Method for controlling integral caving of roof through deep-hole segmented blasting kerf

A technology of deep hole blasting and segmental blasting, which is applied in blasting and other directions, and can solve problems such as the roof of the coal seam hanging and not falling, and achieve the effects of reducing the number of layouts, improving the stress environment, and reducing the difficulty of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

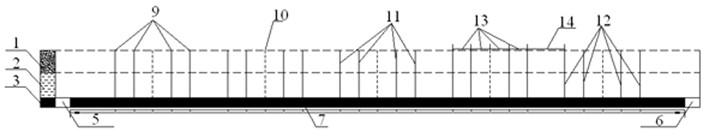

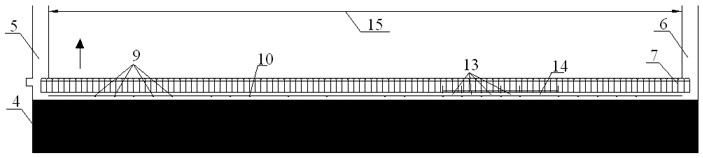

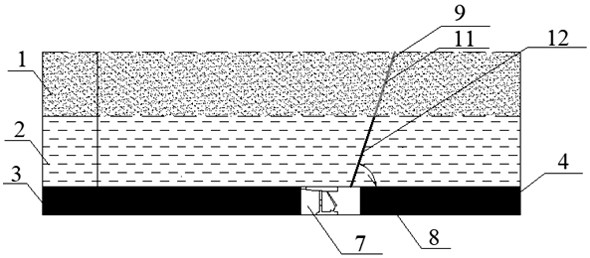

[0050]The average thickness of coal seam 3 in a mine is 2.45m and the average inclination angle is 4°. The old roof 1 of the coal seam is fine-grained sandstone with an average thickness of 6m, and the direct roof 2 of the coal seam is mudstone with an average thickness of 6.65m. The initial collapse step of the roof is about 35m, and the periodic pressure step is about 20m. The mine pressure is strong and the leading influence section of the mining roadway is deformed seriously. Therefore, deep hole segmental blasting is used in the lower section of the working face to cut the seam. Control the overall roof collapse method to reduce the initial collapse step of the working face.

[0051]The old roof of the coal seam is 12.65m away from the roof of the roadway, and the blasting cut-top height H is determined to be H=12.65m; the average thickness of the old roof is 6m, so the vertical height H of the charge section in the deep hole blasting hole is determined1=6m, the vertical height of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com