Patents

Literature

100results about How to "Improve stress environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

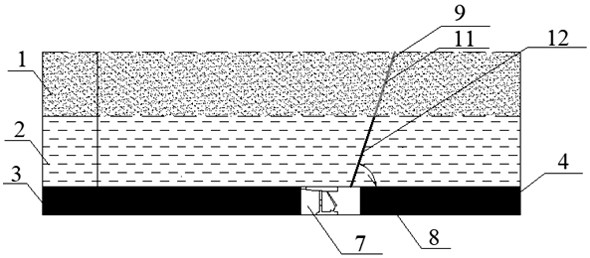

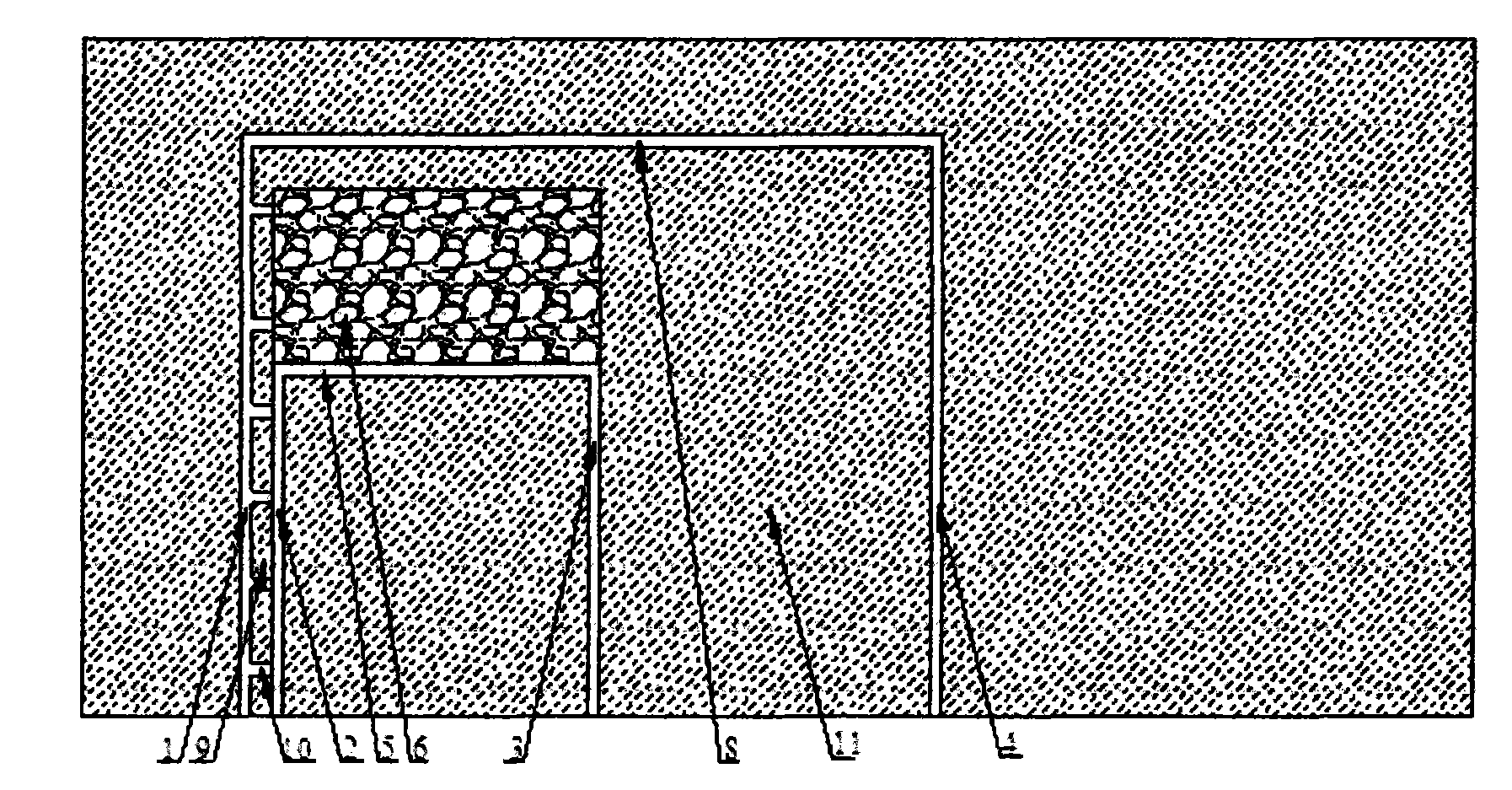

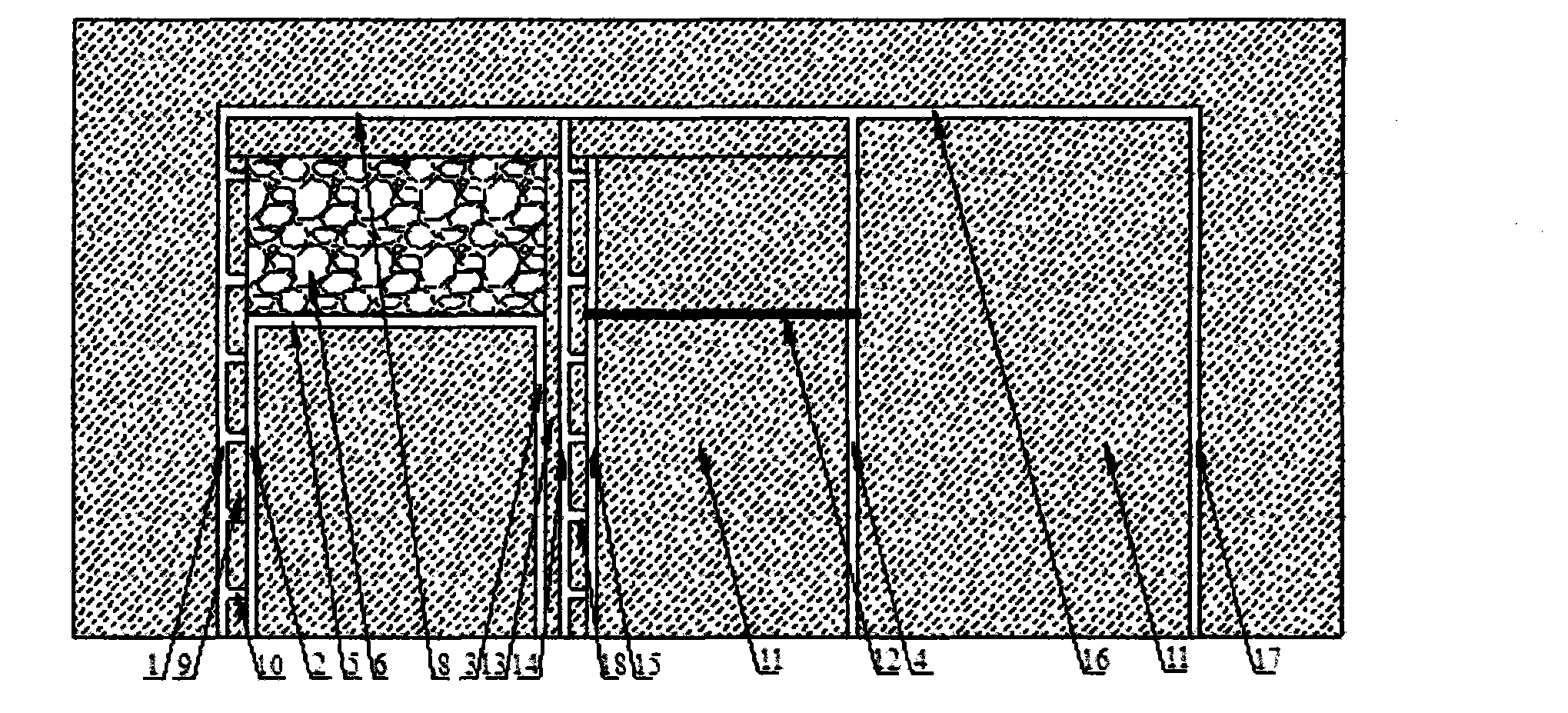

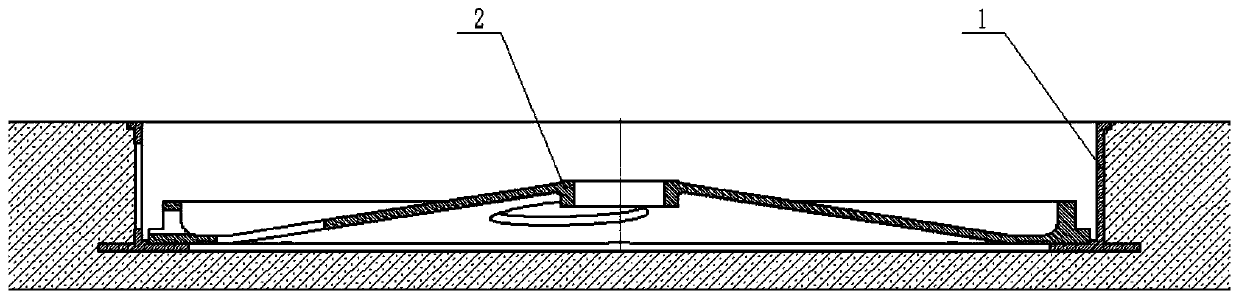

Ground fissure tunnel asphalt concrete composite lining and supporting method thereof

InactiveCN101737063AImprove stress environmentSimple structureUnderground chambersTunnel liningAsphalt masticHot melt

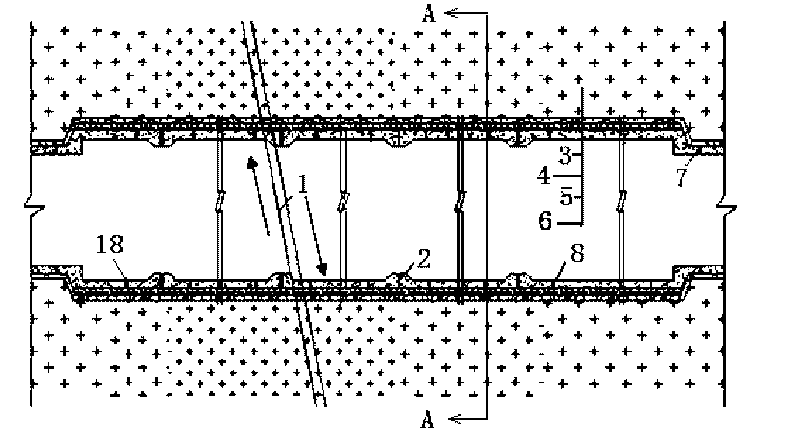

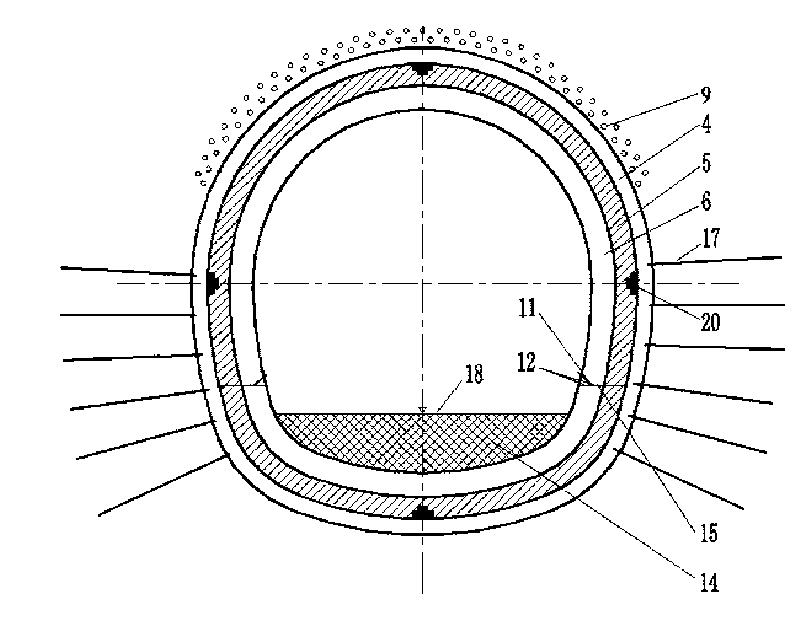

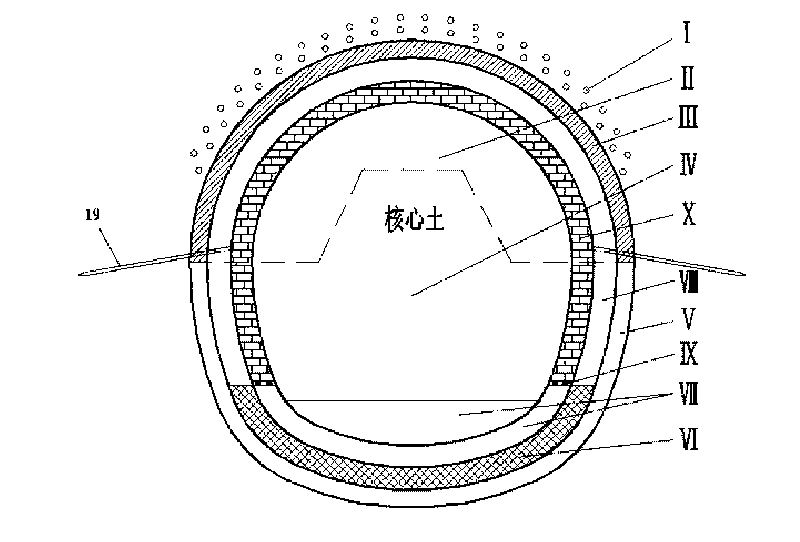

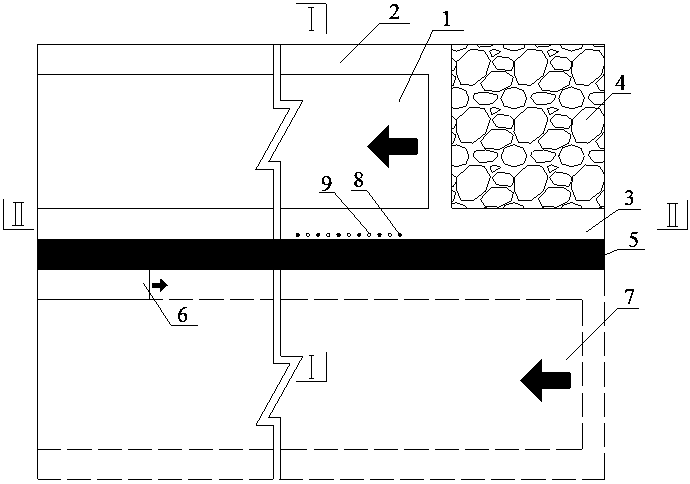

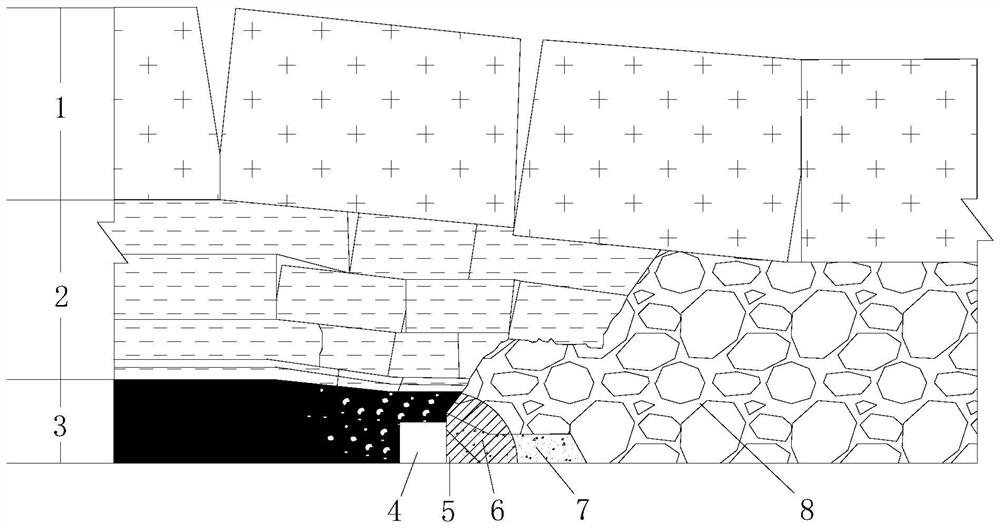

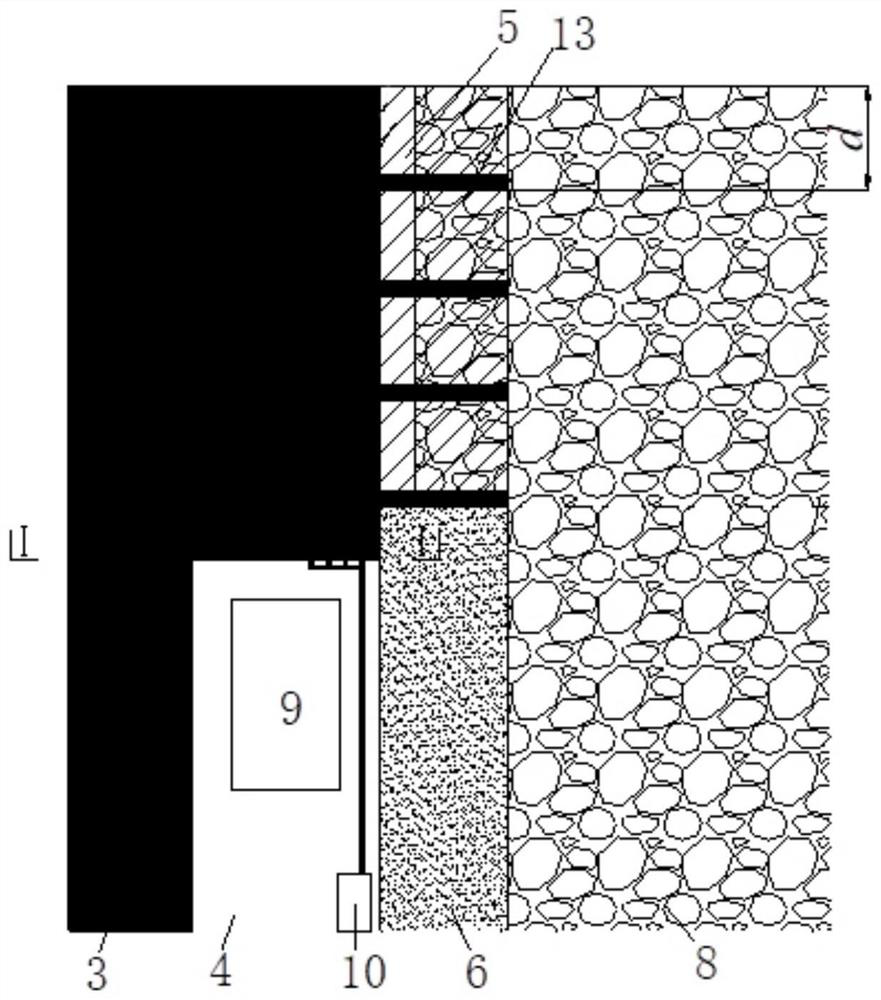

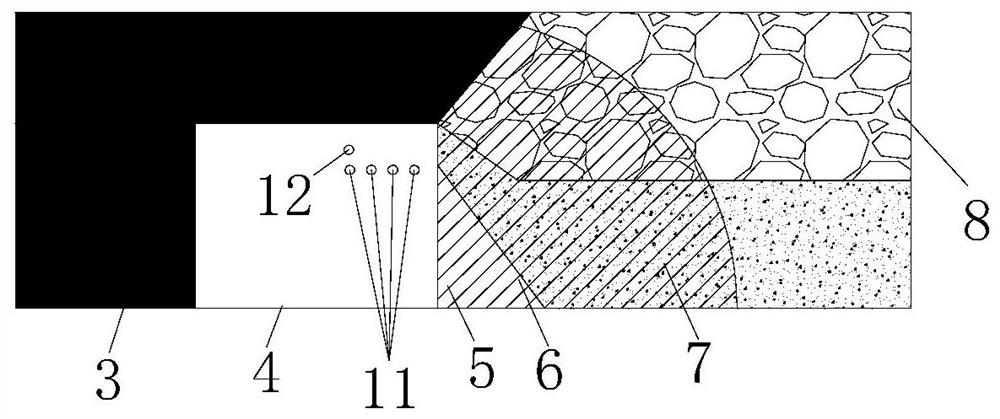

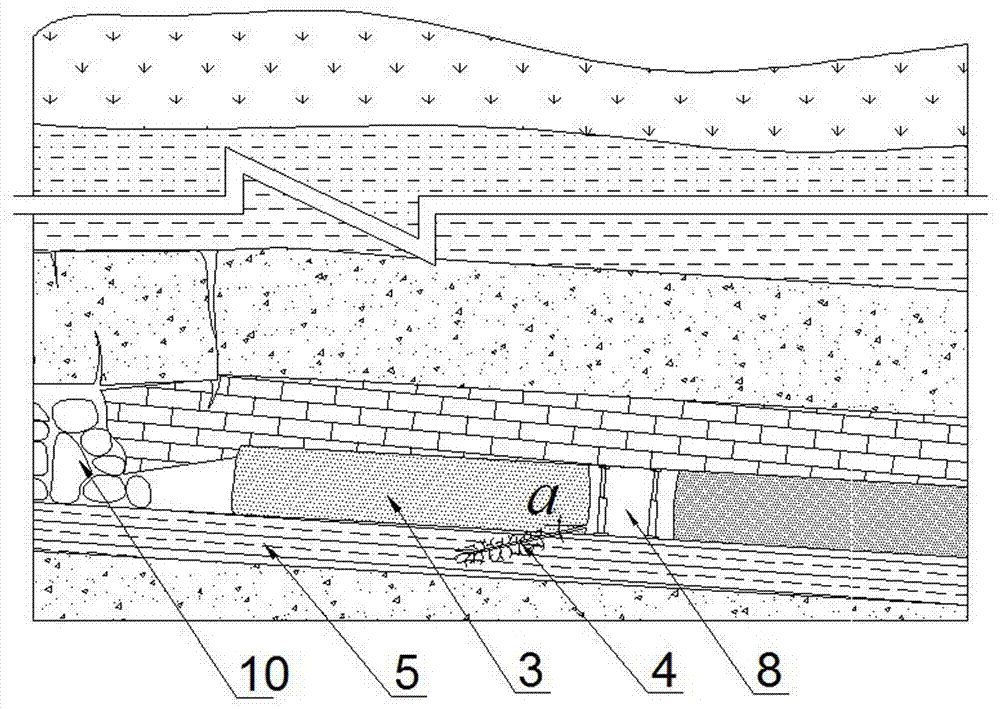

The invention discloses a ground fissure tunnel asphalt concrete composite lining, wherein an initial lining, an asphalt concrete composite lining and an inside lining are sequentially arranged in an influence interval of a ground fissure from a surrounding rock soil body to a tunnel axial center, deformation joints A are arranged on the inside lining at intervals along a tunnel axis, injected holes are reserved at the bottom of the inside lining at both sides of the deformation joints A, and a displacement monitor is installed at the outer side of the asphalt concrete composite lining. The invention also discloses a supporting method of the ground fissure tunnel asphalt concrete composite lining, and an asphalt concrete pouring material is prepared by mixing modified asphalt after hot melting with sand and stones by adopting a stepped excavation and mining construction method; an asphalt mastic material is filled in the deformation joints A to flexibly connect the two adjacent segments of inside linings and carry out waterproof processing and the like for construction joints at the section of the inside lining. The composite lining has simple structure, convenient construction, safety and reliability and is suitable for being used in ground fissure active regions or meizoseismal regions.

