Detachable assembled shear wall structure with replaceable component and assembling method

A shear wall and prefabricated technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of inability to disassemble the structural system, affect the seismic performance of the structural system, and complicate the structure of the connecting nodes, so as to improve the seismic performance of the structure , The force transmission path is clear and the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

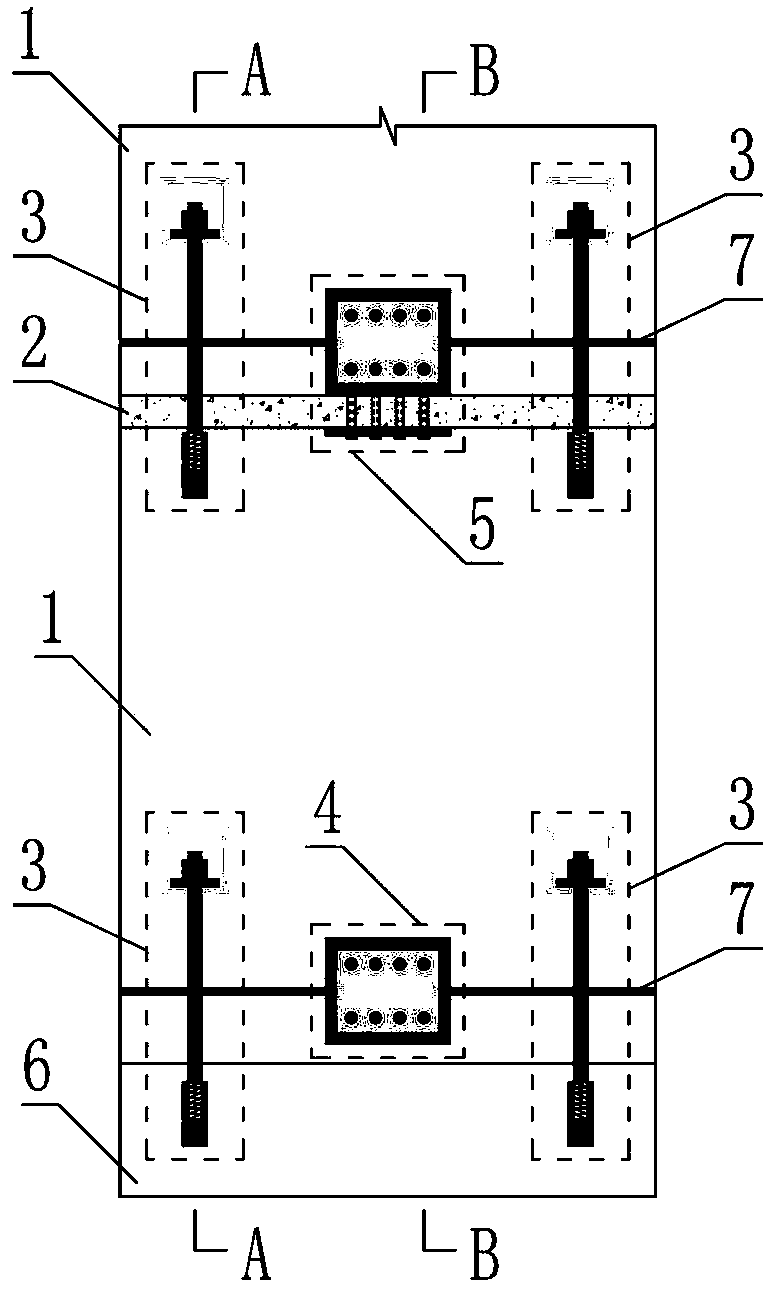

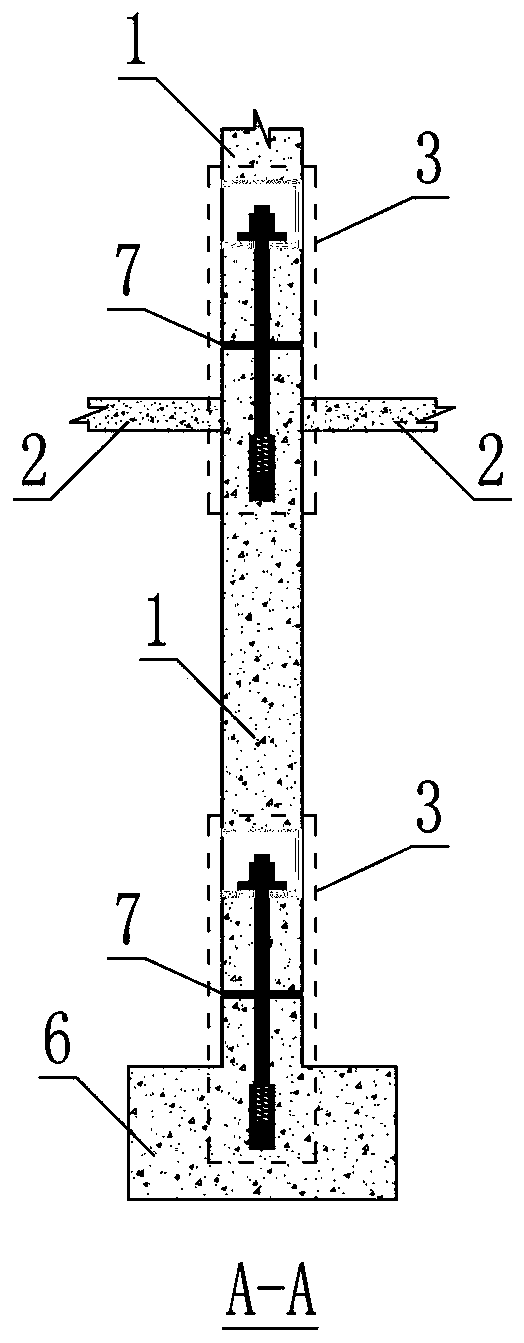

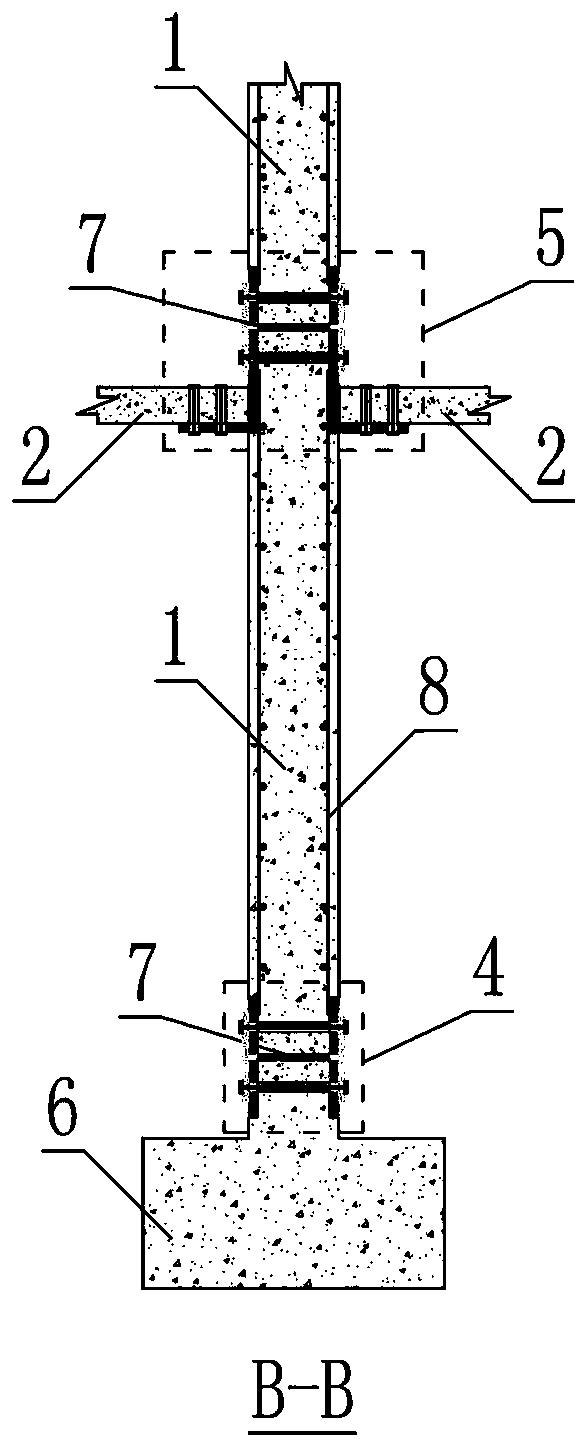

[0035] Such as Figure 1-9 As shown, the present invention provides a detachably assembled shear wall structure with replaceable components. It is used for the connection between the prefabricated shear wall 1 and the foundation 6, and between the upper and lower prefabricated shear walls 1 through replaceable components. The connection between the prefabricated shear wall 1 and the prefabricated floor 2 is completed by ordinary bolts 18.

[0036]Each replaceable component and construction in the aforementioned detachable assembled shear wall horizontal seam bolt connection method can be prefabricated in the factory, and then installed after being transported to the site. The prefabricated shear wall 1 is a reinforced concrete shear wall industrially manufactured and produced by a prefabricated factory. Prefabricated floor slab 2 is the reinforced concrete floor slab that prefabricated factory industrialization makes and produces. The replaceable components are divided into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com