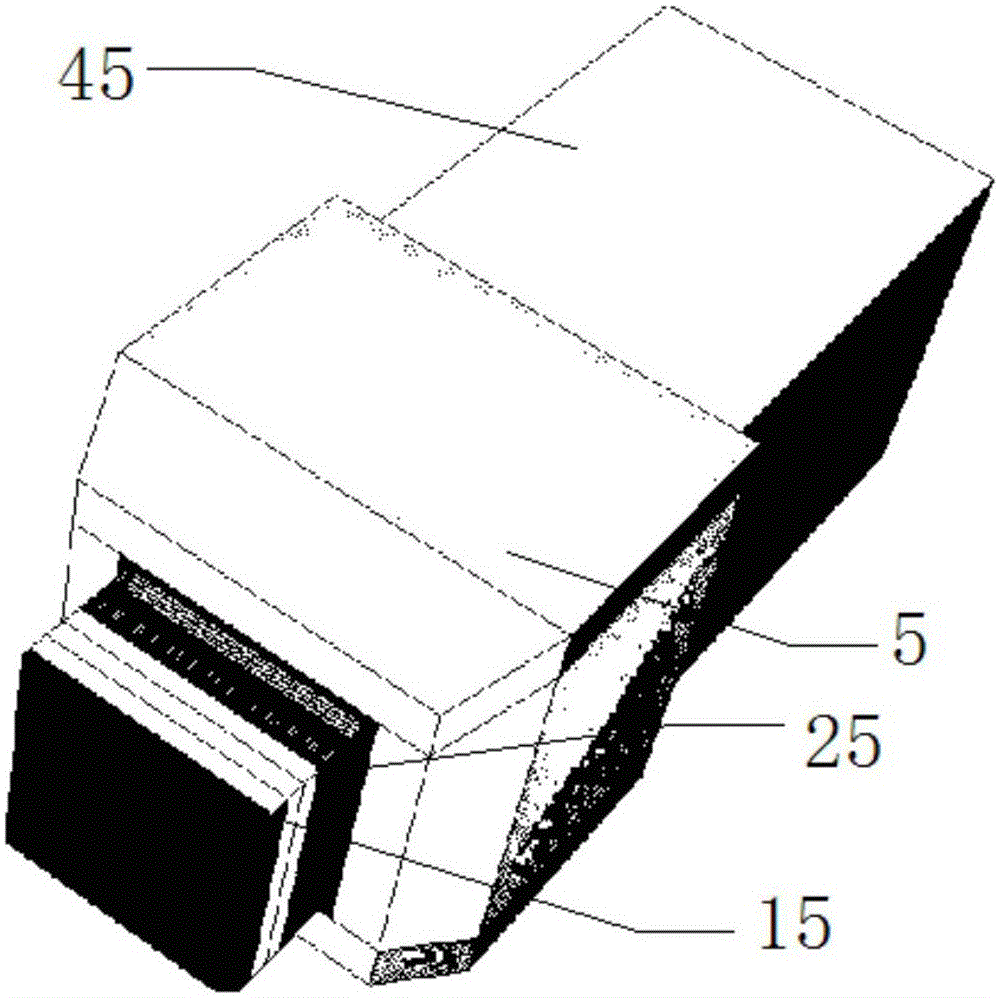

Marine wind power blade carbon fiber automatic forming equipment and laying process method

InactiveCN110789155AReal-time adjustmentReal-time detection of temperature changesFiberCarbon fibers

The invention relates to the technical field of wind power generation equipment, in particular to marine wind power blade carbon fiber automatic forming equipment and a laying process method. A horizontal three-degree-of-freedom parallel mechanism is used, and the horizontal three-degree-of-freedom parallel mechanism comprises a laying component used for laying fibers and a three-axis adjustable control mechanism used for realizing coordinate conversion of a filament laying mechanism and realizing multi-axis motion. A conveying device of the filament laying mechanism adopts a speed sensor anda plurality of compression rollers to control a filament bundle to be conveyed to a filament bundle tension control device, the high surface roughness is adjusted to ensure that the filament bundle does not slip, the filament bundle respectively passes through a re-transmission mechanism and a cutting device with cylinder cover, the filament bundle is melted under the action of an infrared radiation lamp tube heating device, and finally carbon fibers are laid through the pressurization cooling treatment of a cooling device. According to the marine wind power blade carbon fiber automatic forming equipment and the laying process method, through a motion platform capable of realizing multi-axis motion, a fiber laying head is driven to complete the laying work of the carbon fibers, the layingprocess is completed, the stable and uniform laying can be guaranteed, the filament laying process can be fed back and monitored in real time through a self-provided monitoring device, and the filament laying quality is improved.

Owner:JIANGSU UNIV OF SCI & TECH

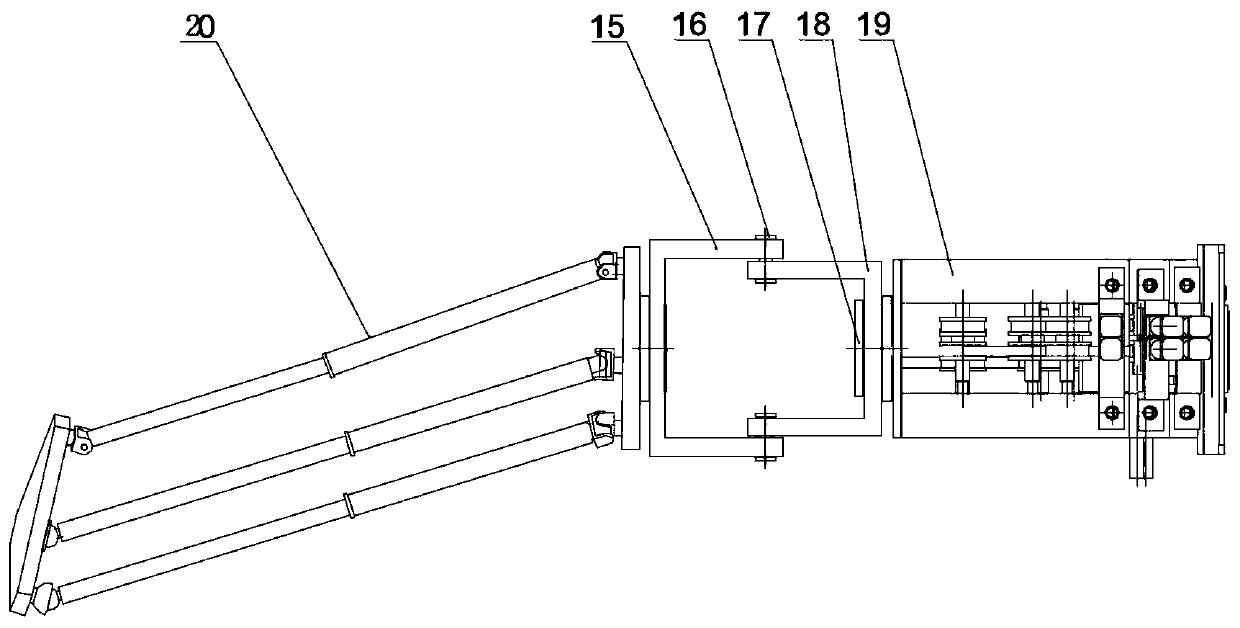

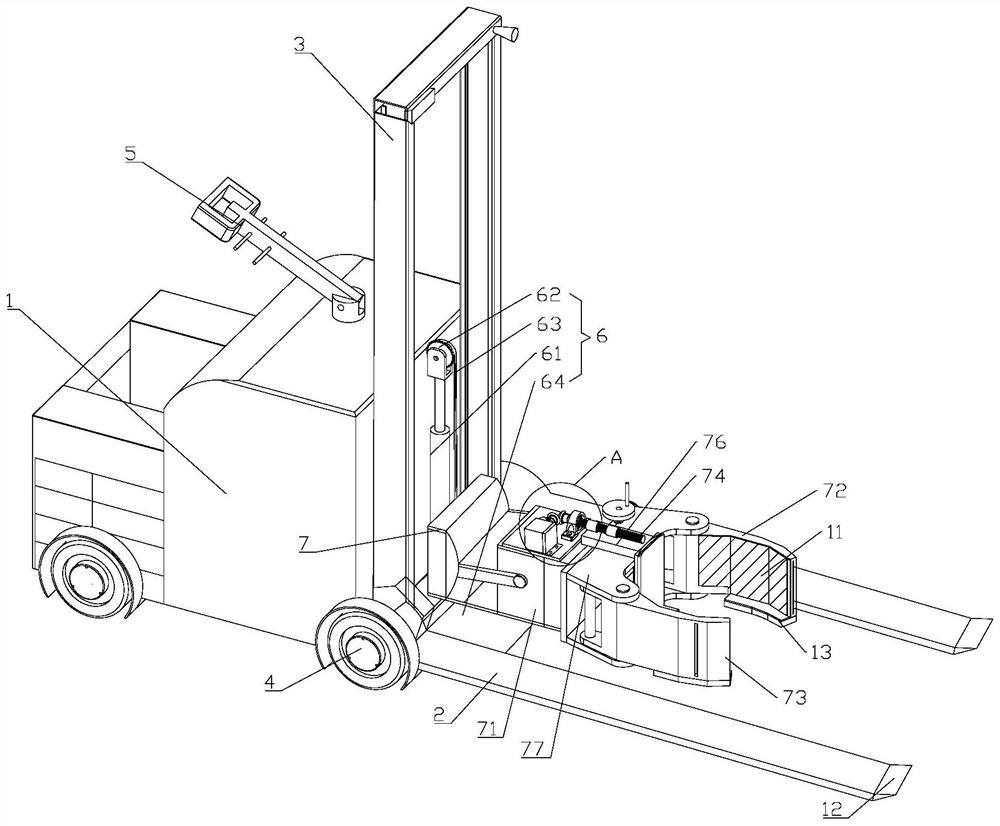

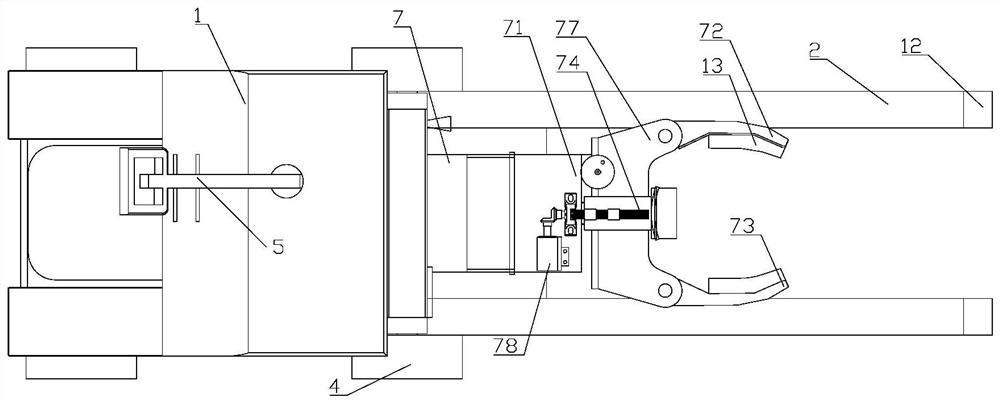

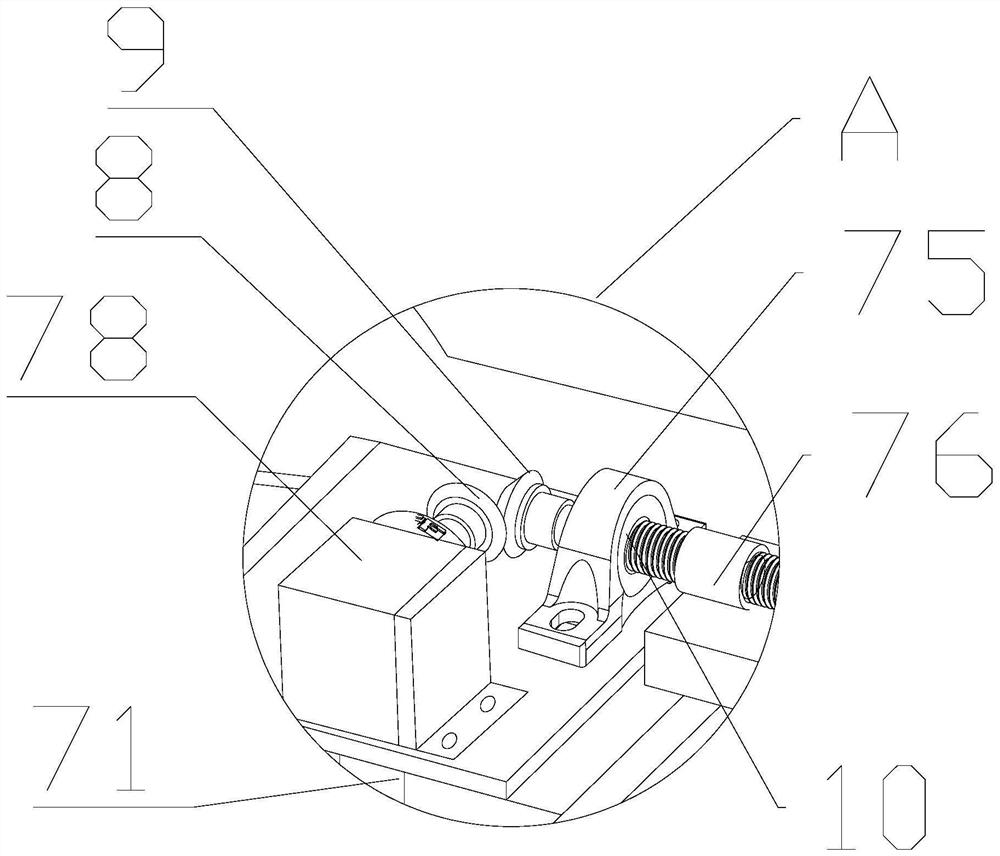

Forklift robot with picking and placing function

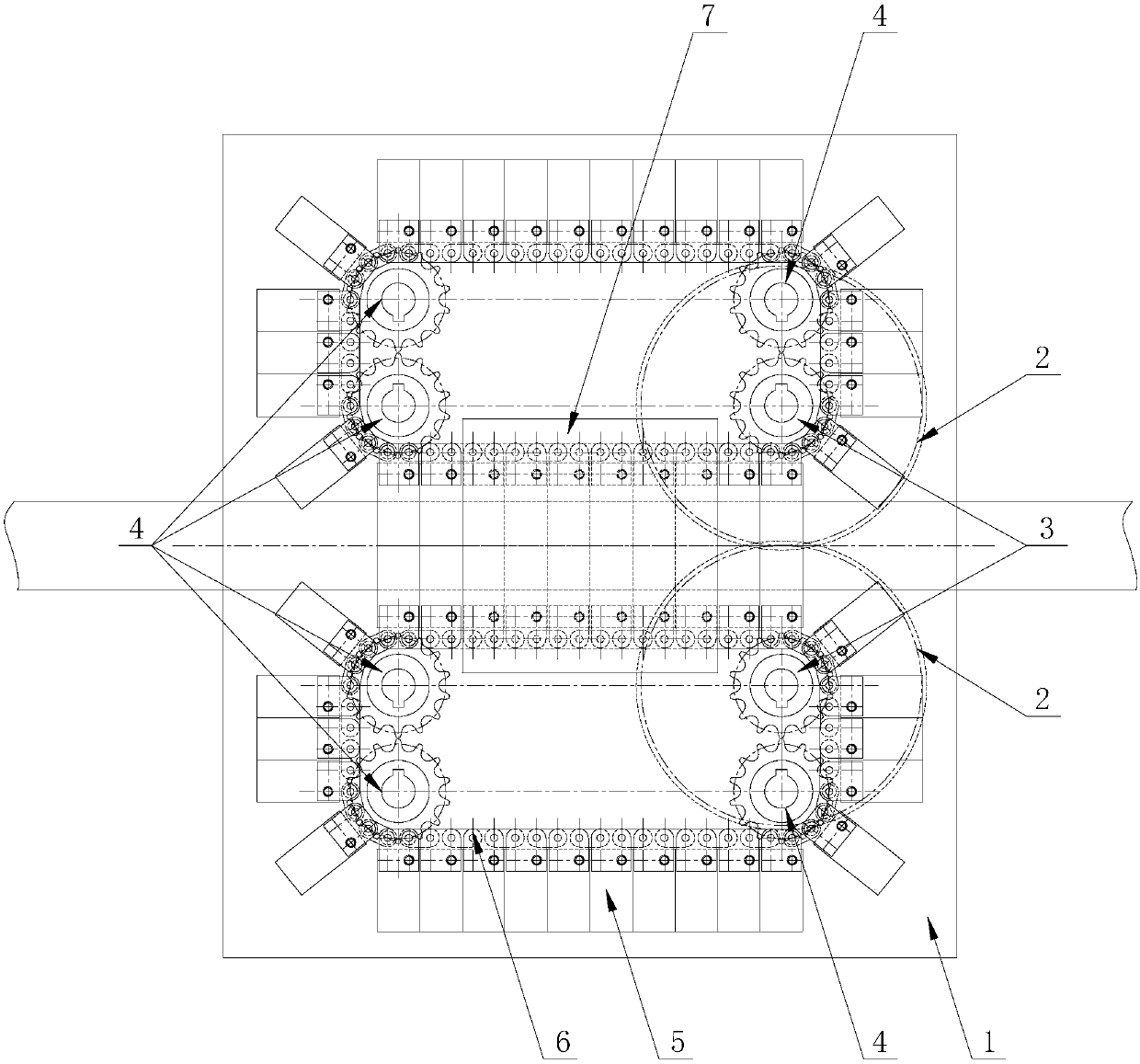

PendingCN111807270AGuaranteed not to slipWith clamping functionLifting devicesElectric machinerySprocket

The invention discloses a forklift robot with a picking and placing function and belongs to the technical field of forklift robots. The forklift robot comprises a vehicle body, a fork, a lifting mechanism and a clamping mechanism; the lifting mechanism comprises a lifting air cylinder, a chain wheel, a chain and a connecting plate, a telescopic shaft of the lifting air cylinder is fixed to the chain wheel through a bracket, the two ends of the chain are fixedly connected with the front end of the vehicle body and the bottom of the connecting plate correspondingly, and the chain sleeves the chain wheel; the telescopic shaft of the lifting air cylinder drives the chain wheel to lift up and down to enable the connecting plate to drive the fork to lift up and down; the clamping mechanism comprises a mounting seat, a connecting box, a first clamping arm, a second clamping arm, a lead screw, a limiting piece, a moving nut, a connecting frame, a motor and a driving air cylinder; and the motordrives the lead screw to rotate so that the moving nut can drive the connecting frame to move back and forth. The forklift robot has a clamping function and can be matched with the fork to lift, theclamping mechanism is convenient to fold, and space is saved.