Owner:XIAN UNIV OF TECH

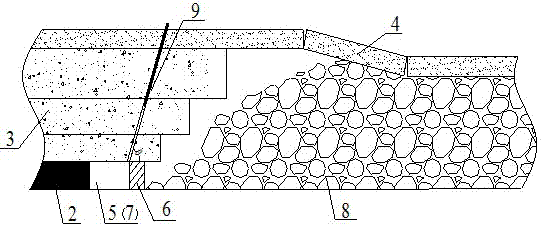

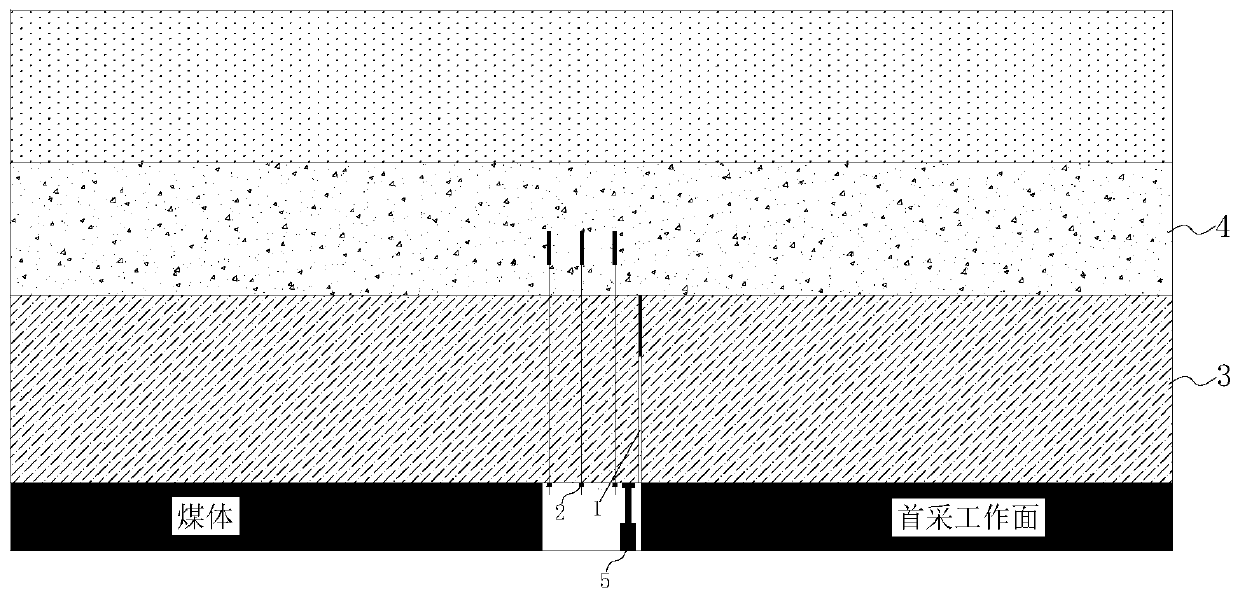

Method of roof cutting pressure relief of narrow coal pillar gob side through static bursting for gob-side entry driving

ActiveCN107701188AEliminate dynamic pressure effectsAlleviate connection tensionUnderground miningSurface miningBurstingEngineering

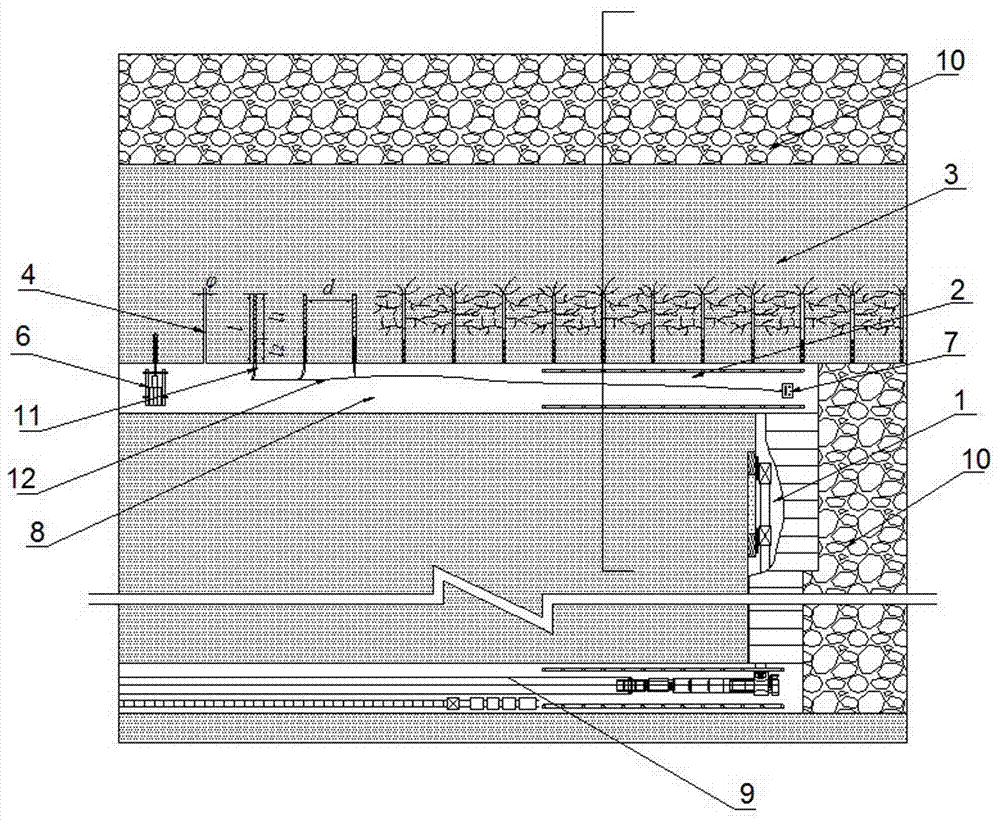

The invention discloses a method of roof cutting pressure relief of the narrow coal pillar gob side through static bursting for gob-side entry driving. According to the method, firstly, the drilling position and drilling relevant parameters of the separation distance, the diameter, the angle and the depth are determined; secondly, drilling construction and hole sealing operation are conducted; thirdly, slurry grouting of a static bursting agent is conducted, and roof cutting pressure relief is conducted through static bursting; and fourthly, gob-side entry driving is conducted. According to the method, recovery of an upper section working face and forward groove driving of a lower section working face are conducted simultaneously, and the problem of intense linkage of mine excavation is effectively relieved; and after entry-side roof cutting pressure relief, the stress environment of gob-side entry driving surrounding rock is greatly improved, surrounding rock deformation is greatly reduced in the entry driving process and after entry forming, the engineering quantity of entry supporting is small, and the repair rate is low.

Owner:TAIYUAN UNIV OF TECH

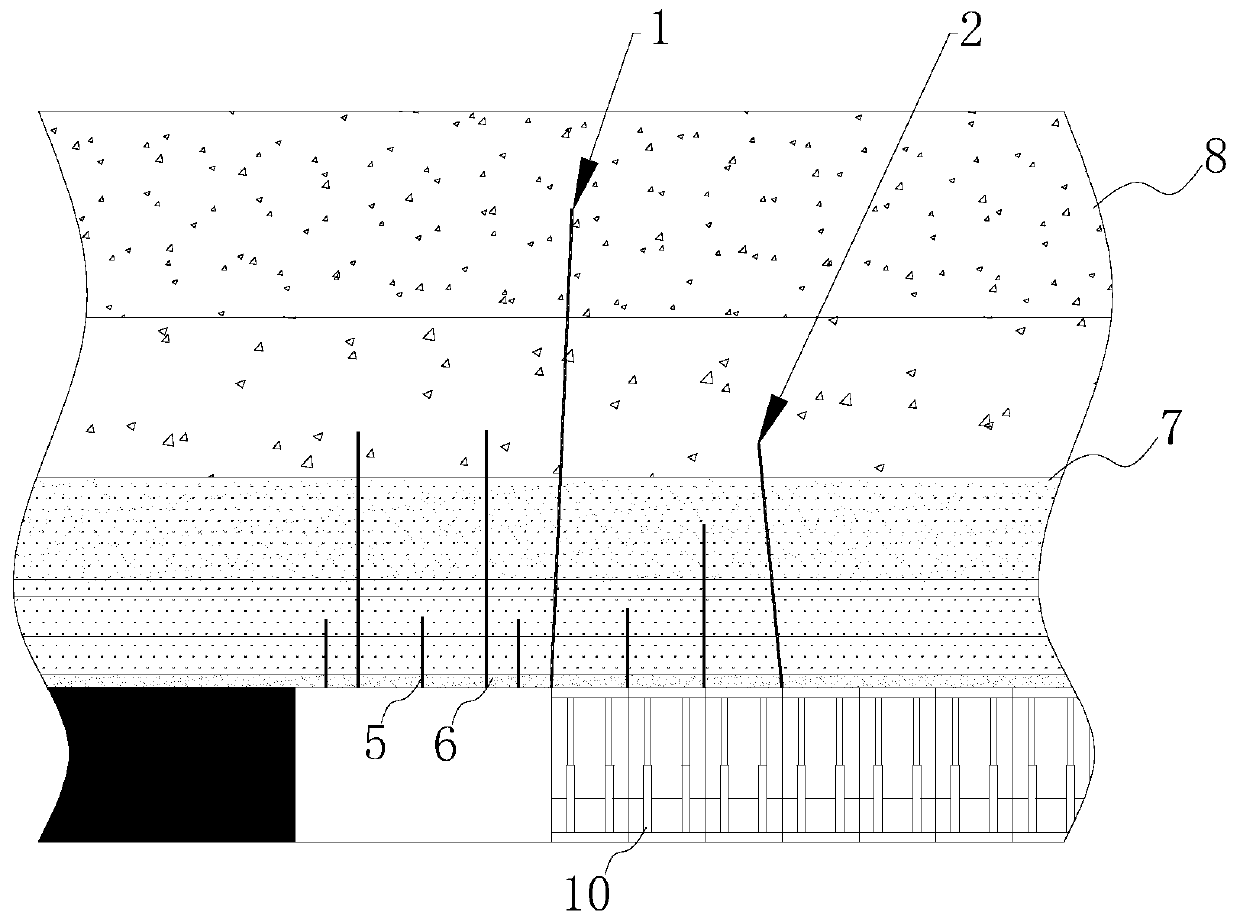

Static breaking roof cutting and pressure releasing method for gob-side retained roadway

InactiveCN107035370AFull collapseImprove stress environmentUnderground miningBlastingStress concentrationPunching

A static breaking roof cutting and pressure releasing method for a gob-side retained roadway comprises the steps that the roof cutting position is selected; the intervals, diameters, angles and depths of drilled holes are determined; drilling construction and charging are conducted; the dosage of static blasting agents is calculated; and punching, charging and hole sealing serve as one time of roof cutting and pressure releasing working circulation and are conducted circularly. Roof cutting and pressure releasing construction is conducted in the retained roadway on the rear portion of the working surface, so that the working procedures of punching, charging, hole sealing and the like, working surface stoping and manual wall building do not interfere with one another, and smooth conducting of roof cutting and pressure releasing is facilitated; and roof cutting beside the roadway is achieved before retained roadway surrounding rock deforms to destroy a suspending roof structure of the retained roadway gob side, so that a suspending roof beside the roadway fully collapses, the stress environment is improved, and the purpose of reducing stress concentration and mining pressure of a roof on the side of the gob-side retained roadway is achieved.

