Automatic packing system in full-component press line end and method

A technology of automatic packing and punching line, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of not being able to realize automatic packing and not considering position deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

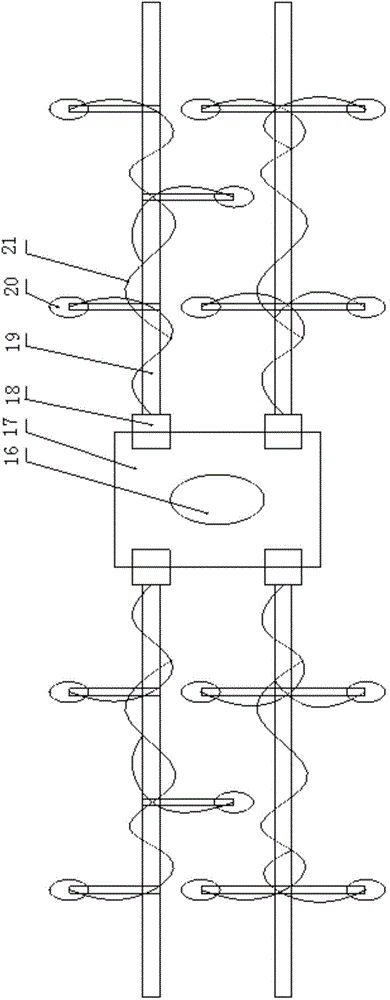

[0042] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

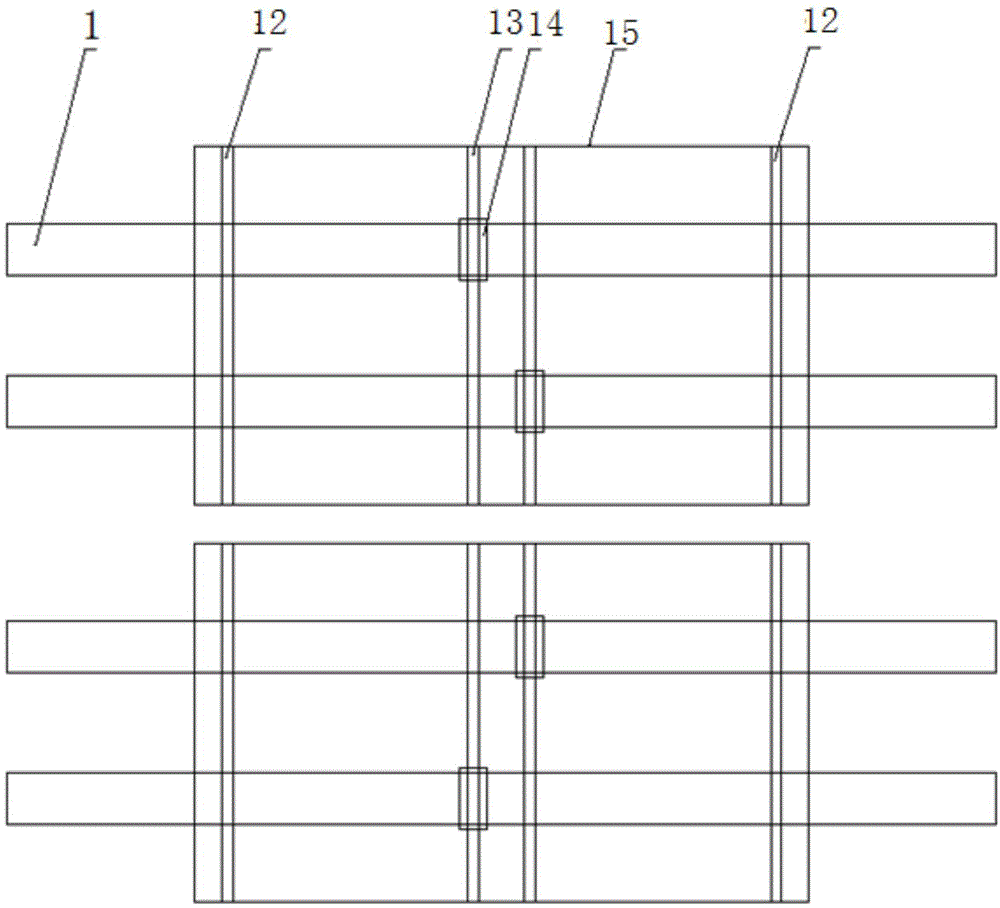

[0043] It should be understood that the number of servo synchronous belt 1, vision system, robot and material basket 7 involved in the embodiment of the present invention is only a specific implementation mode given in this embodiment, and those skilled