Marine wind power blade carbon fiber automatic forming equipment and laying process method

An automatic forming, offshore wind power technology, applied in the field of wind power generation equipment, can solve the problem of less research on the process, achieve the effect of smooth and even laying, and improve the quality of wire laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

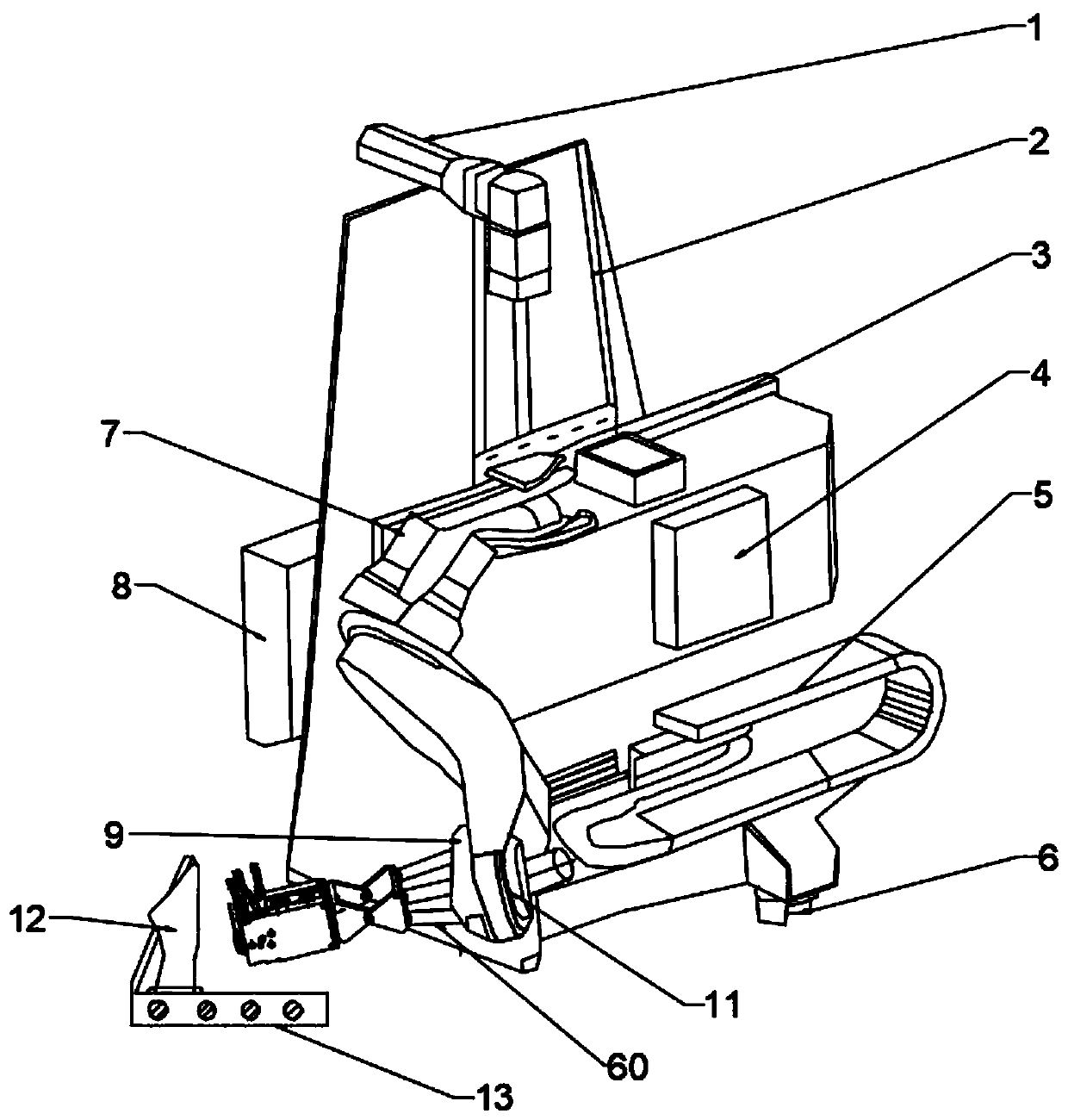

[0045] Example: such as figure 1 As shown, in the motion platform in the present invention, it mainly consists of a hydraulic drive device 1, motion guide rails 2, 3, a control panel 4, a motion crawler belt 5, a support device 6, a connecting cable 7, a motion control cabinet 8, and a multi-axis conversion Device 9 , wire laying mechanism 10 , clamping device 11 , wind power blade positioning device 13 , wind power blade 12 .