Owner:TAIYUAN UNIV OF TECH

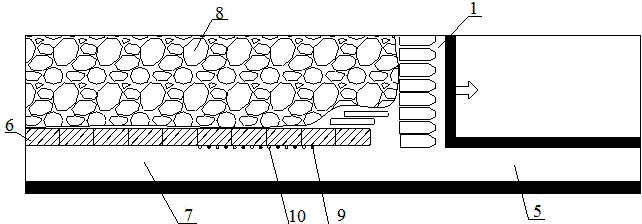

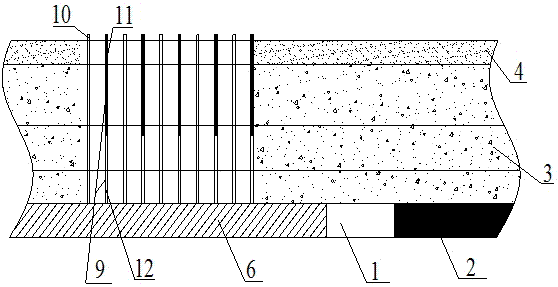

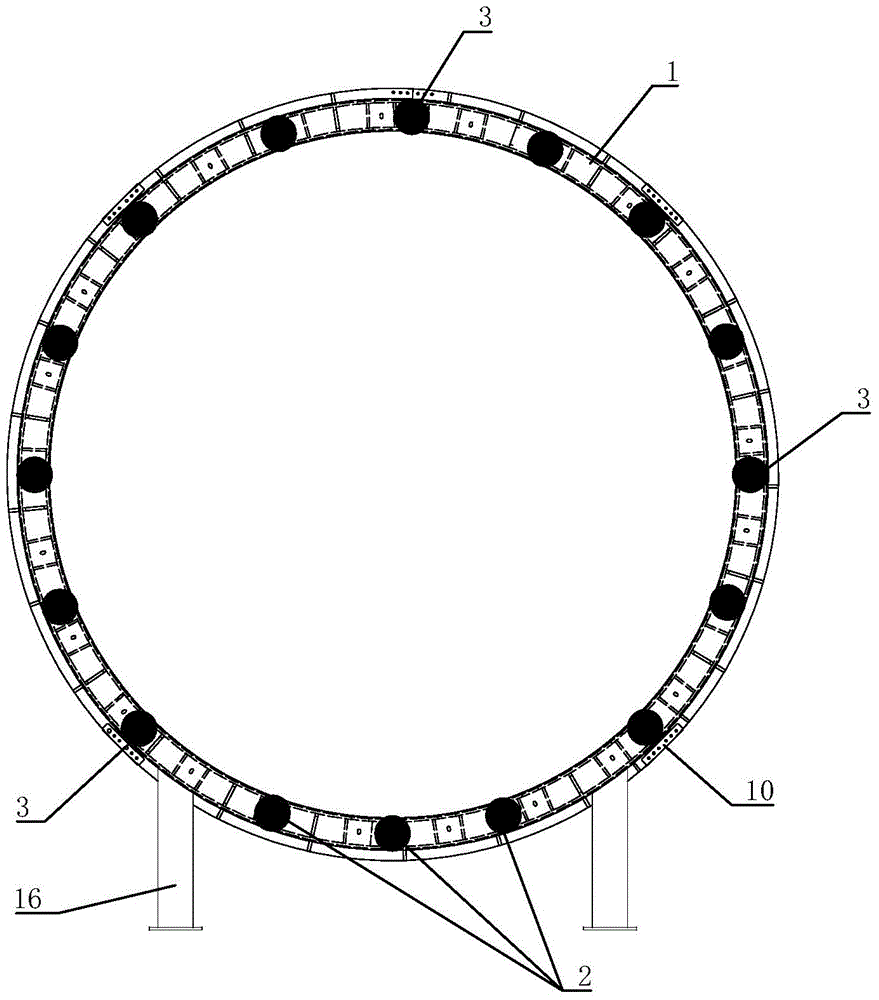

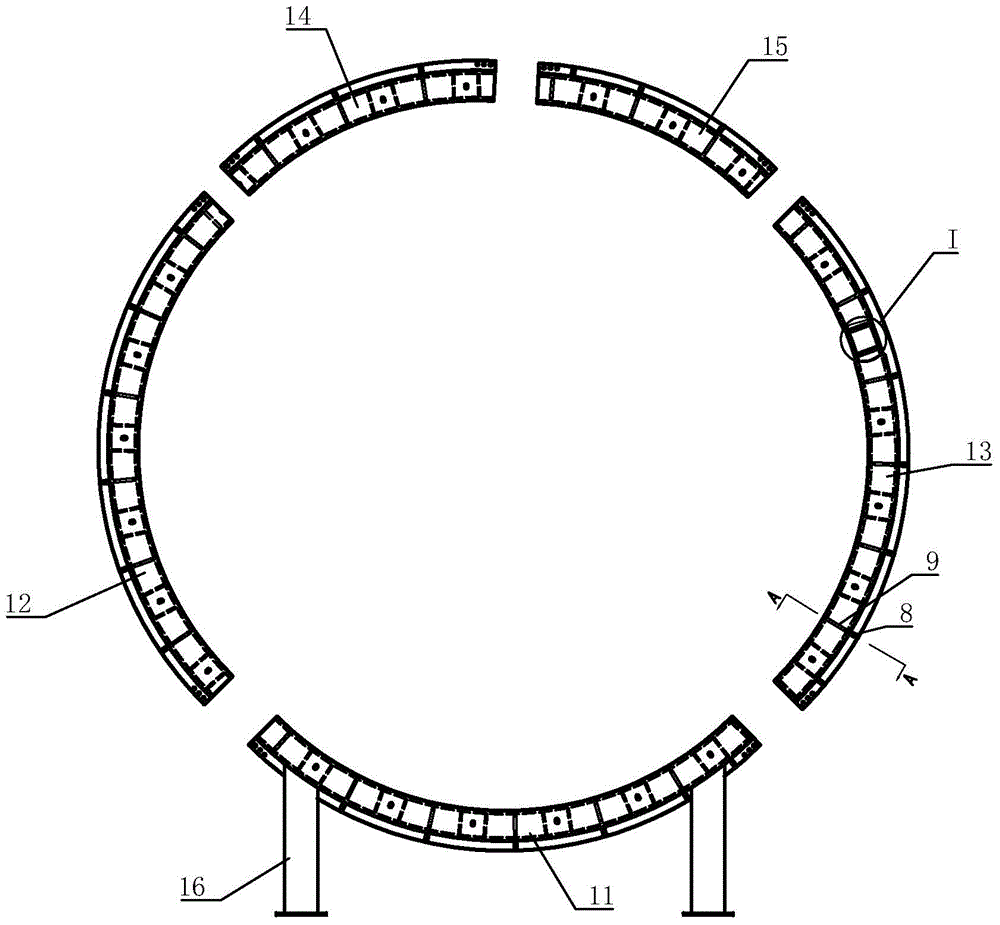

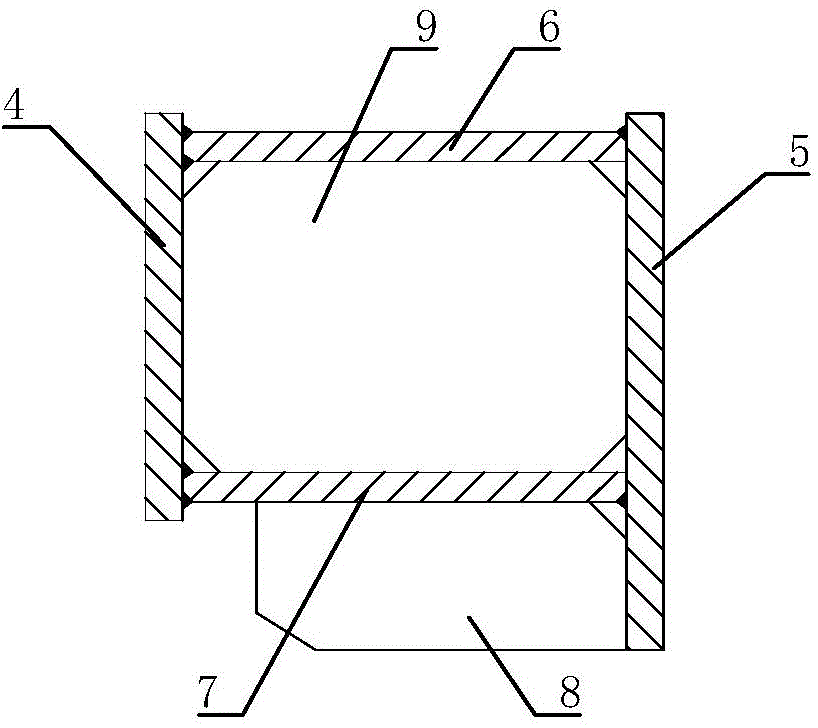

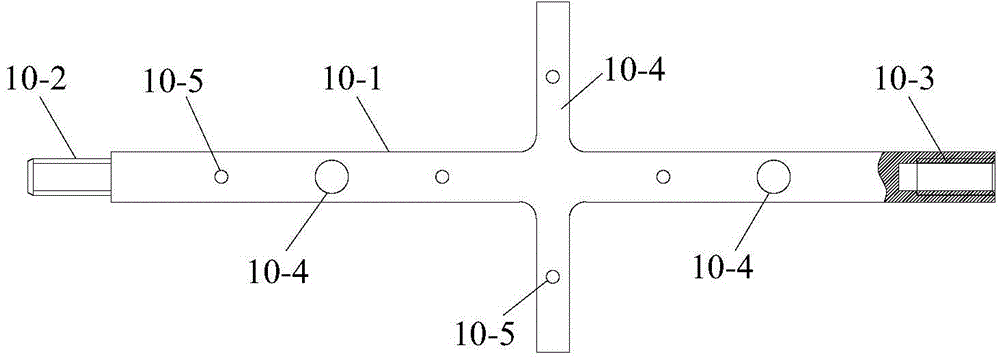

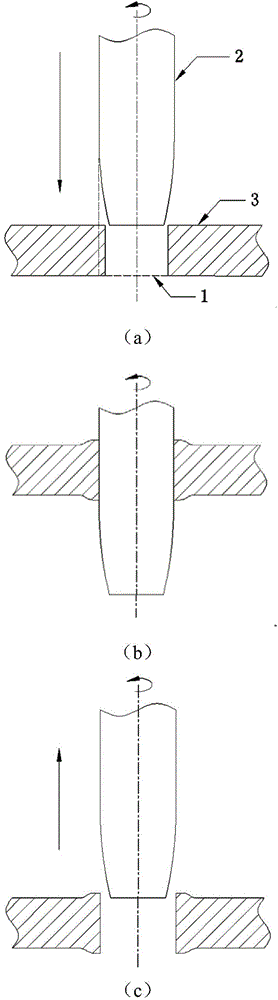

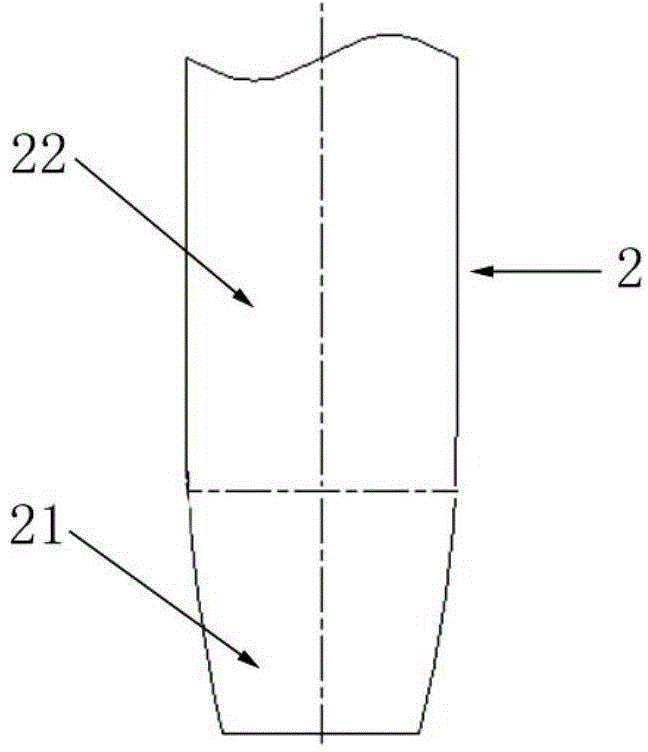

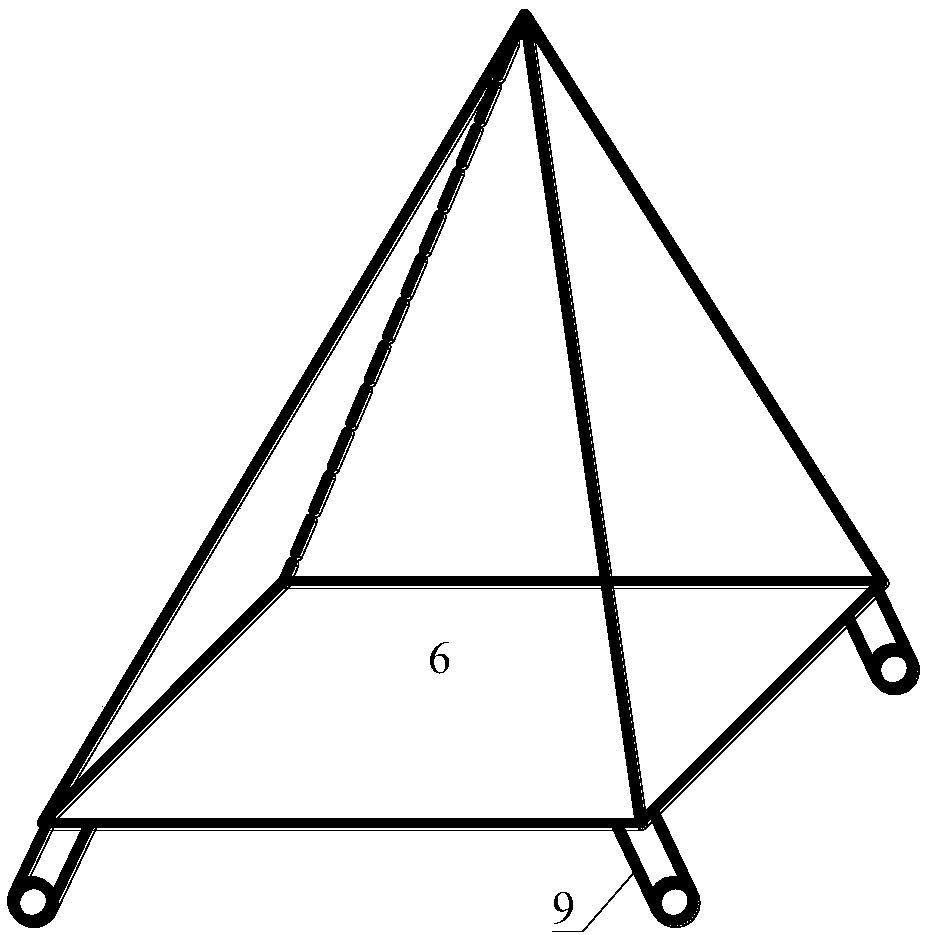

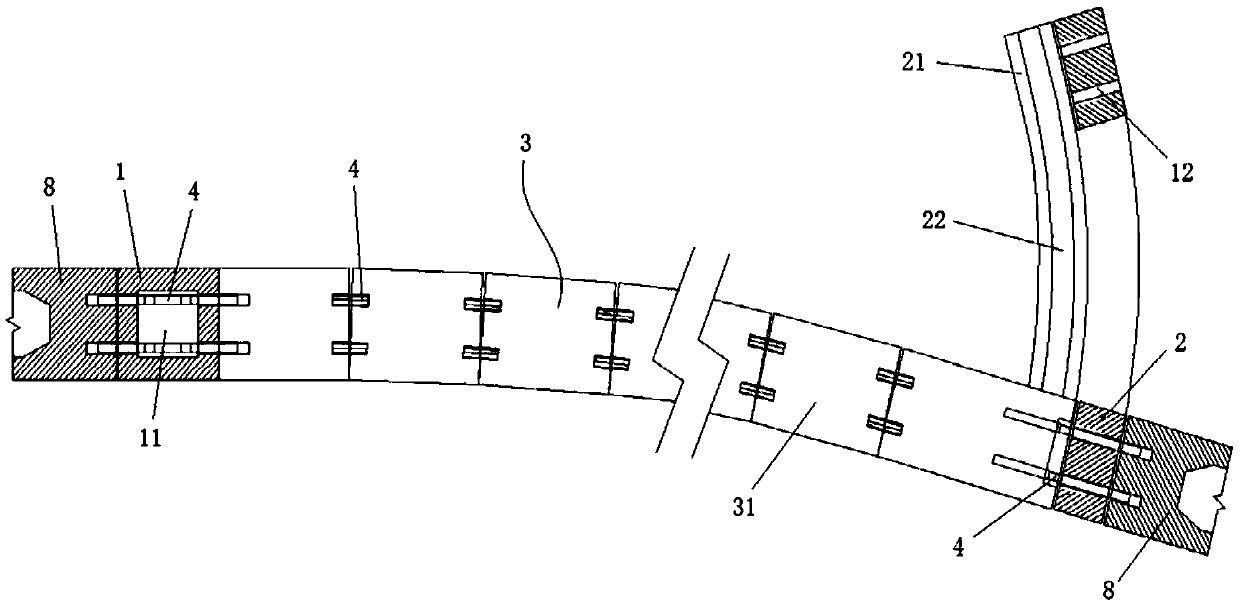

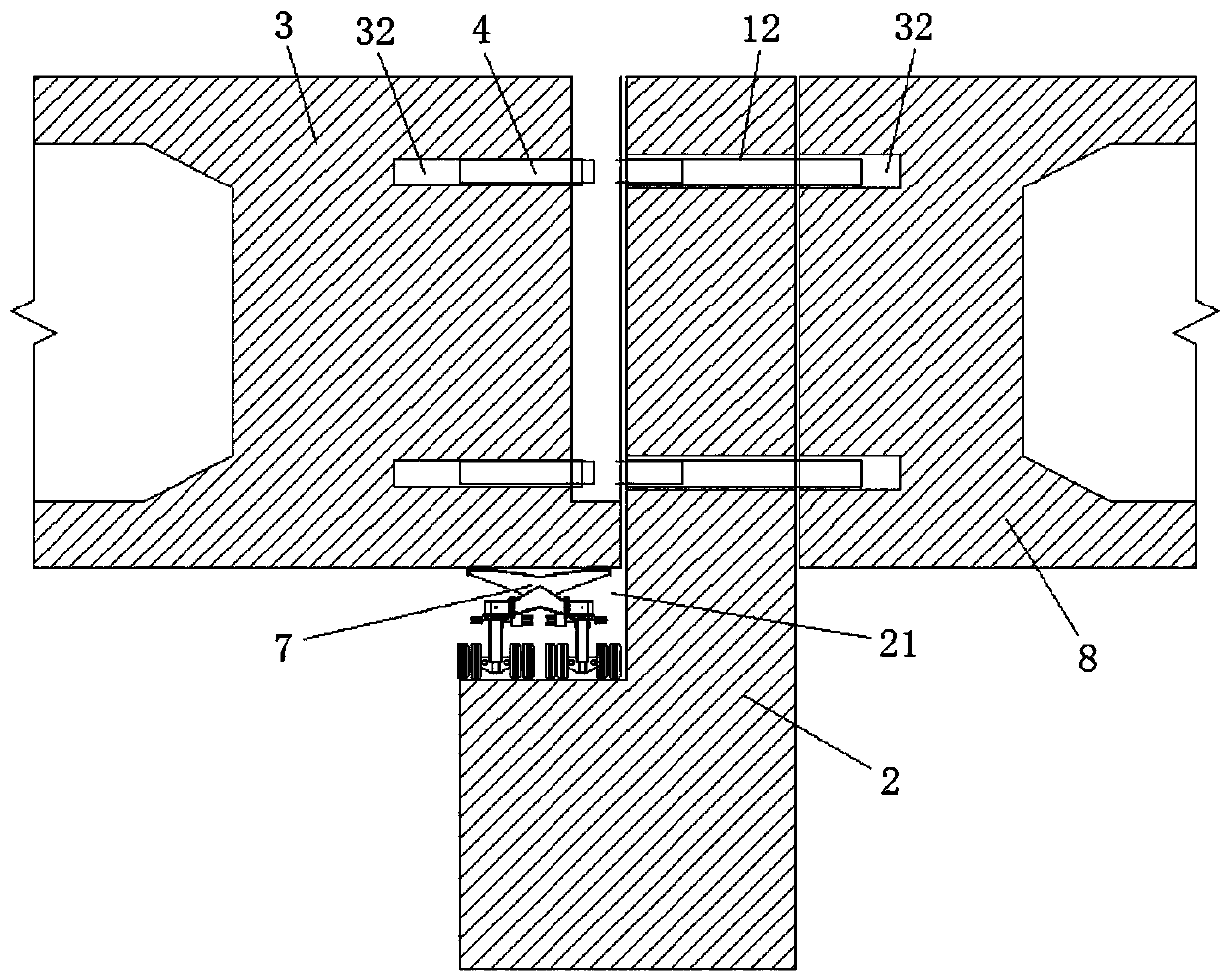

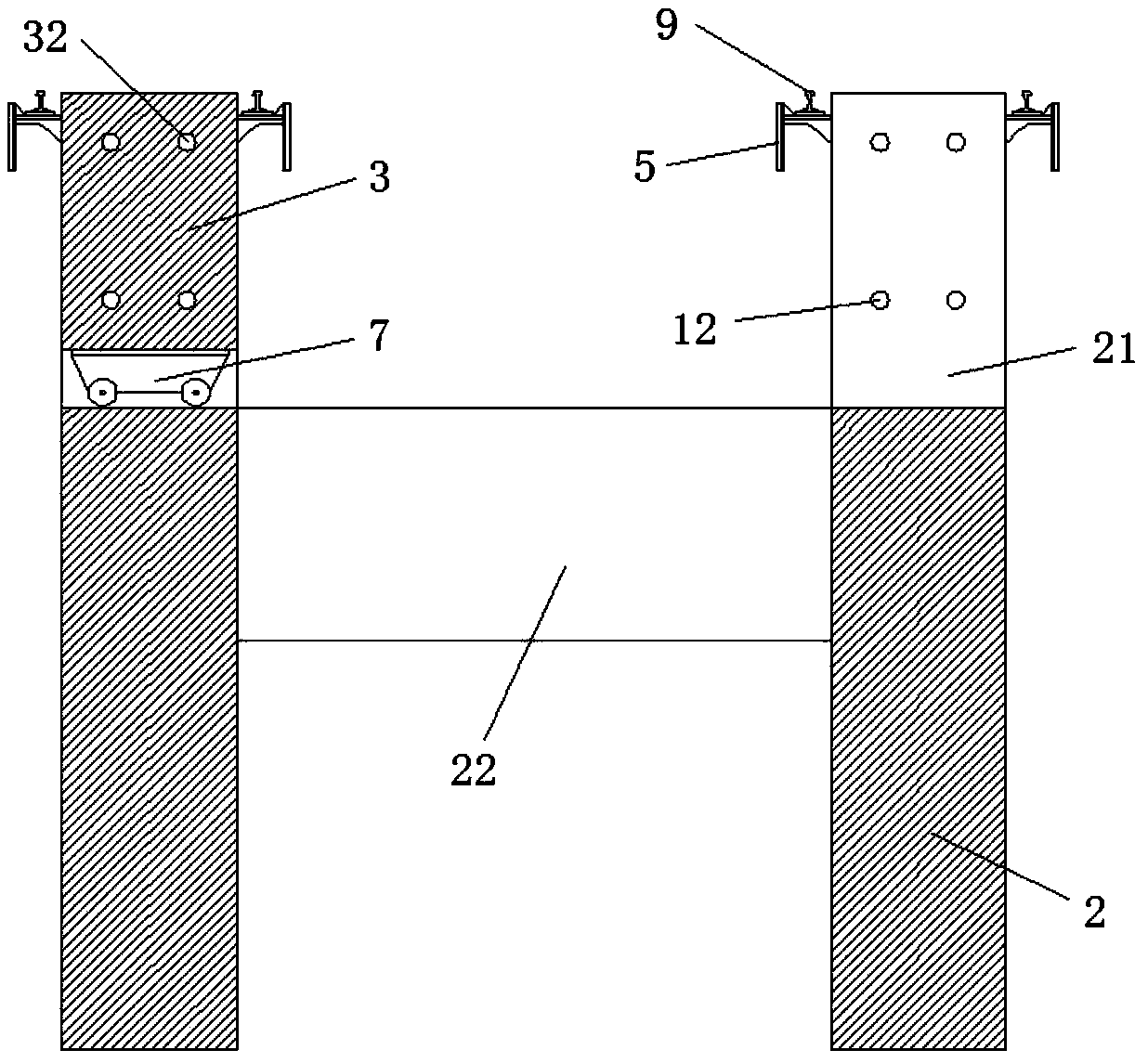

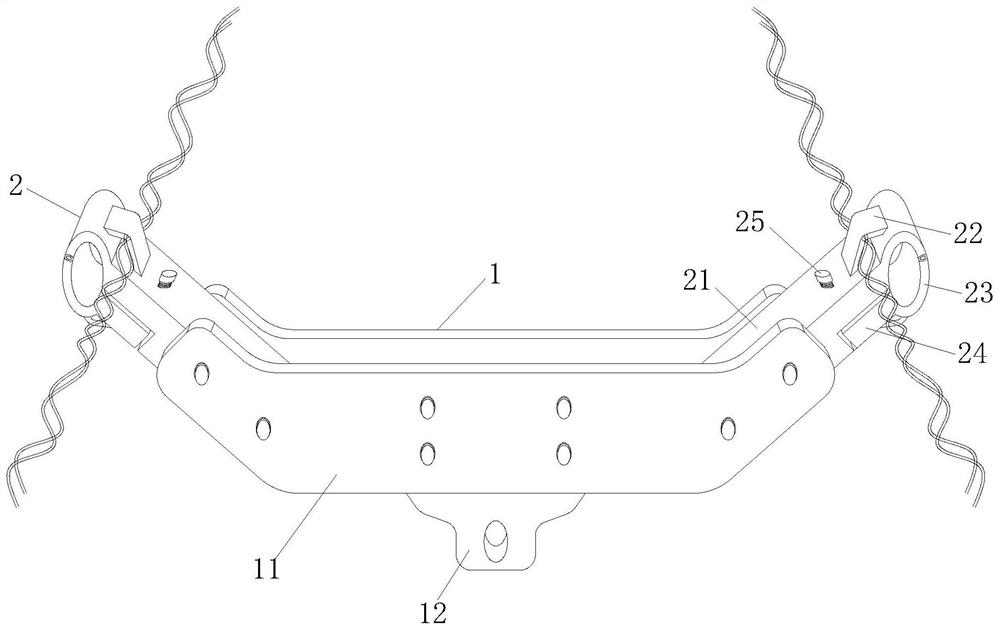

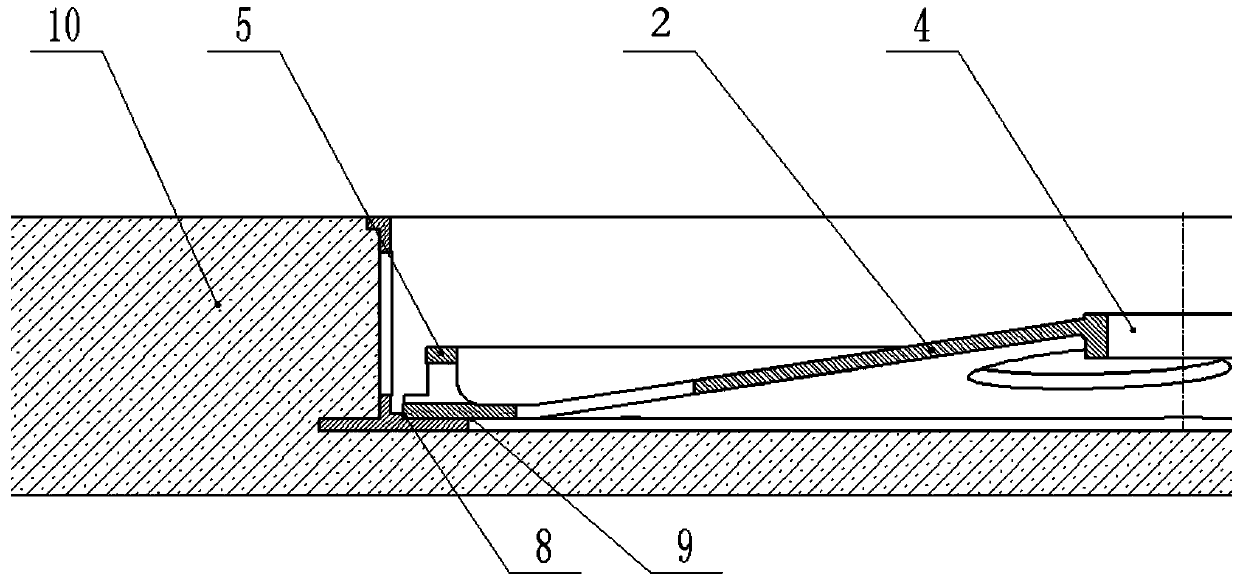

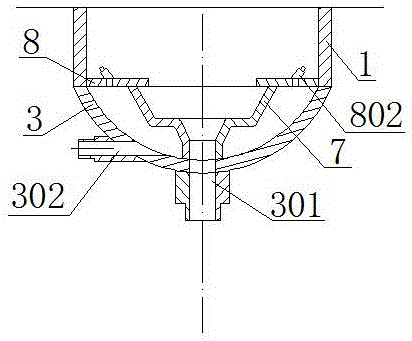

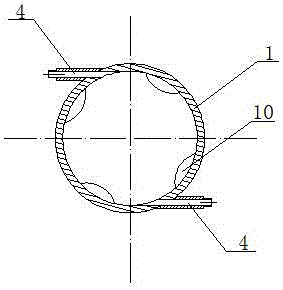

Shield launching counter-force frame and installation and use method thereof

ActiveCN103953353AIncreased driving safetyImprove stress environmentTunnelsShield tunnelingUltimate tensile strength

The invention relates to a shield launching counter-force frame. Counter-force is supplied for launching of a shield tunneling machine in a formed circular tunnel by means of an annular steel ring body favorably, thus the stress environment of the counter-force frame is improved well, the transmission pathway of the counter-force is transformed, 16 steel supports are arranged on the steel ring body, the steel supports act on the steel ring body simultaneously, the integral strength, stiffness and stability of the counter-force frame are improved, the stress of the counter-force frame is reduced, meanwhile, the steel ring body is formed by splicing multiple arc segments, thus installation and construction of the counter-force frame in the tunnel are facilitated, the risk of construction work is reduced, and the safety of the shield tunneling is increased. The invention also relates to an installation and use method of the shield launching counter-force frame. The shield launching counter-force frame and the installation and use method thereof can be applied to shield construction of the circular tunnel.

Owner:CHINA RAILWAY 15TH CONSTR BUREAU GRP

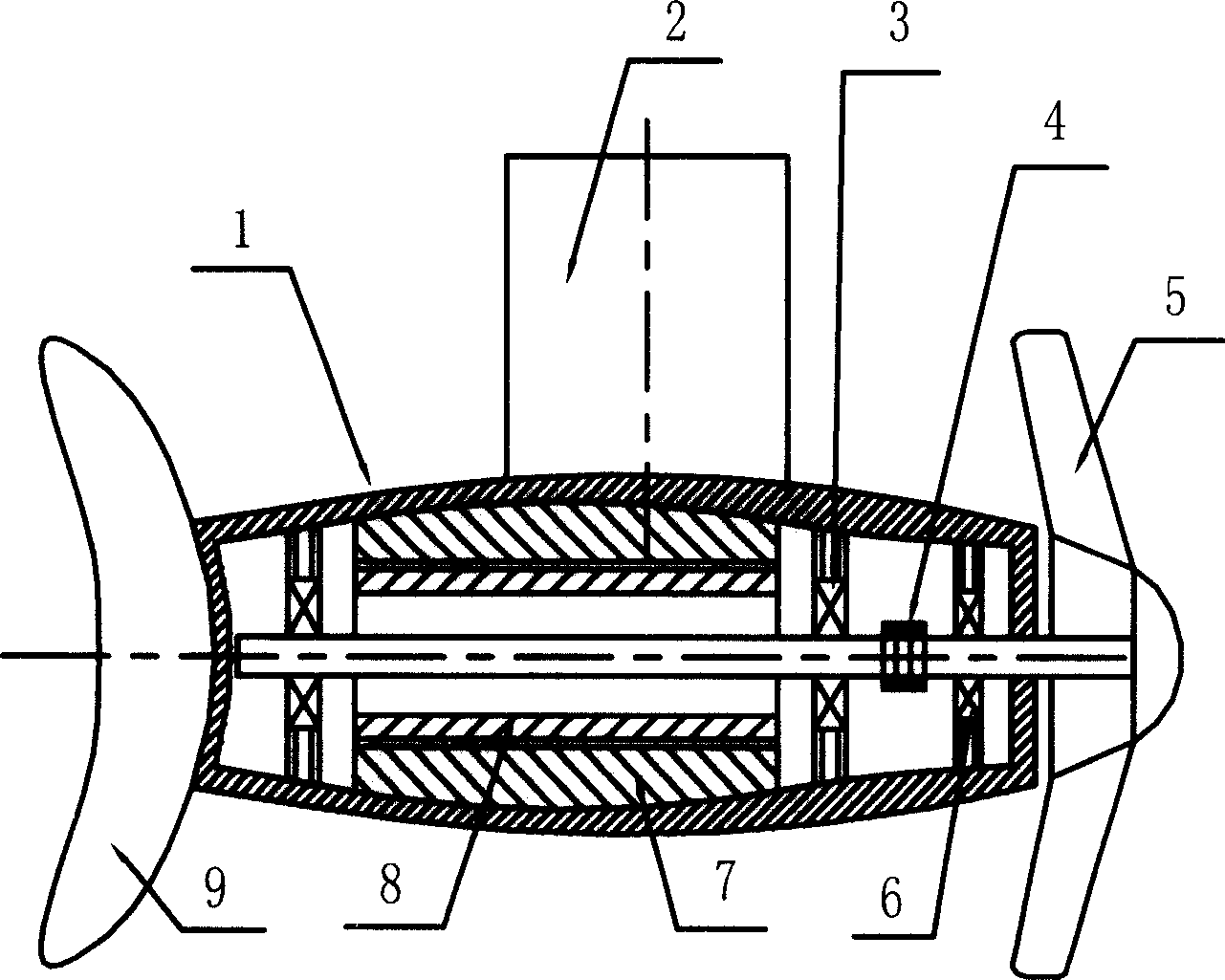

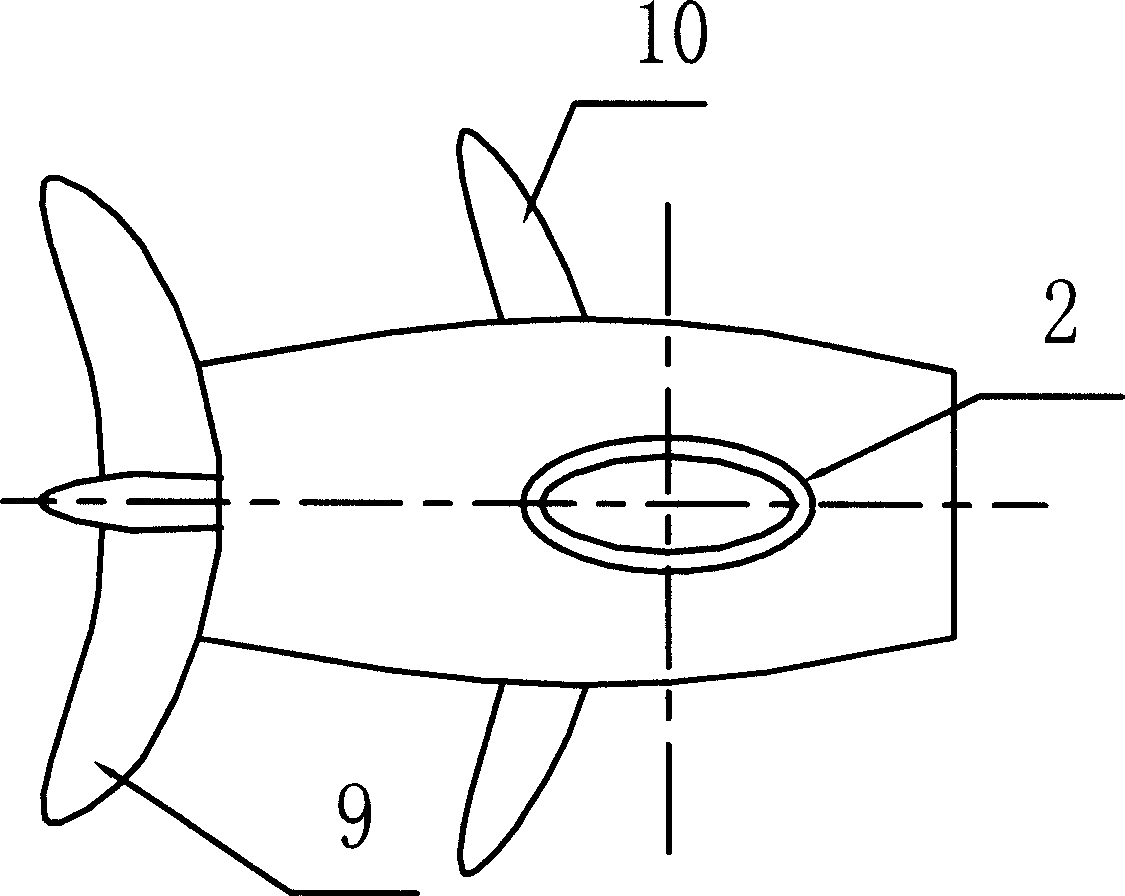

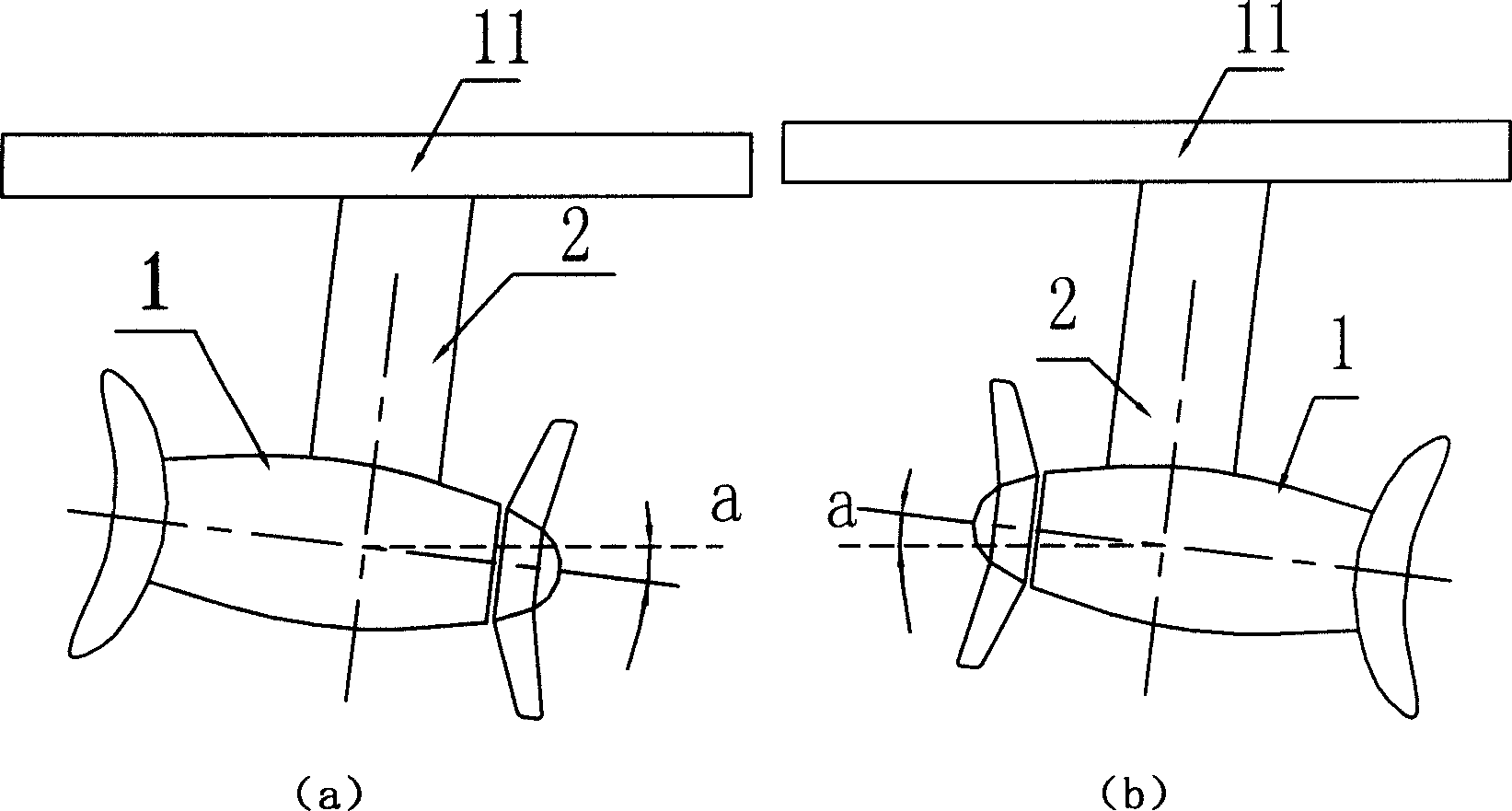

Fish shape simulating nacelle propeller

InactiveCN1749104AImprove wake fieldImprove propulsion efficiencyPropulsion power plantsOutboard propulsion unitsNacelleCoupling

The present invention is one kind of fish-shaped nacelle propeller and belongs to the field of ship propelling technology. The fish-shaped nacelle propeller of the present invention includes nacelle body, support, motor bearings, shaft coupling, screw propeller, screw propeller bearing, propelling motor stator, propelling motor rotor, tail fin and two side fins. The nacelle body is connected with the support; the screw propeller has one end fixed via the screw propeller bearing inside the nacelle body; the propelling motor stator is set via the motor bearings and the support inside the nacelle body; the propelling motor rotor shaft is connected to the shaft of the screw propeller via shaft coupling; and the tail fin and the side fins are connected to the nacelle body smoothly. The present invention has optimized streamline outer shape, effectively improved tail flow field, improved hydrodynamic performance, and raised propeller efficiency.