Owner:京良(广州)科技股份有限公司

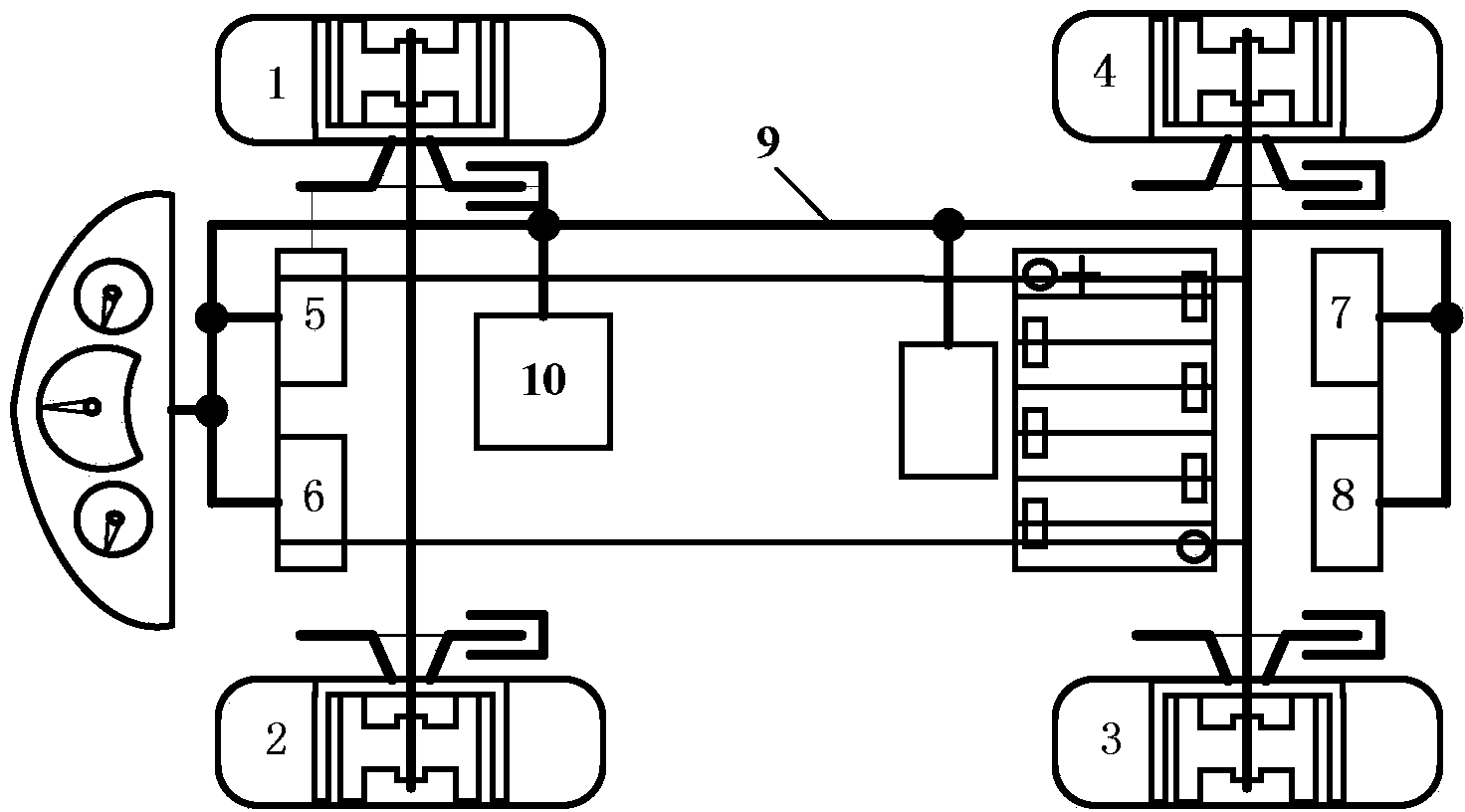

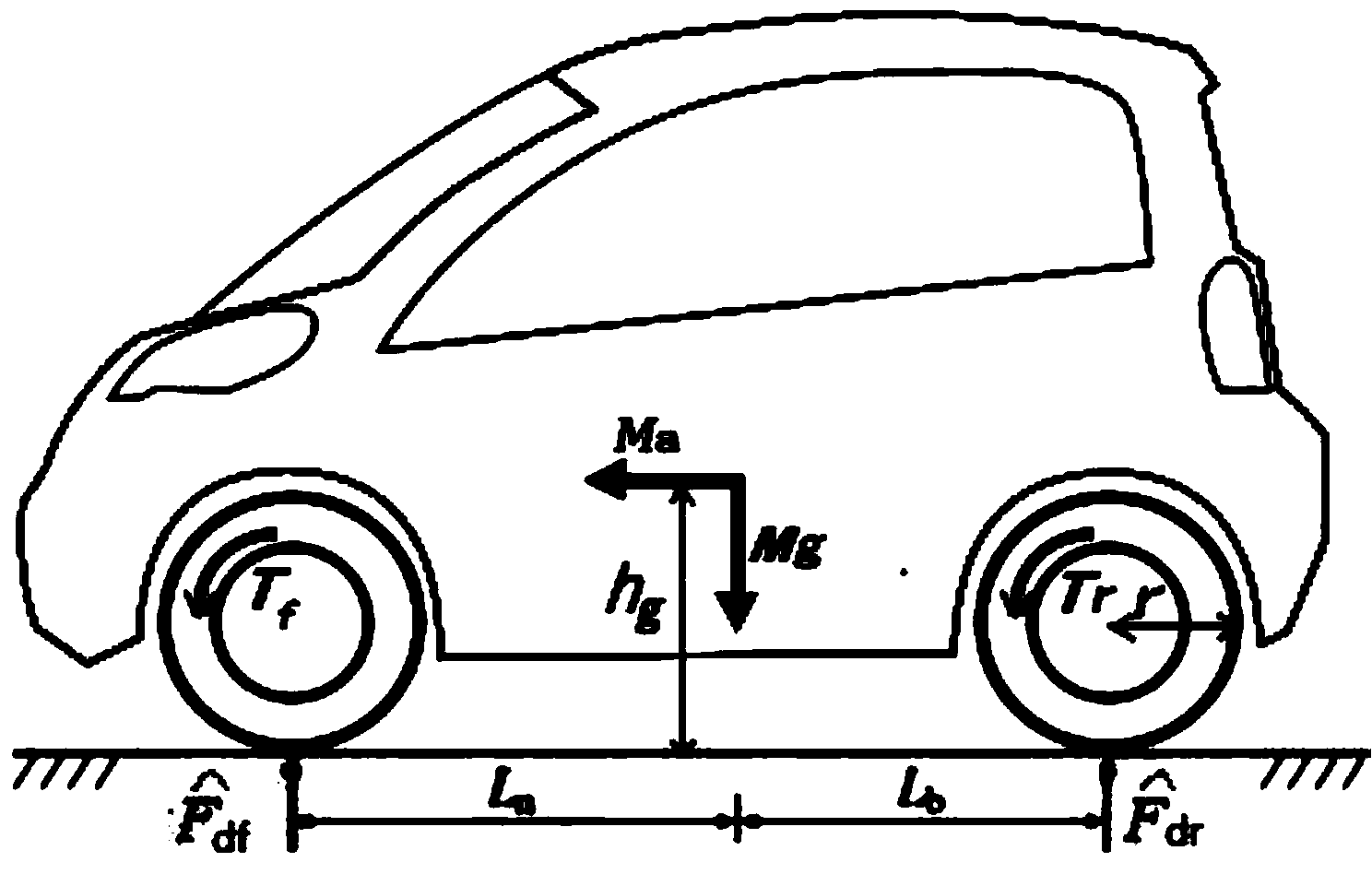

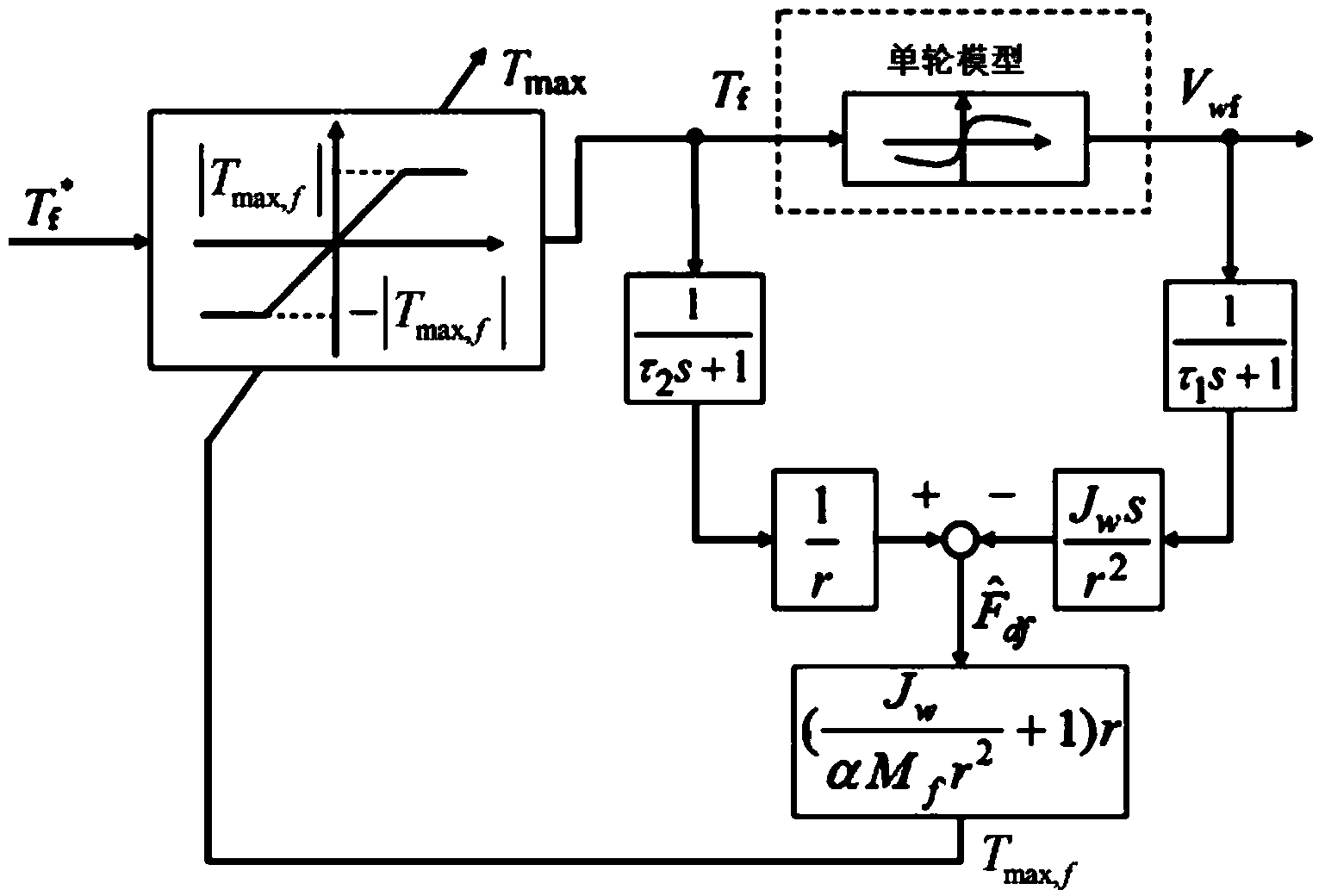

Maximum torque estimation and acceleration slip regulation algorithm for four-wheel independently driven electric vehicle

ActiveCN103879305AImprove stabilityImprove securitySpeed controllerElectric energy managementMaximum torqueNew energy

The invention discloses a maximum torque estimation and acceleration slip regulation algorithm for a four-wheel independently driven electric vehicle, and belongs to the technical field of new energy vehicle control. The method includes the steps that (1) torque values Twf and Twr of a drive motor used for acceleration of front wheels and rear wheels are calculated and obtained according to the speed Vwf of the front wheels and the speed Vwr of the rear wheels; (2) according to output torques Tf and Tr of the drive motor of the front wheels and the rear wheels, corresponding ground drive force static response values Ff and Fr are calculated and obtained; (3) according to calculation results in the step (1) and the step (2), action force between the current front wheels, rear wheels and the ground can be estimated, as specified in the specification; (4) according to the calculation result in the step (3), the maximum torque output values Tmax,f and Tmax,r of the front wheels and the rear wheels are calculated. By means of the method, speed and acceleration speed sensors are not needed, system cost is lowered, system reliability is improved, quick and accurate response is achieved, it is guaranteed that the wheels do not slip, stability and safety of a vehicle in the running process are improved, and the method is easy to complement in engineering and can be widely applied to an acceleration slip regulation system of the four-wheel driven electric vehicle.

Owner:TSINGHUA UNIV

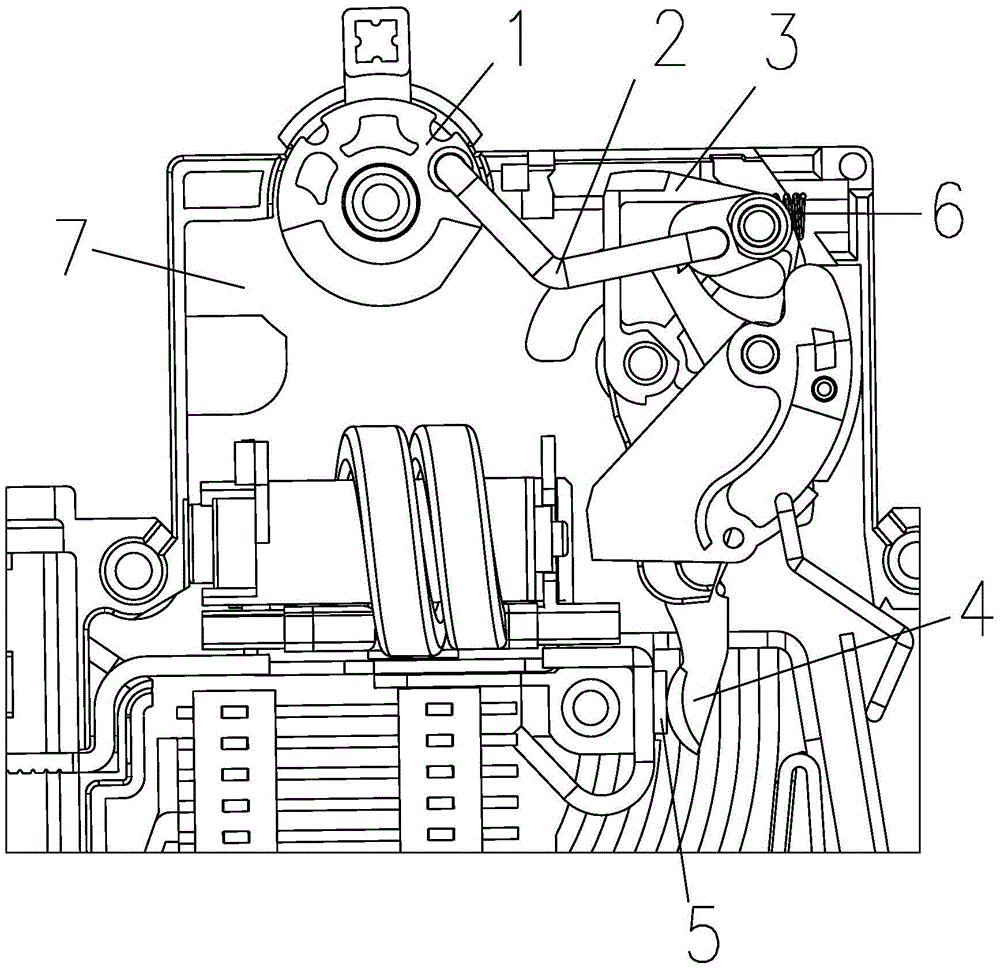

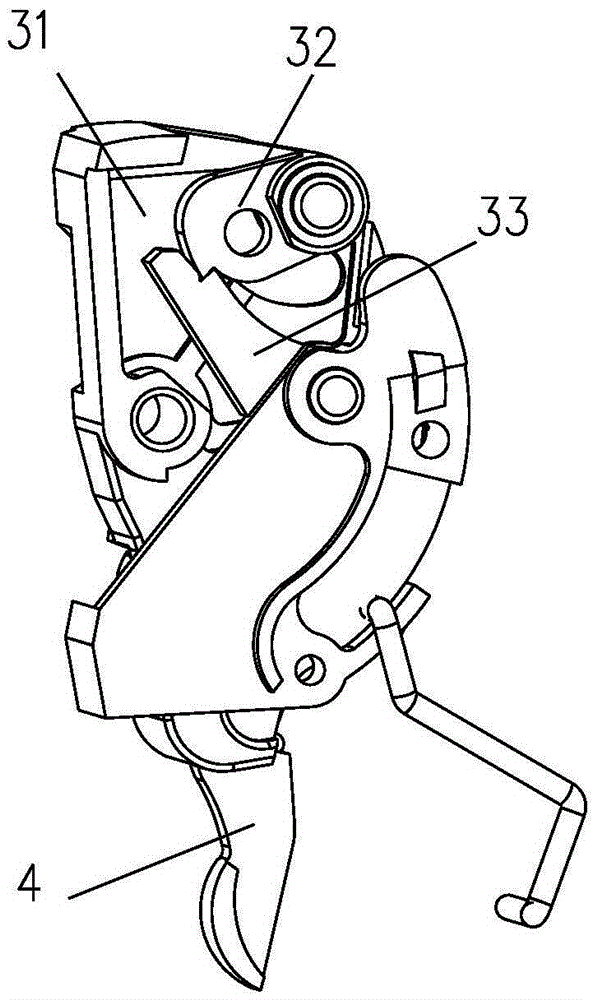

Breaker

InactiveCN105632850AAvoid damageEnsure safetyProtective switch operating/release mechanismsCircuit-breaking switch contactsPower flowElectrical conductor

The present invention provides a breaker. The breaker comprises housing, a fixed contact, a moving contact cooperating with the fixed contact and an operation mechanism connected with the moving contact. The moving contact is in contact conduction with the fixed contact under the effect of the operation mechanism, the moving contact and the fixed contact are both provided with repulsion sections, and the repulsion sections are conductor structures extending from the contact area of the moving contact and the fixed contact. A pair of reverse currents is formed when a heavy current flows through the two repulsion sections, and the reverse current allows the moving contact and the fixed current to generate mutually repellent repulsive forces, and the repulsive forces may instantaneously drive the movement of the moving contact, so that the moving contact and the fixed contact are broken off; and moreover, compared with the traditional releasing system, the breaker is faster in response speed, and is able to avoid the damaging of heavy current to the breaker and the lines and ensure the safety of the breaker and the lines.

Owner:ZHEJIANG PEOPLE ELE APPLIANCE

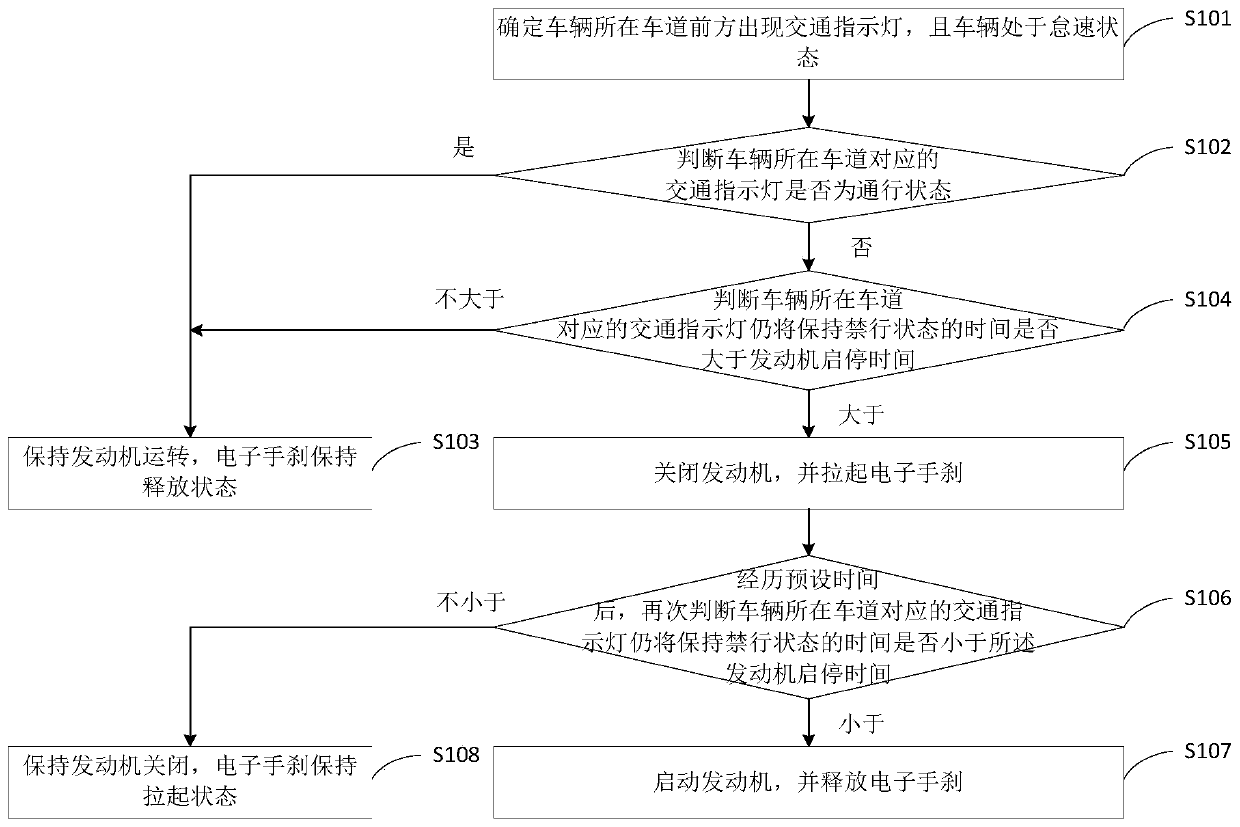

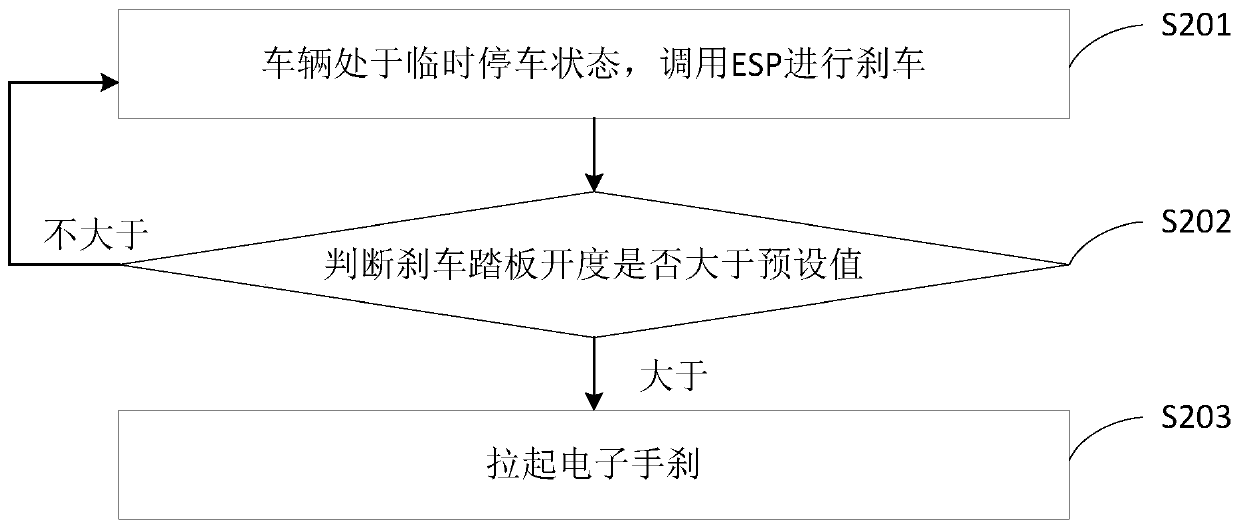

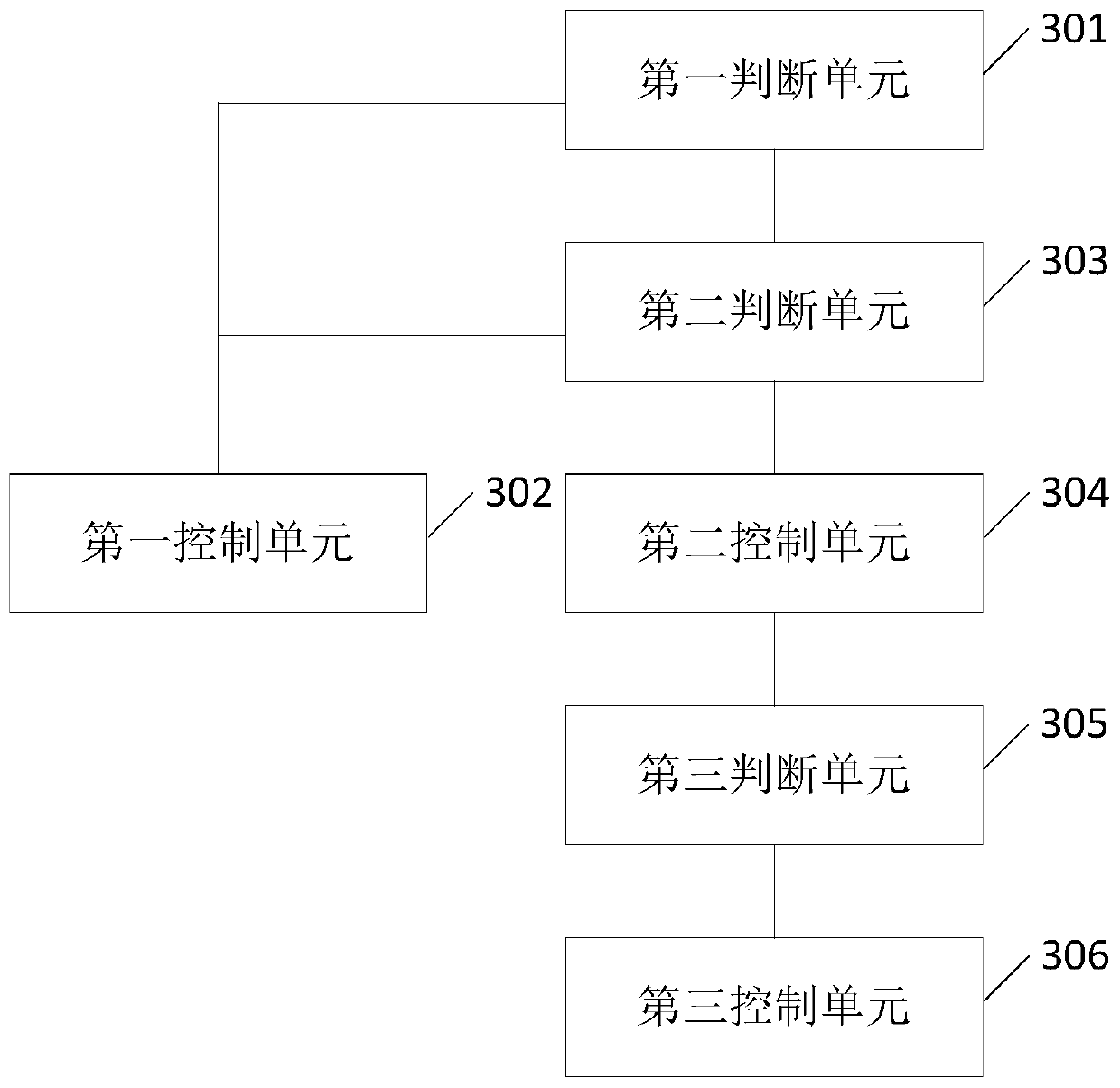

Engine start-stop control method and device

ActiveCN110641469AAvoid resource consumptionGuaranteed not to slipDetection of traffic movementDriver/operatorReal-time computing

