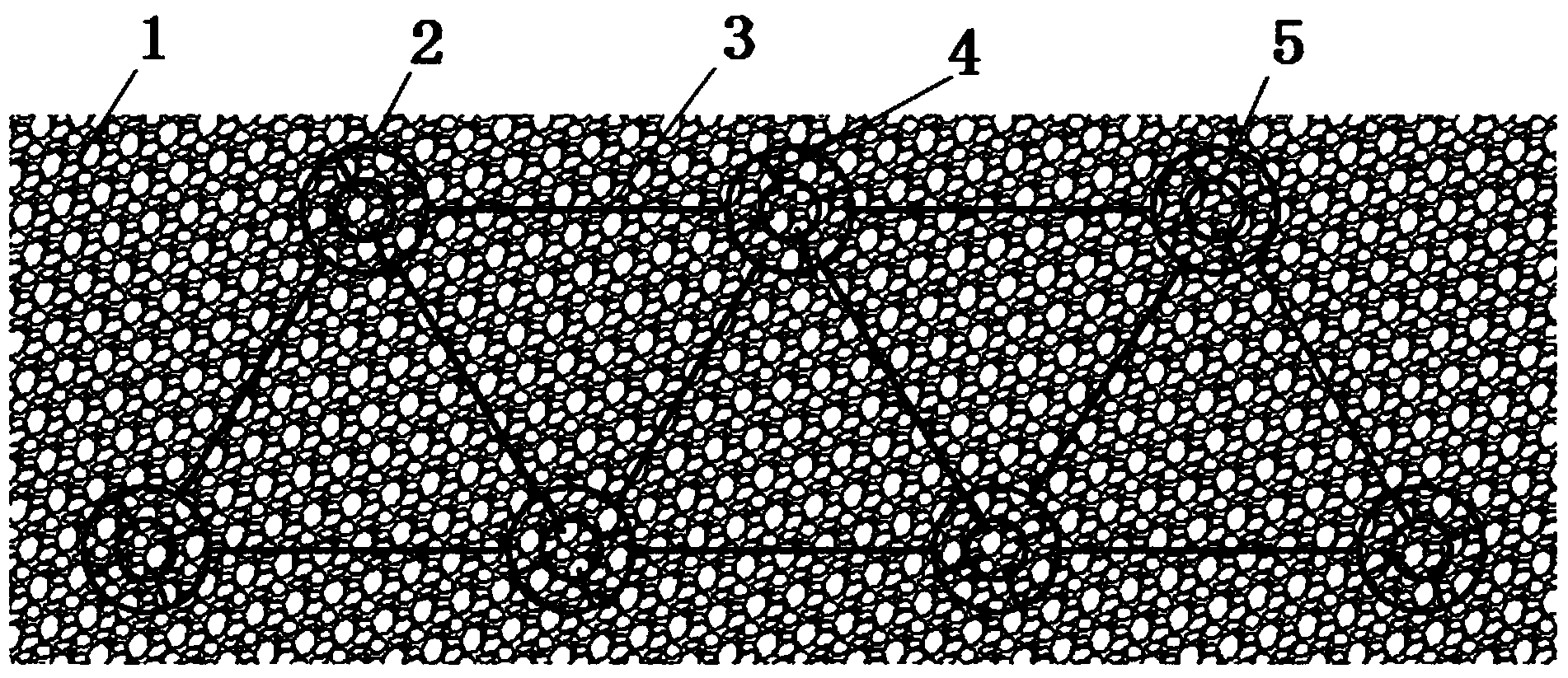

Composite reinforced roadbed and construction method

A technology of roadbed and water permeability, applied in the direction of roads, roads, buildings, etc., to achieve the effect of strong anti-corrosion ability, enhancing overall performance and reducing settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