Owner:SHANGHAI JIAO TONG UNIV

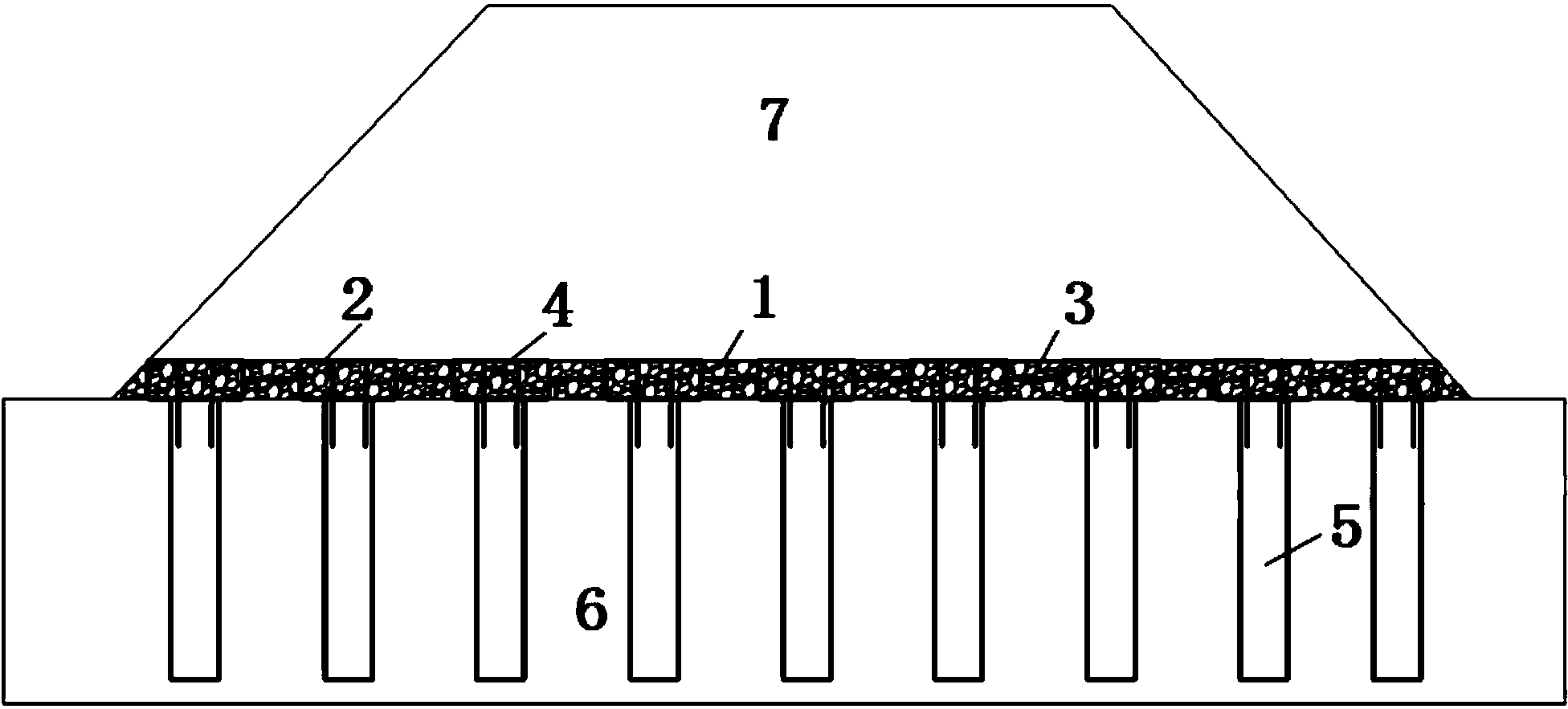

Composite reinforced roadbed and construction method

InactiveCN103711053AIncrease the sliding safety factorImprove skid resistanceRoadwaysIsoetes triquetraCrushed stone

The invention discloses a composite reinforced roadbed and a construction method. The composite reinforced roadbed comprises water-permeable concrete piles, waste tires, connection pieces and gravels, wherein the water-permeable concrete piles are sequentially poured to peaks of triangles according to the shapes of equilateral triangles; each longitudinally cut waste tire is fixed on a steel bar of each water-permeable concrete pile; the water-permeable concrete piles are connected through the connection pieces in sequence and are buried on the roadbed; the equilateral triangles and the tires are filled with the gravels; the structure is filled with the soil roadbed. According to the composite reinforced roadbed, the waste tires are arranged at the bottom of the roadbed and replace part of the soil body; compared with the friction force in the soil body, the friction force between the soil body and the waste tires or the friction force caused by indirect contact between the gravels and the tires is obviously increased; in spite of cohesive soil or non-cohesive soil, the cohesive force of the soil body or the inner friction angle of the soil body can be increased; the stability of a slope of the roadbed is improved.

Owner:SHANDONG UNIV

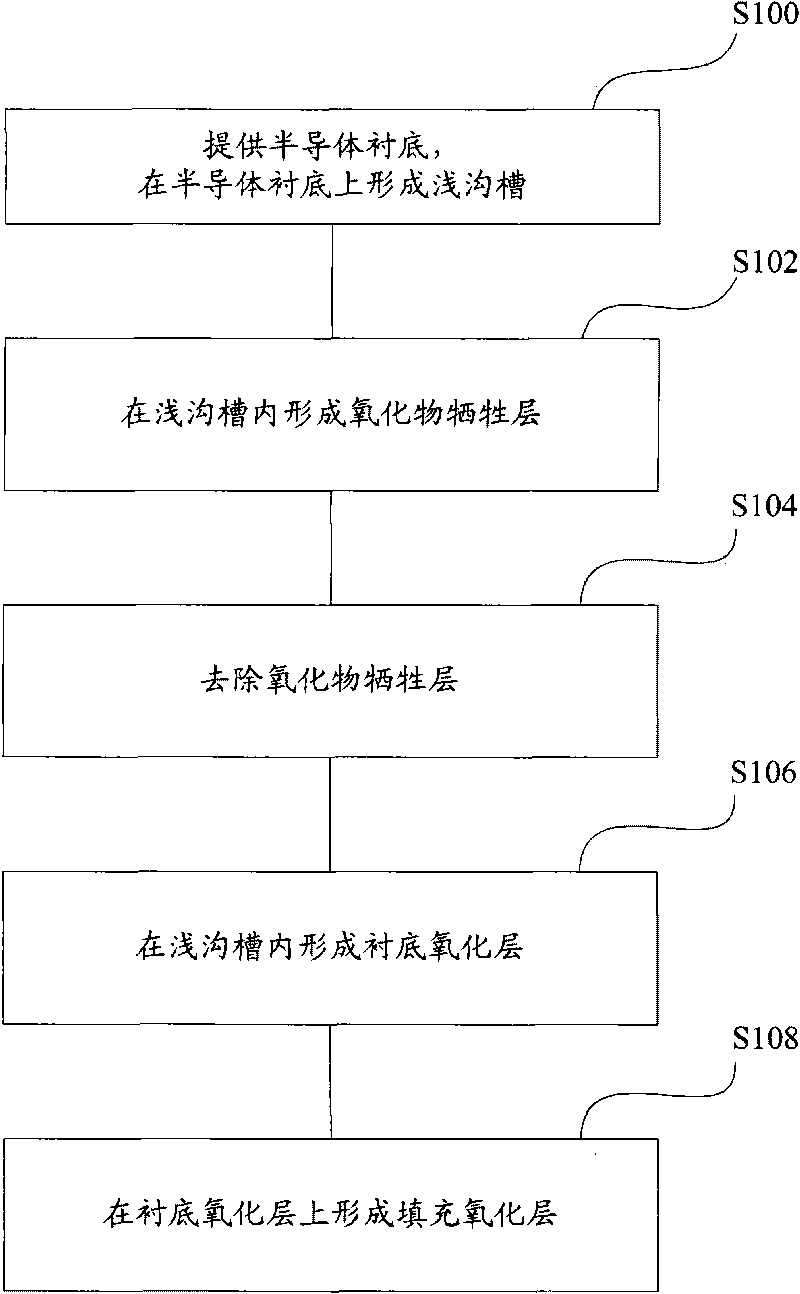

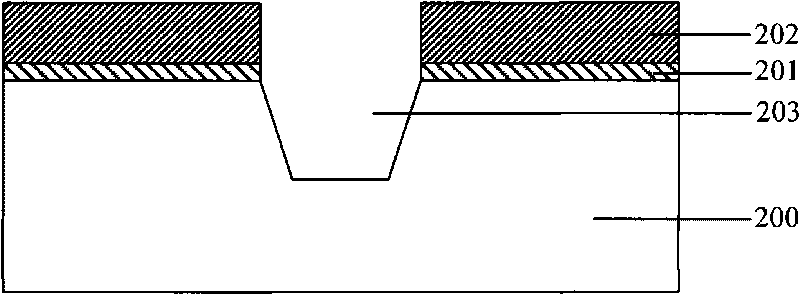

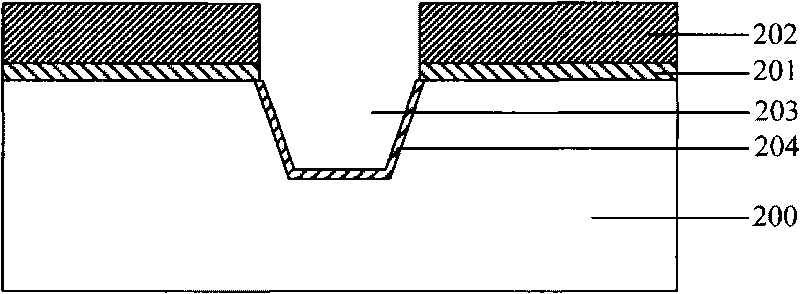

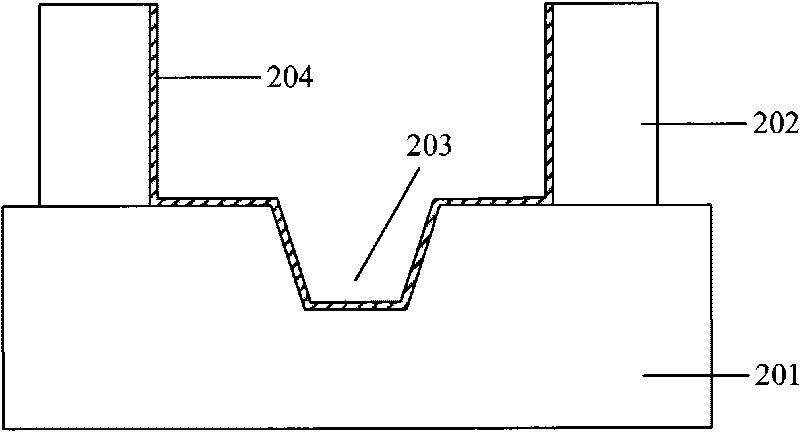

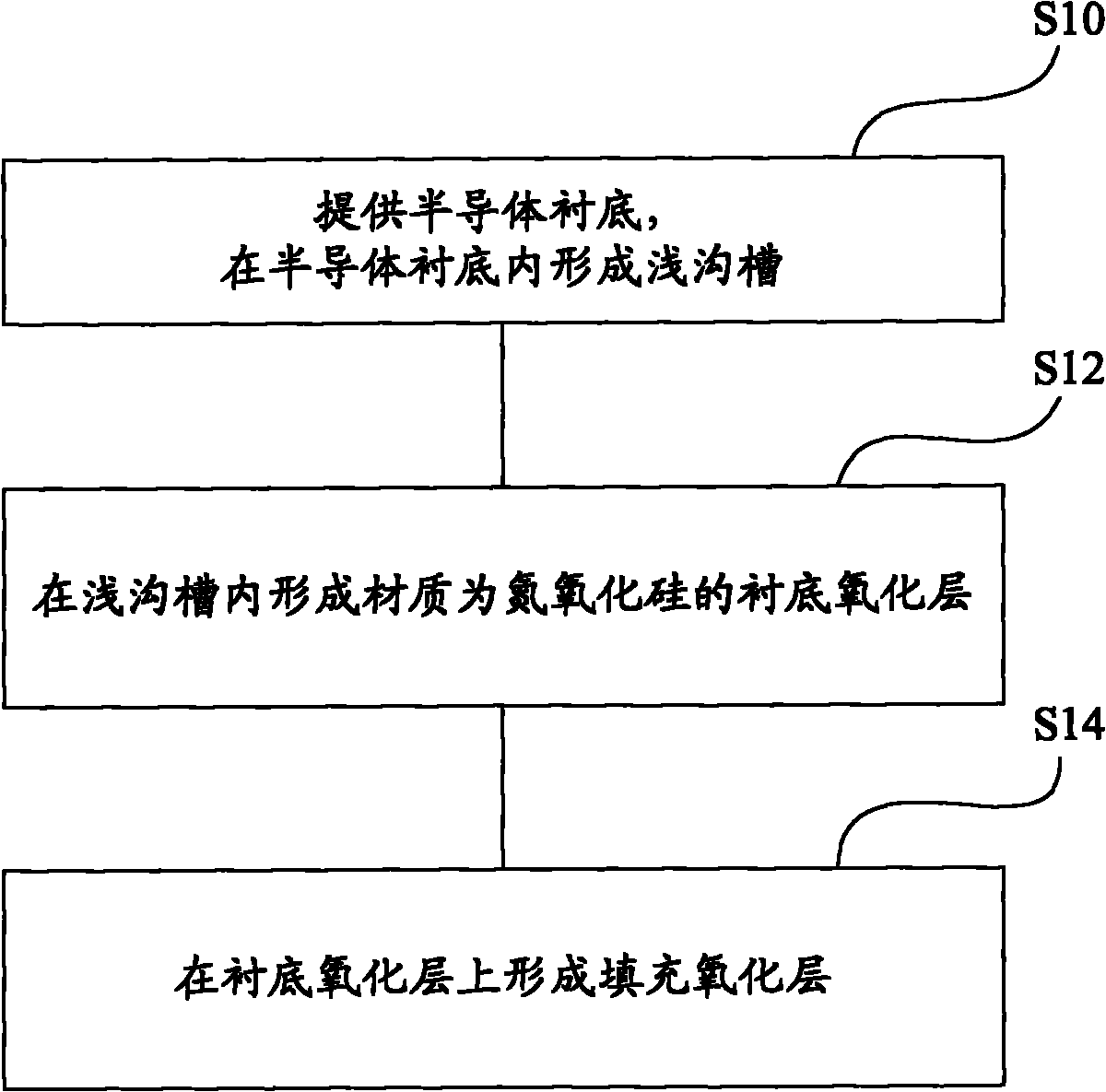

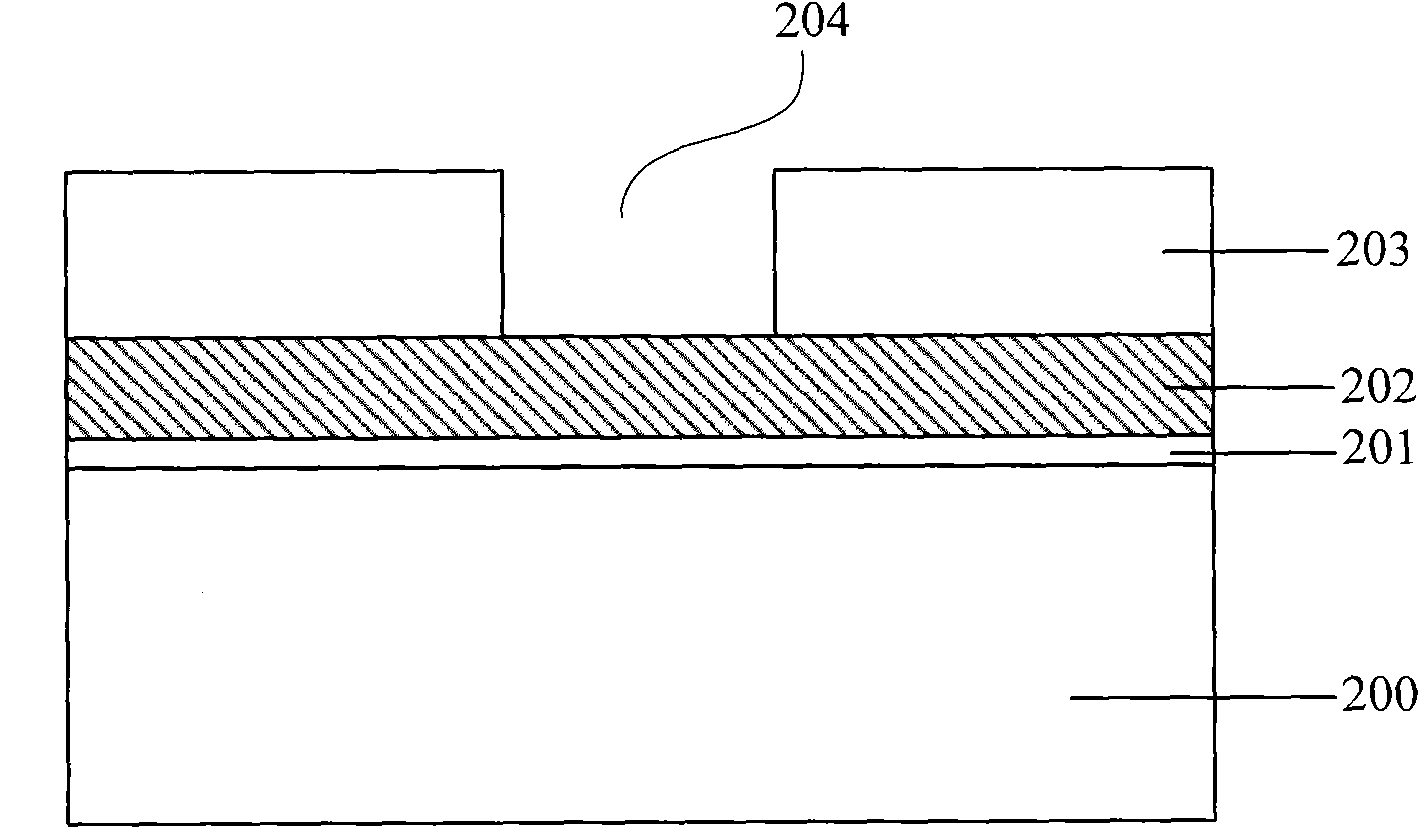

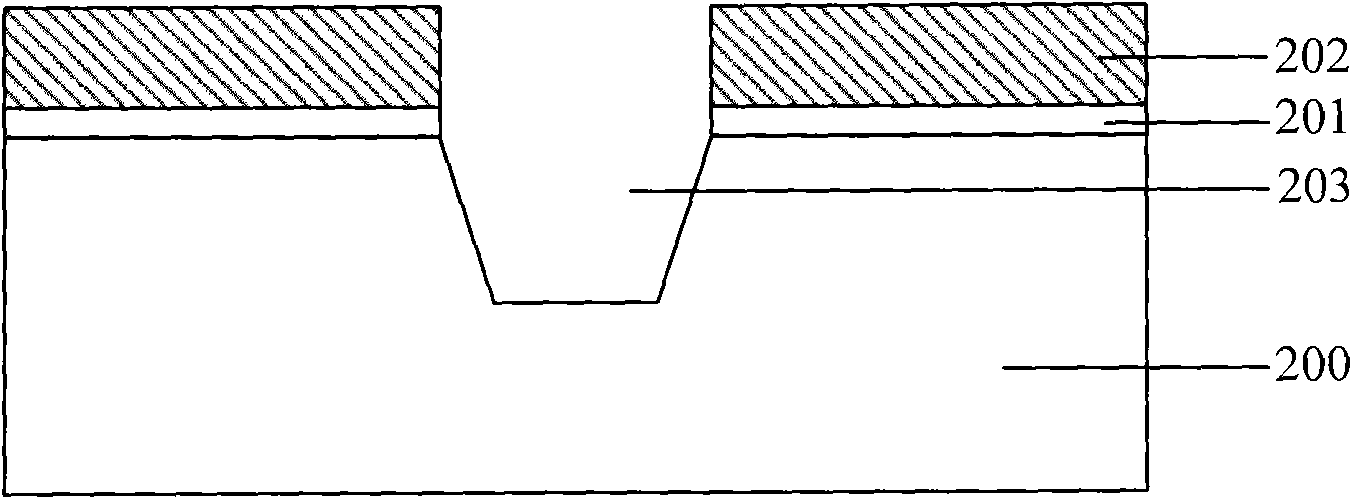

Manufacturing method of shallow trench structure

InactiveCN101740458AImprove stress environmentAvoid destructionSemiconductor/solid-state device manufacturingOxideEngineering

The invention relates to a manufacturing method of a shallow trench structure, which comprises the following steps of: providing a semiconductor substrate and forming a shallow trench on the semiconductor substrate; forming an oxide sacrifice layer in the shallow trench; removing the oxide sacrifice layer; forming a substrate oxide layer in the shallow trench; and forming a filling oxide layer for filling the shallow trench on the substrate oxide layer. Through the technical scheme, a corner at the top end of the shallow trench can be rounded in the forming process, thereby improving the stress environment in the shallow trench, avoiding the damage of a subsequent process to the shallow trench, improving the electrical performance of a semiconductor device and enhancing the yield of a semiconductor product.