Owner:BEIJING JINGWEI HIRAIN TECH CO INC

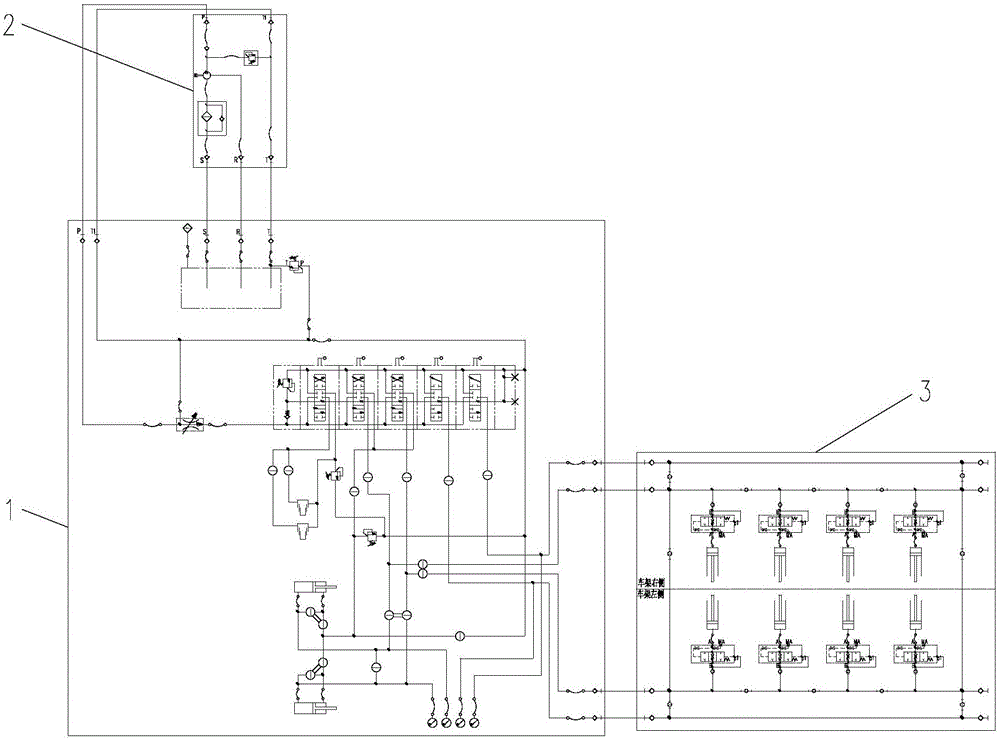

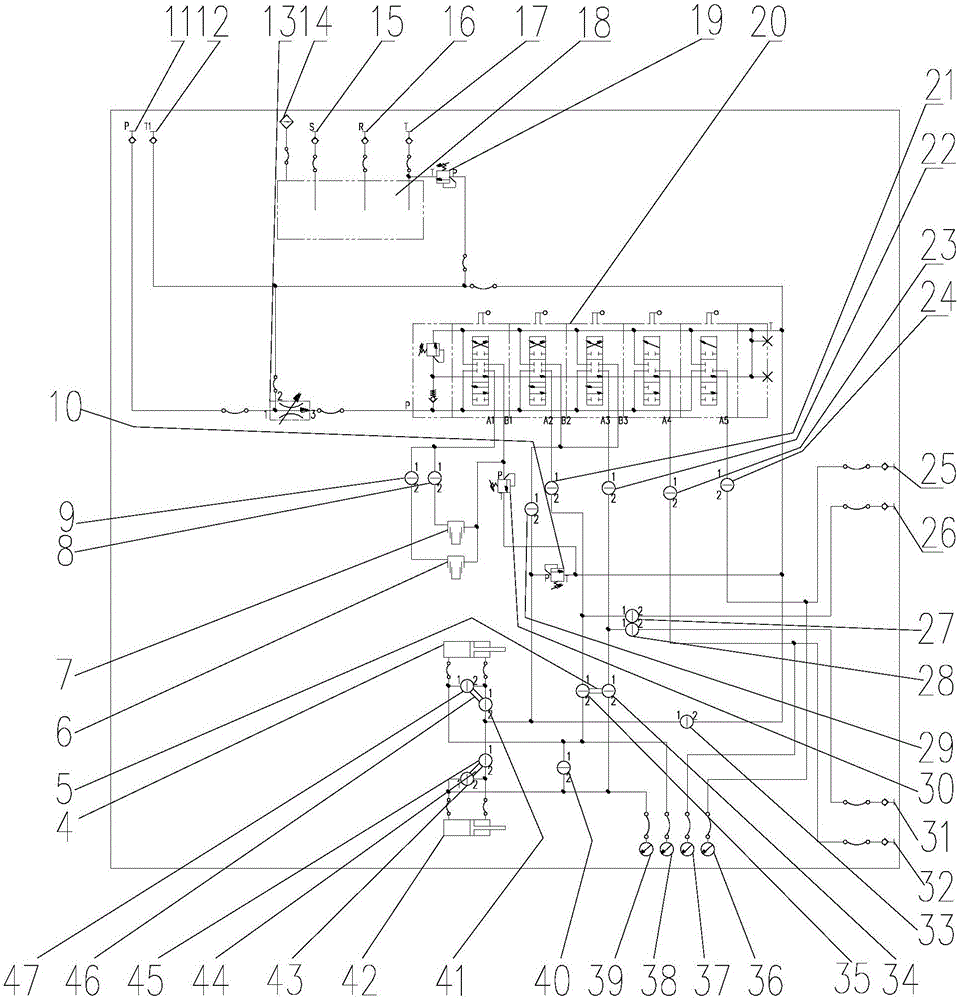

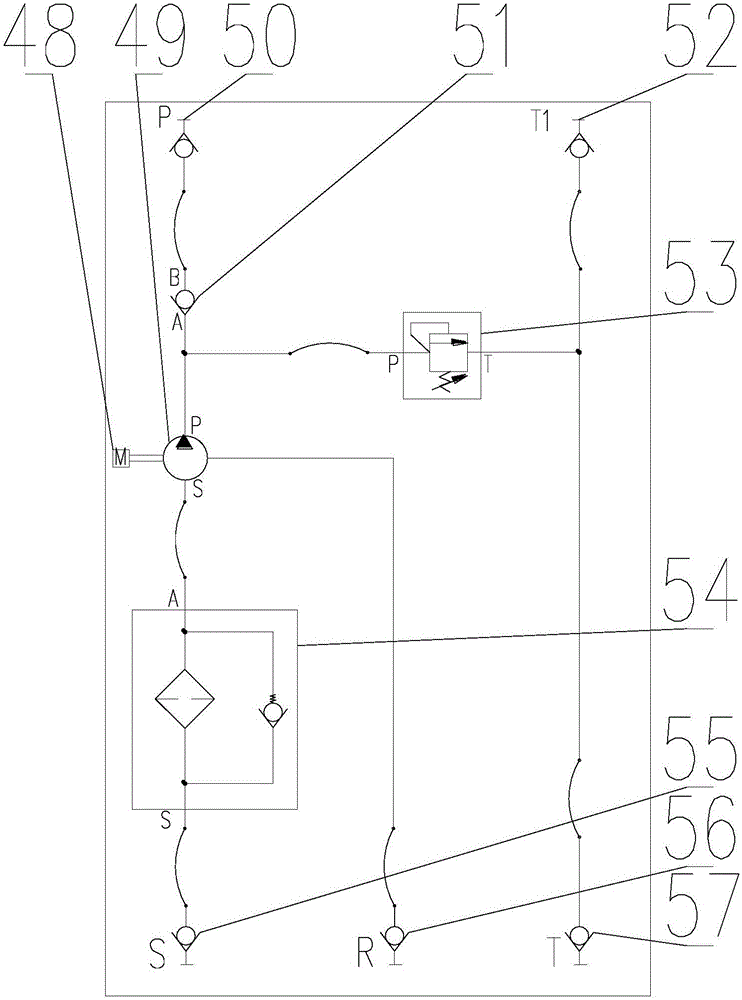

Loading and lifting hydraulic system of semitrailer

ActiveCN106168236AExtended service lifeEasy to disengageServomotor componentsServomotorsDual effectSingle effect

The invention discloses a loading and lifting hydraulic system of a semitrailer. The system comprises a gooseneck hydraulic system, a power source hydraulic system and a trailer hydraulic system. The power source hydraulic system is connected with the gooseneck hydraulic system and used for providing hydraulic oil needed by work of the gooseneck hydraulic system. A multi-way valve in the gooseneck hydraulic system is connected with a first dual-effect multi-stage oil cylinder and a second dual-effect multi-stage oil cylinder, and separation of a gooseneck from a tractor is achieved through the cooperation of the multi-way valve and a switch ball valve. The multi-way valve is connected with the first dual-effect oil cylinder and the second dual-effect oil cylinder. pitching operation of the gooseneck is achieved through the cooperation of the multi-way valve and the switch ball valve. The trailer hydraulic system is connected with the gooseneck hydraulic system. Multiple single-effect oil cylinders in the trailer hydraulic system are made communicated and matched with the switch ball valve to achieve switching between semitrailer three-point bearing and four-point bearing. The first dual-effect oil cylinder and the second dual-effect oil cylinder are connected with the single-effect oil cylinder in the front of trailer suspension, and different loading modes are selected according to the load and road surface working conditions to achieve fifth round of gooseneck loading.

Owner:HUBEI SANJIANG SPACE WANSHAN SPECIAL VEHICLE

Bidirectional association bidirectional tensioning device with variable damping device

Owner:NINGBO FENGMAO FAR EAST RUBBER

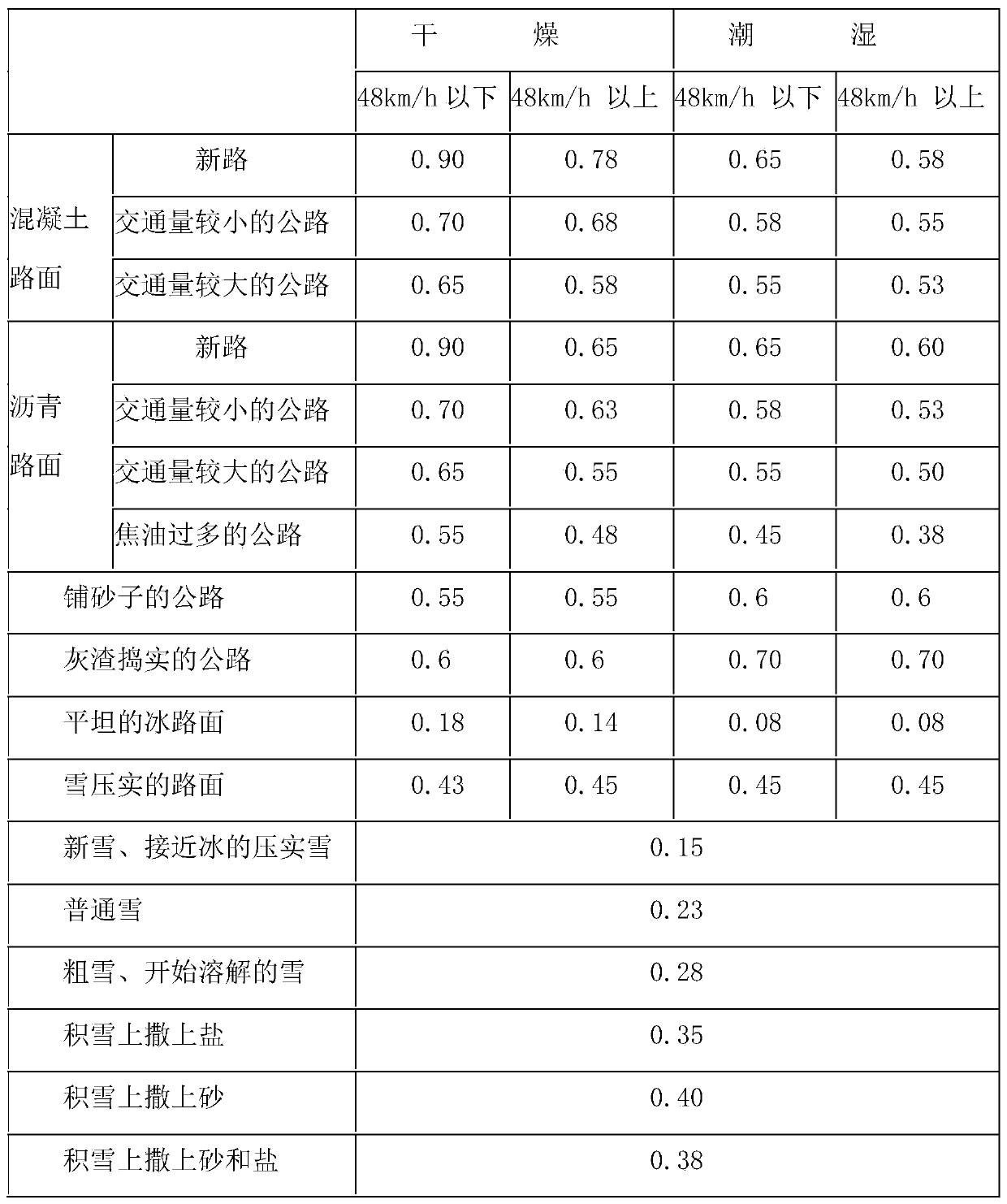

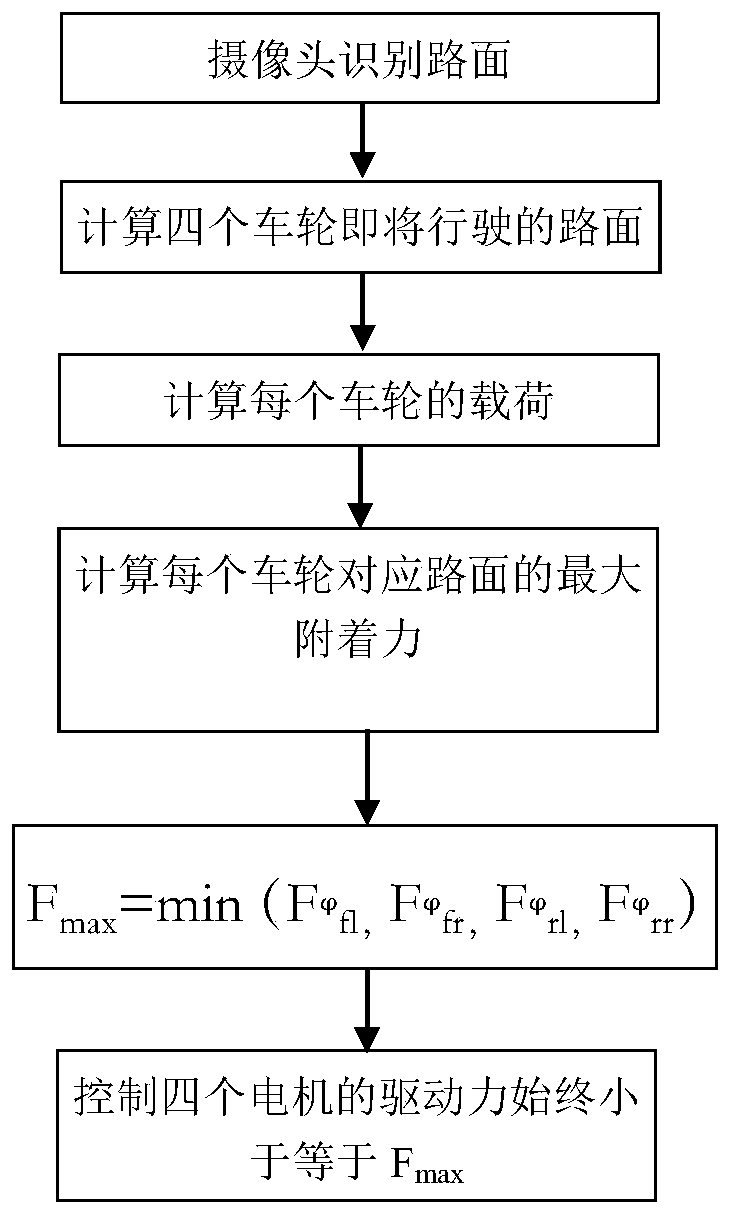

Acceleration slip regulation control method and system based on road surface recognition

ActiveCN110843783AReduced effectGuaranteed not to slipSpeed controllerControl devicesElectric machineryAutomotive engineering

The invention discloses an acceleration slip regulation control method and system based on road surface recognition. The control method comprises the following steps of detecting and recognizing a road surface by utilizing cameras on a vehicle; calculating the road surface to be driven by four wheels; calculating the load of each wheel by using force sensors; calculating the maximum adhesion forceof each wheel corresponding to the road surface by using a road surface adhesion coefficient definition formula and an adhesion coefficient table; obtaining the maximum value of the driving force ofeach wheel; and controlling the driving force of four motors to be always smaller than or equal to F<max>. The acceleration slip regulation control method and system based on the road surface recognition solve the problem that the control is applied when the wheels slip, and a pre-control system is additionally arranged; and the road surface to be driven is detected and recognized through the cameras, the driving force of the motors is correspondingly reduced in advance if the road surface adhesion coefficient becomes smaller, and the wheels do not slip when the output torque of the motors issmaller than the minimum adhesion force provided by the road surface.

Owner:的卢技术有限公司

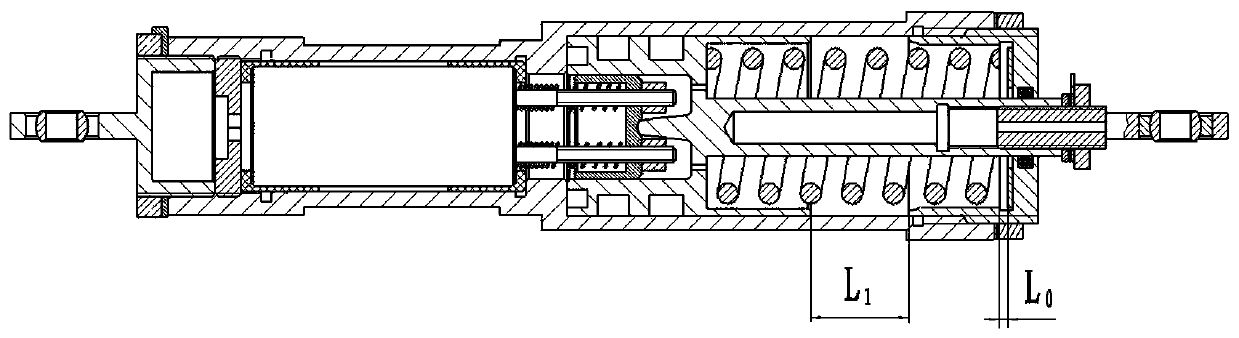

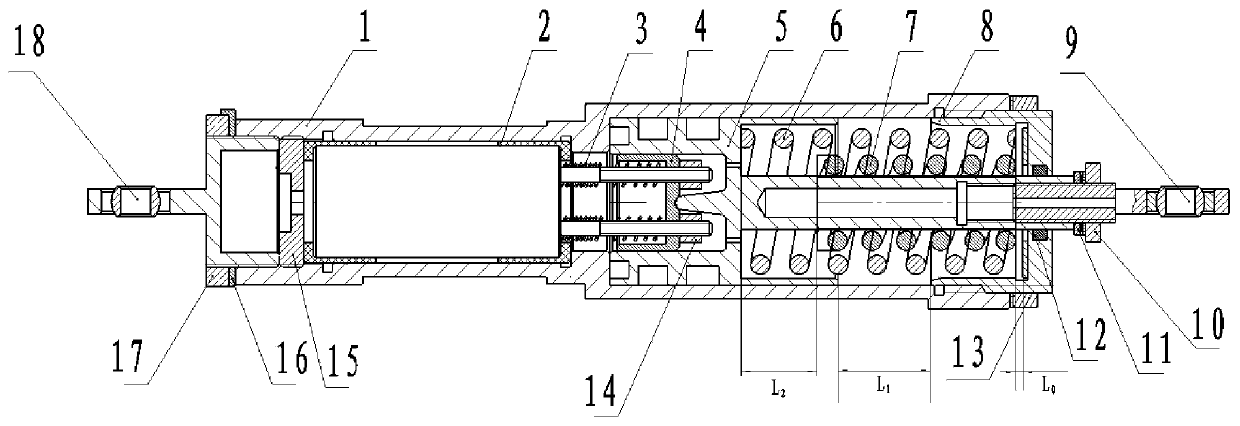

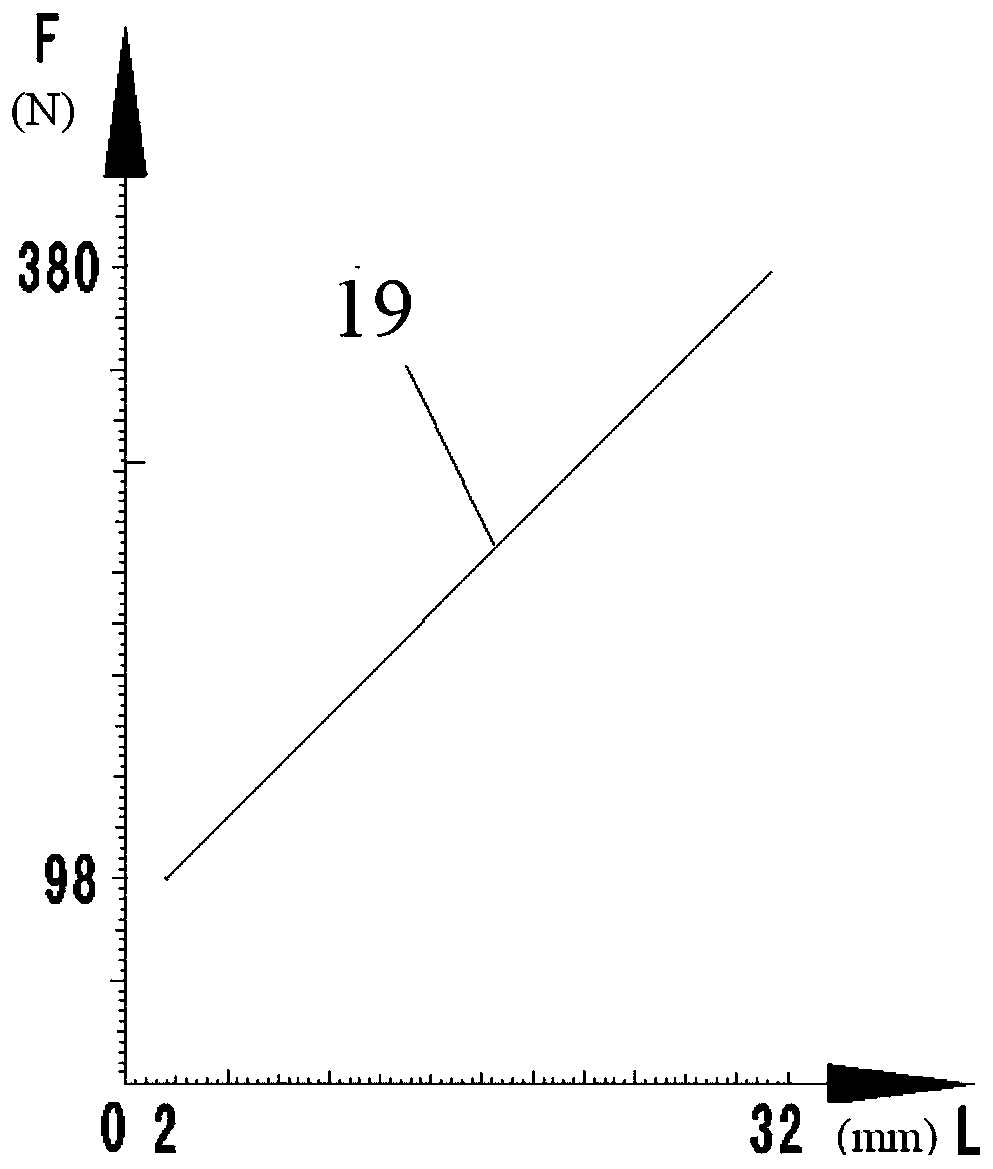

Variable-gain brake command sensor and method for determining design parameter

PendingCN110207858AGuaranteed not to slipImprove adaptabilityGround installationsForce measurement by elastic gauge deformationBraking systemAirplane

The invention relate to a variable-gain brake command sensor and a method for determining a design parameter. A first force sensing spring and a second force sensing spring that have different lengthsare disposed in the brake command sensor; and thus the variable-gain brake command sensor has different control forces and stroke gains to meet aircraft's requirements for different landing conditions. When an aircraft is in n abnormal landing state, a maximum controlling force is outputted and the stroke of the command sensor is maximized, and the first force sensing spring and the second forcesensing spring work simultaneously to ensure safe braking of the aircraft. When the aircraft is in a normal landing brake state, the outputted controlling force is not larger than the median controlling force and only the first force sensing spring works to ensure that the aircraft does not slip during the braking process, so that the requirements of the braking system by various landing states of the aircraft are met. The adaptability of the braking system to the various take-off and landing states of the aircraft is improved; the number of anti-skidding of the wheel in the landing braking process of the aircraft can be reduced and even anti-skidding can be prevented completely; the tire wearing uniformity is ensured; the service life of the brake wheel is prolonged; and the braking efficiency is improved.

Owner:XIAN AVIATION BRAKE TECH

Preparation technology of low-twist cotton and nylon wrapped yarns

The invention relate to the field of production of low-twist cotton and nylon wrapped yarns and in particular relates to a preparation technology of the low-twist cotton and nylon wrapped yarns. The preparation technology comprises the following steps: (1) preparing yarns: preparing two threads of fiber single yarns including cotton, viscose cotton, viscose, Tencel, hemp and the like; combining double threads into a piled yarn; (2) preparing a core yarn: twisting one thread S with one thread Z of polyamide yarns with the same thickness, and crossly winding together by utilizing the same twisting degree, wherein the thickness is the same and the twisting degree is the same and rotation directions are opposite so that double thread yarns have no twisting; (3) coating and twisting: coating and twisting on a mechanical coating machine and penetrating the core yarn from the middle of a spindle; rotating bobbin pre-twisted yarns of the mechanical coating machine around the core yarn and twisting, wherein the twisting direction is opposite to that of the single yarn. According to the preparation technology provided by the invention, warp and weft yarns for burnt-out clothes are mainly solved, and the low-twist cotton and nylon wrapped yarns are produced; two core-yarn cotton yarns are crossly wound together with the same thickness and the same twisting degree and have zero twisting, so that the friction force is increased by the core yarns exposed from a burnt-out part of the clothes, a slippage phenomenon between yarns is greatly alleviated and the clothes are more beautiful.

