Coir mat conveyor

A technology of conveying equipment and palm pads, applied in the field of palm pad conveying equipment, can solve the problems of high cost of conveyor belts, inconvenience to convey palm pads, low friction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

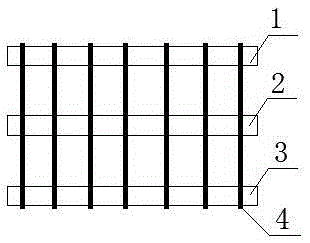

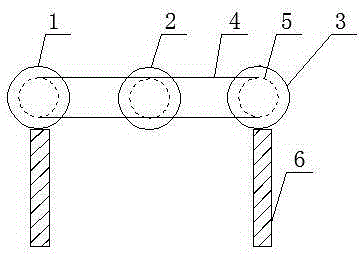

[0015] Such as figure 1 , figure 2 The palm mat conveying equipment shown includes a base frame 6, a driving shaft 1, an auxiliary support shaft 2, a driven shaft 3, a driving device, and a rope 4; the bottom of the base frame 6 is fixed on the ground, and the base frame 6 is used to place Drive shaft 1, auxiliary support shaft 2, driven shaft 3, a guide rail is set on the base frame 6 for placing bearings; the drive shaft 1 and base frame 6 are connected by bearings, and the bearings are placed in the base frame guide rail, and Fix the bearing bracket on the base frame 6; the driven shaft 3 is connected with the base frame 6 by bearings, the bearing is placed in the base frame guide rail, and the bearing bracket and the guide rail are connected by bolts; the driving shaft 1, auxiliary support shaft 2. The driven shaft 3 is provided with an annular groove 5 at the same position, and the surface of the annular groove 5 is rough, and the rope 4 is set in the annular groove 5 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com