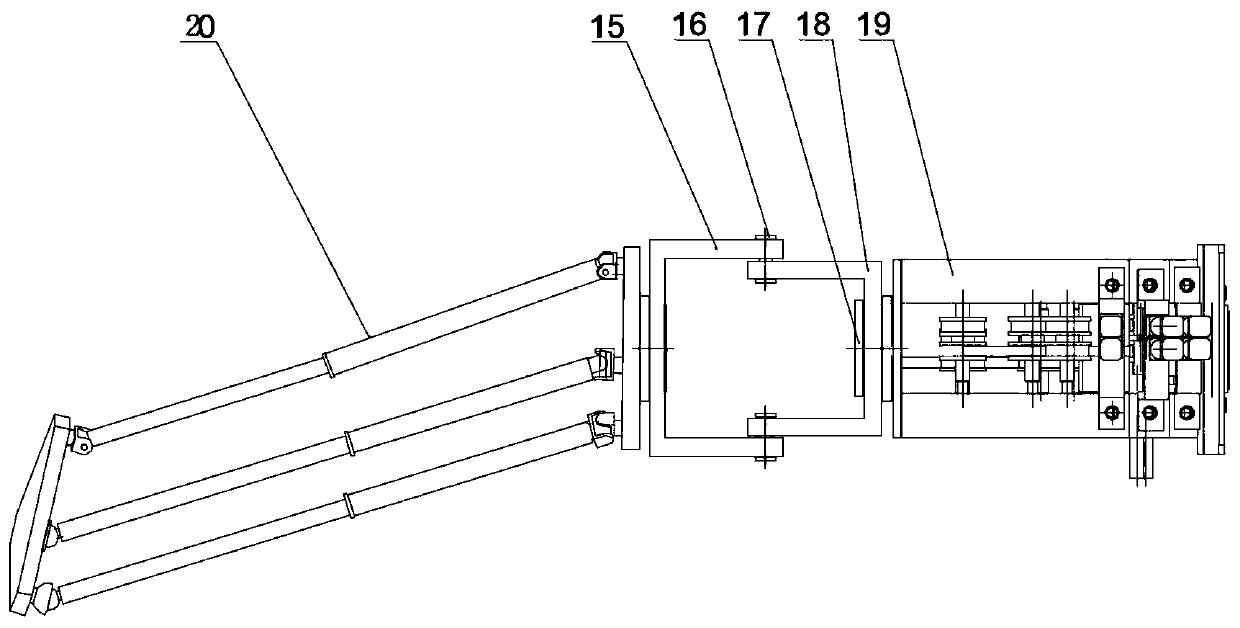

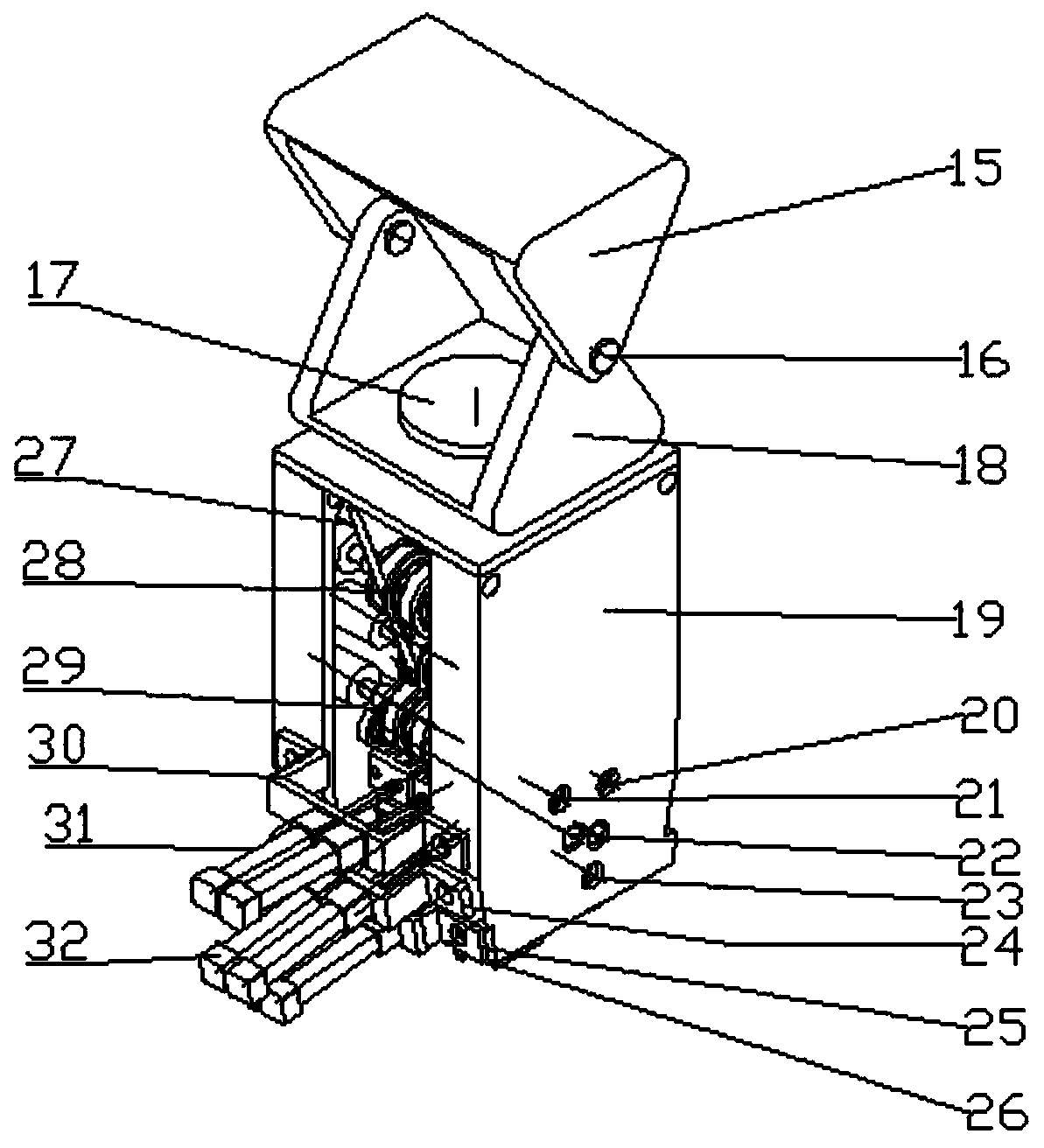

[0046] In this example, if figure 2 As shown in the design of the three-degree-of-freedom laying mechanism, the upper end is used to connect the three-degree-of-freedom movement, which is used to connect the motion platform and the three-axis adjustable control mechanism. The lower end connecting device is connected by 16 bolts in the middle, and the two connecting devices 15 and 18 are connected, the fixed shaft 17 connects the load-bearing frame 19 of the laying equipment, and the bolt 16 connects the load-bearing frames 19 on both sides together t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com