Owner:张家港市隆利氨纶纱线厂

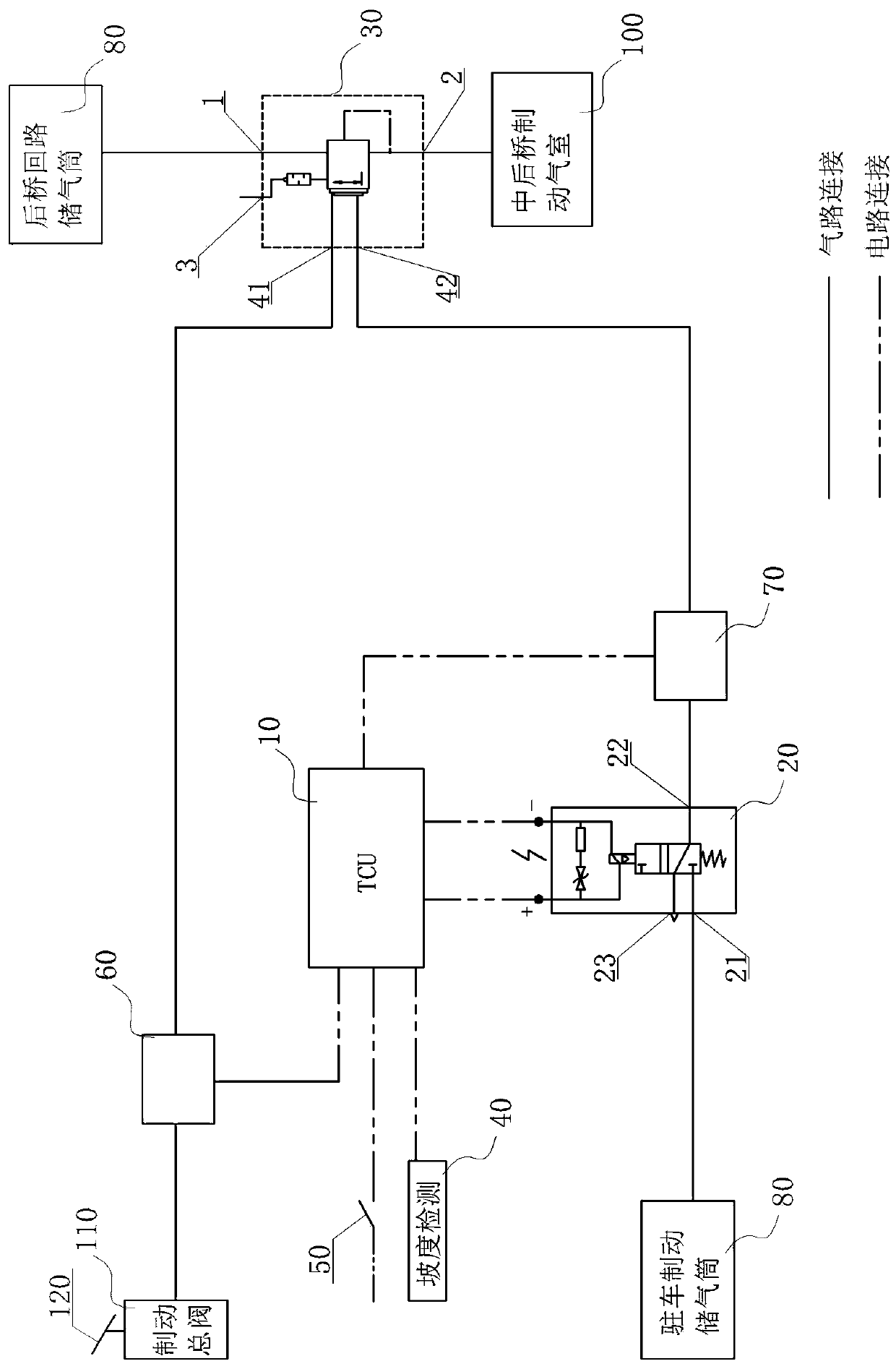

Hill starting assistance system

InactiveCN110103970AGuaranteed not to slipNo impactExternal condition input parametersDriver input parametersControlled releaseRelay valve

The invention provides a hill starting assistance system, which gathers multifaceted electrical signals, automatically controls releasing and triggering of a hill starting assistance function, and does not affect the normal driving operation; and the function is achieved simply, calibration is easy, and the cost is low. A total braking valve is connected with a first pressure switch, and then is connected into a first opening of a relay control piston of a differential relay valve in a communication mode, a parking braking air cylinder is connected with an air inlet of a two-position three-waynormally closed solenoid valve, an air outlet of the two-position three-way normally closed solenoid valve is connected with a second pressure switch, and then connected with a second opening of therelay control piston of the differential relay valve in a communication mode, an air vent of the two-position three-way normally closed solenoid valve is in communication with the atmosphere, a firstcommunication opening of a main piston of the differential relay valve is connected with a rear bridge loop air cylinder, a second communication opening of the main piston of the differential relay valve is connected with a middle rear bridge brake chamber, and TCUs are correspondingly electrically connected with the first pressure switch, the second pressure switch, the two-position three-way normally closed solenoid valve, a hill detection unit, and a function release switch through connecting lines.

Owner:SUZHOU LVKON TRANSMISSION TECH CO LTD

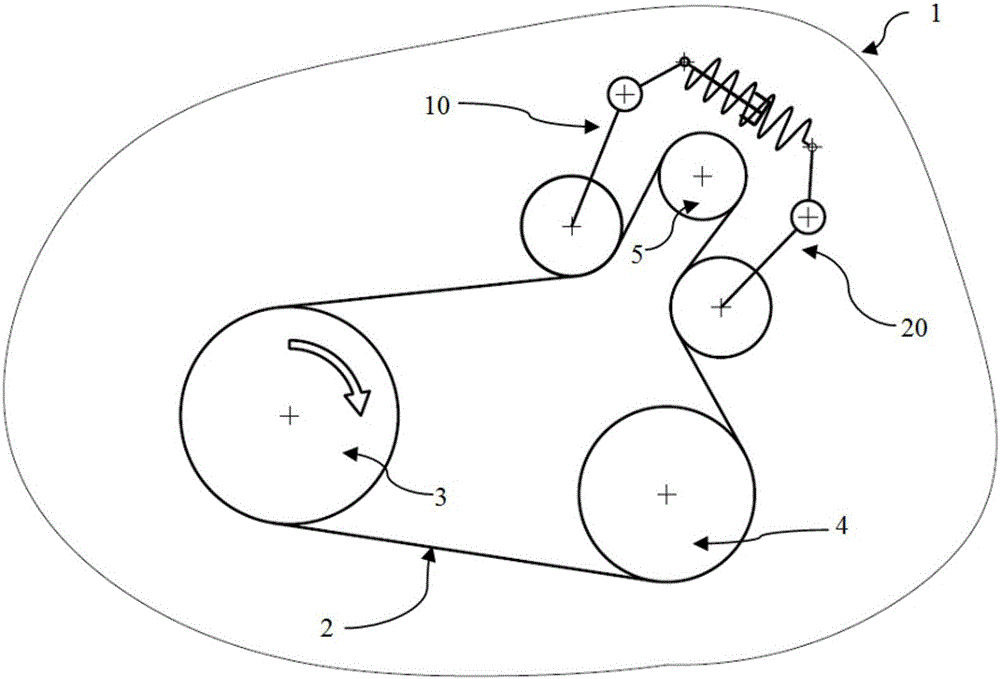

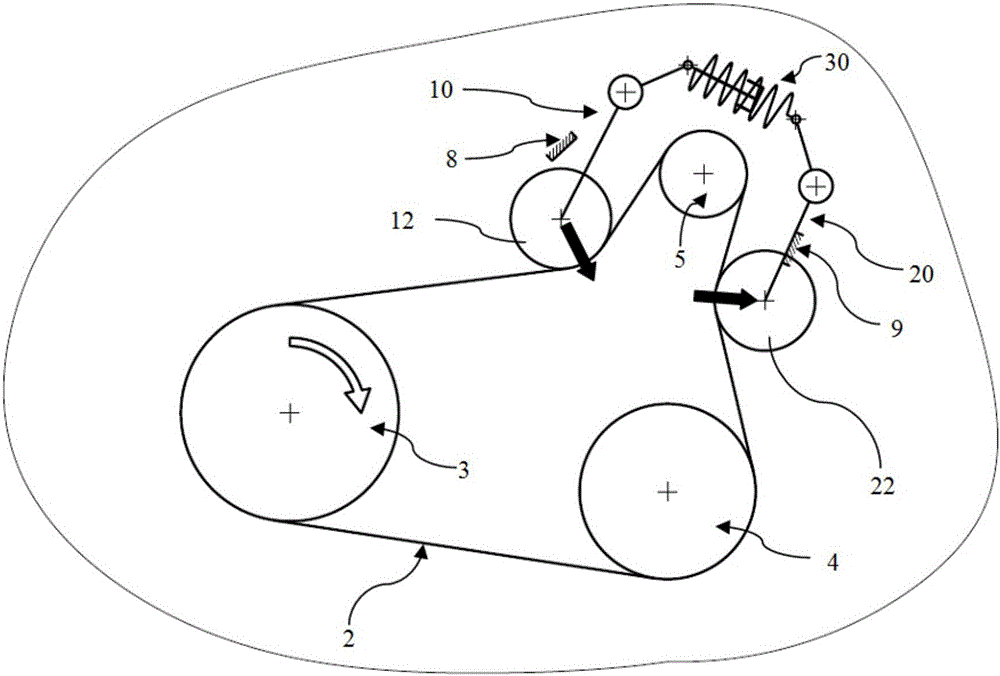

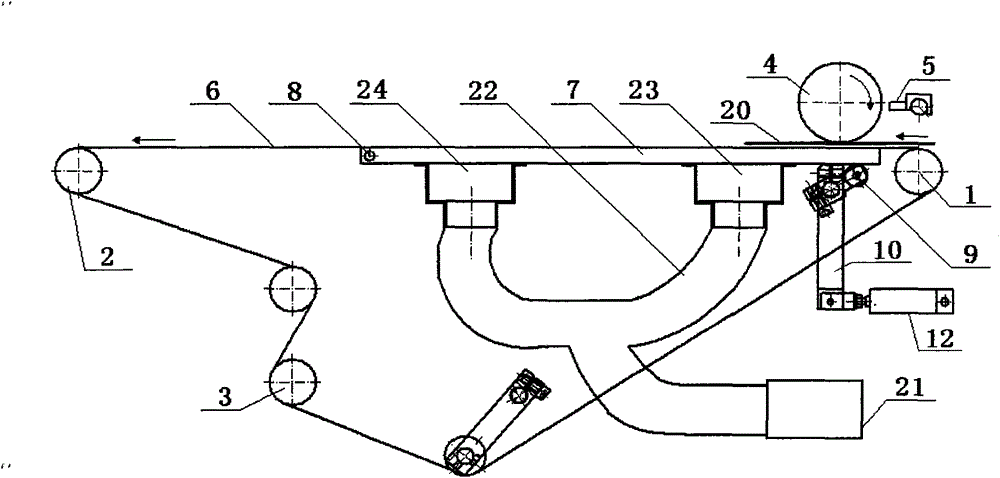

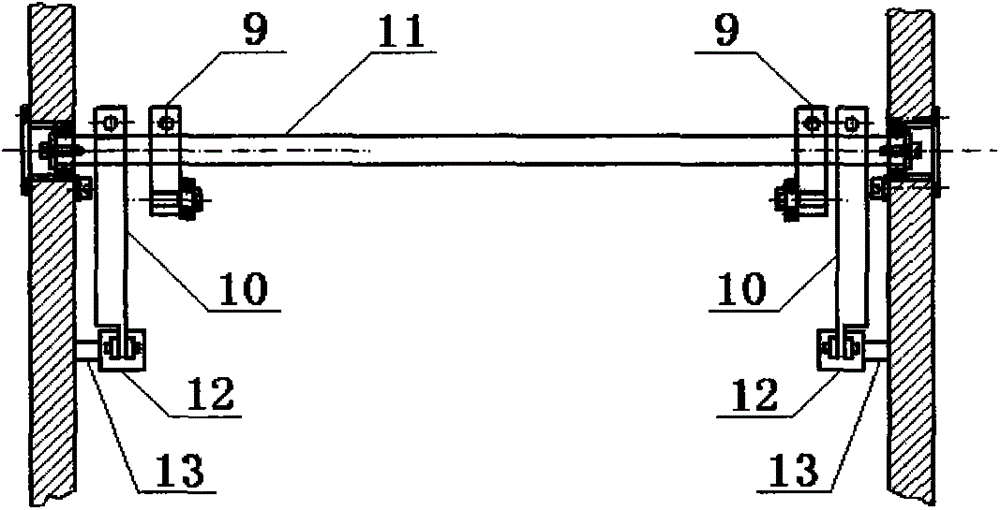

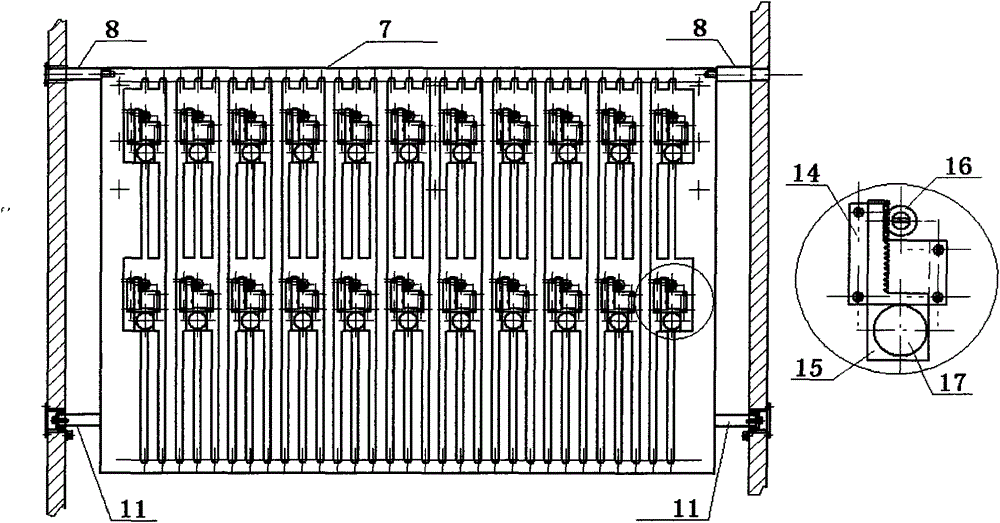

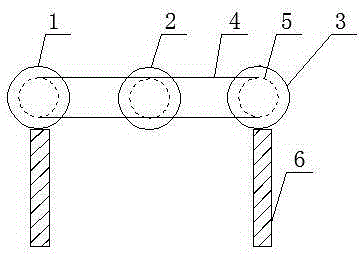

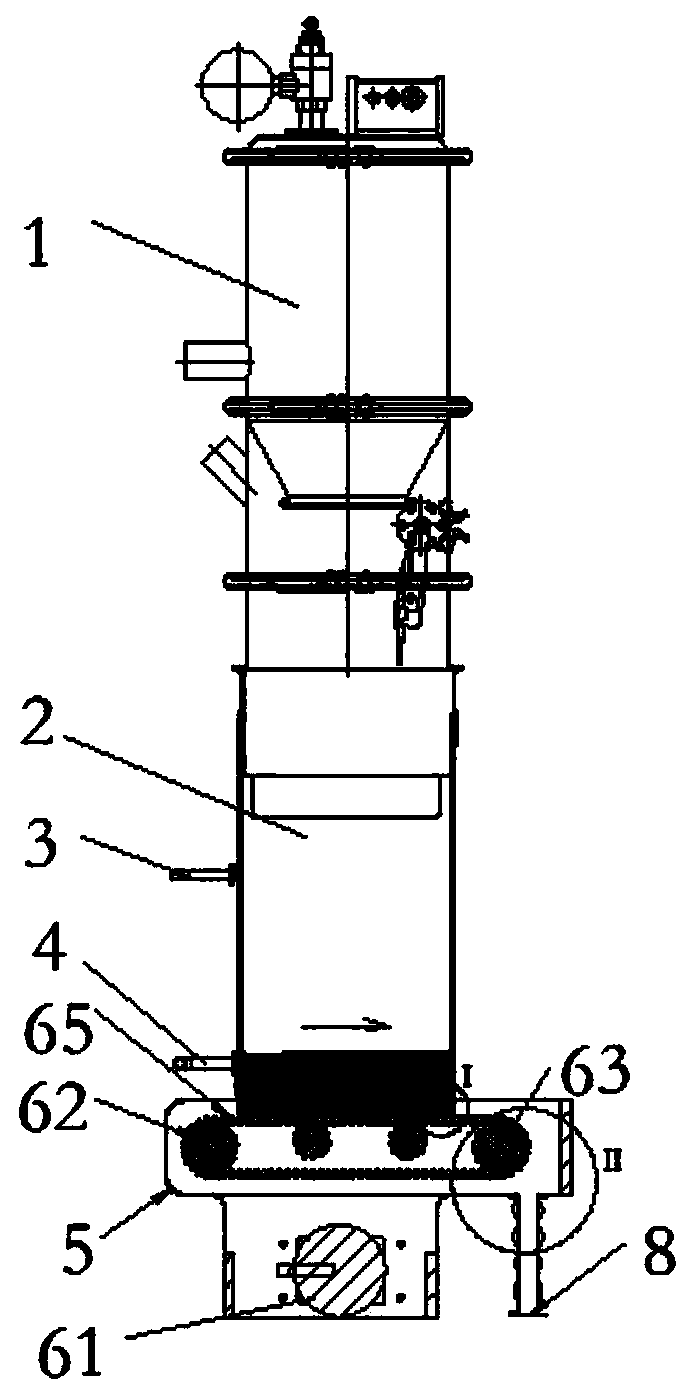

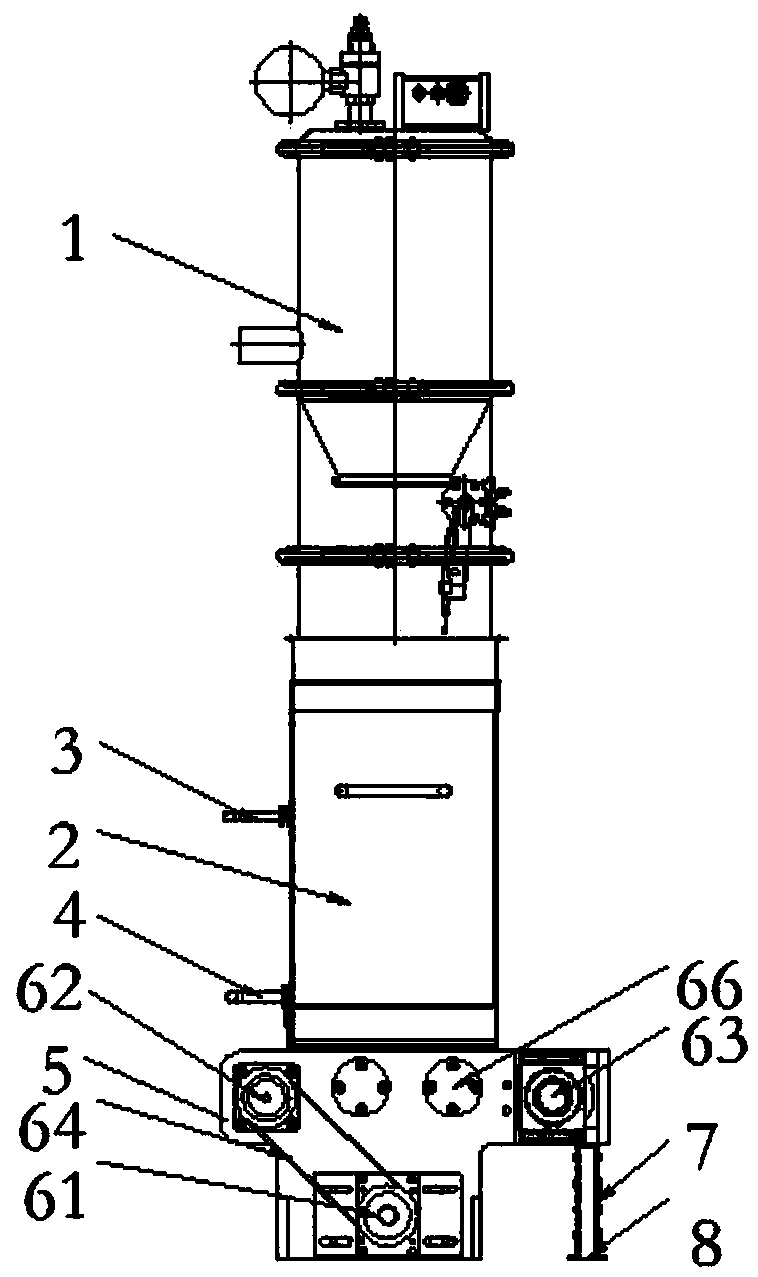

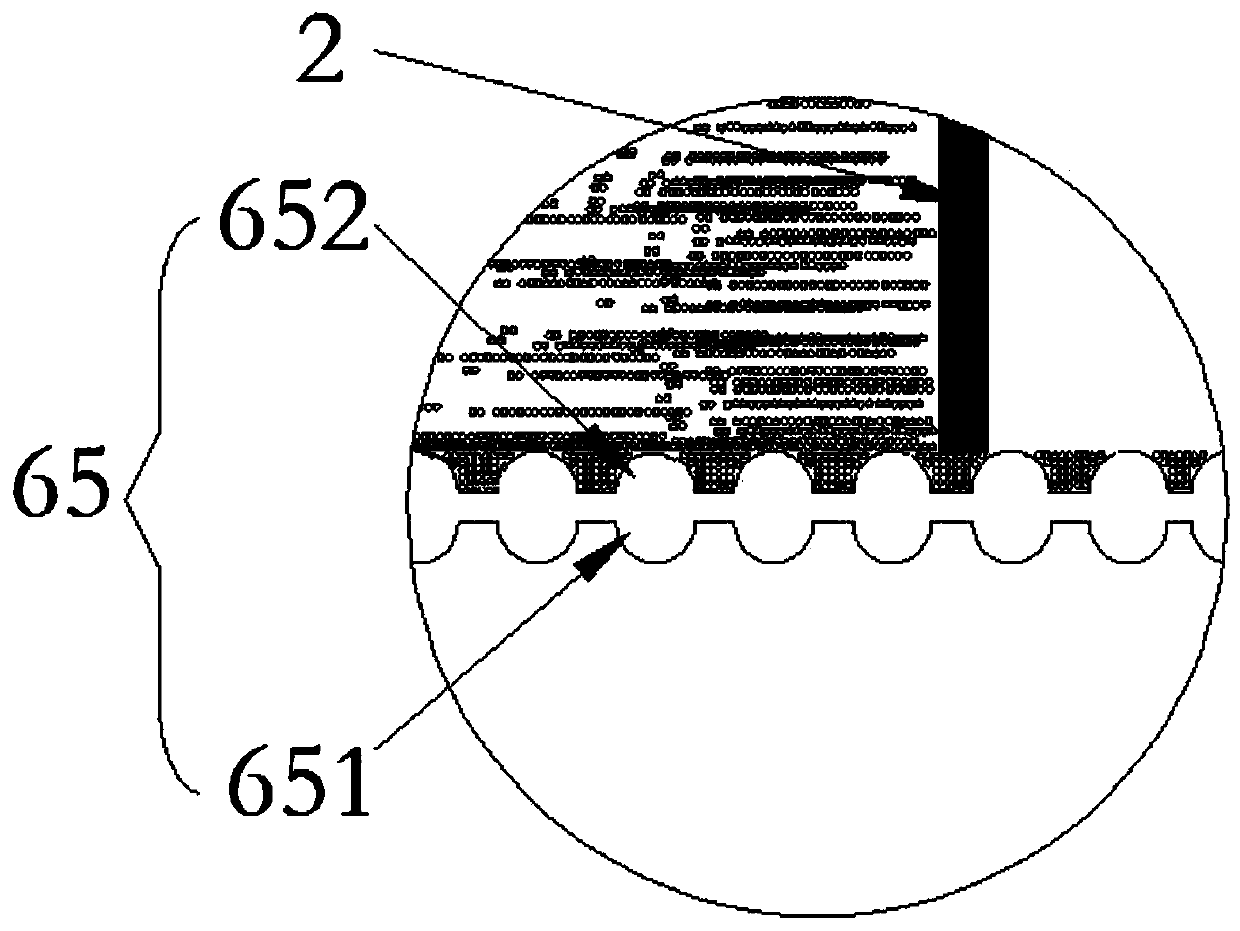

Adjustable air-suction paper-feeding mechanism

ActiveCN105314424AUniform suction distributionGuaranteed not to slipArticle feedersAir volumeEngineering

The invention discloses an adjustable air-suction paper-feeding mechanism. The adjustable air-suction paper-feeding mechanism comprises a front belt roller, a rear belt roller, a driving roller, a photoelectric switch, a printing rubber roller, an air-suction belt, an air chamber plate, air bellows, a hinge pin, top frames, swing arms, a swing arm shaft, cylinders and air hole switch assemblies. The two ends of the front belt roller, the two ends of the rear belt roller and the two sides of the driving roller are arranged on wall boards of the two sides respectively, the photoelectric switch is arranged in front of the printing rubber roller, the front belt roller, the rear belt roller and the driving rollers are wrapped with the air-suction belt, the air bellows of a front row and a rear row are installed below the air chamber plate, one end of the air chamber plate is positioned on the wall boards of the two sides, and the other end of the air chamber plate is arranged on the top frames; the top frames and the swing arms are fixed on the same swing arm shaft, the swing arm shaft is arranged on the wall boards of the two sides, the other end of the each swing arm is hinged to the corresponding cylinder, the cylinders are fixed on the wall boards of the two sides through fixing shafts, and the air hole switch assemblies are installed on the air chamber plate. According to adjustable air-suction paper-feeding mechanism, air suction is even, the air suction area and the air volume are adjustable, and rapid and stable conveying can be achieved whether paper is big or small.

