Continuous constant-volume quantitative feeding device for powder materials

A technology of a feeding device and a powder conveying device is applied in the field of 3D printing to achieve the effects of simple structure, improved accuracy and avoidance of insufficient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Exemplary embodiments, features, and performance aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

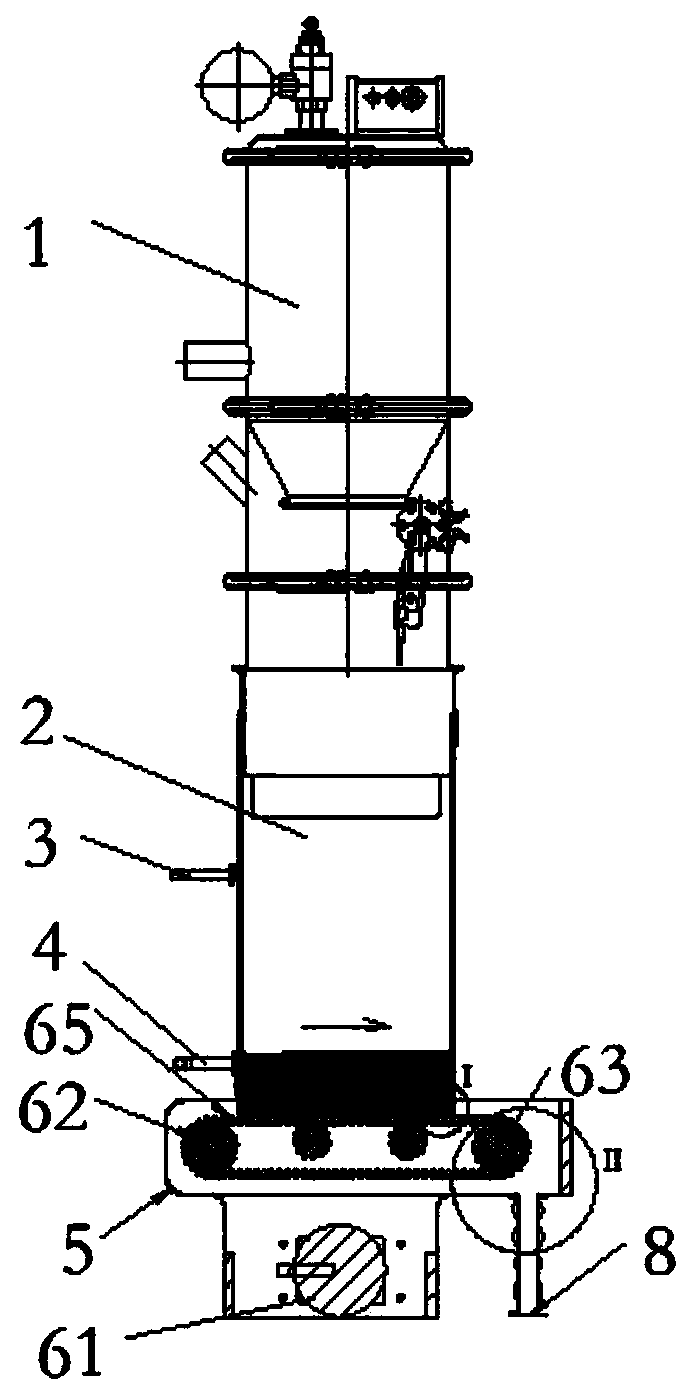

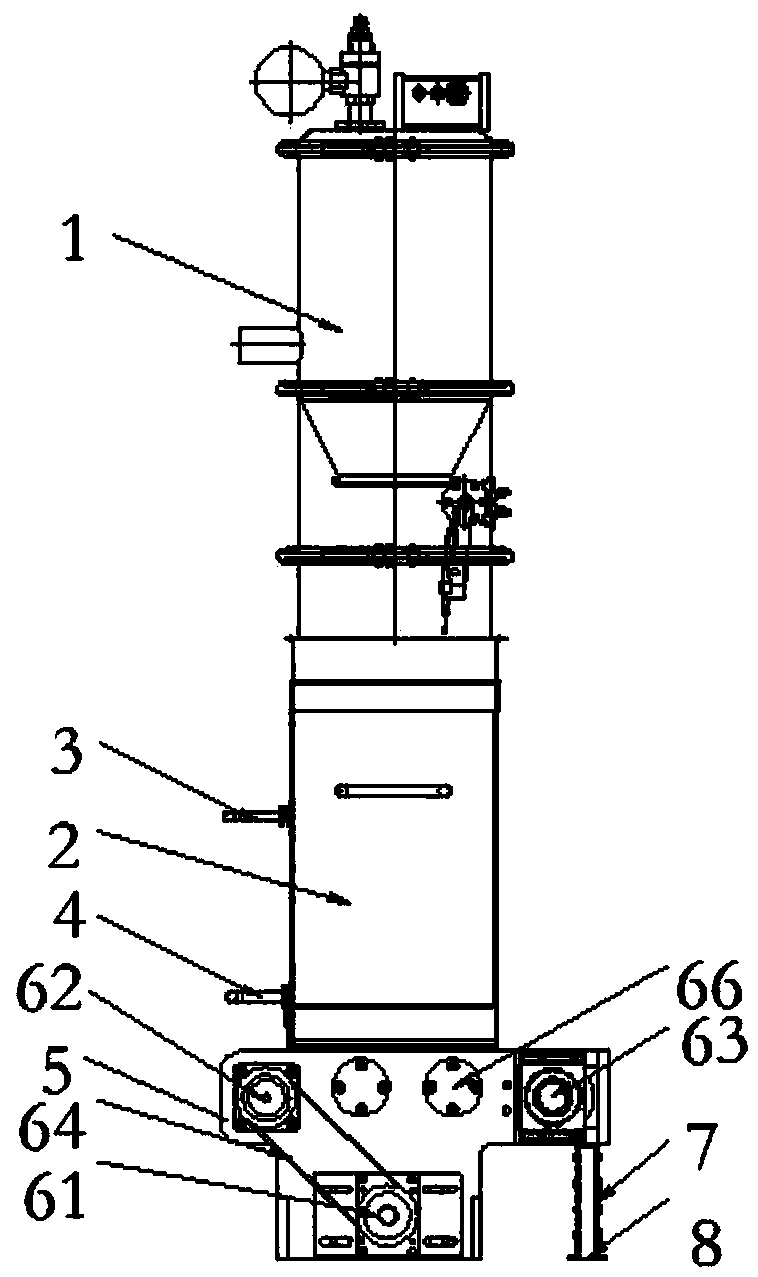

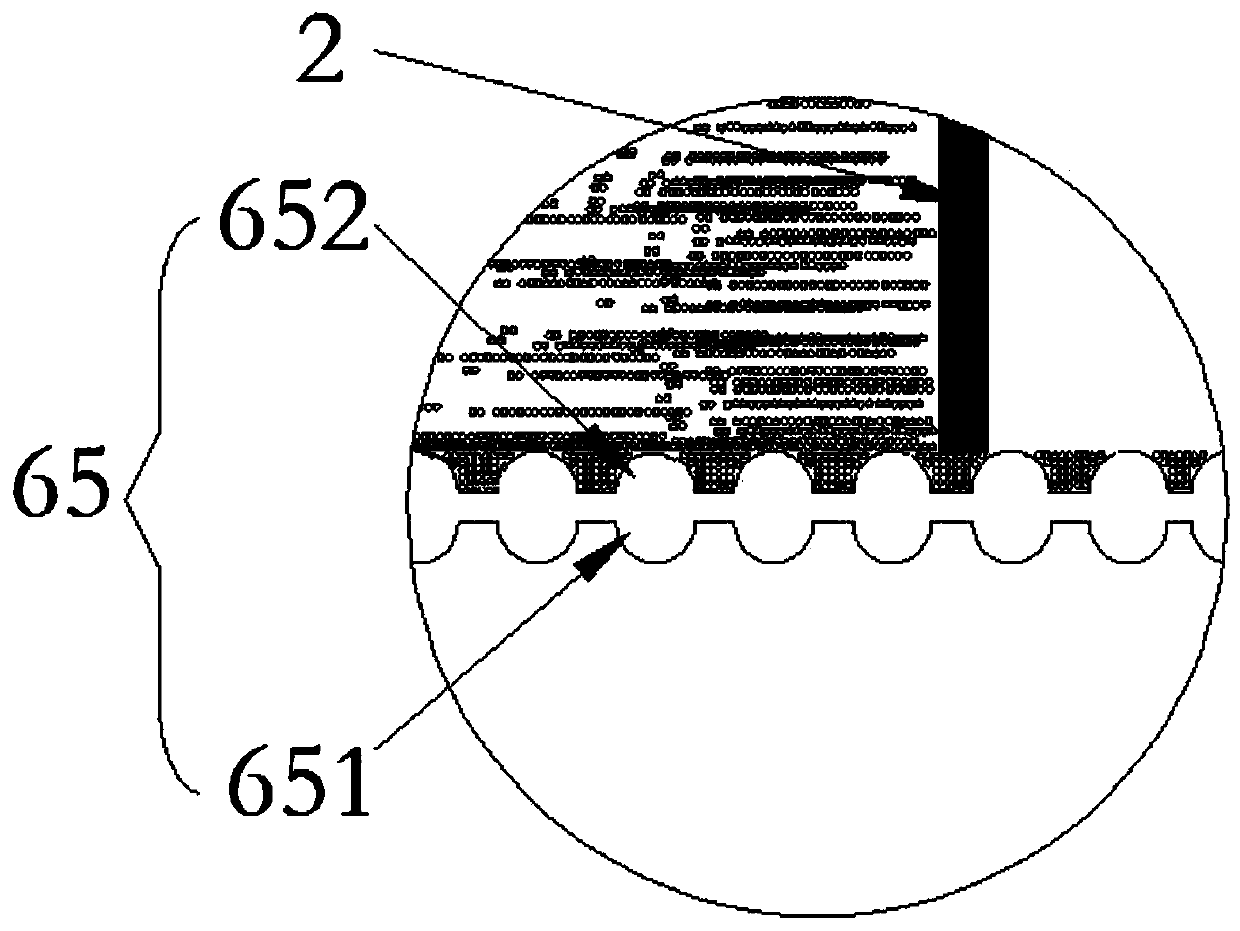

[0028] Such as figure 1 and 2 As shown, a continuous constant volume and quantitative feeding device for powder materials includes a vacuum feeder 1, a storage box 2, an upper material level sensor 3, a lower material level sensor 4, a sealed cavity 5, a powder conveying device, The multi-stage powder cleaning device 67 and the link platform 8, the vacuum feeder 1 is fixed above the storage box 2, the storage box 2 is fixed above the sealed cavity 5, the storage box 2 is connected with the sealed cavity 5, and the powder is transported The device is accommodated in the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com