in the art have the ability to make adjustments for each according to actual needs. The number of components can be set by itself, and the relative position of each component of the system can be adjusted according to the corresponding quantity.

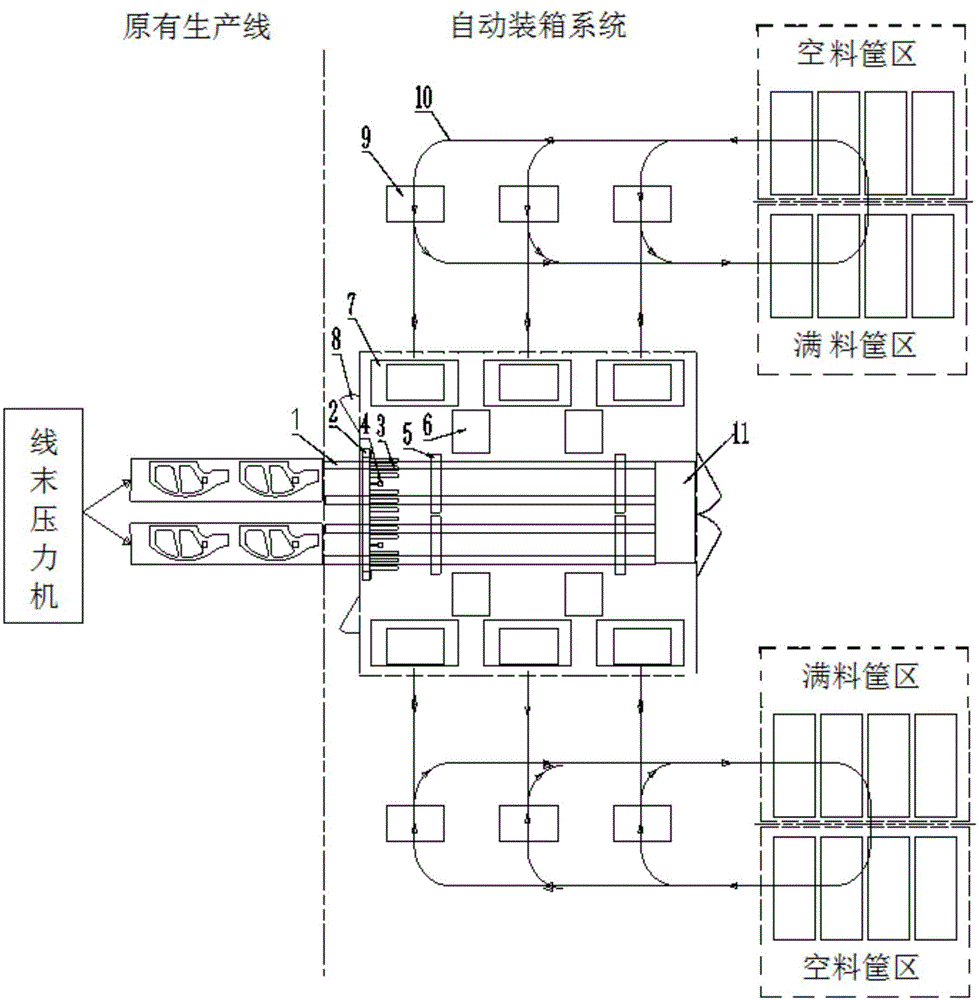

[0044] An automatic boxing system at the end of the stamping line for all parts, such as figure 1 As shown, including: servo synchronous belt system, vision system, PLC controller, robot system 6, robot controller, material basket 7, material basket replacement system and safety protection system 8;

[0045] The robot system 6 is respectively arranged at both ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com