Owner:SEMICON MFG INT (SHANGHAI) CORP

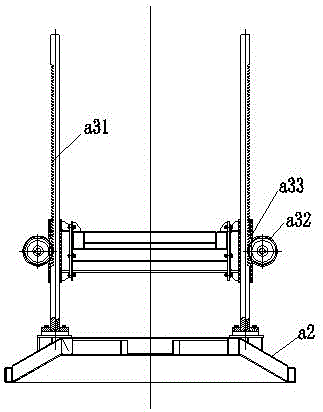

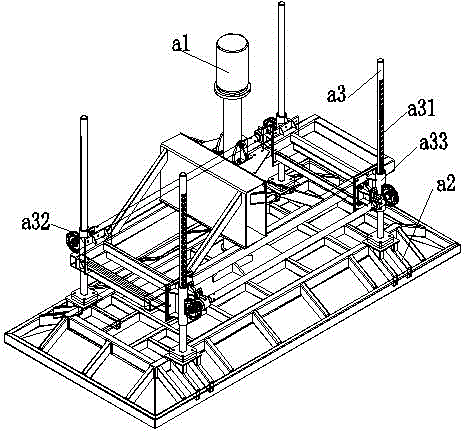

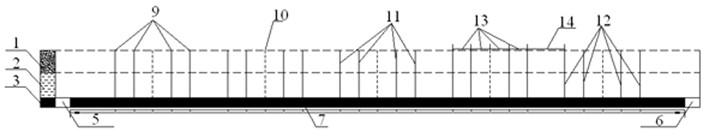

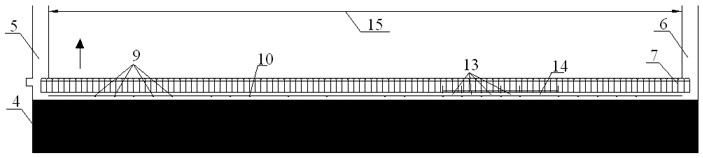

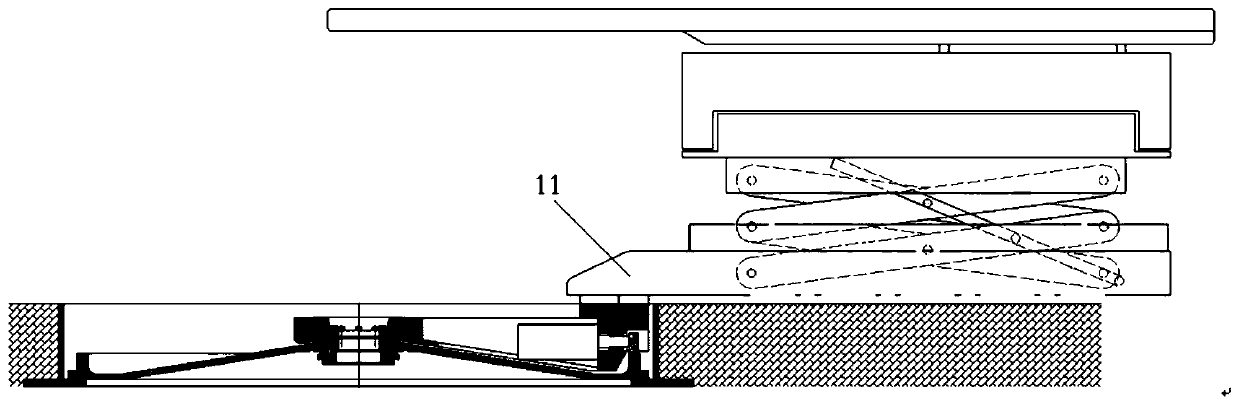

Intelligent continuous fermentation system for solid-state Baijiu

PendingCN106479815AAchieve continuous fermentationHigh yieldAlcoholic beverage preparationContinuous fermentationTemperature control

The invention relates to an intelligent continuous fermentation system for solid-state Baijiu. The intelligent continuous fermentation system comprises a fermented-grain mild compression machine, an operation transfer vehicle, an upper cover grabbing device, a fermentation tank lifting device, an operation vehicle, a fermentation tank, a fermentation temperature control bin and a turnover discharge device. Fermented grains are fed into the fermentation tank, the fermentation tank is stopped below the fermented-grain mild compression machine, and the fermented-grain mild compression machine performs compaction by an electric-hydraulic pusher pushing down a compression panel; after the compaction, the fermentation tank is transferred to the fermentation tank lifting device through the operation vehicle and just stopped above the upper cover grabbing device in a position-limited manner, and the upper cover grabbing device stably places an upper cover on the fermentation tank through lifting and unhooking; the fermentation tank is placed into the fermentation temperature control bin, the fermentation tank is moved through the operation transfer vehicle, the fermentation tank is moved out of the temperature control bin after the fermentation, and discharging is performed through the turnover discharge device to complete the whole fermentation process. The intelligent continuous fermentation system for the solid-state Baijiu is reasonable in structure and capable of achieving mechanical brewing.

Owner:YANGZHOU XIANYE GRP

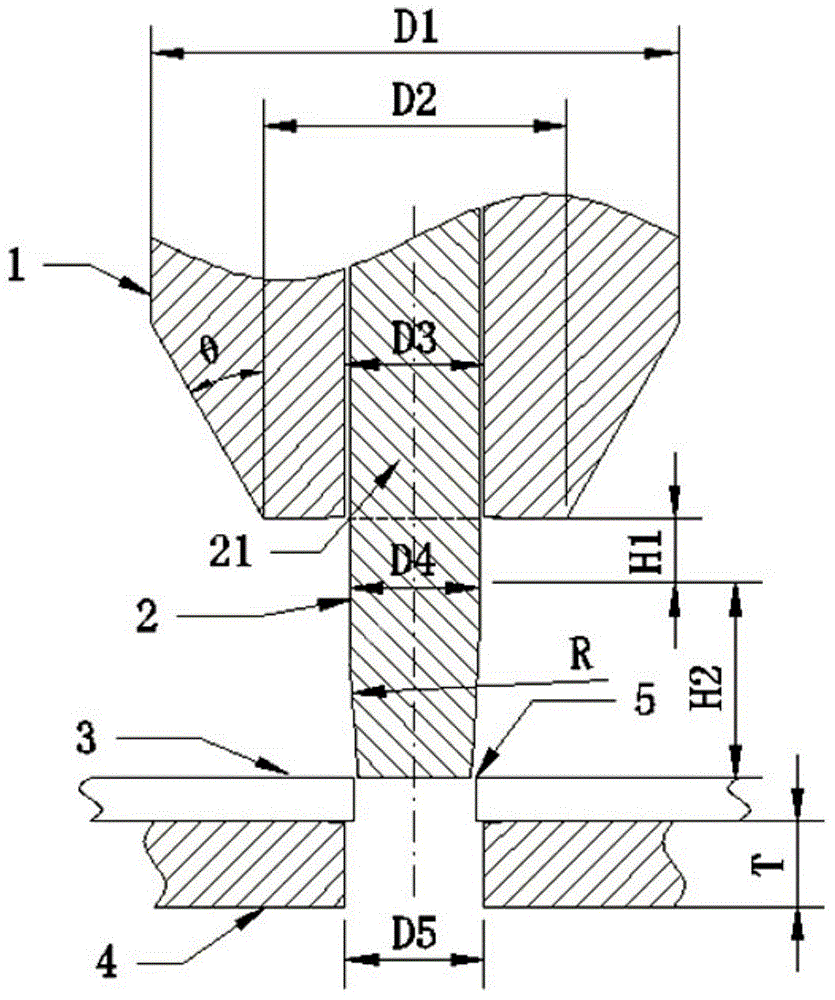

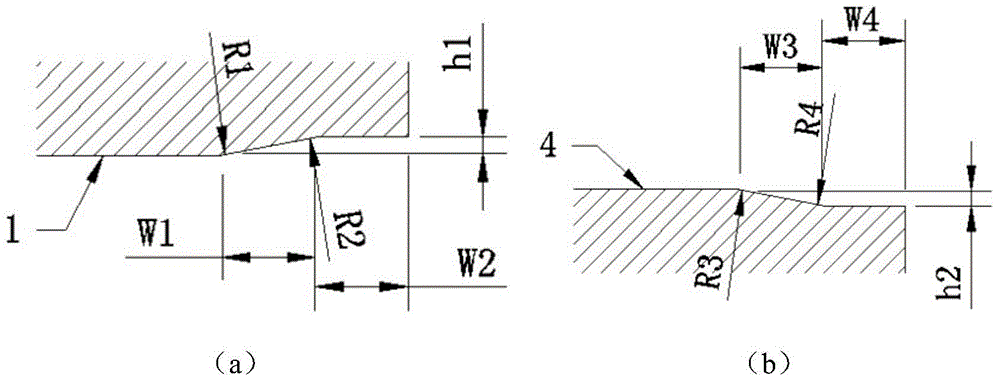

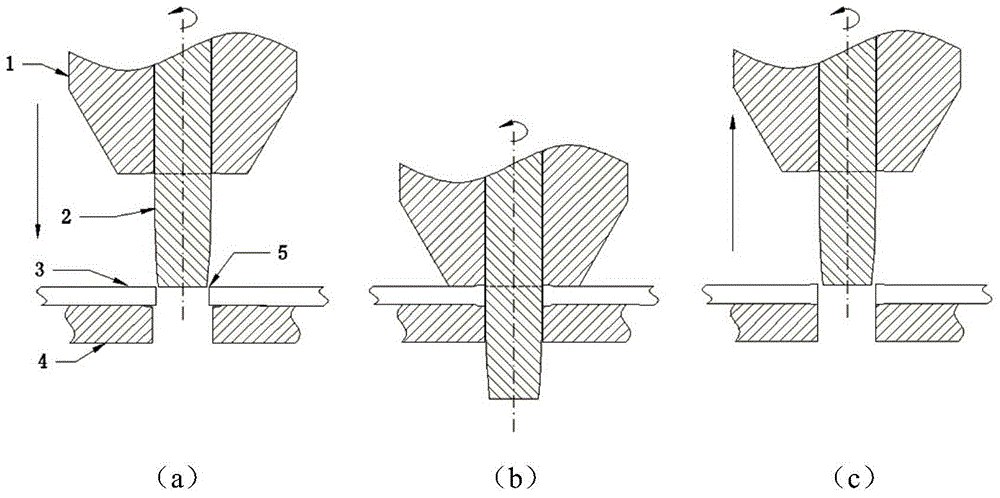

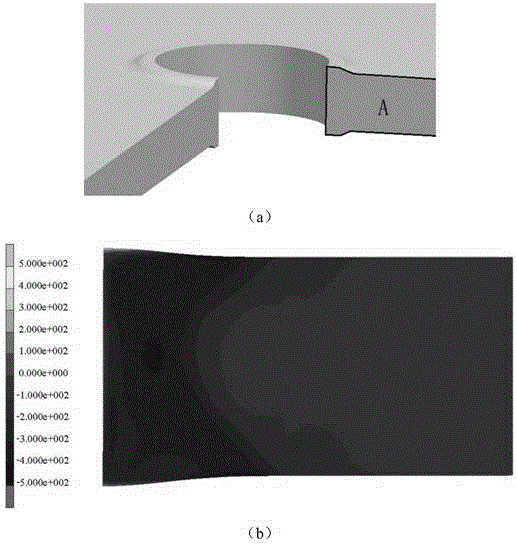

Tool and method for strengthening friction extrusion of structural member connecting hole

The invention discloses a tool and a method for strengthening friction extrusion of structural member connecting holes, and belongs to the technical field of machining. The friction extrusion strengthening tool comprises three parts of a friction extrusion head, a necking, and a base plate. When the tool is used to strengthen a structural member connecting hole, under the condition of maintaining 0.02-1 mm extruding magnitude of interference between the friction extrusion head and the connecting hole, the friction extrusion head is rotated and is inserted into the connecting hole in uniform speed. After stopping rotation for 2-5 s, the friction extrusion head is pulled out. The rotation speed of the friction extrusion head is 100-1000 rpm, the insertion speed is 0.1-2 mm / s, and pulling-out speed is 0.3-2 mm / s. In the above process, residual compressive stress is formed near the wall surface of the hole, and plastic flow occurs to the material near the wall surface of the hole, and the material has lattice distortion, and dislocation density is increased, so as to realize friction extrusion strengthening on the connecting hole. The tool and the method are mainly used in strengthening of important structural member connecting holes in aviation, aerospace, trains, and ships, and other industries.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

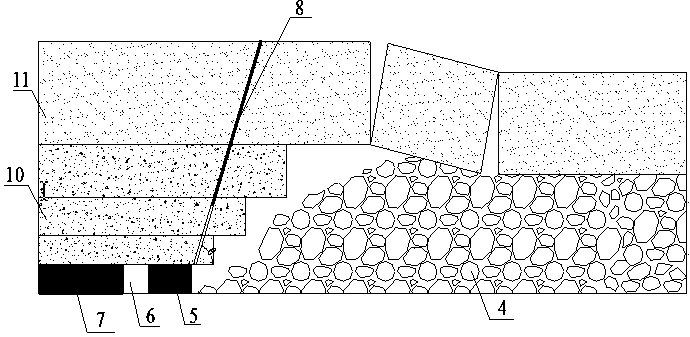

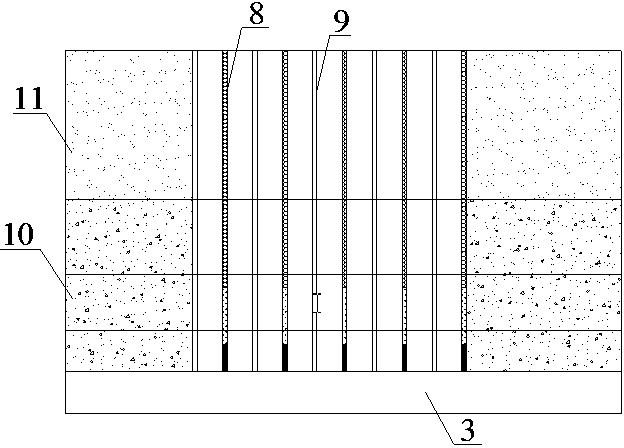

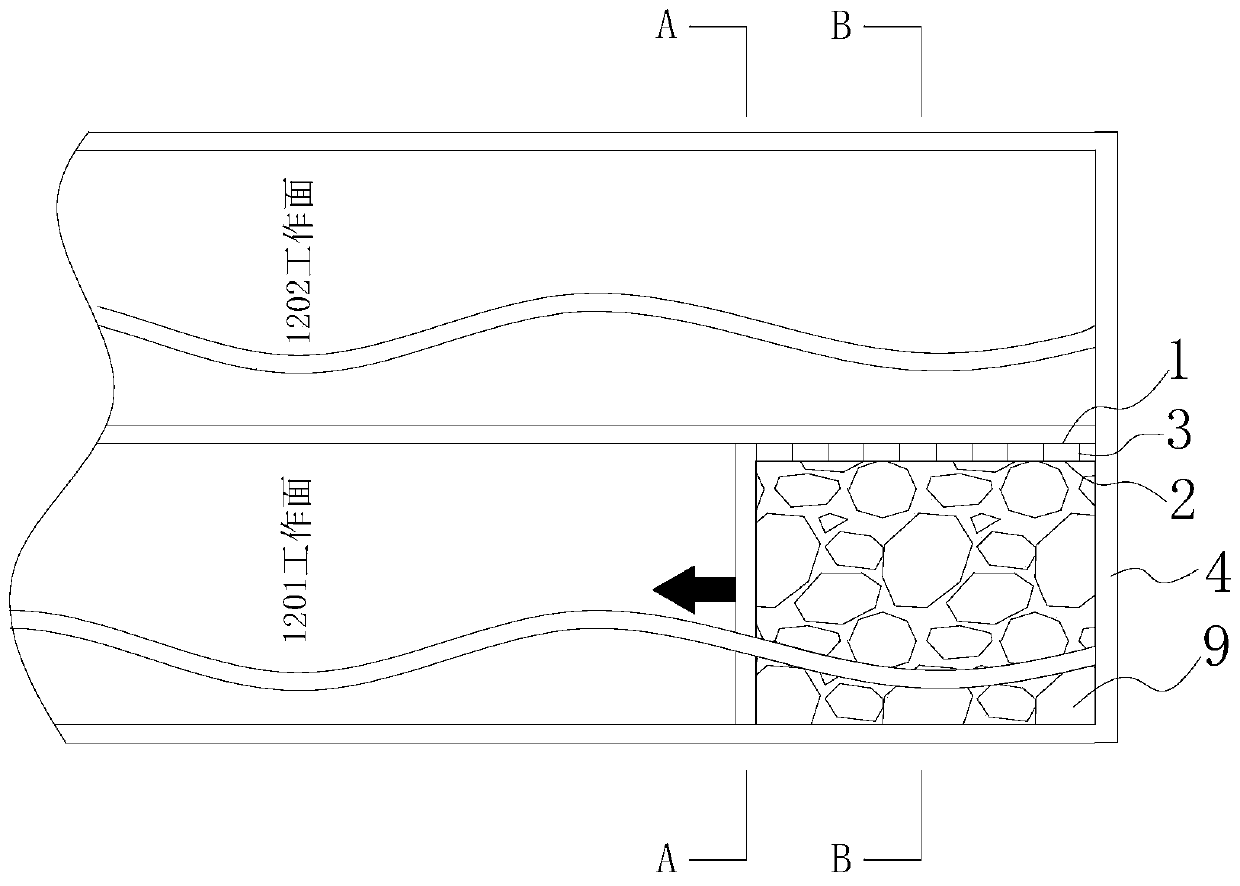

Large mining height gob-side entry retaining method for thick coal seams

ActiveCN104632219AMaintain stabilityRelieve pressureUnderground miningSurface miningStress concentrationCarbonization

The invention relates to a large mining height gob-side entry retaining method for thick coal seams, which is suitable for a mine roadway supporting project. When an upper section mining working surface is mined, a roadway side support wall and a pressure buffer wall which are respectively and internally provided with a vent pipeline are built along the edge of a goaf, and a certain horizontal distance L is maintained between the roadway side support wall and the pressure buffer wall, so that gob-side entry retaining can be formed; when a lower section mining working surface is mined, gob-side entry retaining is implemented in a track roadway of the lower section mining working surface, and a flexible film bag on the surface of the roadway side support wall of the upper section gob-side entry retaining behind the working surface is removed; after the stoping of lower section mining working surface is finished, the vent pipelines of the roadway side support wall and the pressure buffer wall of the upper section mining working surface are filled with carbon dioxide, so that the walls are promoted to have a carbonization reaction so as to be broken and decomposed, and mining without coal pillars can be completely realized. The method is beneficial to whole process maintenance of gob-side entry retaining, so that the gob-side entry retaining of the large mining height working surface for the thick coal seams can be realized, the coal mining rate is remarkably improved, and meanwhile, stress concentration of the upper part and the lower part of a wall can be eliminated.

Owner:CHINA UNIV OF MINING & TECH

Method for controlling integral caving of roof through deep-hole segmented blasting kerf

The invention discloses a method for controlling integral caving of a roof through deep-hole segmented blasting kerf, belongs to the technical field of blasting kerfs, can solve the problem of the coal seam roof suspension without caving. According to the technical scheme provided by the method, and the problem of strong strata pressure behavior caused by the coal seam roof suspension without caving in coal mining is solved. Deep hole blasting is conducted on a main roof stratum so that the roof can be prevented from caving immediately after blasting, the main roof stratum in a blasting section after blasting can form a pre-crack weak face with the inclination angle the same as the spontaneous collapse angle of the stratum along a drilling arrangement line, the integrity of a main roof stratum plate structure is cut off, the roof strata directionally caves along the pre-crack weak face under the action of gravity, so that the concentrated stress in front of a mining roadway and a coalwall caused by large-area roof suspension of the roof can be effectively reduced, the stress environment of the roadway is improved, and meanwhile, timely caving of the roof behind the working face avoids the situations of goaf air leakage, gas gathering and residual coal spontaneous combustion.

Owner:山西吉昌泰矿山工程技术有限公司

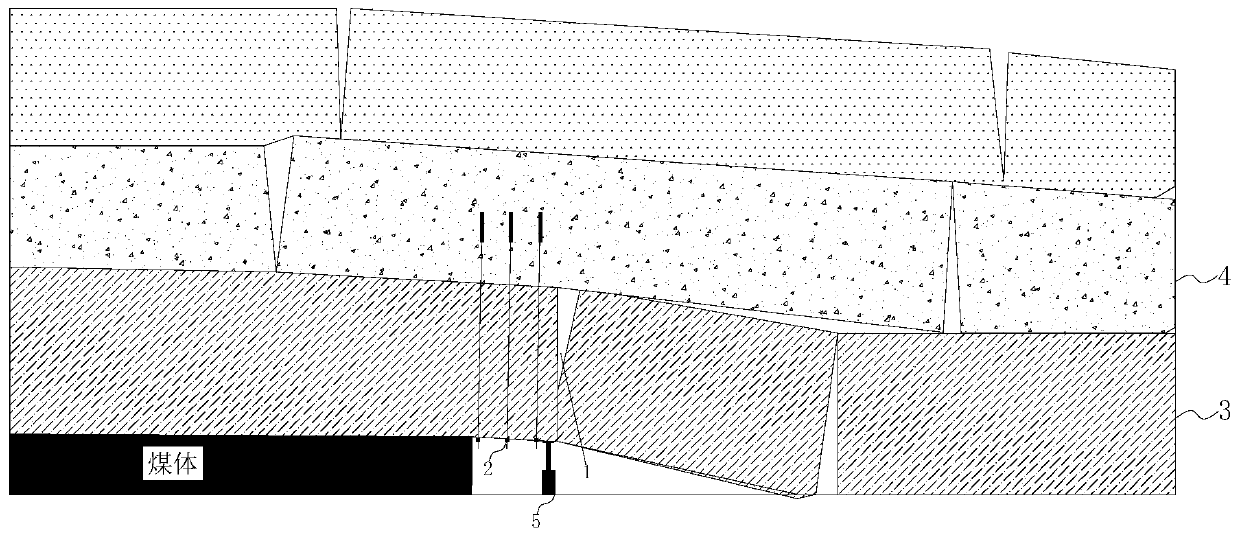

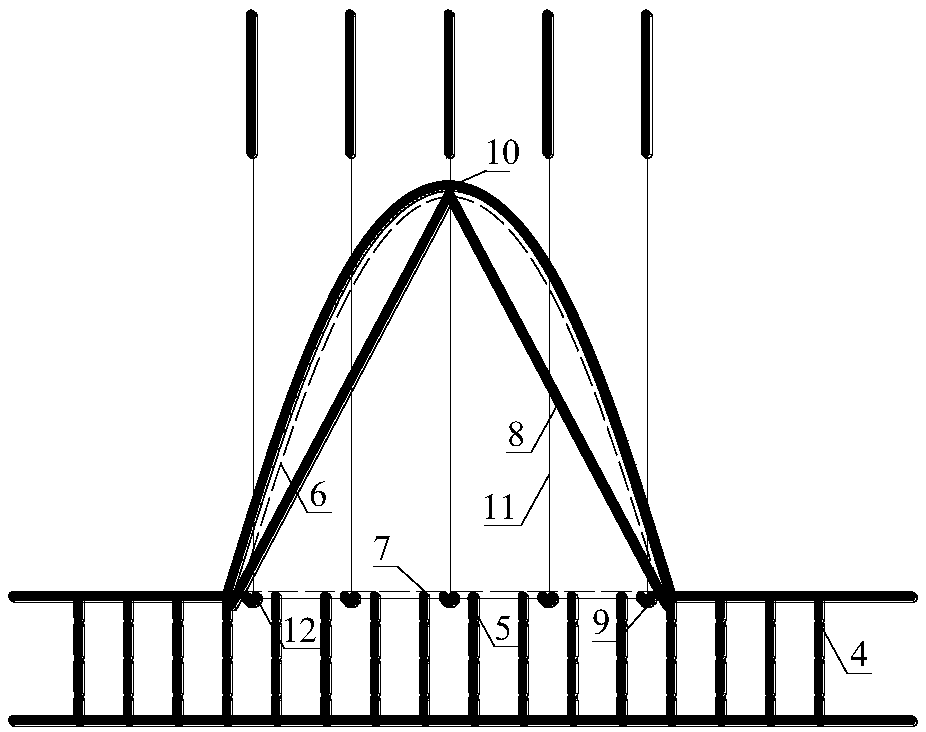

Coal-pillar-free mining method for pre-cracking arching under hard roof condition

ActiveCN109826628AImprove stress environmentReduce distortionUnderground chambersUnderground miningEngineeringCoal pillar

The invention provides a coal-pillar-free mining method for pre-cracking arching under a hard roof condition, and relates to the technical field of underground mining methods. The method comprises thesteps that A, a mining roadway of a first mining working face is excavated, and anchor rods and anchor cables are used for supporting the mining roadway; B, pre-cracking holes are formed in a roof inthe mining roadway along the coal wall of the working face, wherein the pre-cracking holes are perpendicular to the roof, and the length of the pre-cracking holes is equal to the thickness of the immediate roof; C, hydraulic supports are arranged at one side of the coal wall of the first mining working face; D, the pre-cracking holes within the range of 50-70 m on an advanced working face are loaded with explosive for blasting to crack the immediate roof; E, push mining is conducted on the working face, and the immediate roof of a pre-cracking section at the rear portion of the working face is subjected to sinking arching; F, after the sinking amount of the roof is stabilized, the height of the roadway is adjusted; G, a mining roadway of an adjacent working face is excavated, steps A to Fare repeated, and the hydraulic supports in the mining roadway of the last working face are recovered along with pushing of the adjacent working face. The method solves the problem that roofs are broken and easily leak wind, and has the advantages that the deformation amount of the roadways is small, and construction is convenient.

