Climbing tool for maintaining power transmission tower pole fork beam

A transmission tower and pole fork technology, which is applied in the field of climbing tools, can solve problems such as actual operation hazards, difficulties in overhauling tools and anti-corrosion materials, and inconvenient maintenance of cement poles, so as to ensure safe production, fast and convenient installation and disassembly, and improve labor efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

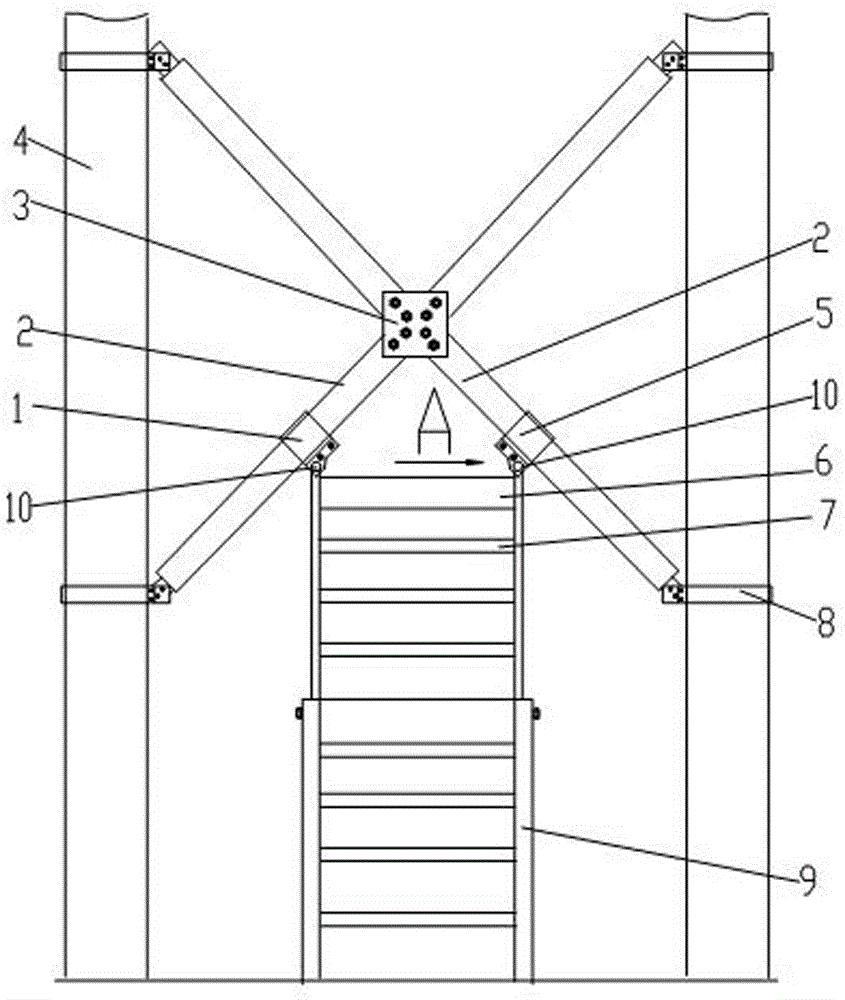

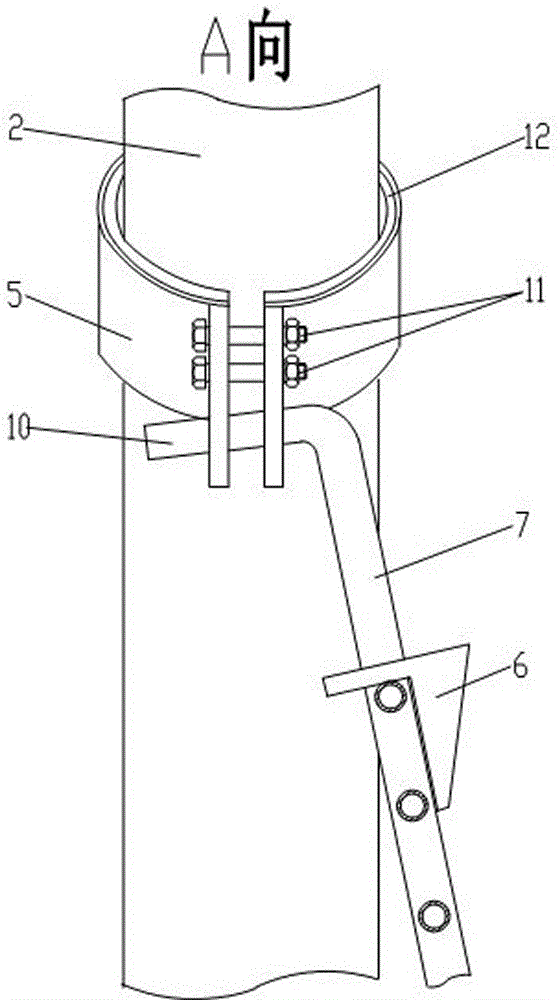

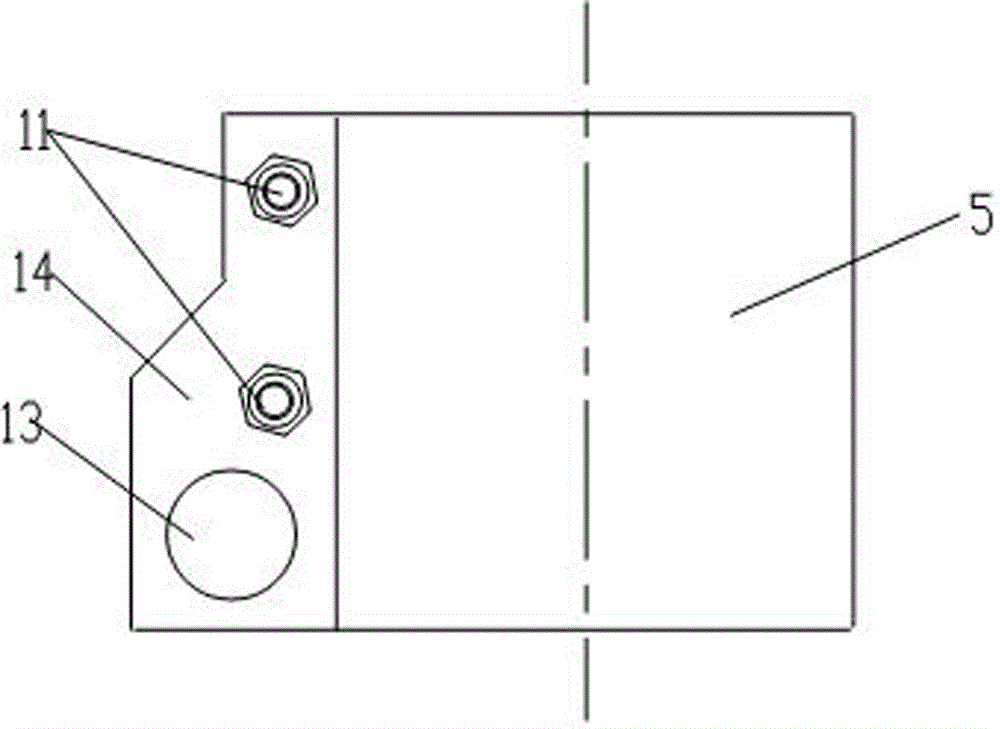

[0017] Embodiment 1: A climbing tool for checking and repairing the fork beam of a power transmission tower, including a symmetrical left hoop 1, a right hoop 5 and a ladder 7; the inner wall of the hoop of the right hoop 5 is provided with an inner lining layer 12, The inner lining layer 12 is made of flexible material, and the lower part of the bolt fastening plate 14 of the right hoop 5 is provided with a through hole 13, and the left hoop 1 and the right hoop 5 are symmetrically installed on the fork beam 2 of the transmission tower pole through bolts 11 And friction-slidingly fit with the fork beam 2 of the transmission tower pole; the upper end of the ladder 7 is provided with two hooks 10, and the two hooks 10 are respectively hung in the through holes 13 of the left hoop 1 and the right hoop 5. A foot platform 6 capable of standing is provided on the top of the ladder 7 . The ladder 7 is an up and down pull-out ladder. The material of the inner lining layer 12 is felt...

Embodiment 2

[0018] Embodiment 2: A climbing tool for checking and repairing the fork beam of a power transmission tower, including a symmetrical left hoop 1, a right hoop 5 and a ladder 7; the inner wall of the hoop of the right hoop 5 is provided with an inner lining layer 12, The inner lining layer 12 is made of flexible material, and the lower part of the bolt fastening plate 14 of the right hoop 5 is provided with a through hole 13, and the left hoop 1 and the right hoop 5 are symmetrically installed on the fork beam 2 of the transmission tower pole through bolts 11 And friction-slidingly fit with the fork beam 2 of the transmission tower pole; the upper end of the ladder 7 is provided with two hooks 10, and the two hooks 10 are respectively hung in the through holes 13 of the left hoop 1 and the right hoop 5. A foot platform 6 capable of standing is provided on the top of the ladder 7 . The ladder 7 is a folding ladder. The material of the inner lining layer 12 is rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com