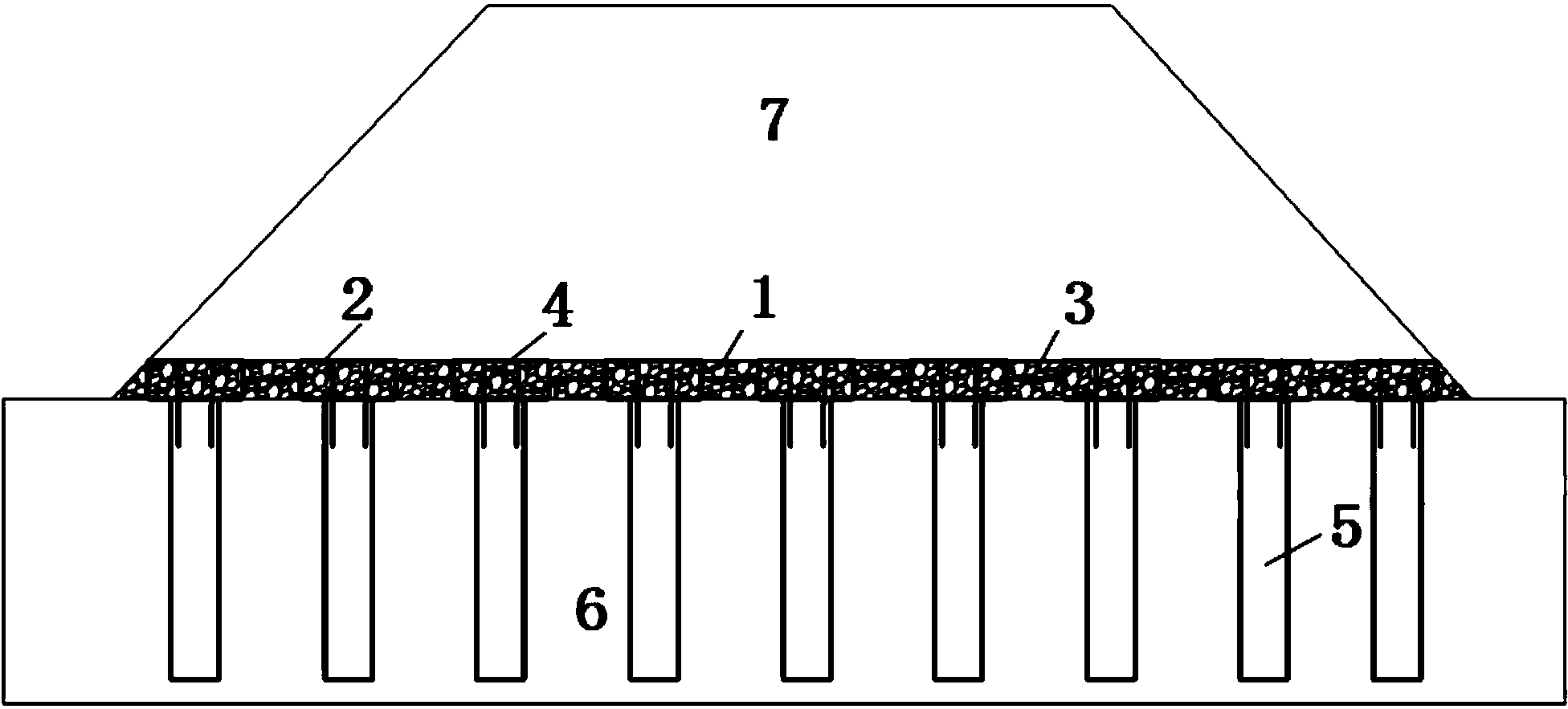

example 1

[0054] In a contract section of Qinglin Road, this method is used to treat the culvert foundation and subgrade to control settlement and reduce the hazard of vehicle jumping. The elevation of the subgrade is 6.5m, the diameter of the permeable concrete pile is 0.5m, the length of the pile under the culvert is 8m, and the treatment length of the subgrade part is 30m , divided into three zones A, B and C, each zone is 10m long, the piles in zone A are 11m long, the piles in zone B are 9m long, and the piles in zone C are 7m long. They are arranged in an equilateral triangle with a pile distance of 1.8m. Above, the gravel filling height is 20cm (tires and gravel are only arranged on the subgrade). The treatment results show that 3 years after the completion of the culvert and subgrade, the post-construction settlement of the culvert was 4.1cm, and the differential settlement compared with the bridge head was 1.8cm. Under the influence of heavy rain and heavy traffic load, there wa...

example 2

[0056] In a contract section of Shandong Provincial Highway S336, this method is used to treat the subgrade at the bridgehead to reduce the hazards of vehicle jumping at the bridgehead. The subgrade elevation of this section is 5.5m, the diameter of the permeable concrete pile is 0.5m, and the treatment length of the subgrade is 30m. It is divided into three types: A, B and C. Each area is 10m long. The piles in area A are 10m long, the piles in area B are 8m long, and the piles in area C are 6m long. They are arranged in an equilateral triangle with a pile distance of 1.5m. Tires are arranged above permeable concrete piles. . The treatment results show that after 5 years of highway operation, the differential settlement between the bridge head and the roadbed is 1.5cm. Under the influence of heavy rain and heavy traffic load, there is no slope collapse phenomenon, and the water content of the subgrade above the gravel cushion is significantly higher than that of the lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com