Owner:YUTIAN DINGYU PRINTING MACHINERY MFG

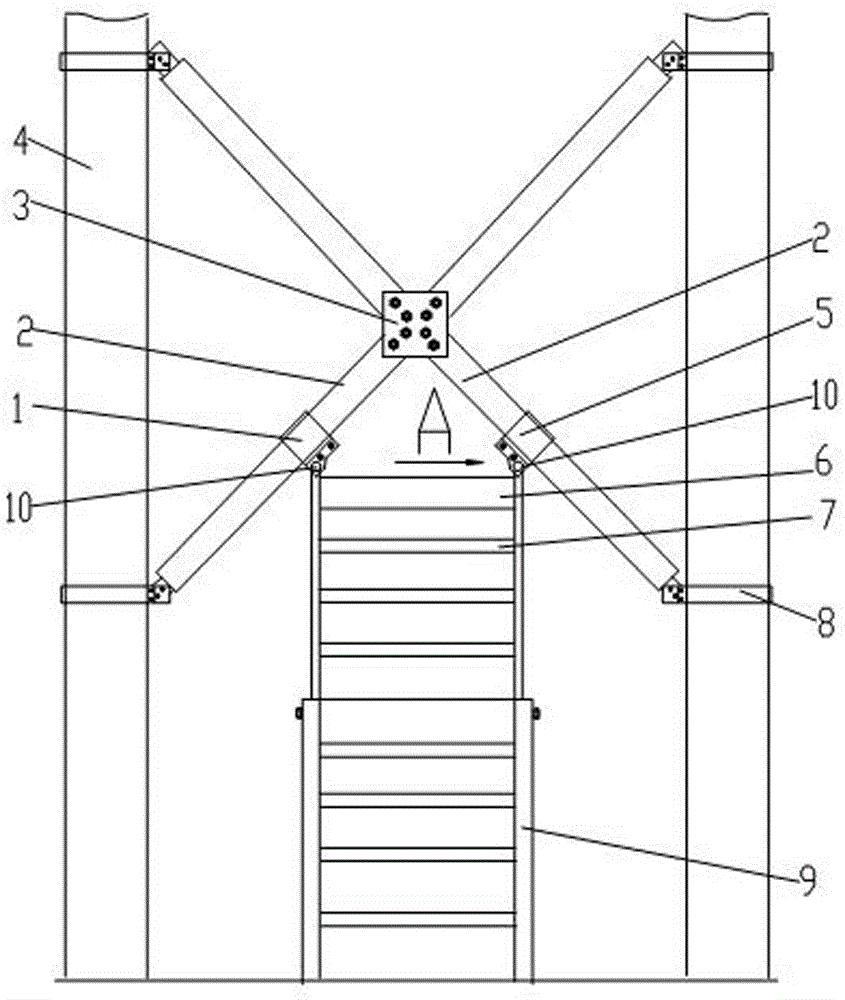

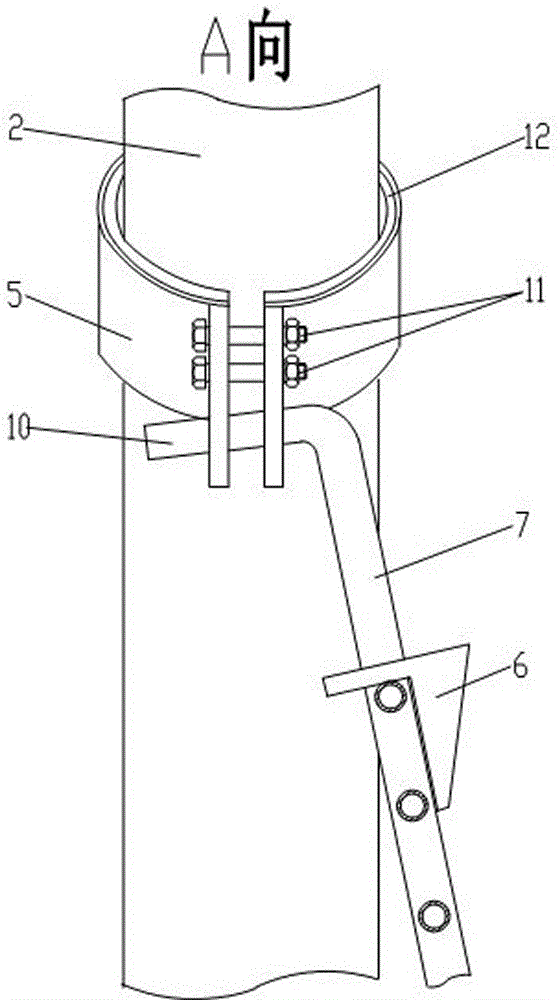

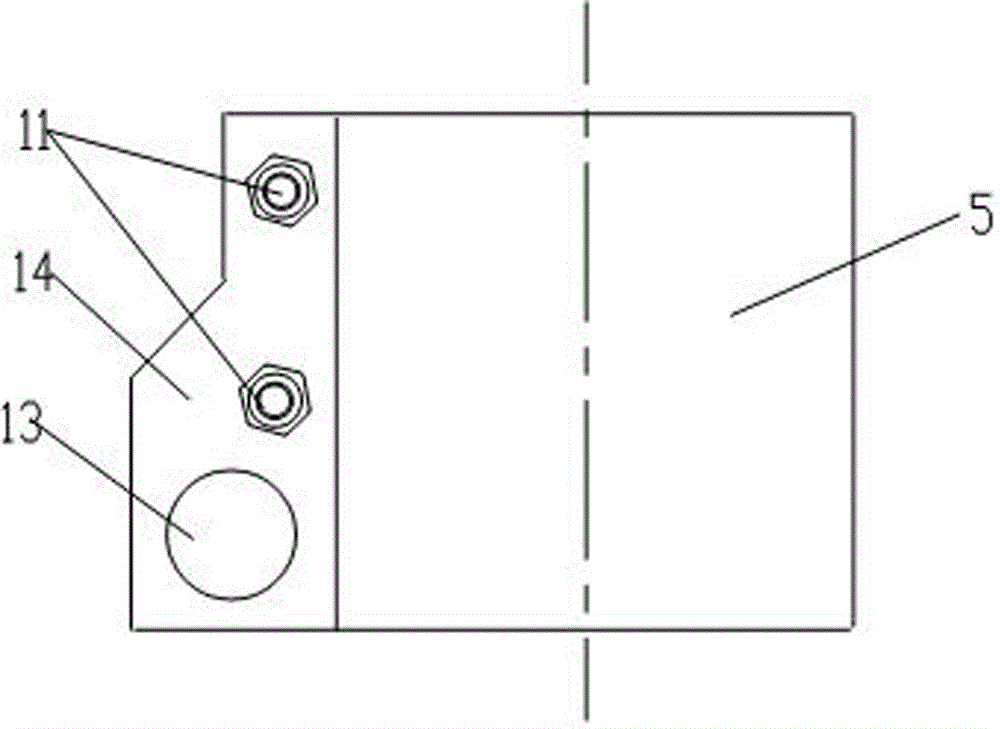

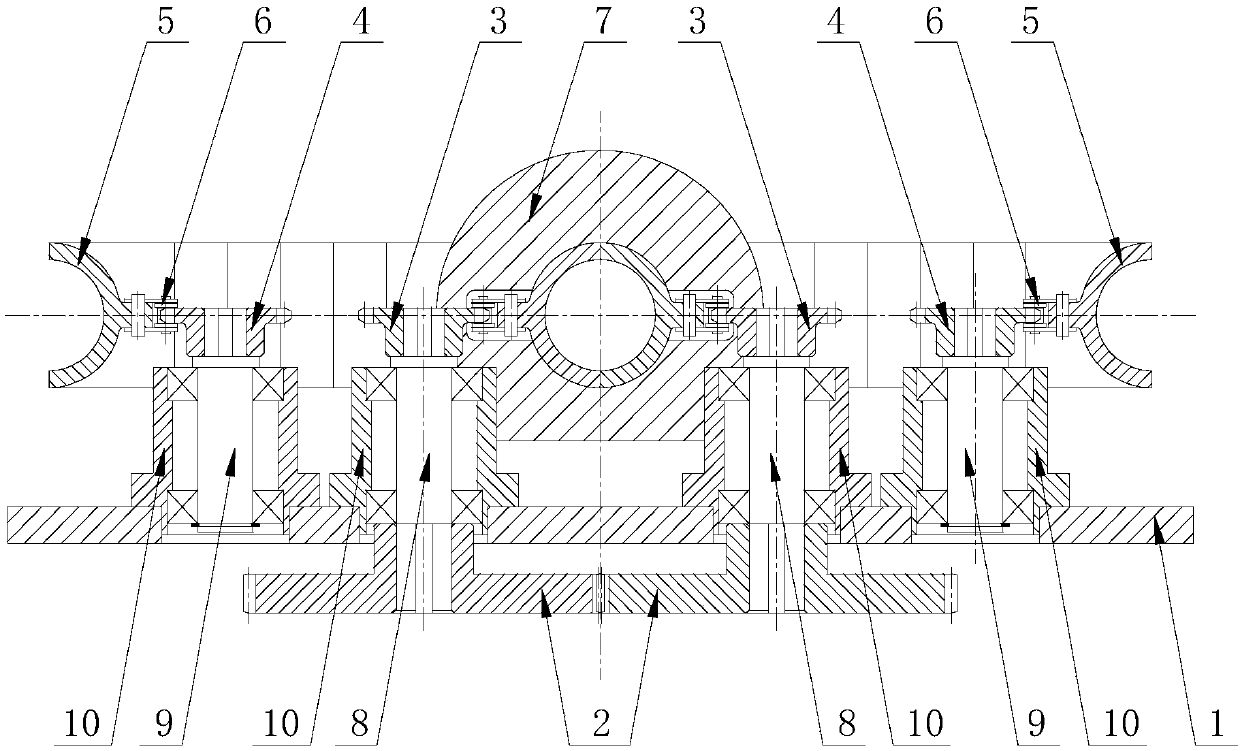

Climbing tool for maintaining power transmission tower pole fork beam

ActiveCN106761361AGuaranteed not to slipSimple structureLaddersTransmission towerUltimate tensile strength

The invention discloses a climbing tool for maintaining a power transmission tower pole fork beam. The climbing tool comprises a left hoop and a right left hoop which are symmetrical, and a ladder, wherein an inside liner is arranged on the hoop inner ring of the right hoop, the inside liner is made from a flexible material, a through hole is formed in the lower part of a bolt fastening plate of the right hoop, and the left hoop and the right hoop are symmetrically installed on the power transmission tower pole fork beam through bolts and are in sliding fit with the power transmission tower pole fork beam frictionally; two hooks are arranged on the upper end of the ladder, and the two hooks are suspended in the through holes of the left hoop and the right hoop respectively. The left hoop and the right hoop are symmetrically installed on the power transmission tower pole fork beam, the hooks of the ladder are suspended in the through holes of the two hoops simultaneously, the two hoops naturally glide through the gravity of the ladder, the two hoops are clamped simultaneously through an oblique plane of the power transmission tower pole fork beam, and the ladder is steadily connected with the two hoops.The climbing tool is simple in structure and quick and convenient to assemble and disassemble, and guarantees that the ladder is non-slip, so that the labor efficiency can be improved, the labor intensity is alleviated, and the safety production is guaranteed.

Owner:HENGSHUI POWER SUPPLY BRANCH OF STATE GRID HEBEI ELECTRIC POWER +2

Transverse type guard bar of medicinal nursing bed

PendingCN107233174AGuaranteed not to slipAvoid accidental injuryNursing bedsAmbulance serviceRotation flapMassage

The invention discloses a cross-bar type guardrail for a medical care bed, which comprises a bed beam, a hinge is welded on the outer wall of the side of the top of the bed beam away from the bed board, and a rotating plate is hinged at the other end of the hinge, and the top of the rotating plate Two side-by-side sliding rails are welded, and a sliding device is provided on the two sliding rails, the sliding device includes an inner cavity, the inner cavity has a convex structure, and a connecting plate is slidably connected to the inner wall at the top of the inner cavity, The bottom end of the connecting plate is welded with a fixed shaft, and a through hole in a horizontal position is opened inside the fixed shaft, and a transmission rod is sleeved in the through hole, and rolling wheels are welded at both ends of the transmission rod. The fixed shaft, transmission rod and rolling wheel are all located in the inner cavity, and the top of the connecting plate is welded with a guardrail body. The invention has beautiful appearance and strong adaptability, can prevent emergencies, can ensure that the guardrail body does not slip when the rotating plate rotates, and can massage the patient to relieve the patient's nerves.

Owner:湖南丹尼尔智能科技有限公司

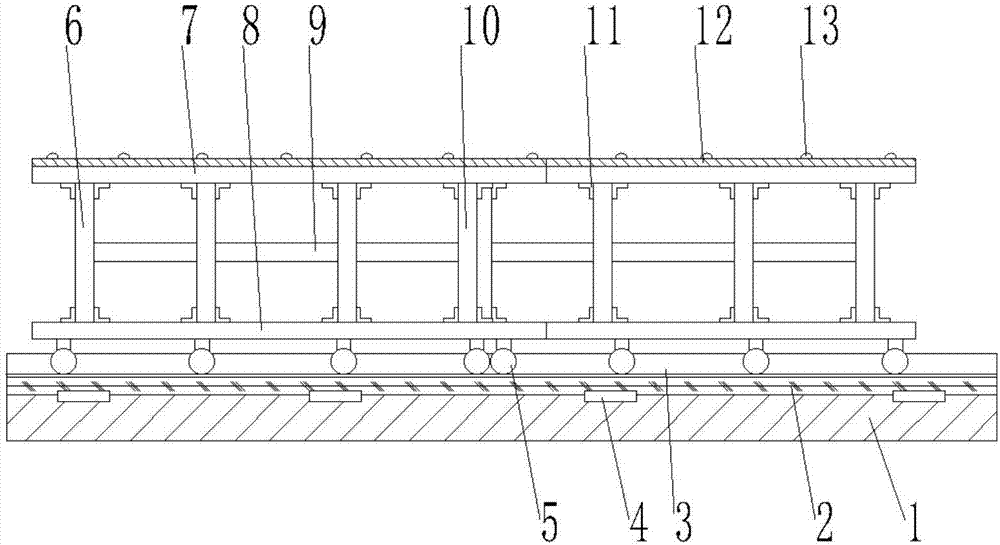

Roller bed bearing block positioning device and manufacturing and application methods thereof

The invention relates to a roller bed bearing block positioning device and manufacturing and application methods thereof. The positioning device comprises a positioning steel plate. Two lateral sides of the positioning plate are tightly attached to bases of adjacent bearing blocks respectively. The lower surface of the positioning steel plate is tightly attached onto the upper surface of a roller bed frame base. The upper surface of the positioning steel plate is provided with a plurality of through holes by milling or drilling. The periphery, in contact with the upper surface of the roller bed frame base, of each through hole of the positioning steel plate is provided with a circular weld by welding. According to the roller bed bearing block positioning device, the welds between the positioning steel plate and the upper surface of the roller bed frame base can bear part of impact of materials under transportation upon the bearing blocks, and slipping of the bearing blocks is avoided.

Owner:SINOSTEEL HENGYANG MACHINERY

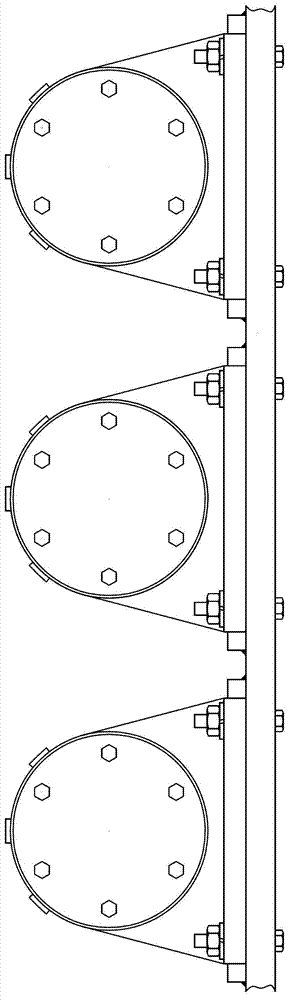

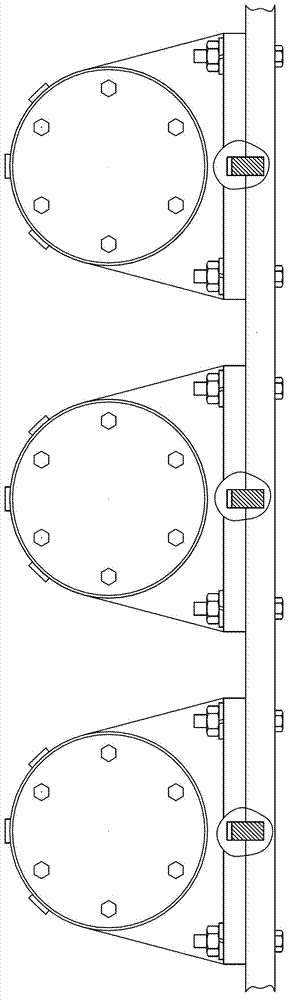

Hose pulling device

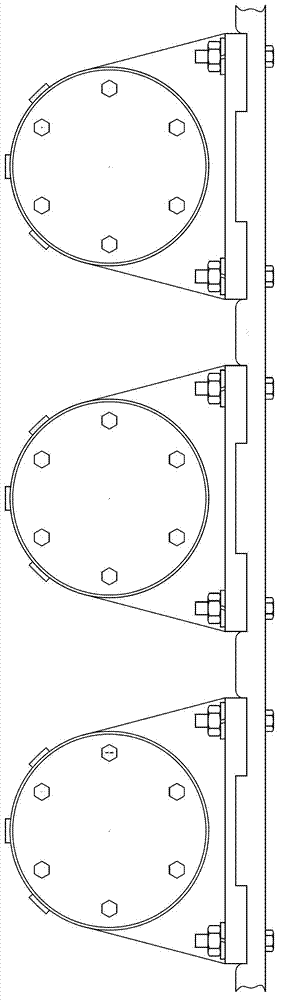

ActiveCN107825686AGuaranteed not to deformGuaranteed not to slipTubular articlesPull forceGear wheel

The invention discloses a hose pulling device. The hose pulling device comprises a mounting base plate, a first pulling mechanism, a second pulling mechanism and a precision positioning sleeve. The first pulling mechanism and the second pulling mechanism each comprise a transmission chain, a driving sprocket, a moving sprocket, a transmission gear and multiple pipe-holding Huff sleeves. Each driving sprocket and the corresponding moving sprocket are in transmission connection with the interior of an inner ring of the corresponding transmission chain to form a rotating transmission structure. Each transmission gear is in transmission connection with the corresponding driving sprocket. The pipe-holding Huff sleeves are uniformly arranged on the corresponding transmission chains in the lengthdirection of the transmission chains. Hose channels for limiting hoses are formed between the pipe-holding Huff sleeves of the adjacent transmission chains of the first pulling mechanism and the second pulling mechanism. A positioning channel and a chain channel are arranged on the precision positioning sleeve. According to the hose pulling device, the outer surfaces of the hoses are held by thesymmetrical pipe-holding Huff sleeves and are pulled, it is guaranteed that the hoses do not deform and pulling can be conducted through whole ring holding of the outer surfaces of the hoses, the enough pulling force is provided, and it is guaranteed that the hoses do not slide in the pulling process.

