Loading and lifting hydraulic system of semitrailer

A hydraulic system and semi-trailer technology, applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problems of heavy workload, low efficiency, increased fuel consumption, etc., achieve good road passability, improve customer Efficiency and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

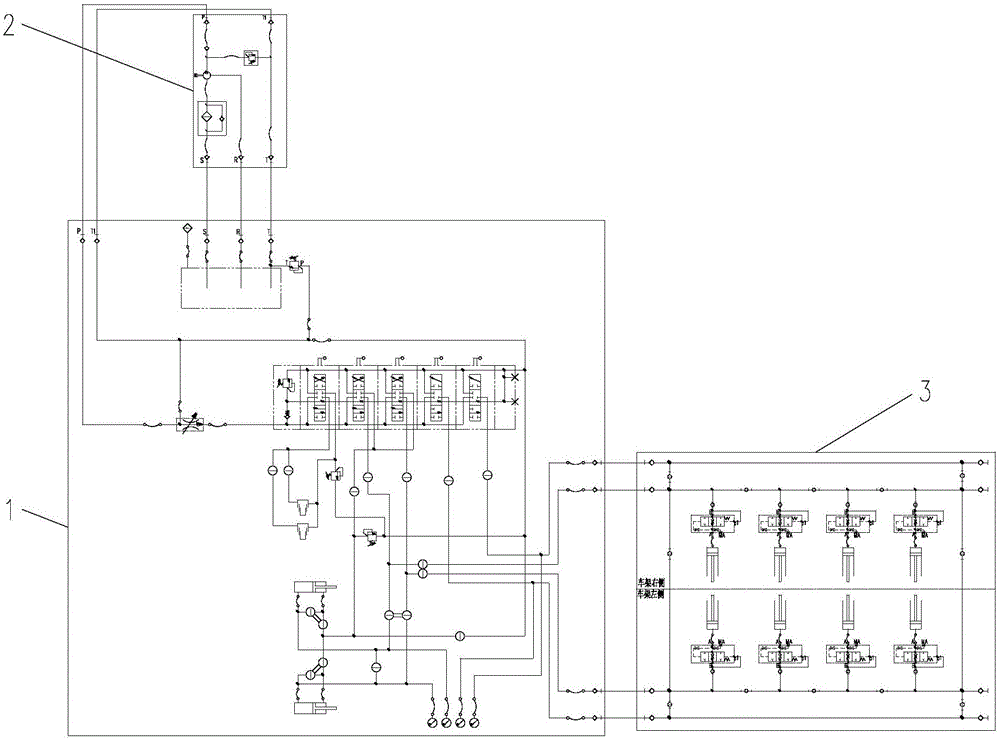

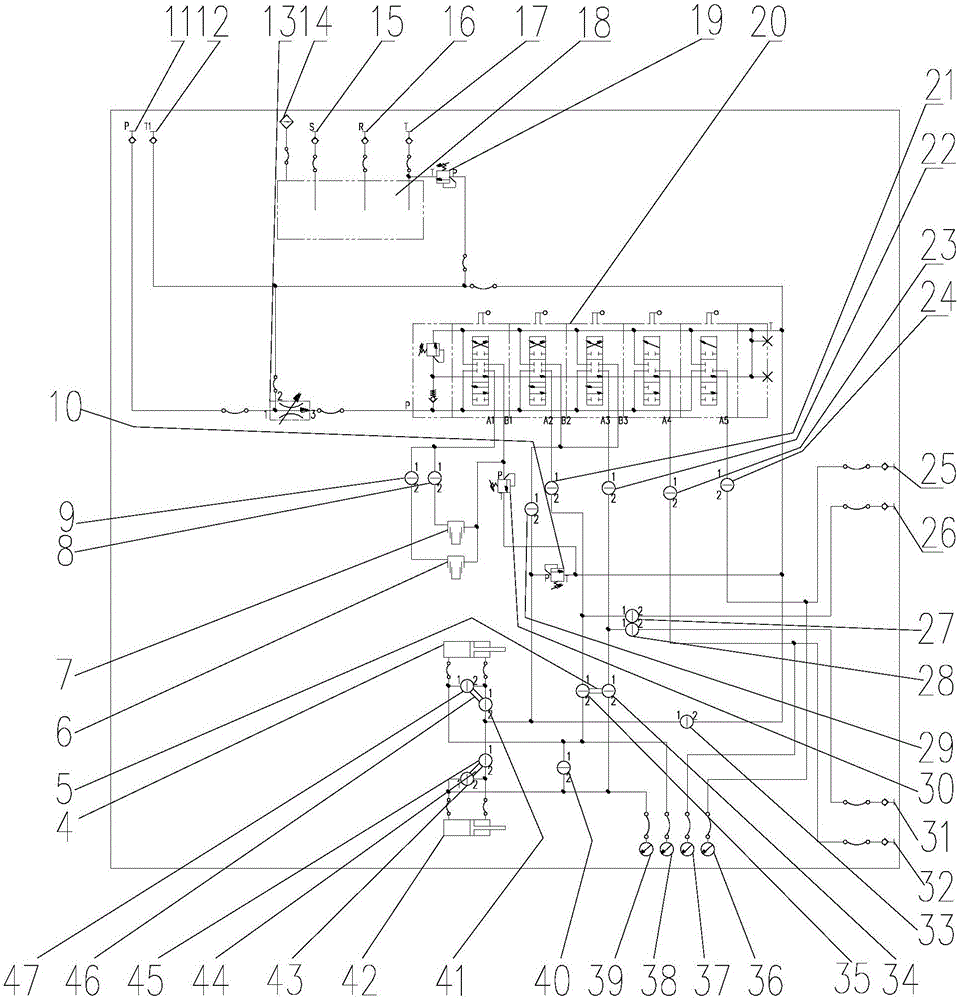

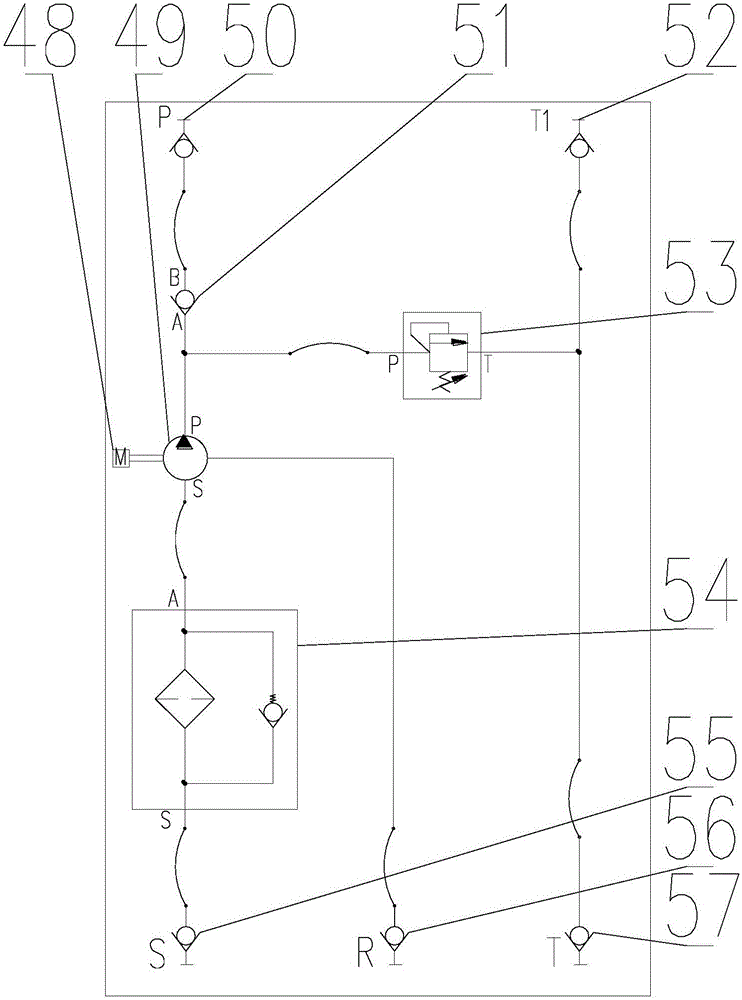

[0051] Embodiment 1: as Figure 1-4 As shown, the present invention provides a loading and lifting hydraulic system for a semi-trailer, including: a gooseneck hydraulic system 1, a power source hydraulic system 2 and a trailer hydraulic system 3; the power source hydraulic system 2 is connected to the gooseneck hydraulic system 1 for Provide the hydraulic oil required for the work of the gooseneck hydraulic system 1; the gooseneck hydraulic system 1 includes the first double-acting multi-stage cylinder 6, the second double-acting multi-stage cylinder 7, the multi-way valve 20, the first double-acting cylinder 4 and the second Two double-acting oil cylinders 42; the multi-way valve 20 is connected with the first double-acting multi-stage oil cylinder 6 and the second double-acting multi-stage oil cylinder 7, and the first double-acting multi-stage oil cylinder 6 and the second double-acting multi-stage oil cylinder 6 are realized by the multi-way valve 20 cooperating with the sw...

Embodiment 2

[0059] Embodiment 2: The semi-trailer using the loading and lifting hydraulic system of the semi-trailer of the present invention mainly has two working modes, the first mode is the adjustment mode, and the second mode is the driving mode. Before the vehicle enters driving mode, the hydraulic system is switched to adjustment mode, so that the gooseneck is connected to the tractor and the fifth wheel is loaded before driving. In the adjustment mode, it also has several other functions, one is the separation of the tractor and the gooseneck, and the other is the suspension lifting of the trailer.

[0060] When power source hydraulic system, gooseneck hydraulic system, trailer hydraulic system press figure 1 After connecting, start the engine and do not operate the multi-way valve at this time. The hydraulic oil pumped out of the hydraulic pump passes through the bridge of the multi-way valve and then directly connects to the T port and returns to the hydraulic oil tank. The whol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com