Owner:SHANDONG UNIV OF SCI & TECH

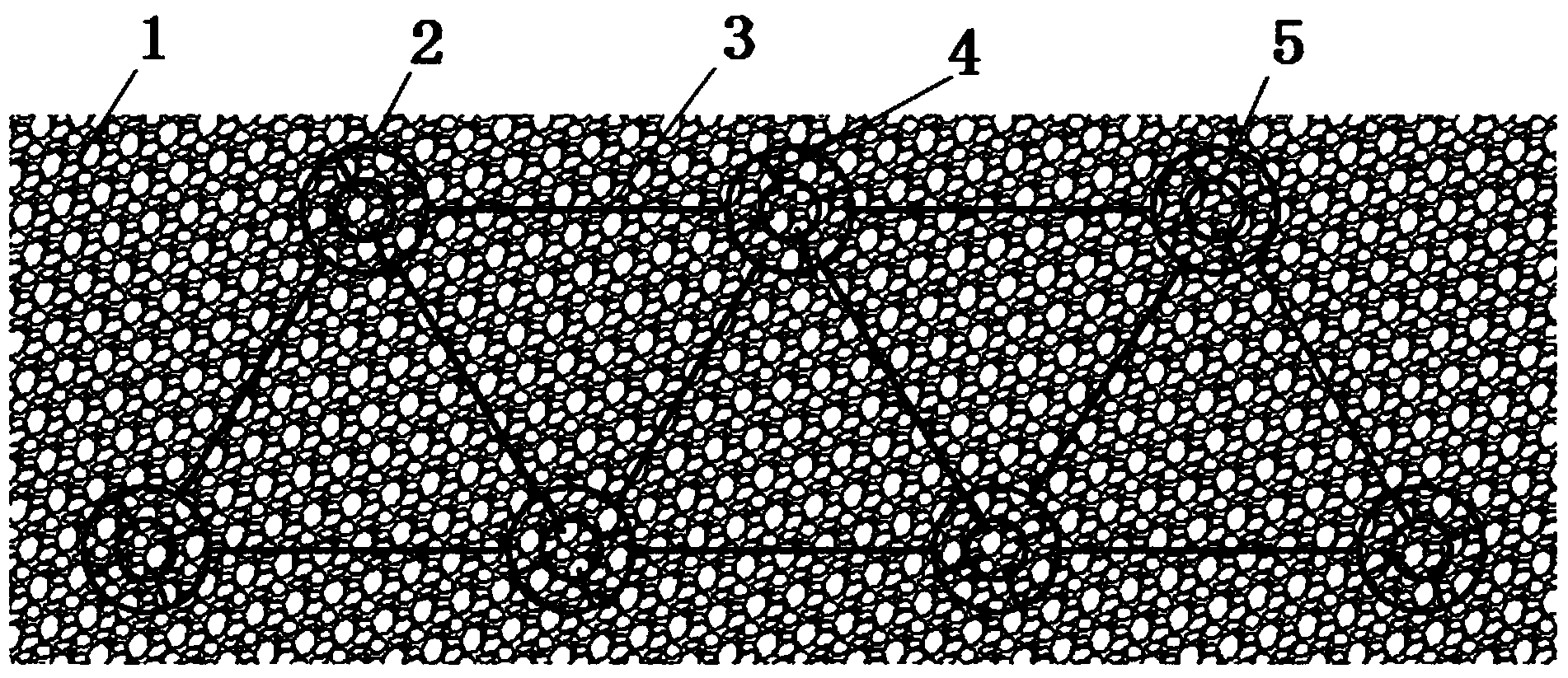

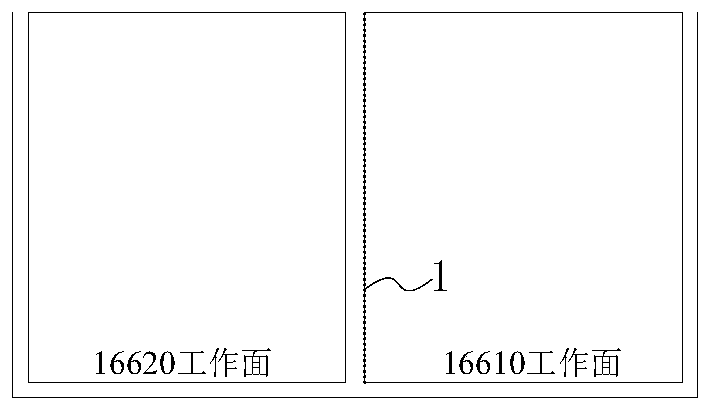

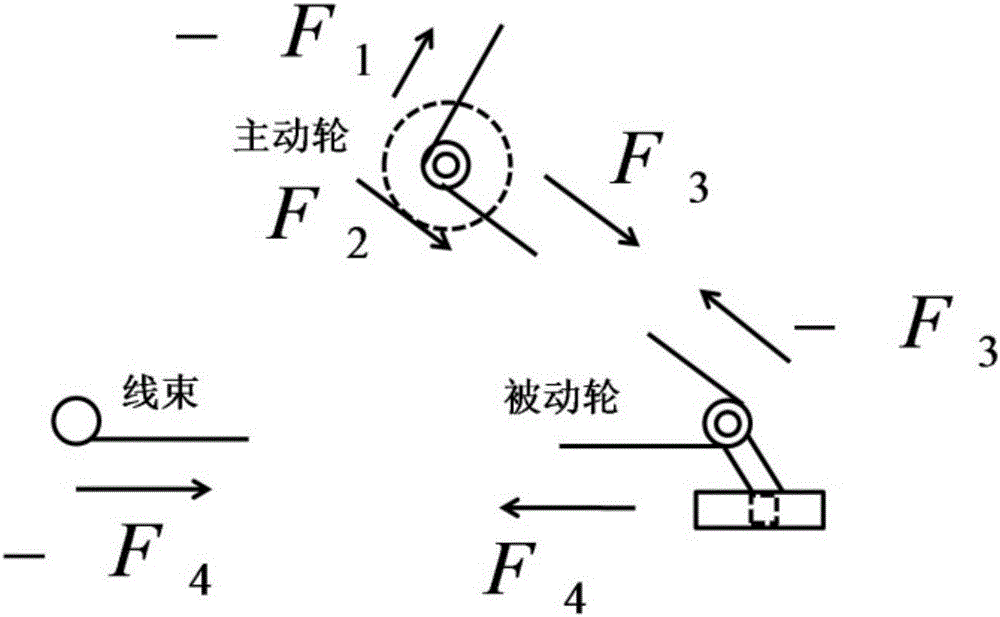

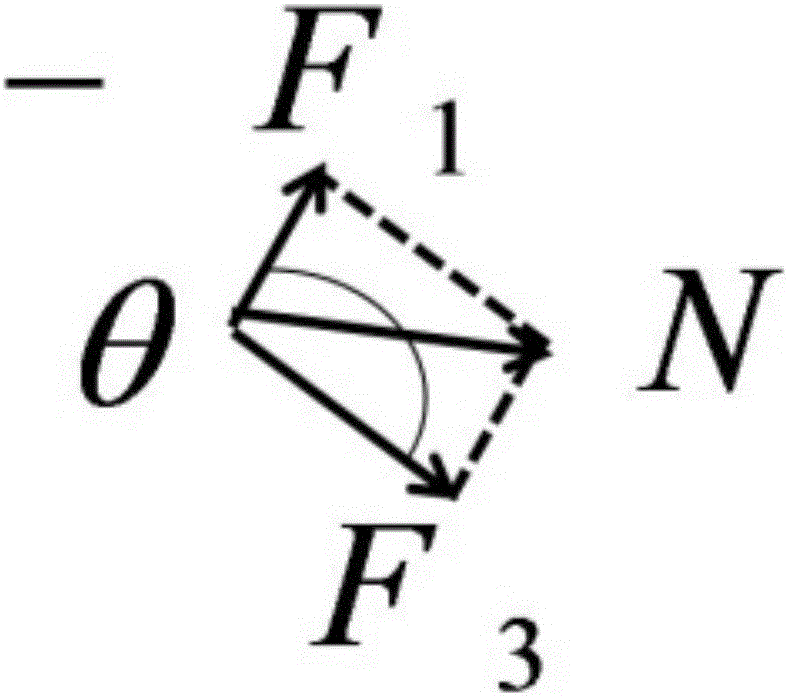

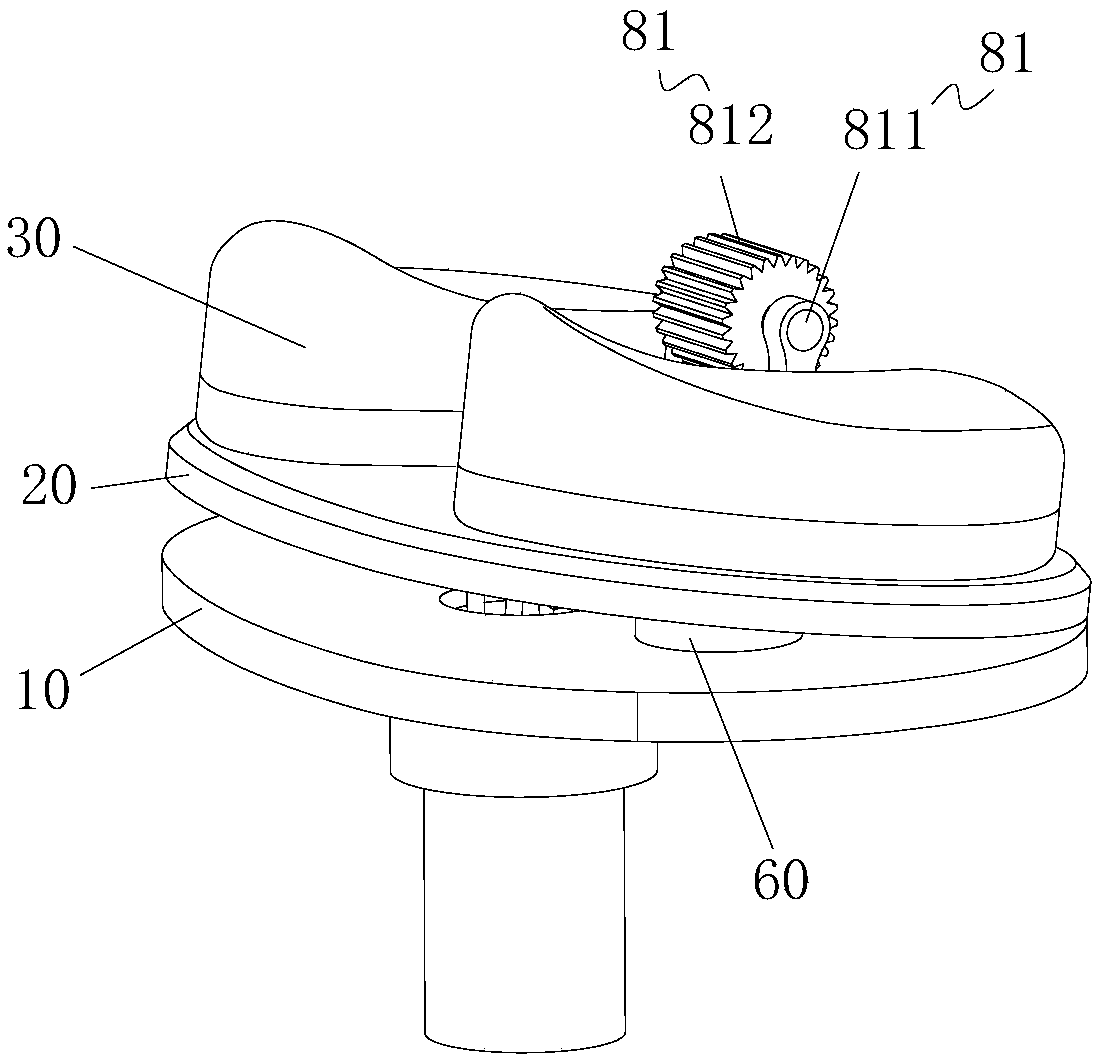

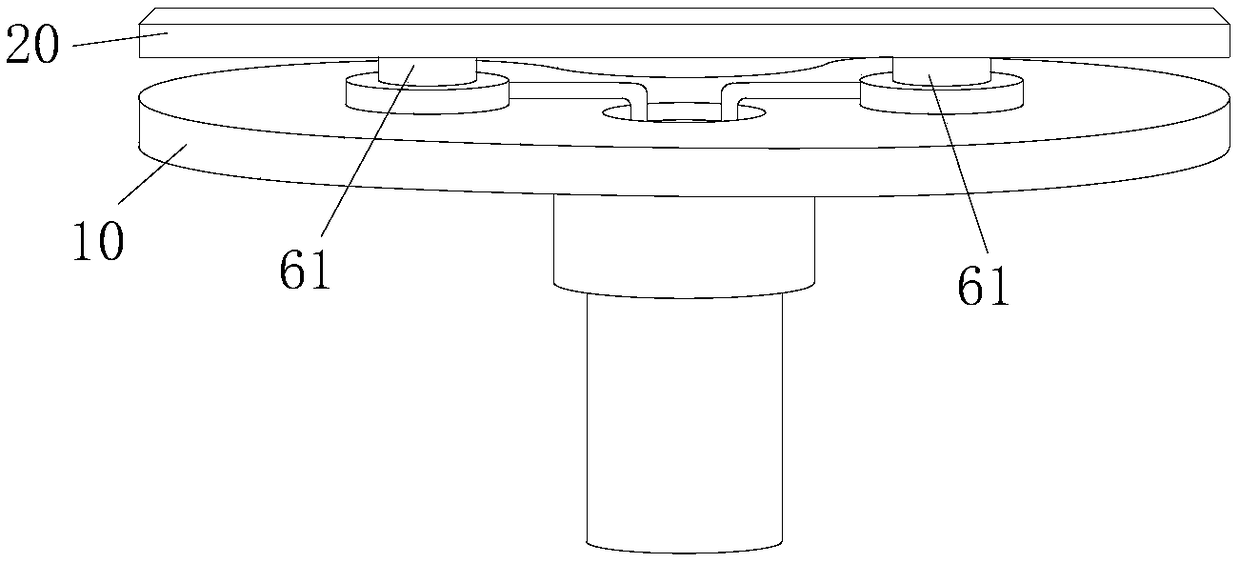

Adhesive tape wrapping machine feeding mechanism with force unloading function and achieving method

ActiveCN105836181AGuaranteed normal feedingGuaranteed feed speedBundling machine detailsEngineeringMaterial supply

The invention discloses an adhesive tape wrapping machine feeding mechanism with a force unloading function and an achieving method. The adhesive tape wrapping machine feeding mechanism comprises a main rotating mechanism body, a feed angle self-adaptive mechanism body, a force unloading mechanism body, a force unloading angle adjusting mechanism body and a material disc mechanism body. The main rotating mechanism body is the carrier of the feed angle self-adaptive mechanism body, the force unloading mechanism body, the force unloading angle adjusting mechanism body and the material disc mechanism body. The feed angle self-adaptive mechanism body, the force unloading mechanism body, the force unloading angle adjusting mechanism body and the material disc mechanism body are all arranged on the same side surface of the main rotating mechanism body. A material belt pulled out through the material plate mechanism body sequentially passes the force unloading angle adjusting mechanism body, the force unloading mechanism body and the feed angle self-adaptive mechanism body and then is used for supplying continuable adhesive tape or a belt-shaped material to the wire hardness wrapping process. According to the adhesive tape wrapping machine feeding mechanism with the force unloading function and the achieving method, the stress environment of the material supply process of an adhesive tape wrapping machine can be improved, the wrapping effect is improved, the wrapping application range is enlarged, and the adhesive tape wrapping machine feeding mechanism with the force unloading function and the achieving method can be applied and popularized in the automobile wire harness industry in a batched mode.

Owner:ZHUJI CANU AUTOMATION EQUIP CO LTD

Deep well coal-pillar-free gob-side entry driving method and formed roadway

PendingCN113187486AReduce air leakageReduce support resistanceMining devicesUnderground chambersArchitectural engineeringStructural engineering

The invention relates to the technical field of coal mining, in particular to a deep well coal-pillar-free gob-side entry driving method and a formed roadway. The deep well coal-pillar-free gob-side entry driving method comprises the steps of constructing a closed wall, constructing an advanced grouting drilling hole, constructing an observation drilling hole, grouting a residual area of a gate road under a previous working face and performing gob-side entry driving construction. Solid coal is positioned on one side of the formed roadway, a filling separation wall is positioned on the other side of the formed roadway, and the filling separation wall is positioned in the residual area of the gate road under the previous working face. According to the deep well coal-pillar-free gob-side entry driving method, a narrow coal pillar in the prior art is omitted, a filling material is used for filling the residual space of the adjacent roadway to form the low-elasticity filling separation wall, resource waste is reduced, meanwhile, the safety of gob-side entry driving is greatly improved, the process is simple, and operation is easy.

Owner:NORTH CHINA INST OF SCI & TECH

Method for controlling roadway deformation by presplitting blasting pressure release of base angle of roadway protection coal pillar

The invention discloses a method for controlling roadway deformation by presplitting blasting pressure release of a base angle of a roadway protection coal pillar. In the method, outside the scope of an advanced supporting area of a working surface, drilling is constructed at a certain angle in the direction towards a bottom plate of the coal pillar at the base angle of the roadway protection coal pillar; the bottom plate is presplit in a group charging one-time blasting, so that concentrated stress of the roadway protection coal pillar and a surrounding rock of a roadway is effectively released, the deformation of the roadway, in particular the deformation of the bottom plate, is reduced, and a control effect of the surrounding rock of the roadway is improved; compared with the traditional heaving floor treatment method of excavation of a pressure relief groove, floor grouting, floor anchoring and the like, the method disclosed by the invention has the advantages that the construction is simple, the labor and the material cost are saved, and high efficiency and stability are realized, therefore, the applicability is wide.

Owner:CHINA UNIV OF MINING & TECH

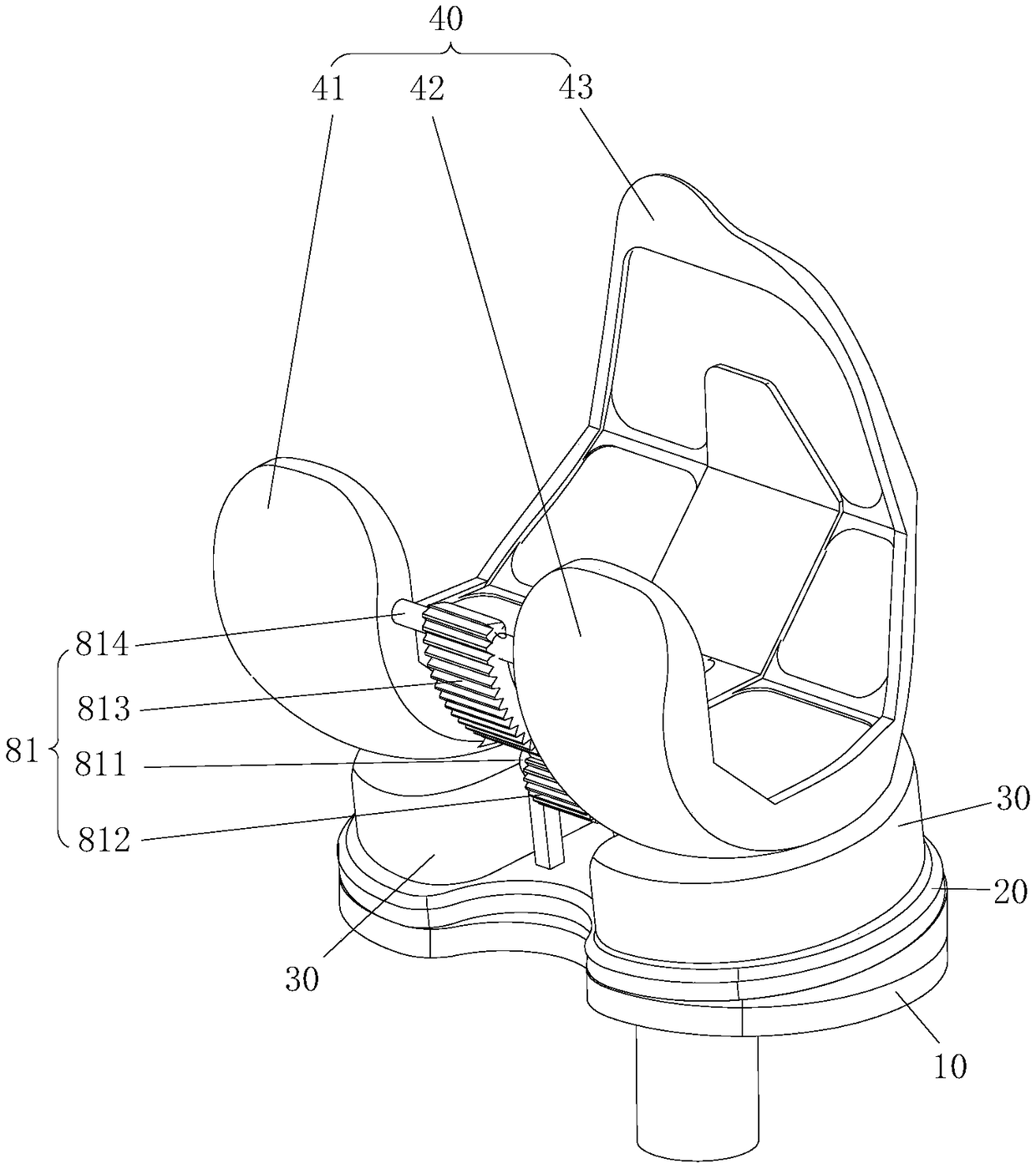

Knee joint prosthesis

PendingCN109481095AImprove stress environmentExtended service lifeJoint implantsKnee jointsPhysical medicine and rehabilitationKnee Joint

The invention provides a knee joint prosthesis comprising: a tibial plateau body; an adjusting member with a rotation point contacting the upper surface of the tibial plateau body; a driving mechanismdisposed on the tibial plateau body, wherein the driving end of the tibial plateau body is in contact with the adjusting member, and the driving mechanism drives the adjusting member to rotate aroundthe rotation point to adjust the inclined angle between the adjusting member and the upper surface of the tibial plateau body. The knee joint prosthesis solves the problem in the prior art that the upper surface of a tibial plateau of a femoral condyle prosthesis is always level.

Owner:BEIJING AKEC MEDICAL

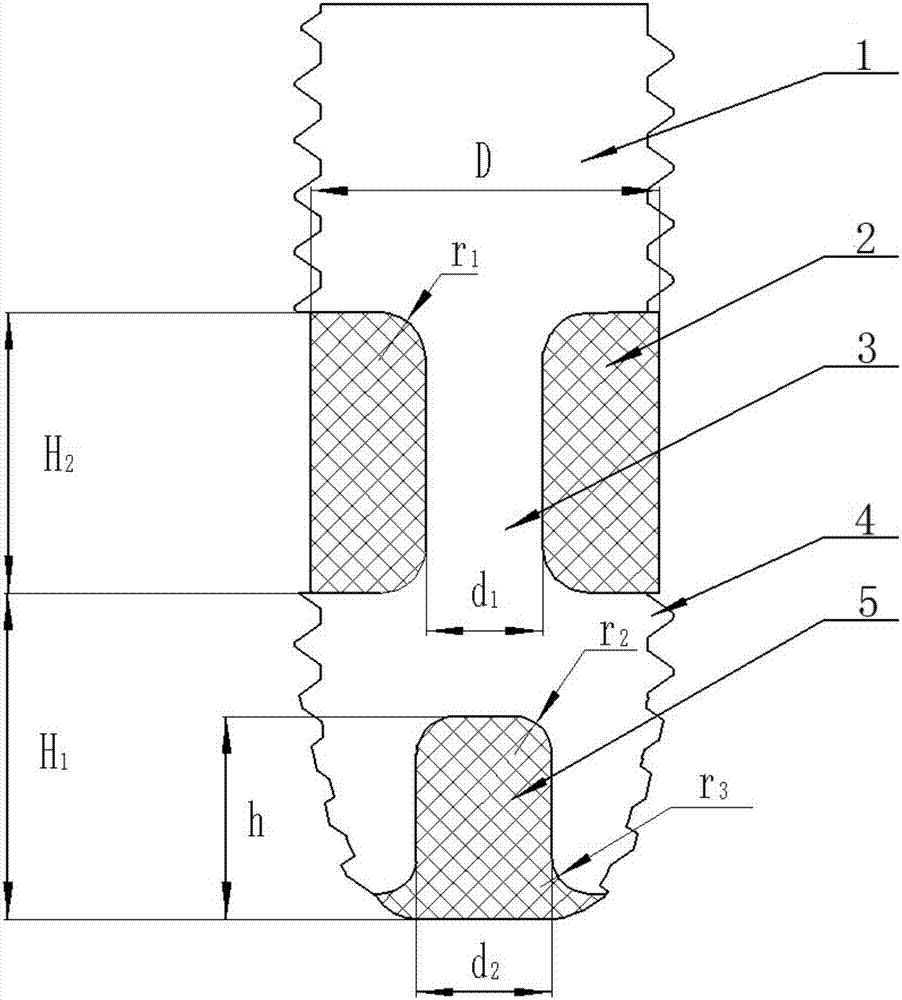

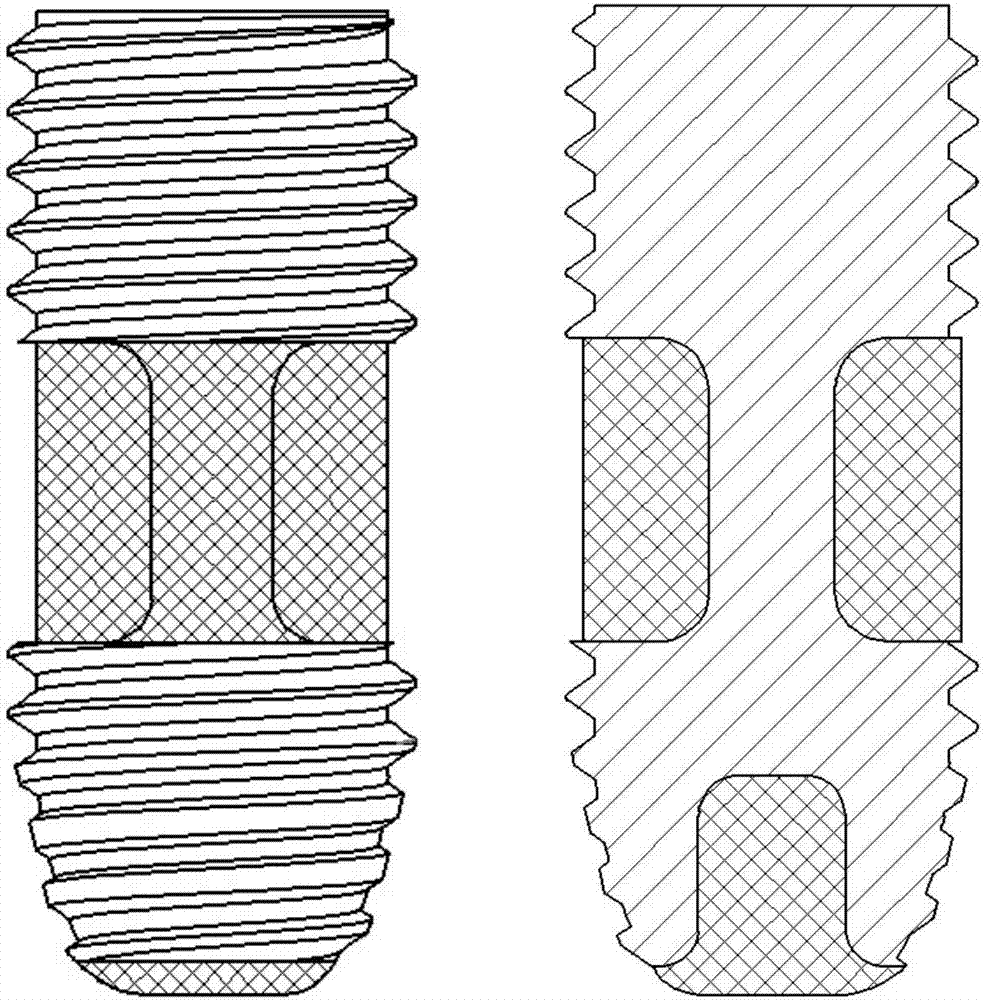

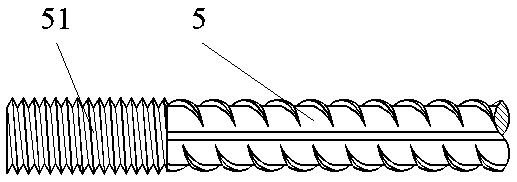

High-strength and low-rigidity porous titanium implant

InactiveCN107126281AIncrease success rateSufficient compressive strengthDental implantsBone tissueHigh intensity

The invention provides a high-strength low-rigidity porous titanium implant. The porous titanium implant comprises threaded parts, a porous structural part, and a support structure part. The upper segment and the lower segment of the porous titanium implant are the threaded parts, porous structures are embedded in the middle segment and the tip end, and the support structure part is embedded in the middle segment porous structure to connect the upper threaded part with the lower threaded part. The porous titanium implant has sufficient compressive strength, and has a controllable elastic modulus similar to that of human skeletons, the contact position of the implant and bone tissues has a good stress environment, and the porous structures capable of promoting bone integration can improve the success rate of the dental implant.