Owner:南通市通州区三槐机械制造有限公司

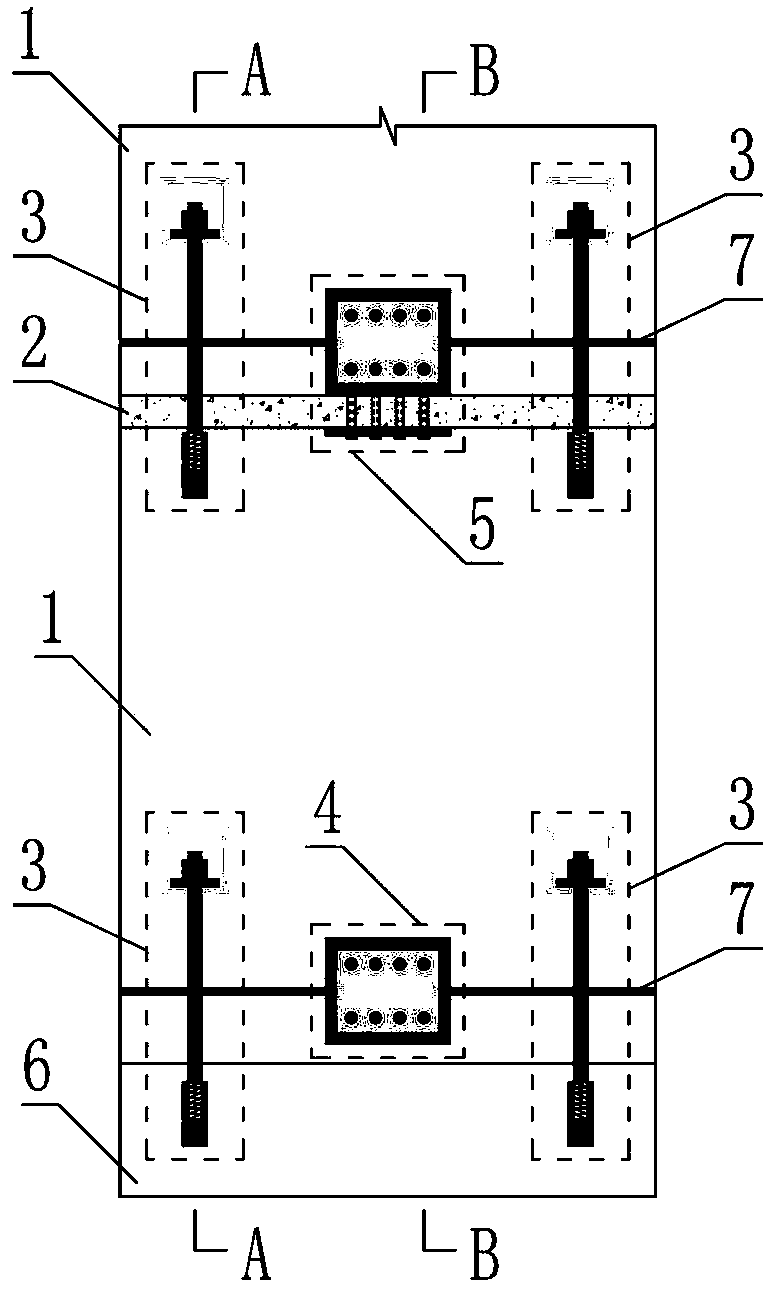

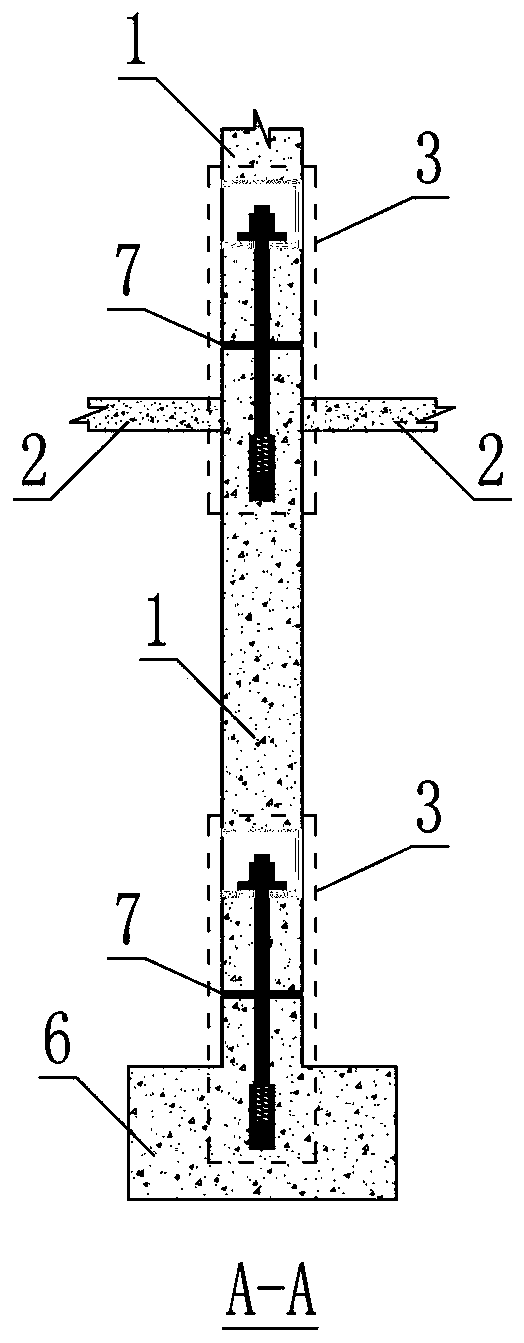

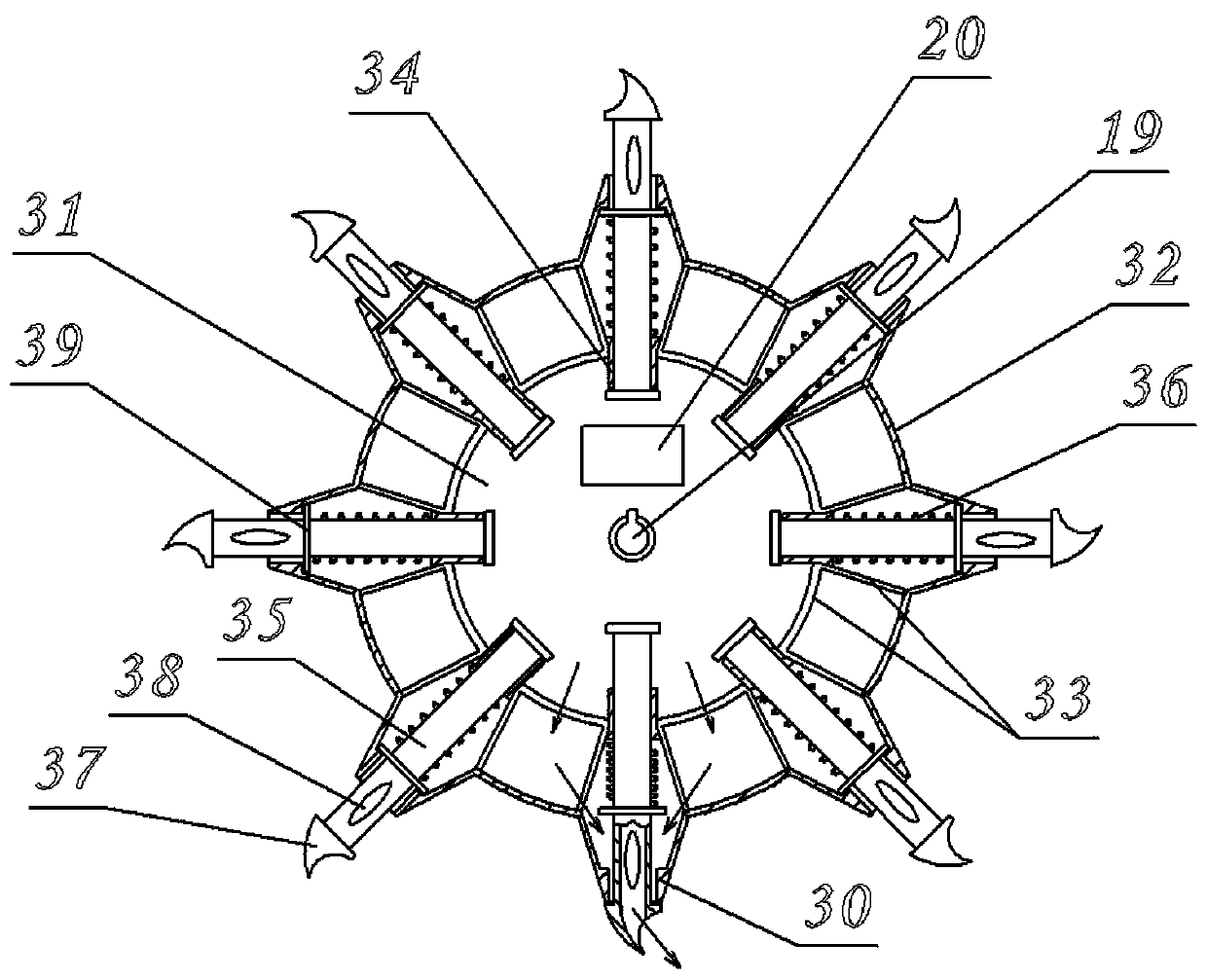

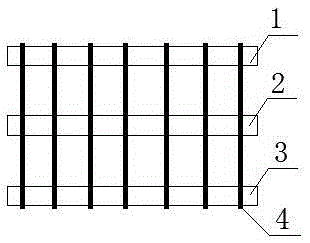

Detachable assembled shear wall structure with replaceable component and assembling method

The invention provides a detachable assembled shear wall structure with replaceable components and an assembling method. Precast shear walls and a foundation and upper and lower layers of precast shear walls are both connected with each other through the replaceable components; and the precast shear walls and a precast floor slab are connected with each other through common bolts. According to thedetachable assembled shear wall structure with the replaceable components, each member and the replaceable components can be all precast in a factory and can be mounted after being transported to thesite. The precast shear walls are reinforced concrete shear walls which are industrially made and produced in a prefabrication factory. The precast floor slab is a reinforced concrete floor slab which is industrially made and produced in the prefabrication factory. According to the detachable assembled shear wall structure with the replaceable components, the detachability of the shear wall and the quick recovery of the structure after earthquake are realized, and requirements of structure assembled construction and building industrialization are satisfied.

Owner:SOUTHWEAT UNIV OF SCI & TECH

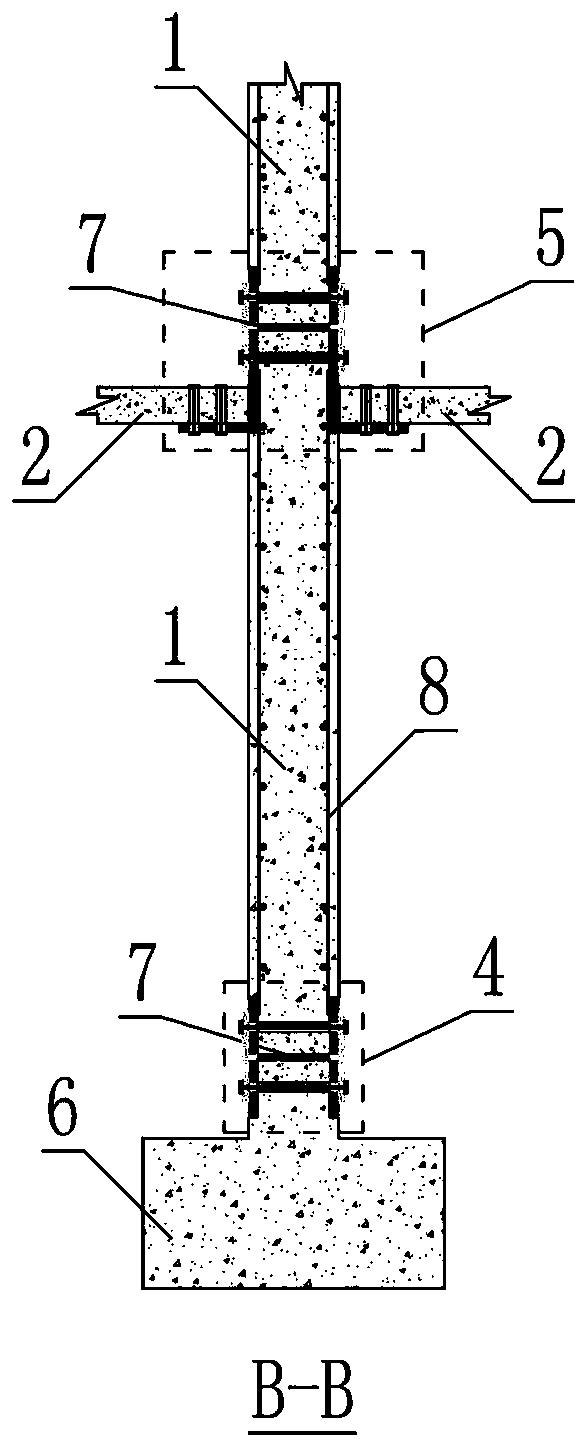

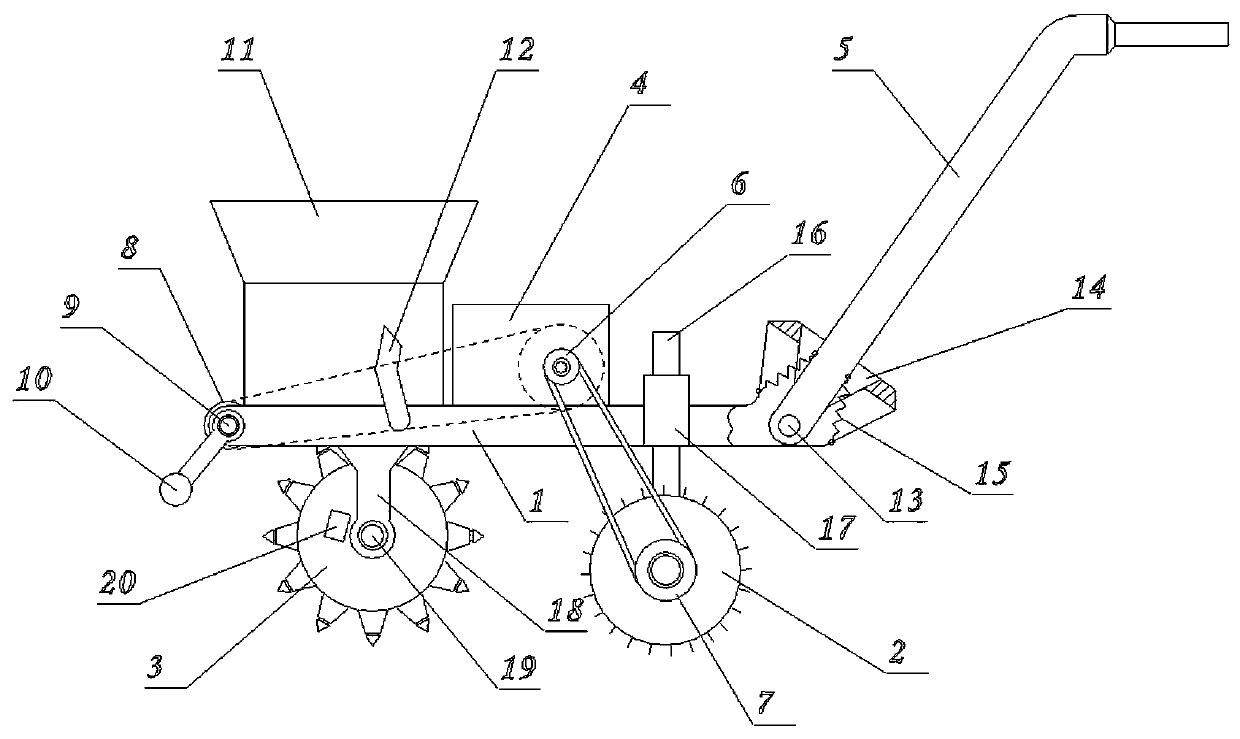

Rapid soil loosening fertilizer applier of plant root zone

The invention discloses a rapid soil loosening fertilizer applier of a plant root zone. The lower part of a frame is provided with a fertilizer applying wheel device and a walking wheel; the fertilizer applying wheel device comprises a disk body mounted on a disk shaft, and the middle part of the disk body is provided with a feeding opening and a seal cover; a circumferential side of the disk bodyis evenly distributed with tunneling teeth, and the disk body is walked upon the contact between every tunneling tooth and the ground; a radial slide rod located in the tunneling tooth is a hollow structure; a feeding hole is arranged at the side wall of the outer section of a stopping ring, and a discharging hole is arranged at the tail end of a tunneling head. The rapid soil loosening fertilizer applier can automatically apply fertilizer during the walking process, the working efficiency is very high and the labor force is saved. As walking with the help of a driving mechanism, the whole machine is very convenient to operate. For adopting a radial slide rod with elasticity, the gravity heights of the disk body after rotating every time are different, thus downwards impacts are formed beneficially, and the tunneling intensity is improved.

Owner:蔡兴礼

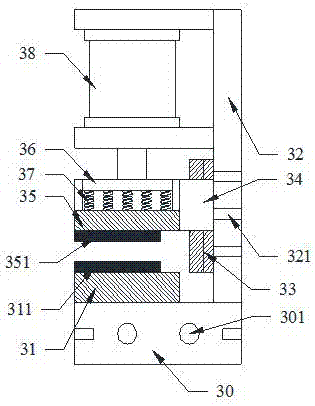

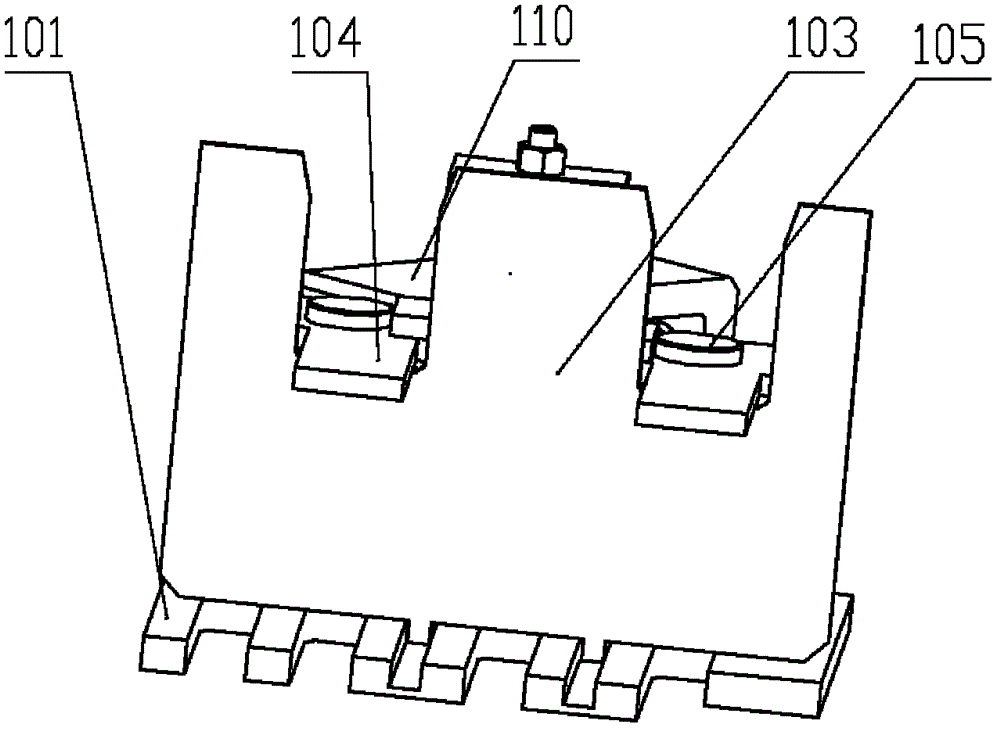

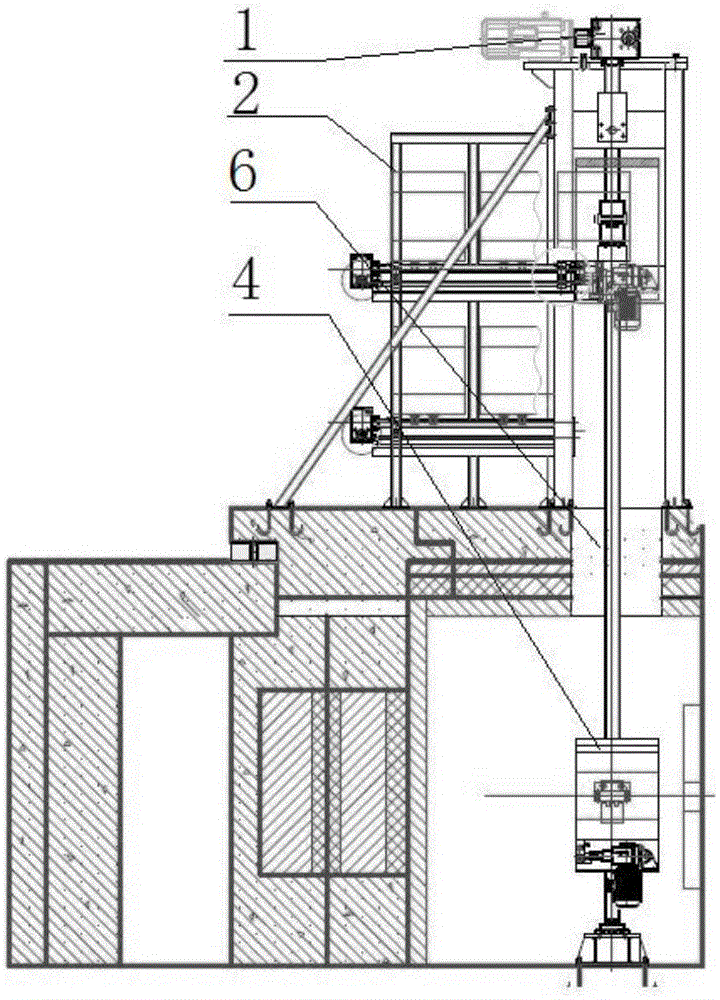

Financial product clamping and conveying device

ActiveCN103058001APrecise positioningGuaranteed not to slipArticle deliveryEngineeringMechanical engineering

The invention belongs to the paper financial product cutting, packaging and production field, and particularly discloses a clamping and conveying device for a thousand pieces of financial products. The clamping and conveying device comprises a lifting servo mechanism, a forward-conveying servo mechanism and a clamping overturning mechanism, wherein the forward-conveying servo mechanism is mounted on the lifting servo mechanism, and the clamping overturning mechanism is mounted on the forward-conveying servo mechanism. By means of the clamping and conveying device, piles of products can be automatically placed onto a space tilting plane (for example, a checking equipment table top) from a horizontal plane (for example, a cutting line table top), and therefore manpower is liberated, and production efficiency is improved.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +3

