Method of roof cutting pressure relief of narrow coal pillar gob side through static bursting for gob-side entry driving

A technology of roof cutting, pressure relief, and narrow coal pillars, which is applied in surface mining, earthwork drilling, underground mining, etc., and can solve problems such as hidden dangers, construction process without given hole layout parameters, and safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

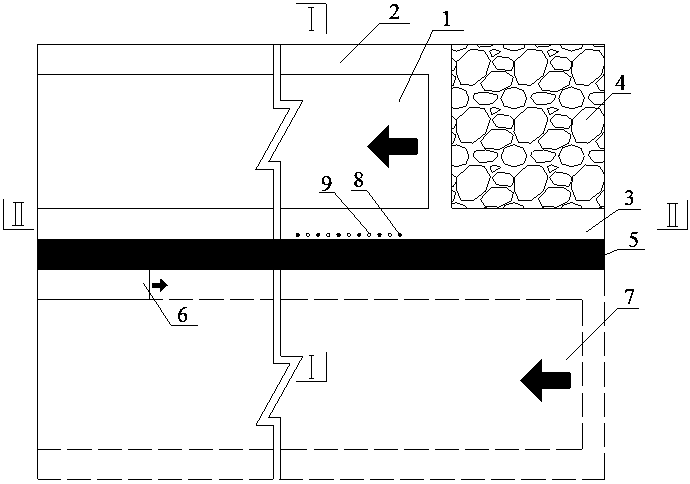

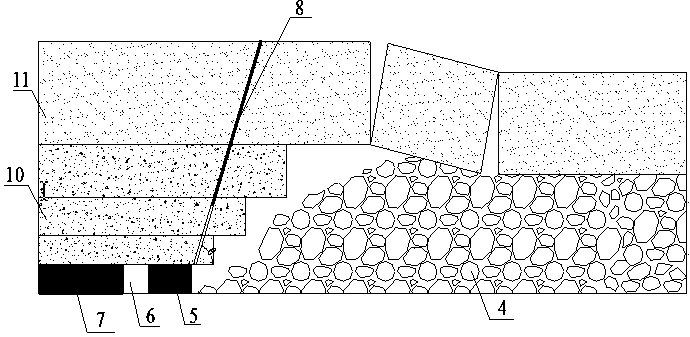

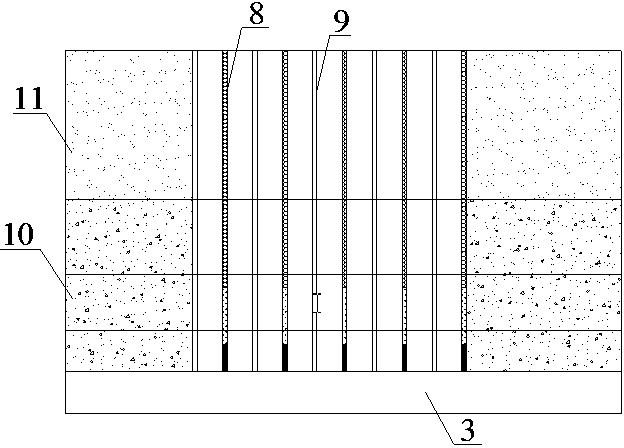

Embodiment 1

[0062] A mine is currently mining the No. 15 coal seam. The average thickness of the No. 15 coal seam is 3.5m. The immediate roof (10) is gray-black mudstone with an average thickness of 7.0m, and the basic roof (11) is fine sandstone with an average thickness of 4.0m. The working face (1) is equipped with two mining roadways, the transportation trough (2) of the upper section working face and the return air chute (3) of the upper section working face. ) mining at the same time, it is necessary to carry out the excavation of the lower section of the working face along the trough (6), so as to ensure that the preparation of the lower section of the working face (7) is completed before the upper section of the working face (1) is mined; in order to reduce the The transport chute (6) of the lower section working face is affected by the dynamic pressure of the mining of the upper section working face (1) when driving along the goaf, so the return air chute (3) of the upper section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com