Owner:SHANGHAI JIAO TONG UNIV

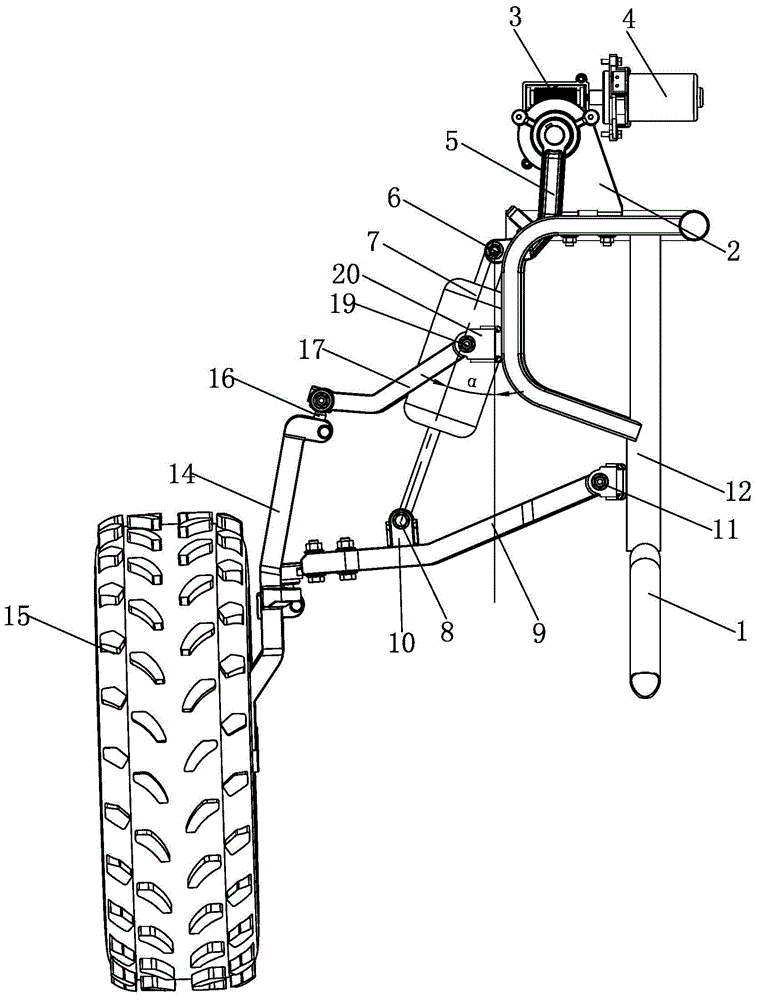

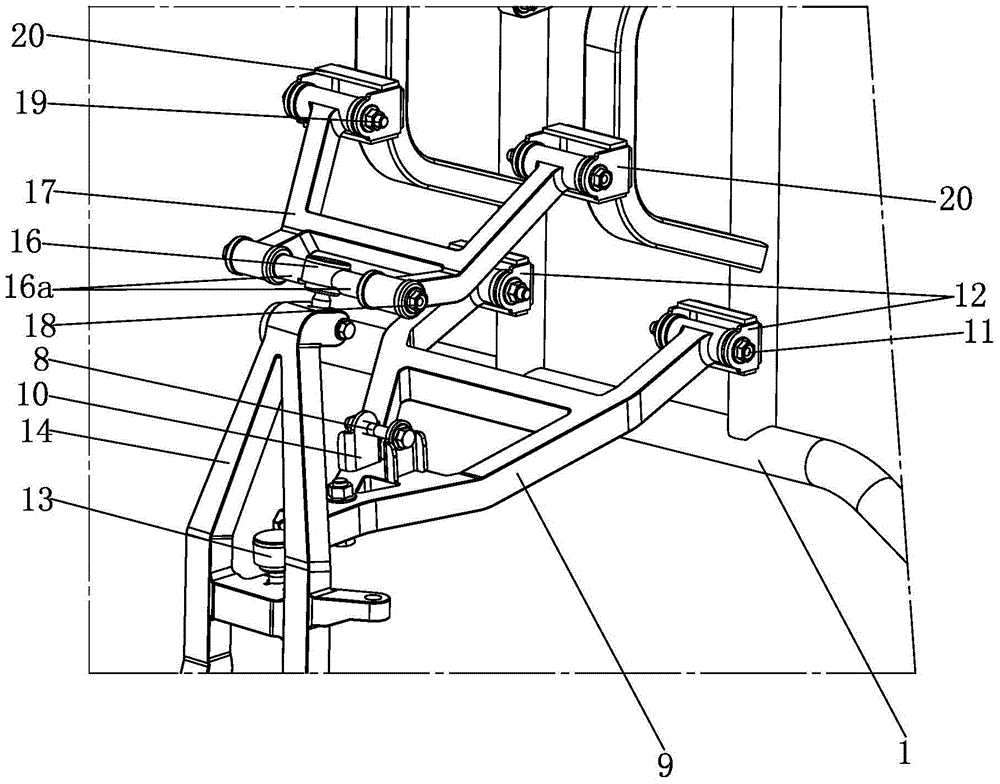

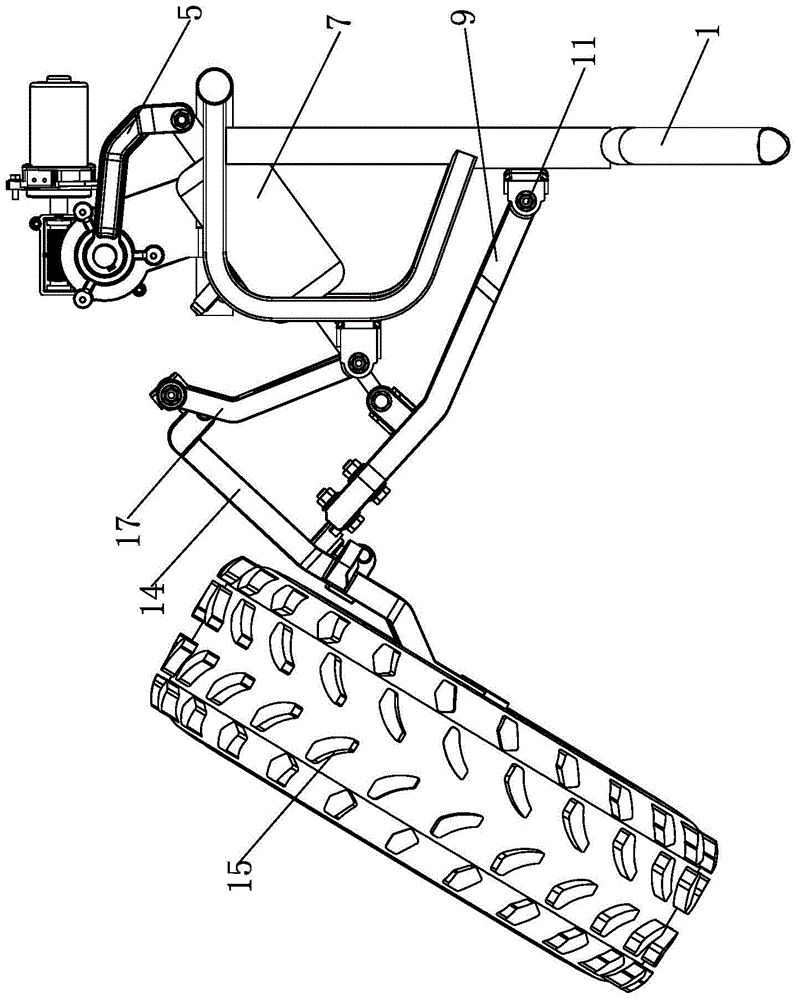

Wheel storing device of amphibious vehicles

InactiveCN105235458ASimple structureCompact structureAmphibious vehiclesVehicle frameReduction drive

The invention discloses a wheel storing device of amphibious vehicles. A rocker arm support and a speed reducer are fixedly installed on the top of a frame assembly. The input end of the speed reducer is connected with an output shaft of a motor, the output end of the speed reducer is coaxially connected with the upper end of a rocker arm, the lower end of the rocker arm is hinged to the upper end of a shock absorber, the lower end of the shock absorber is hinged to a first supporting lug in the middle of a lower cross arm, the inner end of the lower cross arm is hinged to the frame assembly, and the outer end of the lower cross arm is hinged to the middle of a steering arm. A wheel assembly is installed on the bottom of the steering arm. The rotating shaft end of an upper ball joint bearing is fixed to the top of the steering arm, and half shafts are coaxially arranged on the front side and the rear side of a case of the upper ball joint bearing respectively and are installed in sleeve structures at the outer end of an upper cross arm through bushes. The inner end of the upper cross arm is hinged to the upper part of the frame assembly. The frame assembly, the lower cross arm, the steering arm and the upper cross arm form a four-connecting-rod mechanism. According to the invention, on the premise of guaranteeing that wheels are normally stored, the storage angle is large, the gravity center of the whole vehicles is effectively lowered, the overall vehicle arrangement is convenient, and the stressing environment of the shock absorber is improved.

Owner:CHINA JIALING IND GROUP

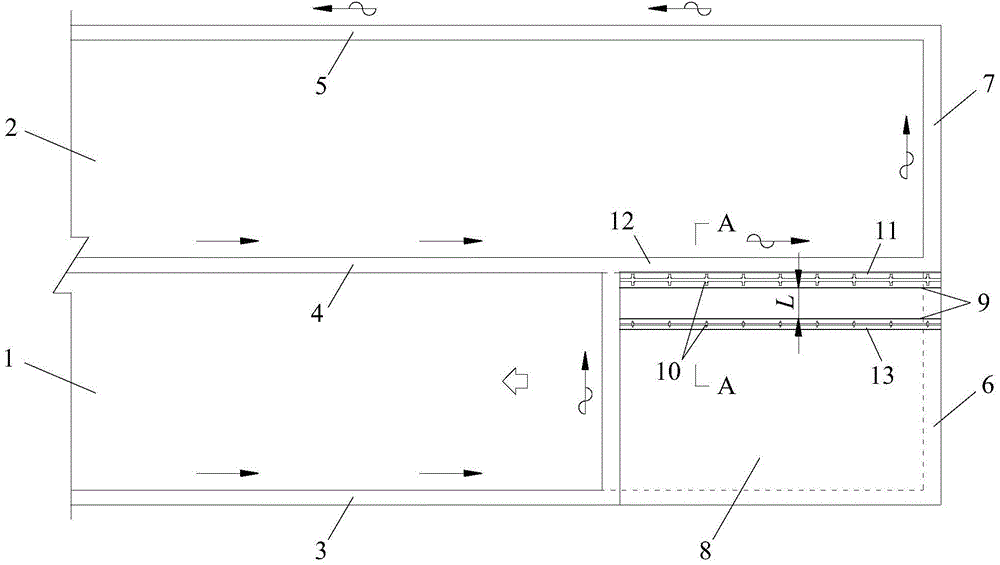

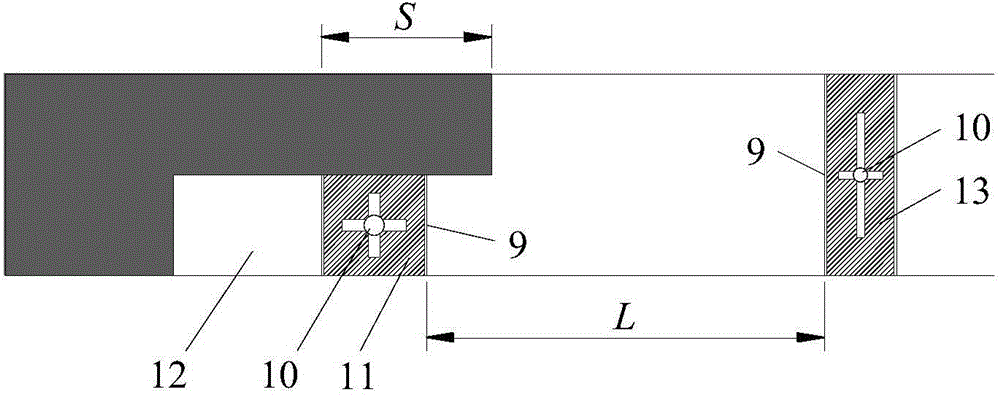

Cross-district double-U-shaped ventilating system for high-gas working face and application method for cross-district double-U-shaped ventilating system

The invention belongs to the field of mines, and relates to a cross-district double-U-shaped ventilating system for a high-gas working face and an application method for the cross-district double-U-shaped ventilating system. The working face is mainly served by an air inlet roadway, an air return roadway, an air inlet gas exhaust tail roadway and an air return gas exhaust tail roadway of the ventilating system, and the air inlet roadway is connected with the air return roadway by the working face, so that an inner U-shaped ventilating system is formed; the air return gas exhaust tail roadway is distanced from the outer side of the air return roadway by 5-20m, the air inlet gas exhaust tail roadway is distanced from the outer side of the air inlet roadway by 150-350m, and the two gas exhaust tail roadways form an outer U-shaped ventilating system by the aid of an auxiliary cut hole. The double-U-shaped ventilating system and the application method have the advantages that the problem of gas accumulation at upper corners and a gob of an existing high-gas working face is solved, an excellent stress environment is provided for roadway driving and maintaining by a cross-district huge coal-pillar entry protection process, the coal recovery rate of each district is increased by means of reducing the width of each coal pillar between the corresponding roadways, and social and economic benefits are obvious.

Owner:CHINA UNIV OF MINING & TECH

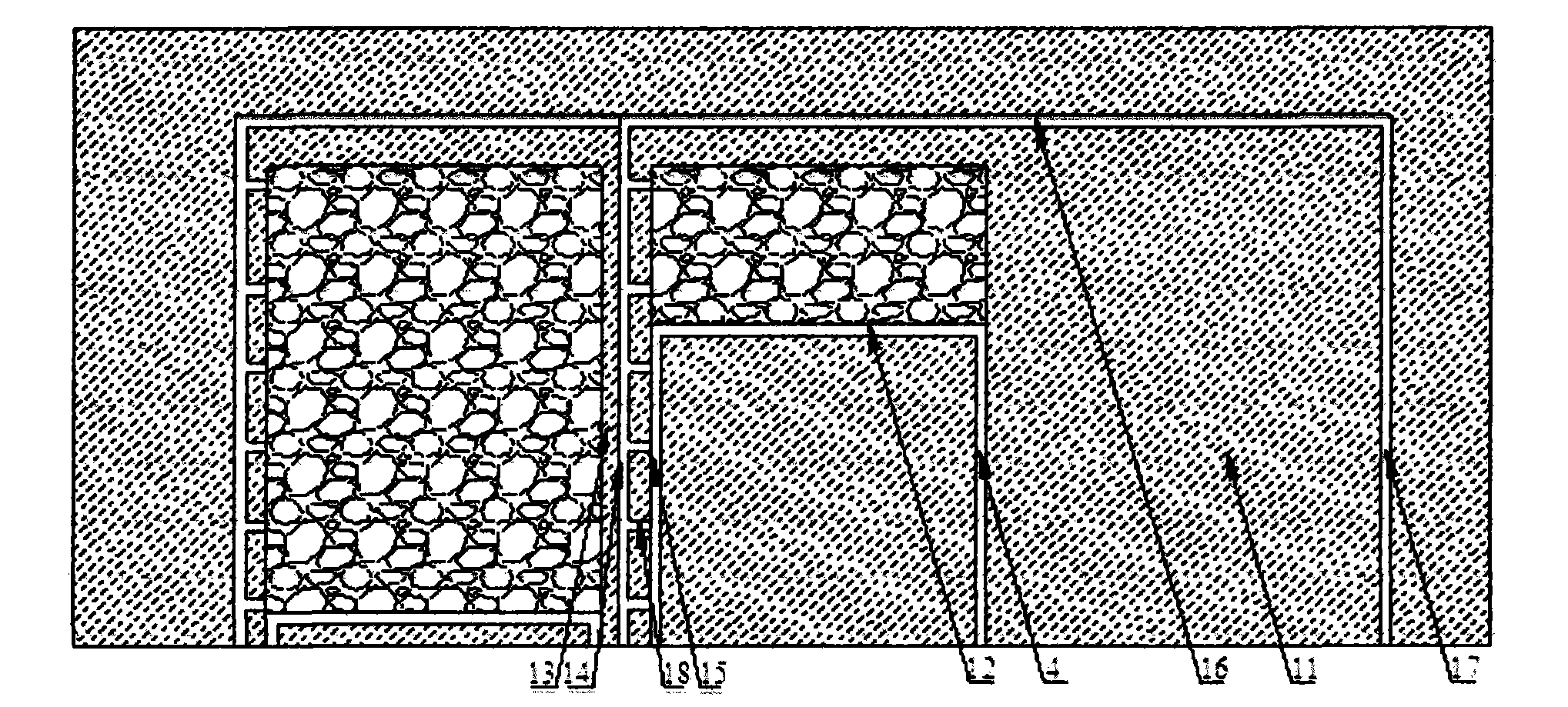

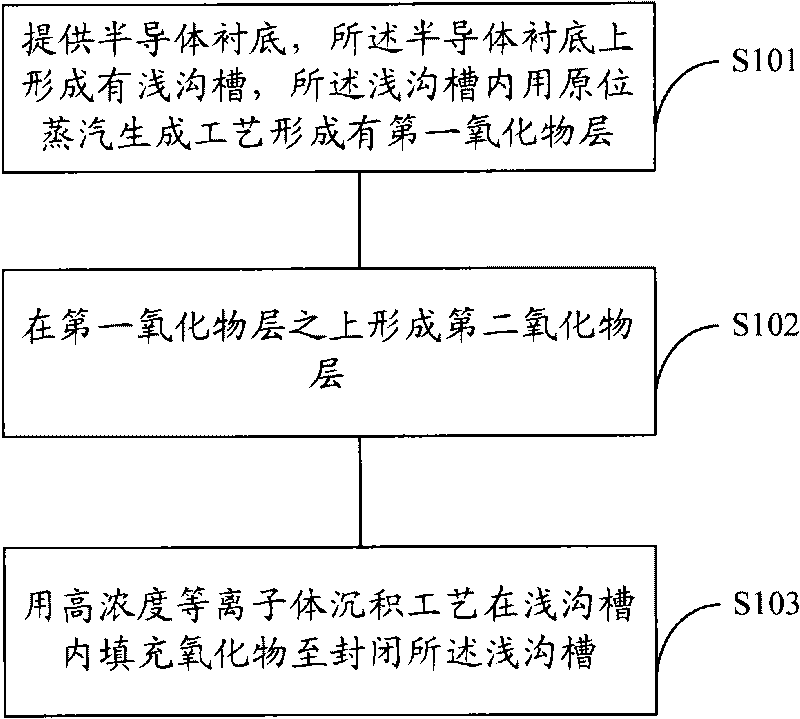

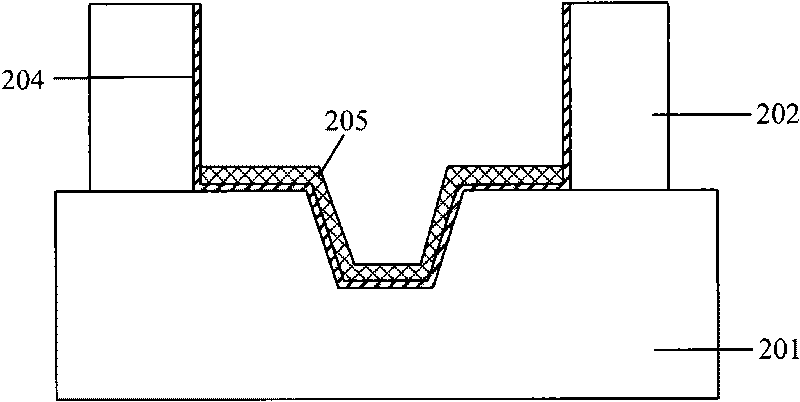

Manufacturing method of shallow trench structure and flash memory

ActiveCN101740456AImprove stress environmentFix bugsSolid-state devicesSemiconductor/solid-state device manufacturingHigh concentrationGas phase

The invention relates to a manufacturing method of a shallow trench structure and a flash memory, wherein the manufacturing method of the shallow trench structure comprises the following steps of: providing a semiconductor substrate, forming a shallow trench on the semiconductor substrate and forming a first oxide layer in the shallow trench according to an in-situ steam generation method; forming a second oxide layer on the first oxide layer; and filling an oxide in the shallow trench until closing the shallow trench through a high concentration plasma-chemical vapor deposition process. Compared with the prior art, a high temperature oxide layer is additionally deposited on an ISSG (In-Situ Steam Generation) oxide layer in the shallow trench in the flash memory, the ISSG oxide layer can be protected from being damaged when the shallow trench is filled, the stress environment in the shallow trench can be improved, and the defects in the shallow trench can be repaired, thereby improving the electrical performance of the flash memory.