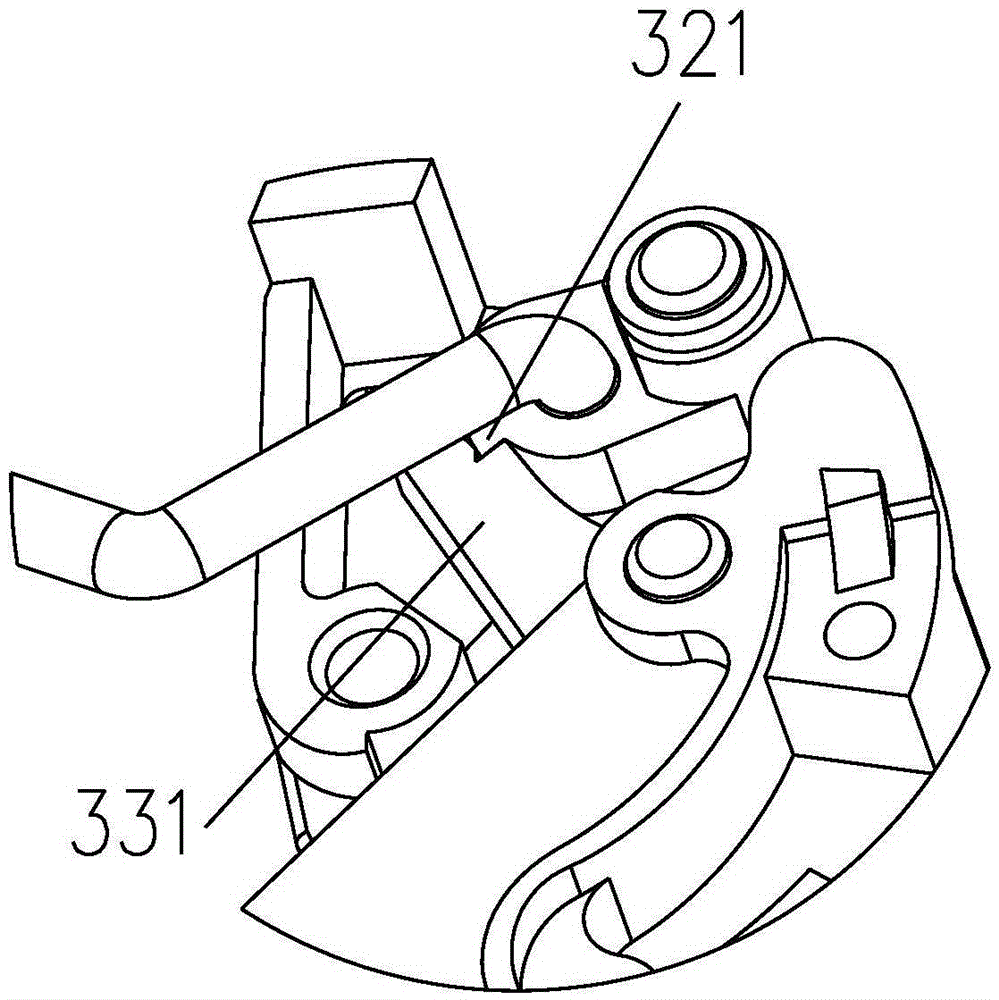

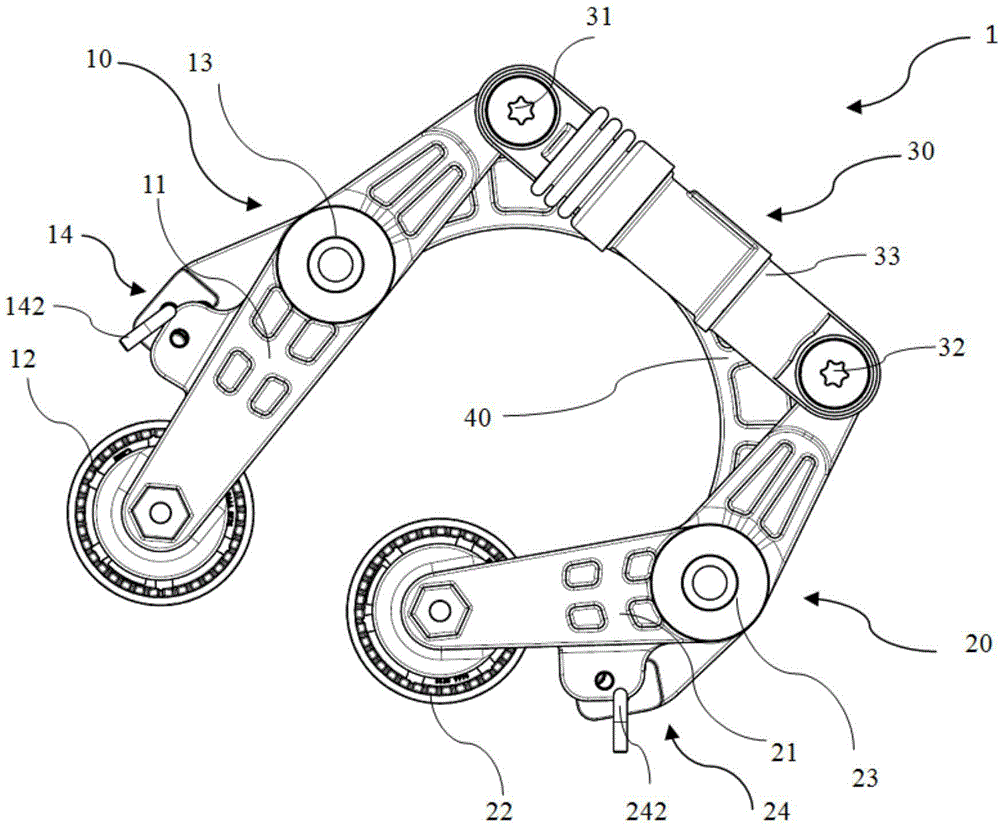

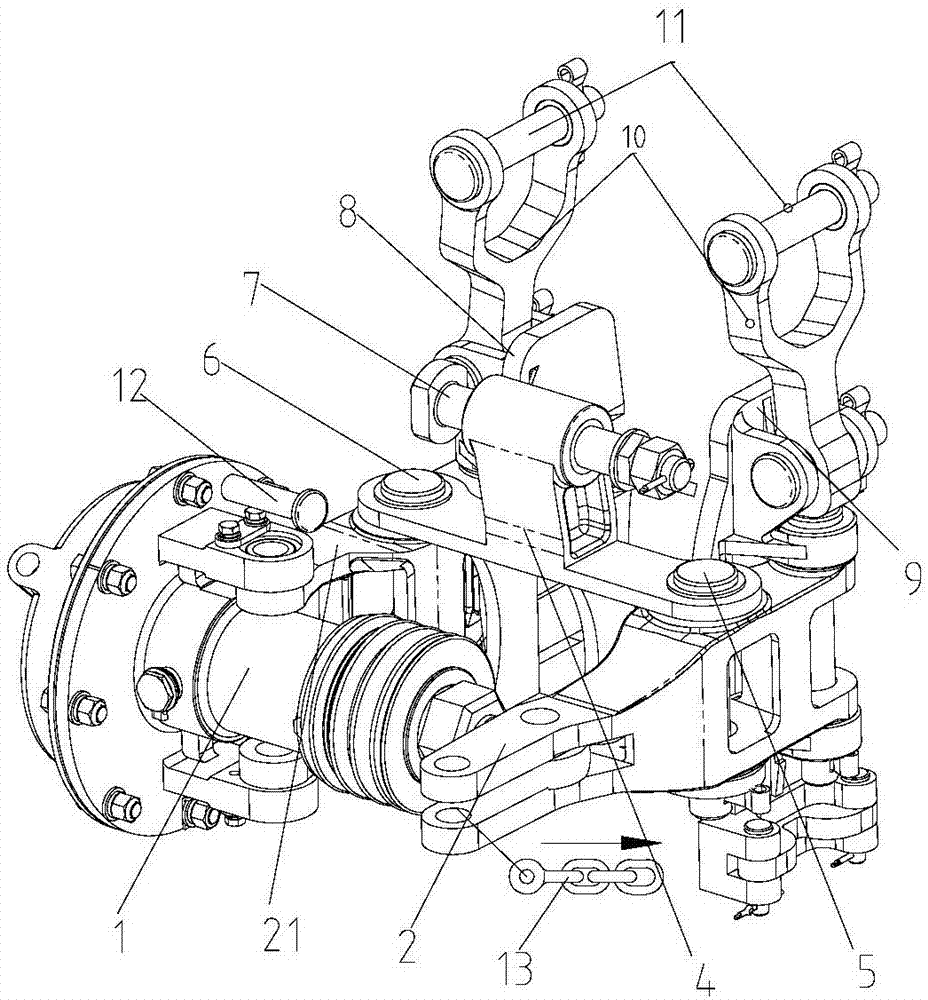

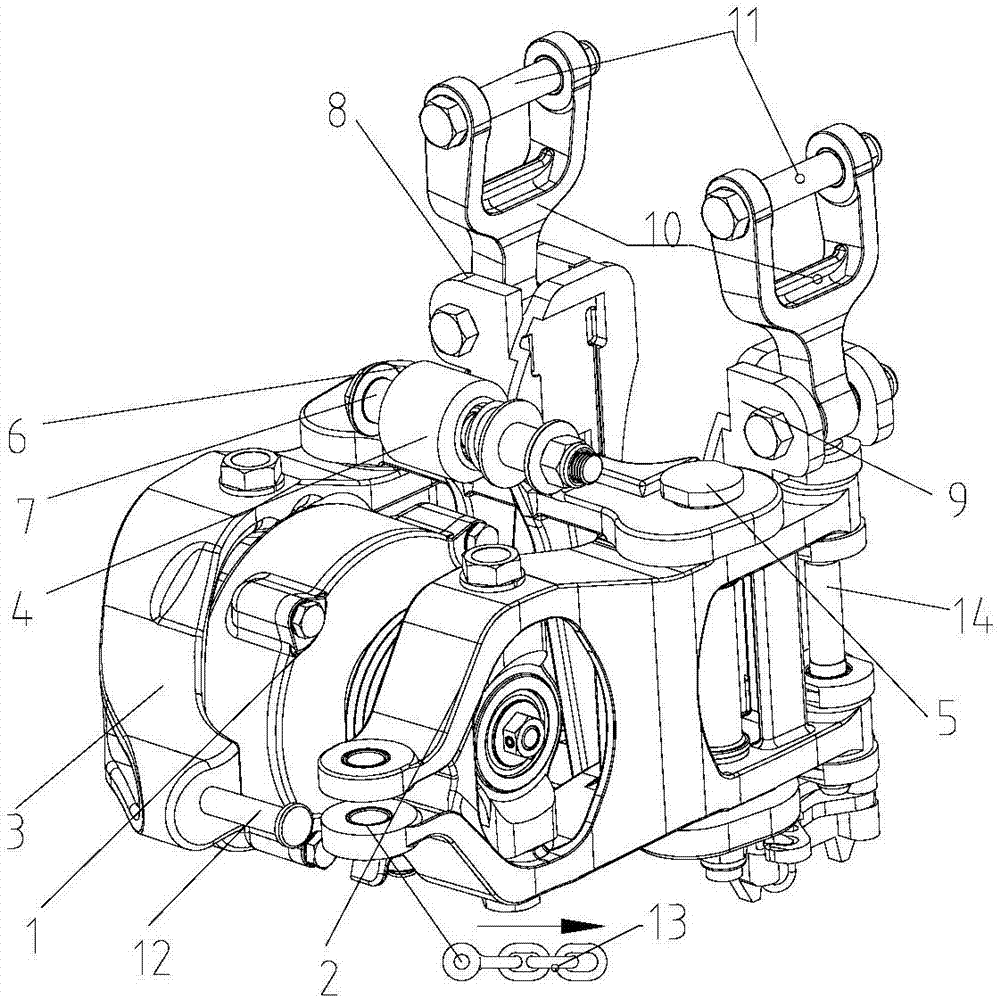

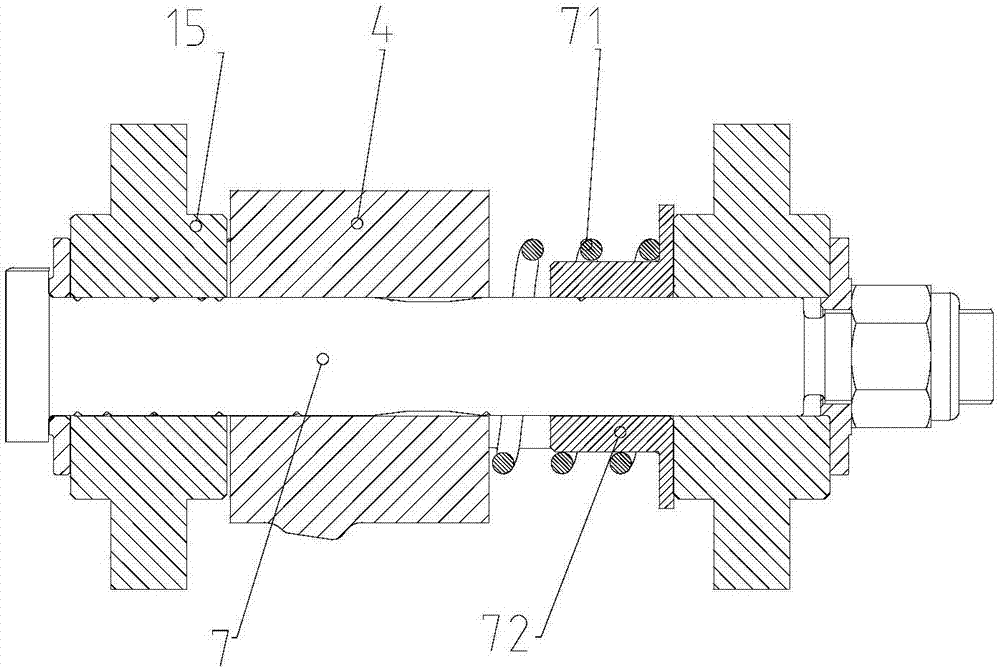

Handbrake caliper device

ActiveCN107458416AIncrease braking powerSolve partial wearRail brake actuationEngineeringDegrees of freedom

The invention provides a handbrake caliper device, which is mounted on a vehicle framework and comprises a unit brake cylinder, as well as a handbrake caliper arm and a stop caliper arm mounted on the both sides of the unit brake cylinder. A connecting frame which can be mounted on the vehicle framework is connected between the handbrake caliper arm and the stop caliper arm. A hanging shaft is mounted on the connecting frame. The connecting frame is provided with a reset unit capable of increasing the horizontal degree of freedom of the connecting frame. The handbrake caliper device can solve the problem of eccentric wear caused by the heavy unit brake cylinder, the both sides of a brake disk are stressed during handbrake, and the unit brake cylinder is avoided being affected by torque.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

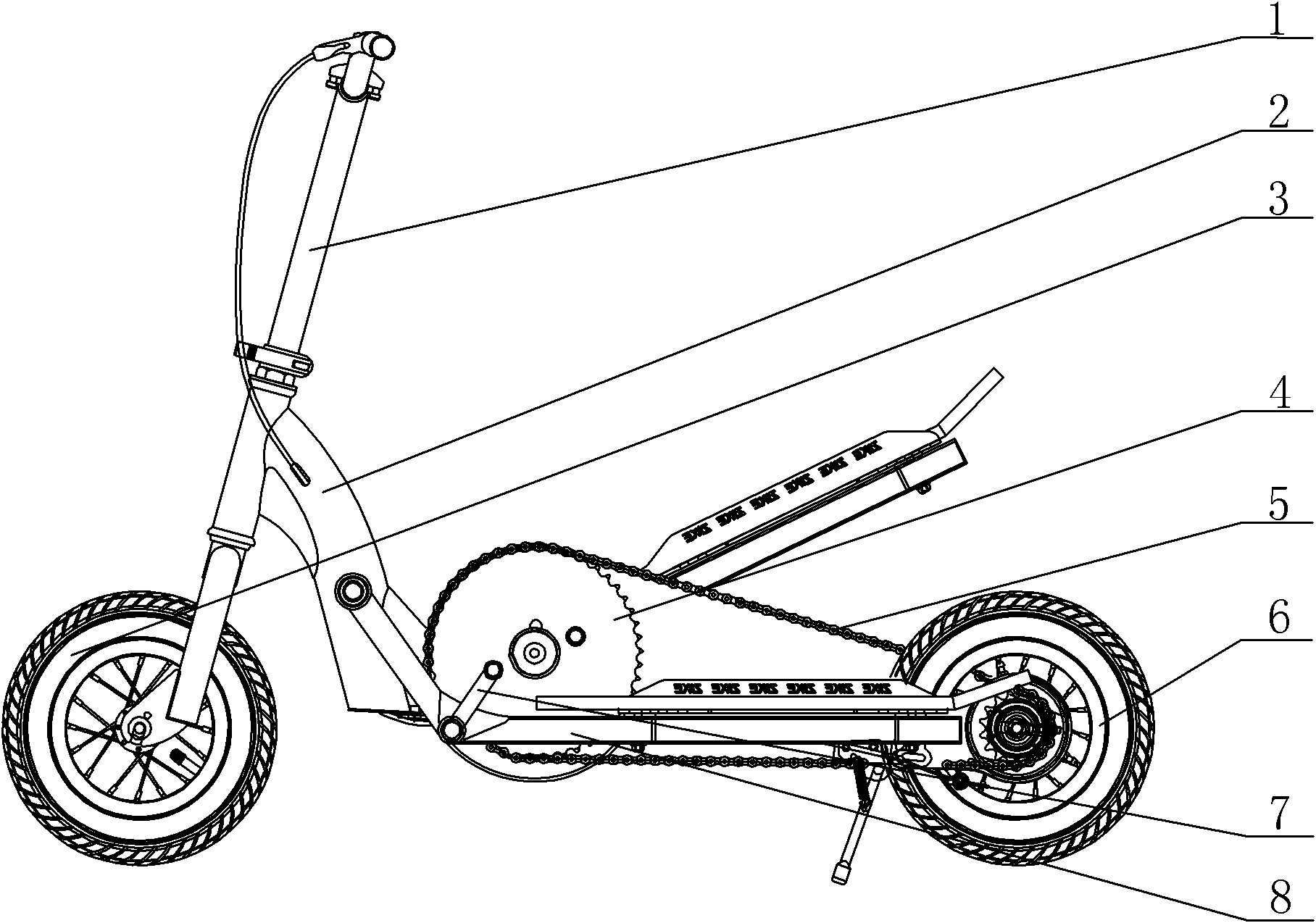

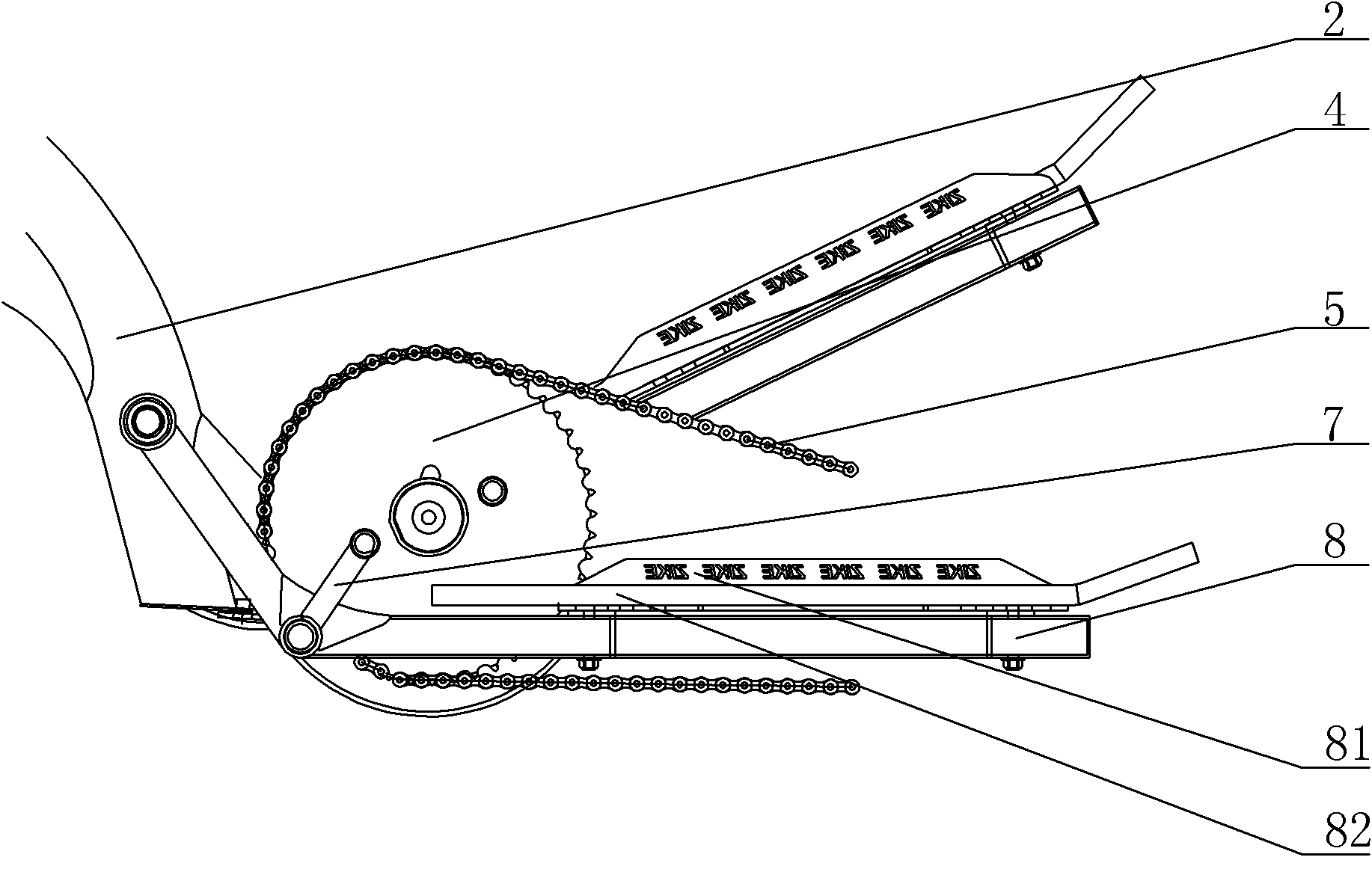

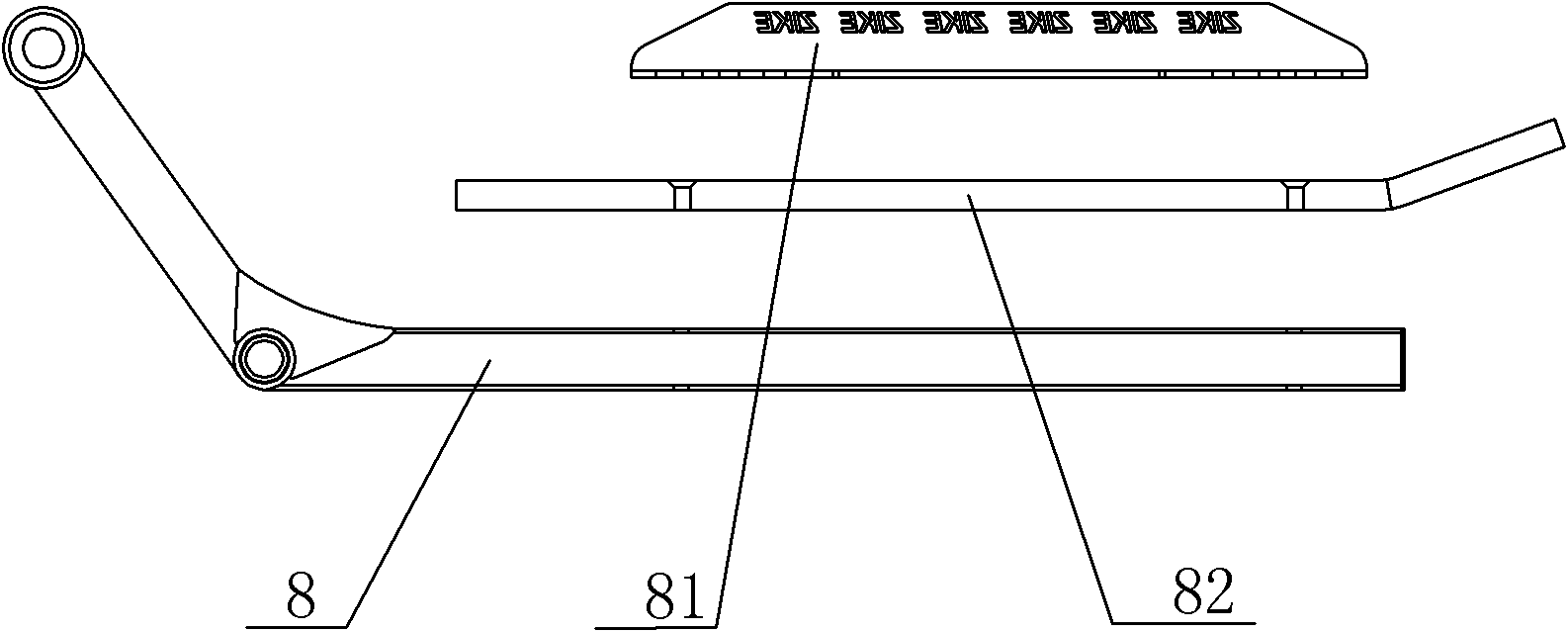

Anti-skidding fitness bicycle

The invention relates to a multifunctional transportation, in particular to an anti-skidding fitness bicycle comprising a bicycle handlebar and a bicycle body; a front wheel is arranged on the bicycle handlebar; a rear wheel is arranged at the tail of the bicycle body; a fluted disc is arranged in the middle of the bicycle body and is in transmission connection with a flywheel of the rear wheel through a chain; two bent levers are arranged on two side disc surfaces of the fluted disc rotatably, and two rotating centers are eccentric on the fluted disc and are in centrally symmetric; the otherends of the bent levers are hinged with the middle parts of pedals; the ends of the two pedals are bilaterally hinged on the bicycle body; and anti-skidding plates are fixedly arranged on the upper surfaces of the pedals. People stands on the pedals and treads the pedals so as to drive the bicycle to move and play a walking role on one hand, and simulate walking action for realizing the exercise on the body on the other hand; the anti-skidding plates are additionally arranged on the pedals, baffles are arranged inside the anti-skidding plates, the tails of the anti-skidding plates are turned up, thus improving the stability of treading and driving.

