Tool and method for strengthening friction extrusion of structural member connecting hole

A technology for connecting holes and structural parts, applied in the field of machining, can solve problems such as narrow application range, cumbersome operation, complex process, etc., to enhance the ability of initiation and expansion, improve the stress environment, and improve the effect of wall surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

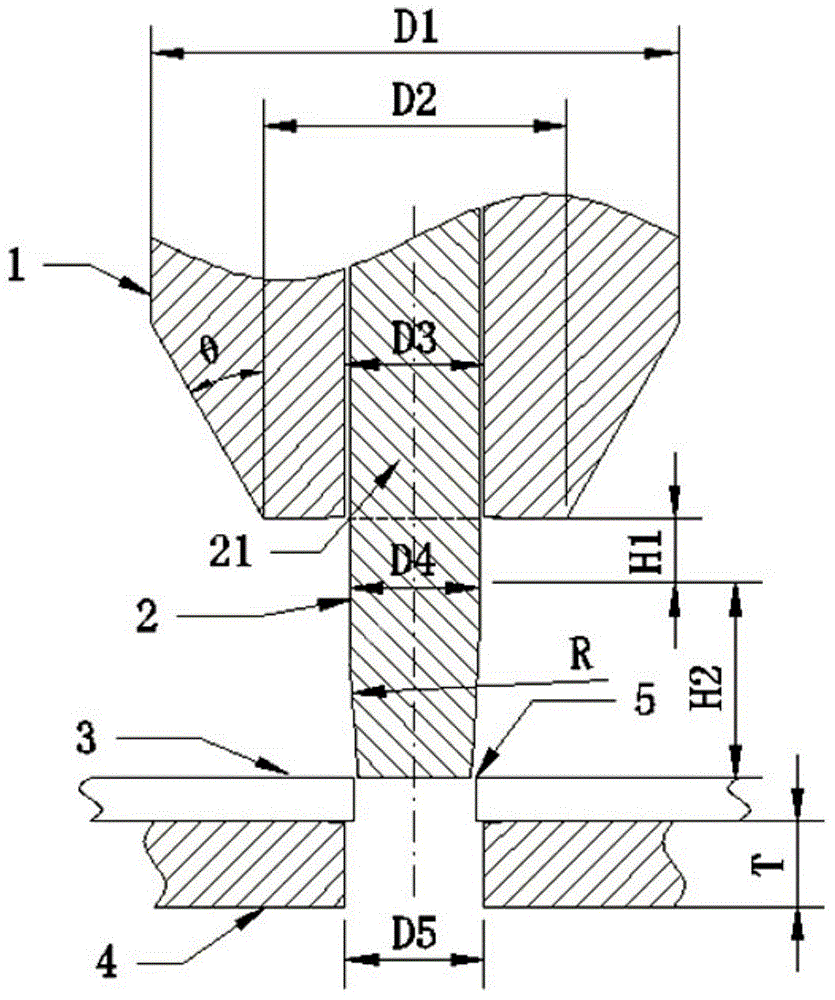

[0055] In this embodiment, the connection holes on the aluminum alloy structural parts are strengthened by friction extrusion, wherein the mother plate is a 2mm thick 7B04 aluminum alloy sheet, and the diameter of the connection holes before strengthening is 5.6mm. The material of the friction extrusion head and pressure shoulder is In718, whose hardness value is much higher than that of 7B04 aluminum alloy. The friction extrusion head and pressure shoulder adopt an integrated design. The specific size parameters are as follows:

[0056] (1) Friction extrusion head: D4=6mm, single-sided extrusion interference is 0.2mm, H1=5mm, R=100mm, H2=10mm, side surface roughness Ra of friction extrusion head=0.2μm.

[0057] (2) Shoulder pressure: D1=24mm, D2=14mm, θ=11.31°, due to the integrated design, D3 is ignored.

[0058] (3) Backing plate: T=15mm, D5=8mm.

[0059] Figure 4 Shown is the manufactured one-piece friction extrusion head and pressure shoulder.

[0060] Use the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com