Owner:SEMICON MFG INT (SHANGHAI) CORP

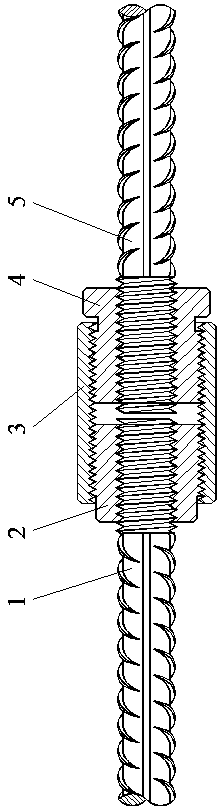

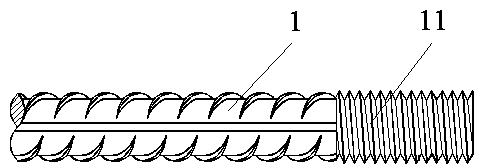

Steel reinforcement connecting device

InactiveCN108560834ARealize self-locking connectionEnsure ultimate bearing capacityBuilding reinforcementsArchitectural engineeringRebar

Owner:宁波市圣钢科技发展有限公司

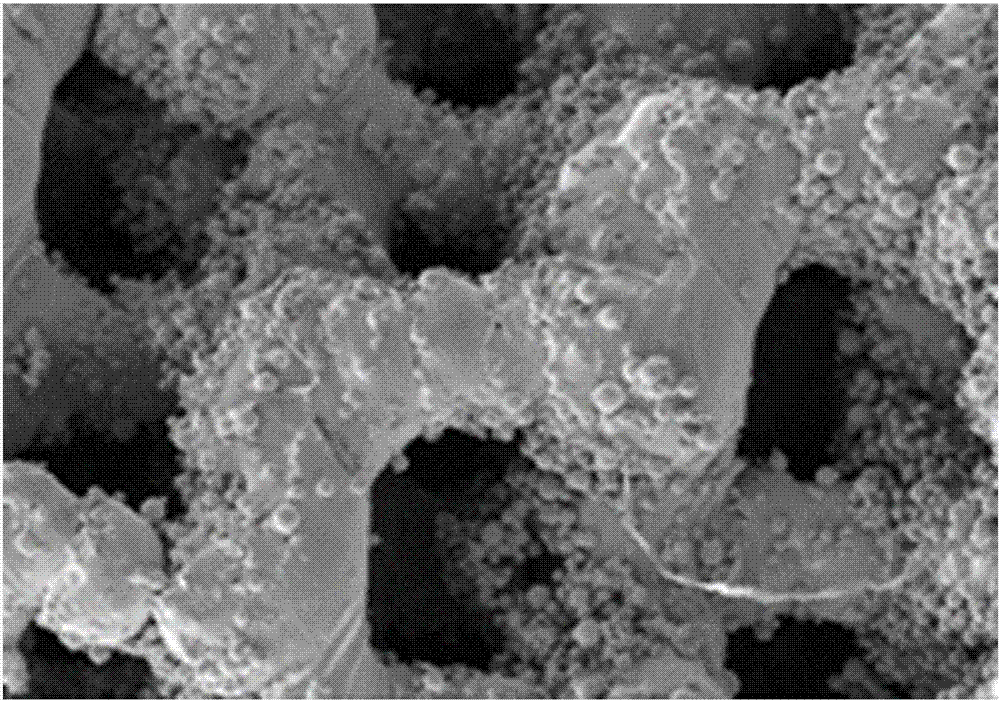

Friction extrusion strengthening method of structural member connecting hole

InactiveCN105855791AImprove stress environmentEnhanced ability to sprout and expandDislocationEngineering

The invention discloses a friction extrusion strengthening method of a structural member connecting hole, and belongs to the technical field of machining. The method comprises: using a friction extrusion head as a friction extrusion strengthening tool, under the condition of maintaining 0.02-1 mm extruding magnitude of interference between the friction extrusion head and a connecting hole, rotating the friction extrusion head and inserting into the connecting hole on a structural member in uniform speed, and stopping rotation for 2-5 s, and then pulling the friction extrusion head out; the rotation speed of the friction extrusion head being 100-1000 rpm, insertion speed being 0.1-2 mm / s, and pulling-out speed being 0.3-2 mm / s. In the above process, residual compressive stress is formed on neighborhood of the wall surface of the hole, and plastic flow occurs to the material near the wall surface of the hole, and the material has lattice distortion, and dislocation density is increased, so as to realize friction extrusion strengthening on the structural member connecting hole. The method is mainly used in strengthening of important structural member connecting holes in aviation, aerospace, trains, and ships, and other industries.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

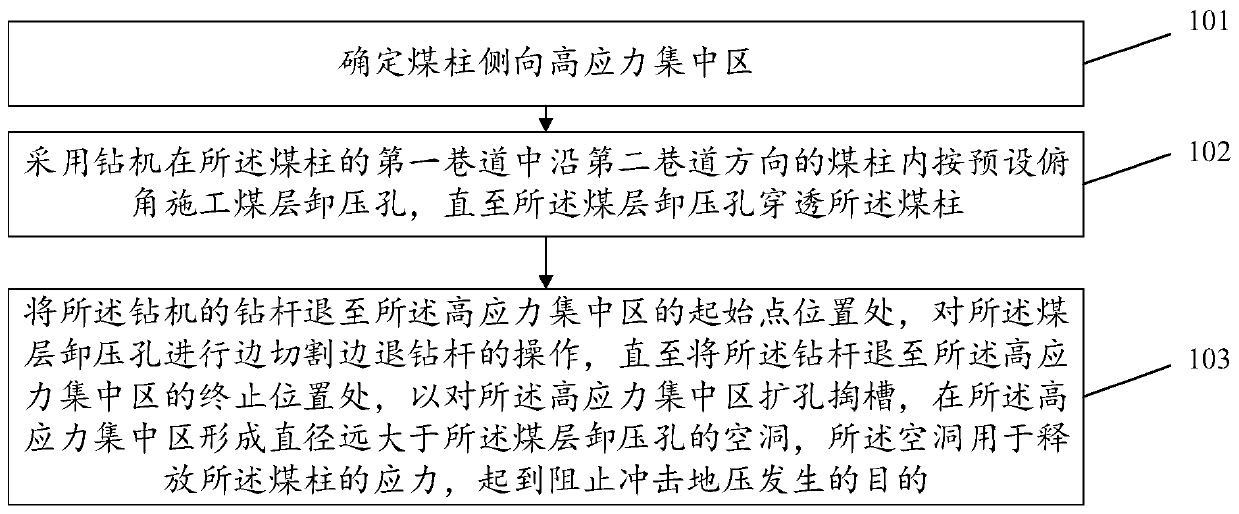

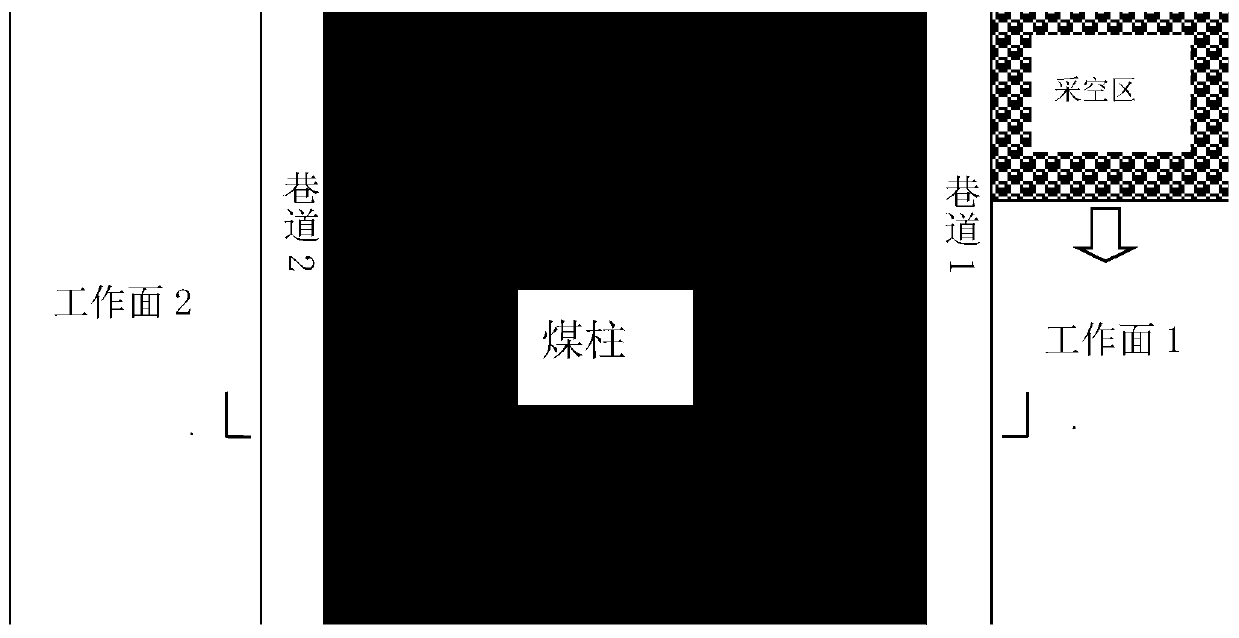

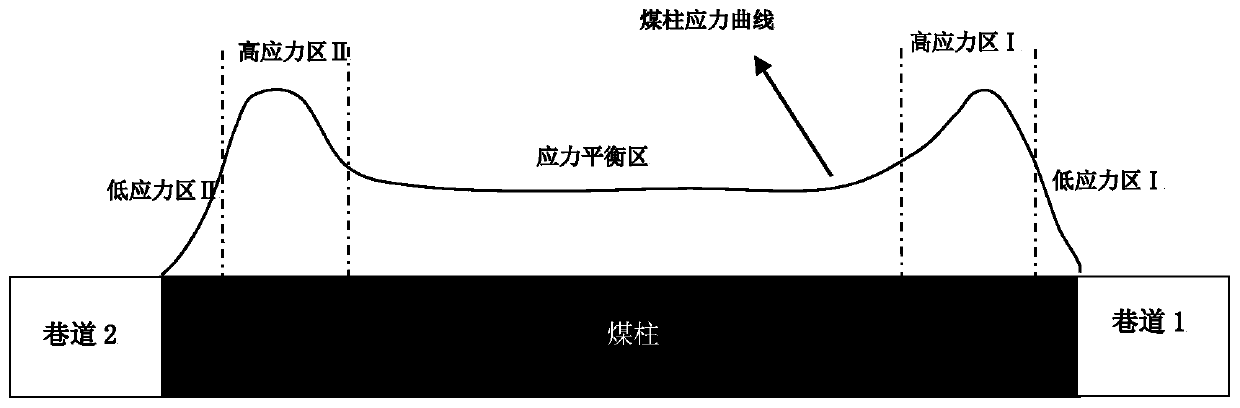

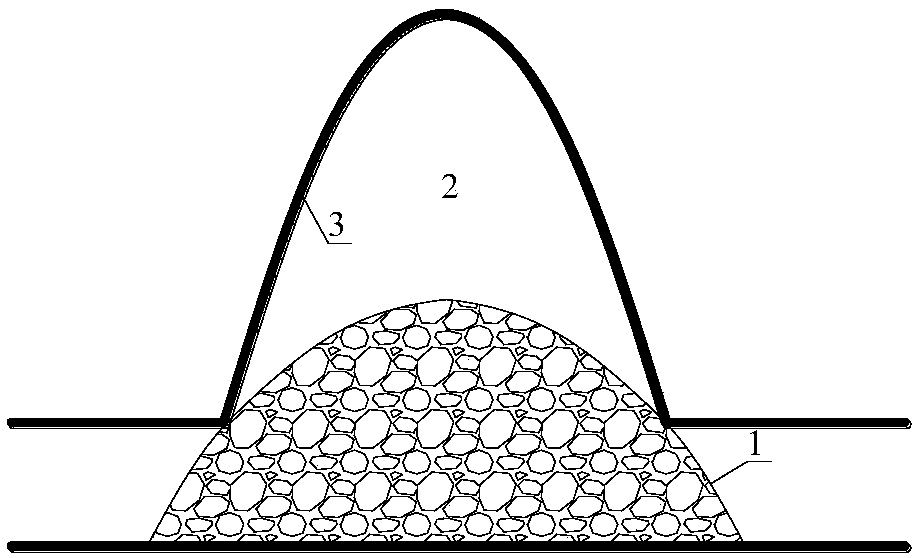

Method for preventing and controlling compression type rock burst of coal pillar

ActiveCN110017140AShock Disaster Risk EliminationImprove stress environmentDisloding machinesUnderground miningStress concentrationHigh stress

The invention discloses a method for preventing and controlling compression type rock burst of a coal pillar, relates to the technical field of coal mining, and mainly aims to reduce the concentrationdegree of high stress in the coal pillar, reduce and even eliminate the hidden danger of severe rock burst caused by high stress of the coal pillar, reduce the anti-impact work amount and reduce theanti-impact cost. The method comprises the following steps: determining a lateral high-stress concentration area of the coal pillar; constructing a coal seam pressure relief hole in the coal pillar ofa first roadway along a second roadway according to a preset depression angle by adopting a drilling machine until the coal seam pressure relief hole penetrates through the coal pillar; withdrawing adrill rod of the drilling machine to the initial point position of the high-stress concentration area, carrying out cutting while withdrawing the drill rod on the pressure relief hole of the coal beduntil the drill rod withdraws to the final position of the high-stress concentration area, so as to perform reaming and slotting on the high-stress concentration area, and forming a cavity with the diameter far larger than that of the pressure relief hole of the coal bed in the high-stress concentration area, wherein the cavity is used for releasing the stress of the coal pillar to achieve the purpose of preventing rock burst.

Owner:TIANDI SCI & TECH CO LTD

Treatment method of dug roadway roof fall

InactiveCN107654238AEliminate floating surfacesImprove stabilityUnderground chambersTunnel liningSlurrySteel frame

The invention discloses a treatment method of a dug roadway roof fall. The treatment method comprises the steps that after roof falling is completed, roof falling gangue is cleaned up timely, and loose coal-rock masses on the surface of a roof fall area are stirred up and fall; then a I-shaped steel frame shed is erected within a certain range of the roof fall area and the two sides and a layer ofwooden plate is tiled on the frame shed; then a filling bag is opened and the periphery of the bottom of the filling bag is fixed to the wooden plate, one end of a steel pipeline extends into the bagfrom a sleeve opening at the bottom of the filling bag and the top of the filling bag is supported to the highest point of the roof fall area, the steel pipeline is fixed and the other end of the steel pipeline is connected with a filling pipeline, the sleeve opening is fastened, and grouting is conducted till the whole roof fall area is filled with grout; and finally after the grout is cured, anchor cables are driven in the range of the roof fall area. According to the treatment method of the dug roadway roof fall, pressure stress can further be actively provided for the coal-rock masses onthe surface of the roof fall area by means of filling bodies while it is ensured that the filling bodies are stable, the stress environment of the coal-rock masses on the surface of the roof fall areais improved, once more roof falling of the roof fall area under the effect of construction disturbance can be effectively prevented, operation is simple, and the applicability is high.

Owner:CHINA UNIV OF MINING & TECH

Shallow trench isolation structure and manufacturing method thereof

ActiveCN102122628AAvoid destructionImprove isolation performanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention discloses a shallow trench isolation structure and a manufacturing method thereof. The manufacturing method comprises the following steps of: providing a semiconductor substrate and forming a shallow trench on the semiconductor substrate; forming a liner layer which is made of silicon oxynitride in the shallow trench; and forming a filling oxide layer for filling the shallow trench on the liner layer. According to the technical scheme, the liner layer which is made of the silicon oxynitride is formed before the shallow trench is filled, so that the smoothness of the shallow trench and a stress environment in the shallow trench can be improved, the liner layer and the semiconductor substrate below the liner layer are prevented from being damaged during implementation of subsequent process manufacturing, isolation performance of the shallow trench isolation structure is enhanced, the electrical property of a semiconductor device is improved, and the yield of a semiconductor product is further improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

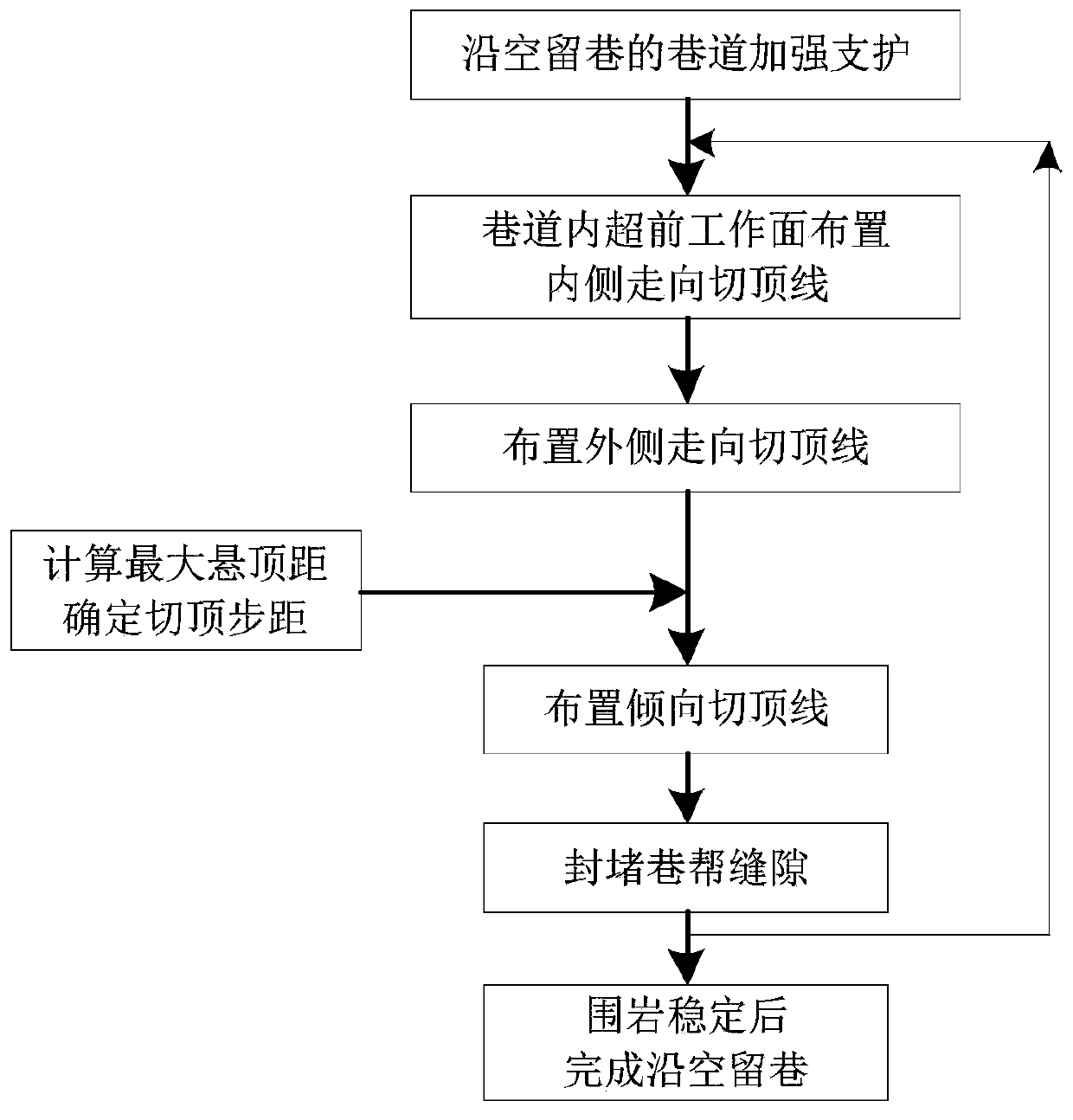

Method for gob-side entry retaining through three-seam periodical roof cutting entry side self-forming in transition support area

ActiveCN110030013AAvoid enteringSavings in blocking gangue and other processesTunnelsAnchoring boltsSelf formingStructural engineering

The invention provides a method for gob-side entry retaining through three-seam periodical roof cutting entry side self-forming in a transition support area, and relates to the technical field of mining engineering. The method comprises the steps: A, an entry for supporting gob-side entry retaining is reinforced through anchor rods and anchor cables, and a single hydraulic prop is arranged besidethe entry; B, an inner side traveling-direction roof cutting line is arranged on the advanced position of an entry working face for gob-side entry retaining; C, anchor rods and anchor cables are additionally arranged while stoping is conducted along with the working face, and an outer side traveling-direction roof cutting line is arranged; D, the maximum suspended roof distance of combined rock beams is calculated, the roof cutting stepping distance is determined, the roof cutting stepping distance is smaller than the maximum suspended roof distance, and an inclination-direction roof cutting line is arranged every time the working face is propelled by the distance exceeding the roof cutting stepping distance; E, the combined rock beams fall to form entry sides, and seams between the entrysides and an entry roof are blocked; and F, propelling is conducted along with the working face, the step B to the step E are repeated, after entry surrounding rock is stabilized, the single hydraulicprop is withdrawn, and gob-side entry retaining is completed. The method solves the technical problem that gangue blocking of a thin coal seam during gob-side entry retaining is difficult and furtherhas the advantages that the entry sides are complete, and the deformation of the surrounding rock is small.

Owner:SHANDONG UNIV OF SCI & TECH

Side-hung type viaduct rail transit turnout system

PendingCN109572719ASolve the torsion problemEasy to disassembleBridge structural detailsElevated railway with suspended vehicleStructural engineeringRail transit

The invention discloses a side-hung type viaduct rail transit turnout system. The side-hung type viaduct rail transit turnout system comprises a beam pier stud and a plurality of turnout pier studs, wherein the turnout pier studs are arranged in the form of an arc shape with the beam pier stud as a circle center; a turnout beam body is connected between the beam pier stud and the turnout pier studs; the turnout beam body comprises a plurality of beam body units; a plurality of beam reserved holes are formed in the two ends of the beam body units; the adjacent beam body units are connected witheach other in a telescopic manner through connecting devices; one end of the turnout beam body is connected with the beam pier stud; the other end of the turnout beam body can swing to be connected with the turnout pier studs; and a driving device used for changing the transmission direction of the turnout beam body is arranged at the swinging end of the turnout beam body. According to the side-hung type viaduct rail transit turnout system, the floor area in rail transit can be effectively reduced, and the ground space can be released, and moreover, the line changing of side-hung type rail transit can be realized, and the operation cost of a train can be reduced.

Owner:GUANGZHOU METRO DESIGN & RES INST

Pre-twisted spacer

PendingCN112821332AAffect performanceReduce difficultyMaintaining distance between parallel conductorsBraced frameElectric cables

The invention relates to the technical field of spacers, and discloses a pre-twisted spacer, which comprises a supporting frame, wire clamps and pre-twisted wires. The supporting frame is composed of two supporting plates and a connecting piece, the connecting piece is located between the two supporting plates, and the supporting plates and the connecting piece are connected through bolts; the two wire clamps are arranged at the two ends of the supporting frame respectively. The wire clamp comprises a wire frame, a positioning frame, a semicircular ring, a fixing block and a screw rod. When the pre-twisted spacer is installed, the wire clamp is opened and clamped on a cable, the screw rod is rotated to close the wire clamp, so that the wire clamp is hung on the cable and cannot clamp the cable, stress concentration cannot be formed, the performance of the cable cannot be influenced, the pre-twisted wire is matched to be wound on the cable, and the wire clamp is fastened on the cable, so that the installation of the spacer is completed.

Owner:GULIFA ELECTRIC +1

Track pedestal for medical accelerator treatment bed

ActiveCN109745633ASimplify the installation and positioning processImprove installation accuracyX-ray/gamma-ray/particle-irradiation therapyEngineeringMedical device

The invention discloses a track pedestal for a medical accelerator treatment bed, and belongs to the technical field of structural design of accelerator medical equipment. The track pedestal comprisesa circular base and a pedestal body; the circular base is fixed inside the foundation of the ground, the pedestal body cooperates with a positioning surface on the circular base for primary positioning, a center positioning hole and a circular track are internally processed in the pedestal body, the center positioning hole serves as a centering hole for the rotation of the treatment bed and has the functions of positioning the center of the bed body of the treatment bed and limiting the vertical direction, and the circular track is located at the edge of the pedestal body and provides supportfor a treatment bed pedestal; the pedestal body achieves the adjustment of the levelness of the circular track and the fixation of the circular base through a plurality of sets of adjustment holes. The track pedestal has the advantages of being simple in structure, high in rigidity, good in flatness of the track, high in installation precision, convenient to adjust, large in circular track diameter and the like, and can be applied to simulated positioner diagnostic beds or other machine tools and equipment with the rotary function.

Owner:江苏海明医疗器械有限公司

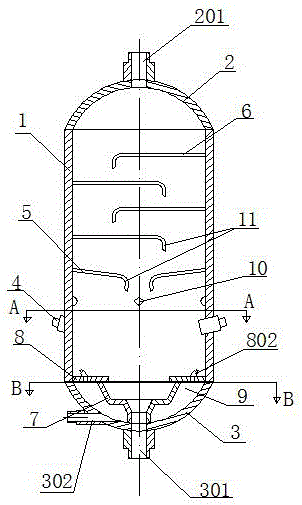

Ozone mixing reactor

InactiveCN106215656AIncrease profitAvoid direct impactAntifouling/underwater paintsDispersed particle separationEnvironmental engineeringUtilization rate

The invention discloses an ozone mixing reactor which comprises a chamber, wherein a plurality of gas inlet tubes are arranged on the side face of the chamber; the gas inlet tubes are eccentric tangential inclined insertion tubes; at least one downwards inclined sloping baffle is arranged above the gas inlet tubes in the chamber; and a plurality of baffle plates are sequentially arranged above the sloping baffle at intervals according to the axis direction of the chamber. The gas inlet tubes are set as the eccentric tangential inclined insertion tubes, and waste gases and ozone form eddy flow so as to be fully mixed and in full contact with each other, so that the ozone utilization rate is improved, the waste gases and ozone are prevented from directly impacting the wall surface of the chamber, the stress environment of the stainless steel chamber is improved, the stainless steel chamber has low probability of oxidation corrosion, and the problem that the stainless steel chamber is short in life is effectively solved. Due to coordination between the sloping baffle and baffle plates, lots of waste gases are fully treated, the ozone utilization rate is further improved, and the ozone mixing reactor is suitable for treatment of lots of waste gases.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com