Owner:ZHEJIANG DEQING JIUSHENG VEHICLE IND

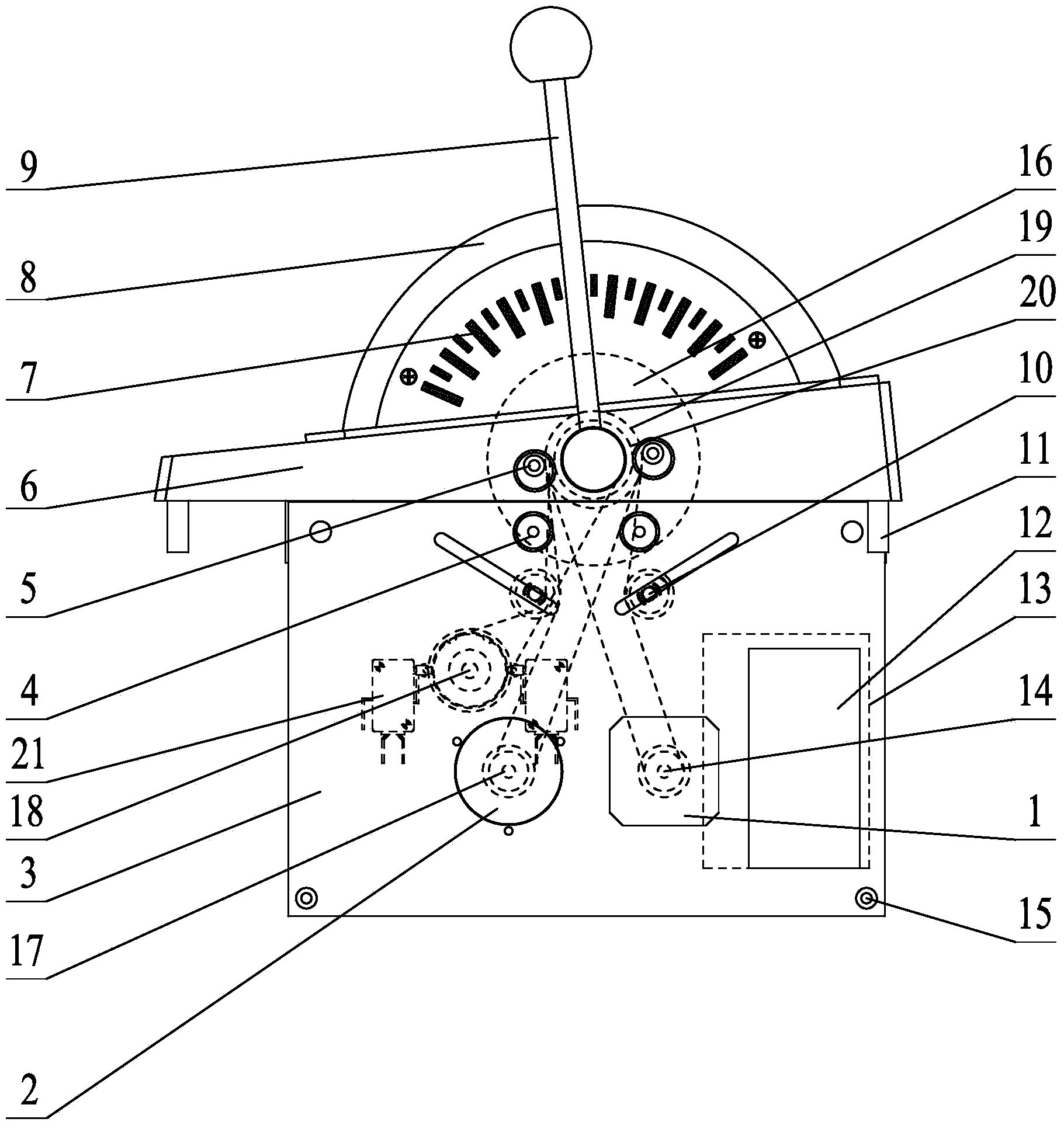

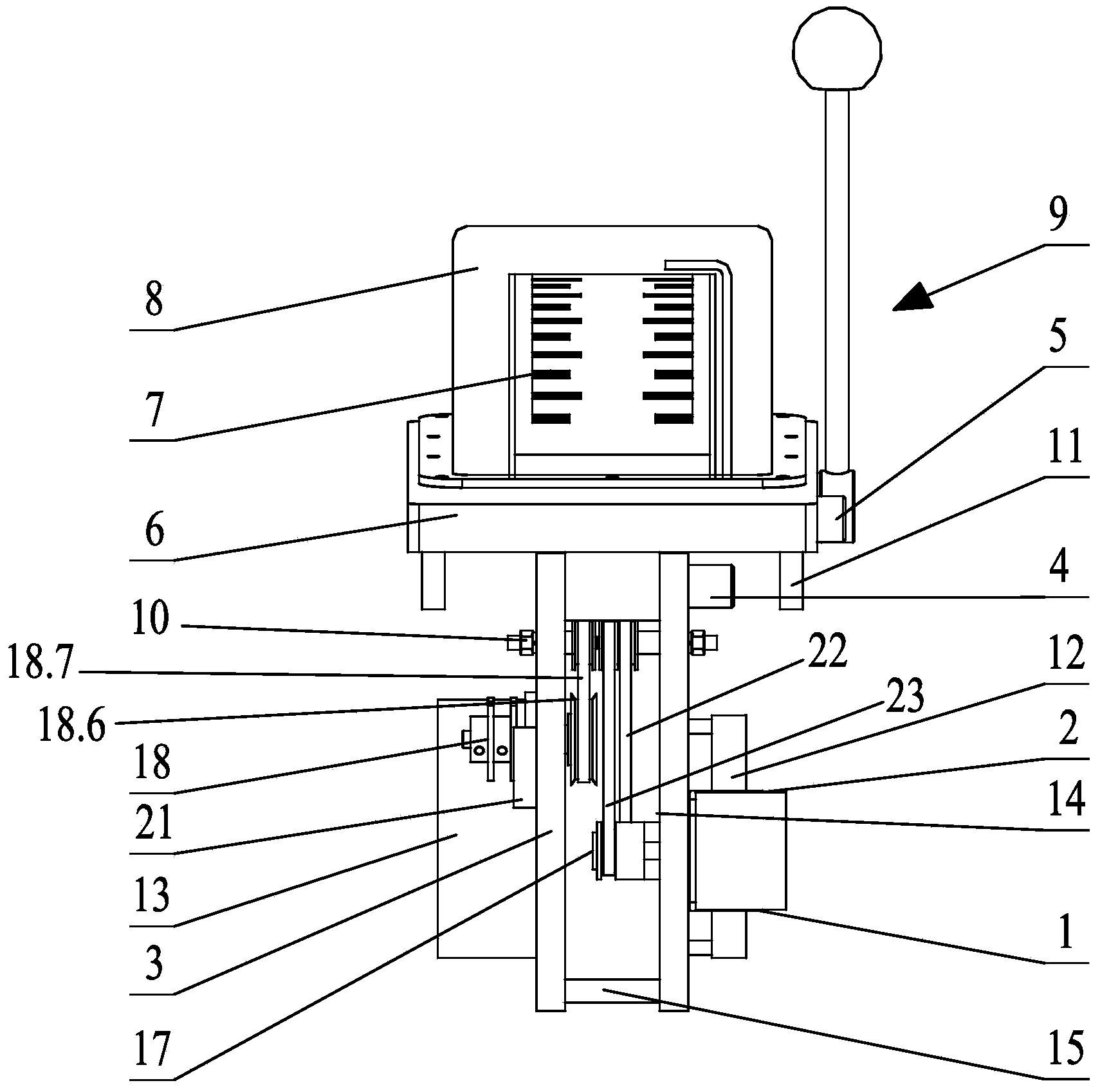

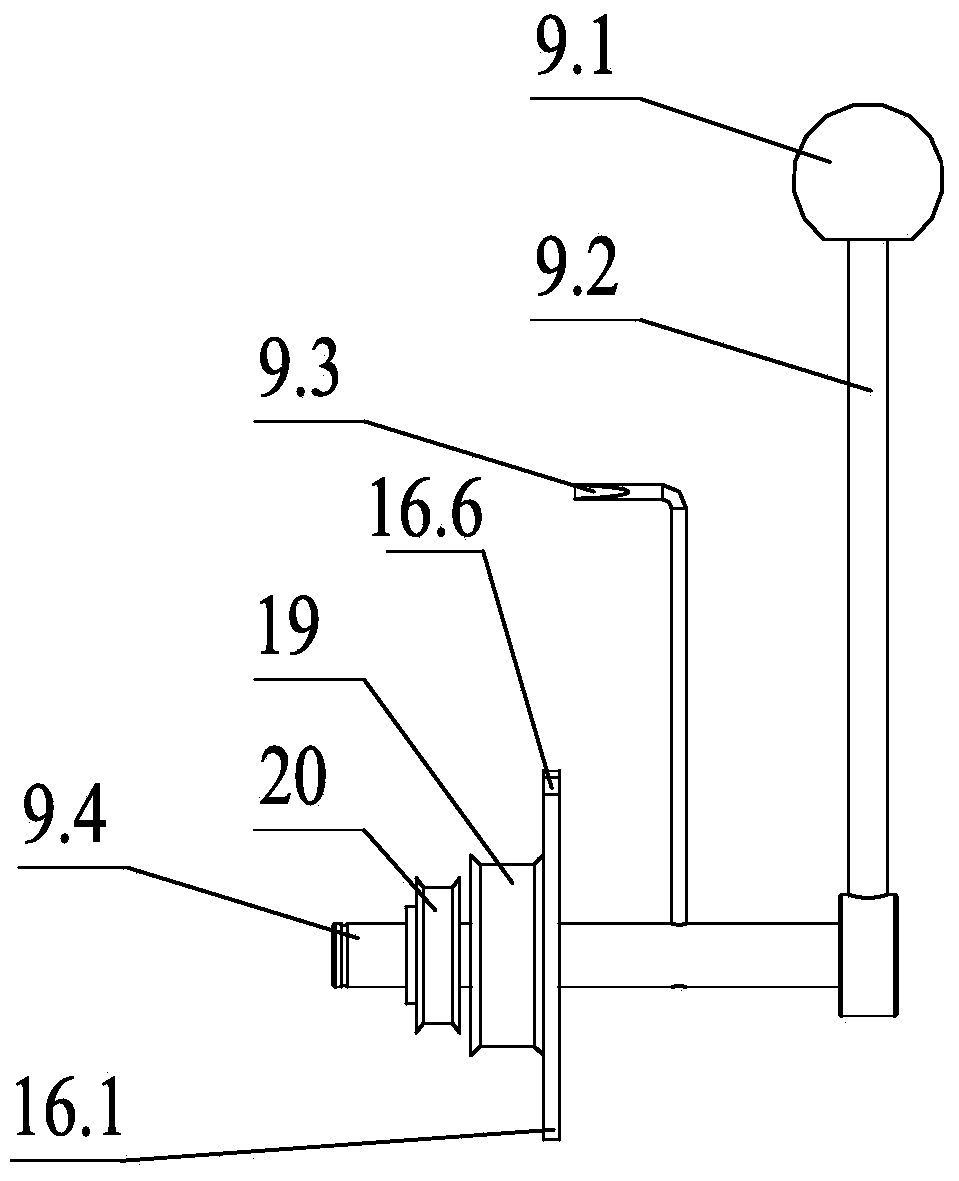

Electronic coaxial master controller of ship

The invention discloses an electronic coaxial master controller of a ship. The electronic coaxial master controller comprises a control terminal, a base shell, a mounting plate, a transmission shaft, a wide synchronous belt pulley, a narrow synchronous belt pulley, a servo motor, a potentiometer, a switching value part, a microswitch matched with the switching value part, and a driver controlling the servo motor. A motor shaft belt pulley is fixed on the servo motor, a potentiometer belt pulley is fixed on the potentiometer, the motor shaft belt pulley is connected with the wide synchronous belt pulley, and the potentiometer belt pulley is connected with the wide synchronous belt pulley; the microswitch is mounted on the other side of the mounting plate, a communication end of the control terminal is connected with a signal input end of the controller driver, a signal output end of the microswitch is connected with the communication end of the control terminal, a communication end of the potentiometer is connected with the communication end of the control terminal and a control end of a main propeller of the ship respectively, and the control terminal is provided with a control bus connector. The electronic coaxial master controller is stable in transmission and convenient to operate, transmission reliability and stability are greatly improved, and service life is prolonged.

Owner:WUHAN HAIWANG MECHANICAL & ELECTRICAL ENGTECH

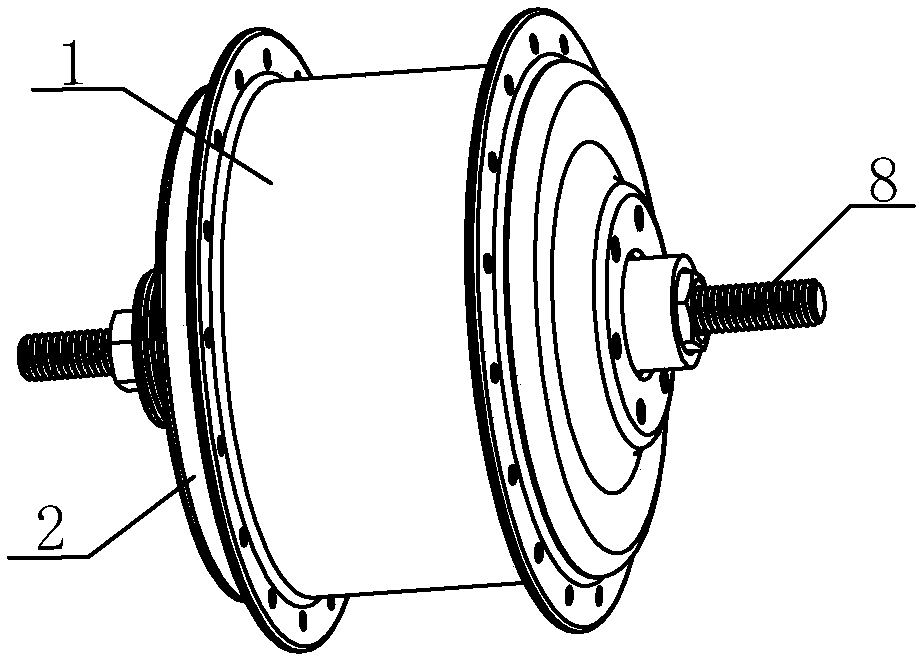

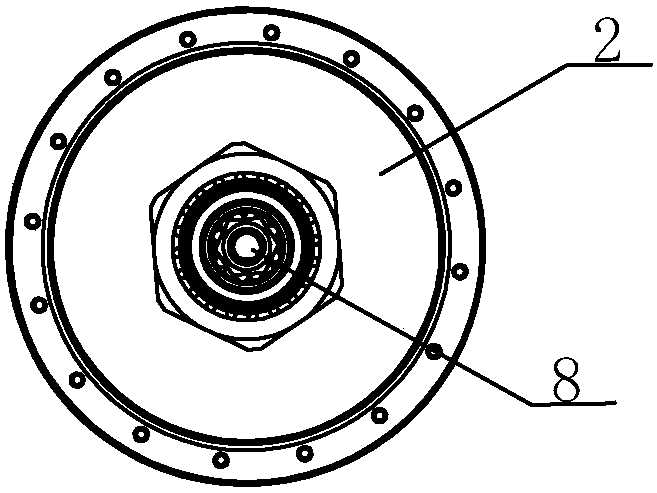

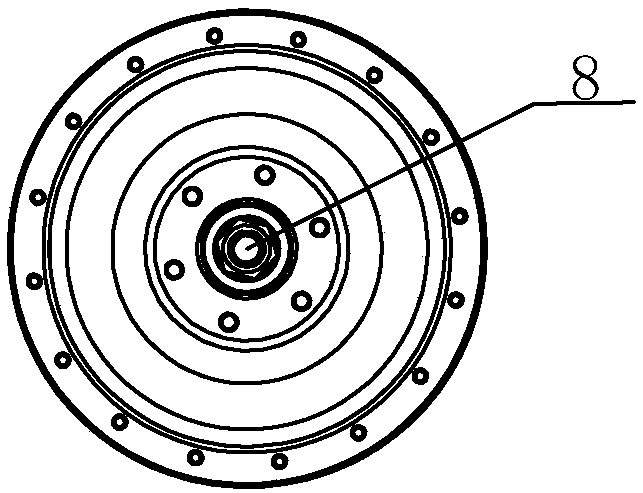

Stepless speed changing device capable of realizing stepless speed changing of bicycle

PendingCN108068988AImprove comfortRealize stepless speed changeWheel based transmissionEngineeringGear ratio

The invention relates to a stepless speed changing device capable of realizing stepless speed changing of a bicycle. The stepless speed changing device is used for being mounted on the bicycle and ischaracterized in that the stepless speed changing device comprises a hub, a hub cover, a hub gear ring, a speed changing body, an input disc, at least three input taper rotors, an output taper rotor and a spindle; the hub, the hub cover, the hub gear ring, the speed changing body, the input disc, the at least three input taper rotors, the output taper rotor and the spindle are used for being connected with a spoke; the hub is in fastening fit with the hub cover; speed changing shafts are arranged between the input taper rotors and the output taper rotor; the speed changing shafts make contactwith the tapered surfaces of the input taper rotors and the tapered surface of the output taper rotor in a jacked mode and can move to different positions along the tapered surfaces of the input taperrotors and the tapered surface of the output taper rotor, so that stepless gear ratio changing is realized by adjusting the positions of the speed changing shafts on the tapered surfaces of the inputtaper rotors and the tapered surface of the output taper rotor, the situation that a rider can self choose the proper gear ratio for riding is met accordingly, and stepless speed changing of the bicycle is realized.

Owner:杨明芳 +2

Coir mat conveyor

The invention relates to the coir mat conveying field, in particular to a coir mat conveyor which comprises a base frame, a drive shaft, a driven shaft, a drive device and a conveyor belt, wherein the bottom of the base frame is fixed to the ground; the drive device is connected to the drive shaft; the drive shaft is rotatably connected to the base frame; the driven shaft is rotatably connected to the base frame; the drive shaft is parallel to the driven shaft; the conveyor belt is arranged outside the drive shaft and the driven shaft in a sleeving mode; the conveyor belt is in interference fit with the drive shaft and the driven shaft; and the conveyor belt is a rope. The technical problem to be solved is that the conveyor belt of a current conveyor is a transmission belt, so that friction force between the conveyor belt and a conveyed object is small during transmission, a coir mat is inconvenient to convey, and the transmission belt is relatively high in cost as the conveyor belt. The invention aims to provide the coir mat conveyor which is high in friction coefficient during transmission and is low in cost.

Owner:CHONGQING YONGCHUAN DISTRICT TAIXING MACHINERY FACTORY

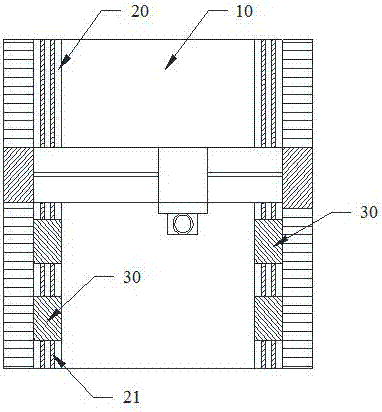

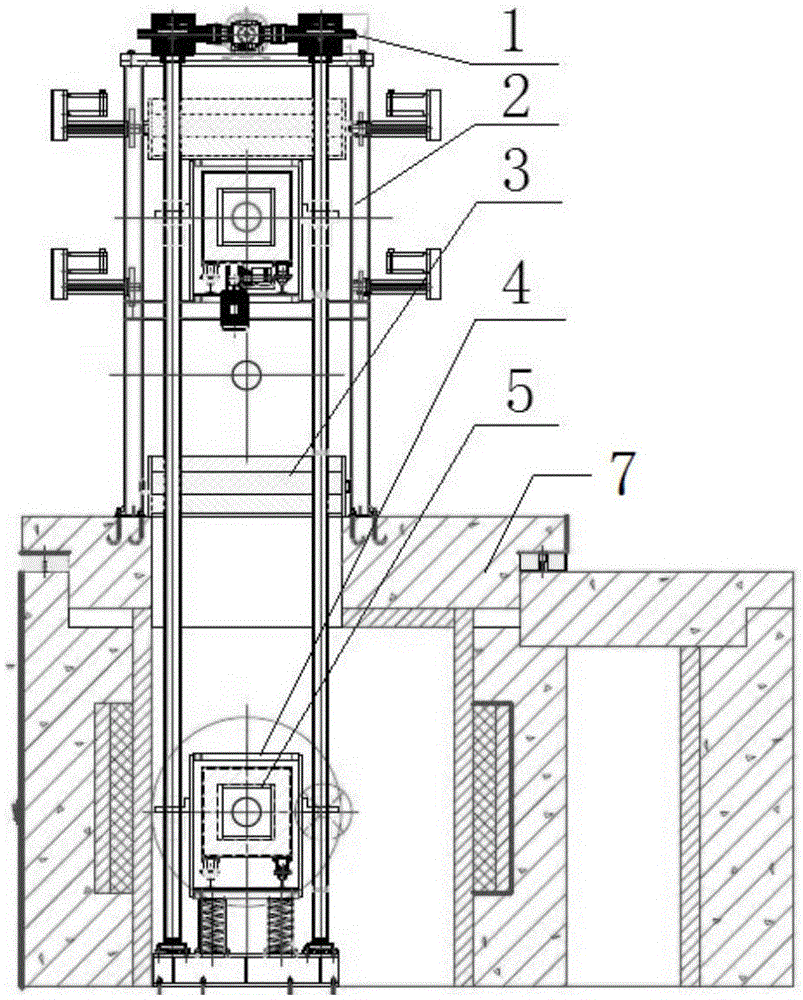

Irradiation experimental device for pulse reactor

InactiveCN105118537AReduce exposure doseQuick changeNuclear energy generationNuclear elementsEngineeringIrradiation

The invention discloses an irradiation experimental device for a pulse reactor. A radial duct is formed in the pulse reactor. The radial duct comprises a duct outlet. A neutron trap is arranged inside the radial duct; a shielding body is arranged outside the radial duct; and a passing hole is formed in the shielding body. The irradiation experimental device comprises a movable shielding cover, a shielding storage rack, a double-screw synchronous drive mechanism and an elevator, wherein the shielding storage rack is arranged at a position, which avoids an area of the passing hole, above the shielding body; the shielding storage rack is used for placing shielding irradiation cavities of different specifications; the elevator comprises an elevator car; and when the elevator car is located in the bottom-most layer, an opening of the elevator car is opposite to the duct outlet. According to the irradiation experimental device disclosed by the invention, the double-screw synchronous drive mechanism is used to drive the elevator car to move, so that automatic transfer and storage can be achieved in the shielding storage rack and the duct outlet, thereby achieving replacement and storage of a plurality of sets of experimental devices in a small experimental space, and also ensuring the radiation protection safety of laboratory personnel.

Owner:NORTHWEST INST OF NUCLEAR TECH

Continuous constant-volume quantitative feeding device for powder materials

PendingCN110920071ASimple structurePrecise feedingAdditive manufacturing apparatus3D object support structuresElectric machineryLevel sensor

The invention relates to a continuous constant-volume quantitative feeding device for powder materials, which comprises a vacuum feeding machine, a storage box, a feeding level sensor, a discharging level sensor, a sealing cavity, a powder conveying device, a multi-stage powder cleaning device and a linking platform, wherein the vacuum feeding machine is fixed above the storage box; the storage box is fixed above the sealing cavity; the powder conveying device and the multi-stage powder cleaning device are accommodated in the sealed cavity; the feeding level sensor and the discharging level sensor are fixed on the side wall of the storage box; the powder conveying device comprises a driving motor, a driving synchronous belt wheel, a driven synchronous belt wheel and a conveying belt; the driving motor is connected with the driving synchronous belt wheel through a synchronous belt; the conveying belt comprises a forward toothed belt and a reverse toothed belt which are integrally formed, the forward toothed belt is arranged on the driving synchronous belt wheel and the driven synchronous belt wheel in a sleeving mode, the convex face of the reverse toothed belt is tangent to the side wall of the storage box, powder in the storage box falls into a groove of the reverse toothed belt, and the sealing cavity is communicated with a linkage platform through a discharging opening.

Owner:BEIJING E PLUS 3D TECH CO LTD

Preparation method of burnt-out lace jeans wear

InactiveCN108754779AGuaranteed not to slipImprove aestheticsGarmentsWoven fabricsEngineeringBurning out

The invention belongs to the field of the preparation of burnt-out jeans wear, and particularly relates to a preparation method of burnt-out lace jeans wear. The method comprises the following steps:preparation of warp and weft yarns, size dyeing, weaving, finishing, processing clothes, burnt discharge, washing and ironing; the warp and weft yarns adopt covered yarns formed by covering core silkthrough double strands of cotton; the covered yarns adopt zero twist or low twist; the core silk adopts 1F to 24F nylon yarns, two strands of nylon yarns with the same thickness are twisted oppositely, the degrees of twist of the two strands of nylon yarns are the same, the two strands of nylon yarns are twined to each other, and generally, the core silk adopts zero twist; the double strands of cotton used for covering are twisted around the core silk; size dyeing adopts low-temperature dyeing and the tension during size dyeing is improved; weaving adopts weft yarn non-joint weaving; finishingadopts outer covered button zero shrink finishing; the clothes are manufactured through a preset style, a template figure is coated with winter cherry for burnt discharge, the clothes are washed with70 to 100 degree water, and drying and ironing are performed. The burnt-out jeans wear is comfortable and artistic, and laces are not slipped.

Owner:张家港市隆利氨纶纱线厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com