Construction method for high face mining support removing passage under complicated geological condition

A construction method and working face technology, which are applied in mining equipment, earthwork drilling, pillars/supports, etc., can solve the problem that the withdrawal channel cannot be recovered and operated and connected, so as to reduce the recovery and withdrawal speed, select appropriate models, and reduce the effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

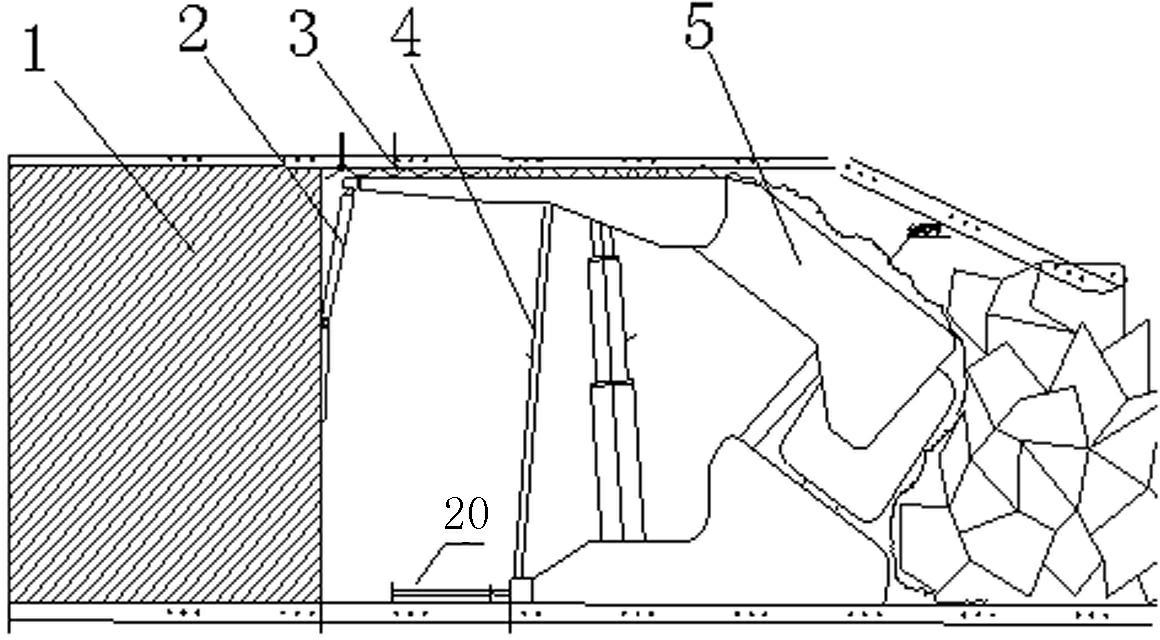

[0029] A construction method for the instant withdrawal channel used in the 6.2-meter mining height working face with complex geological conditions, the steps include:

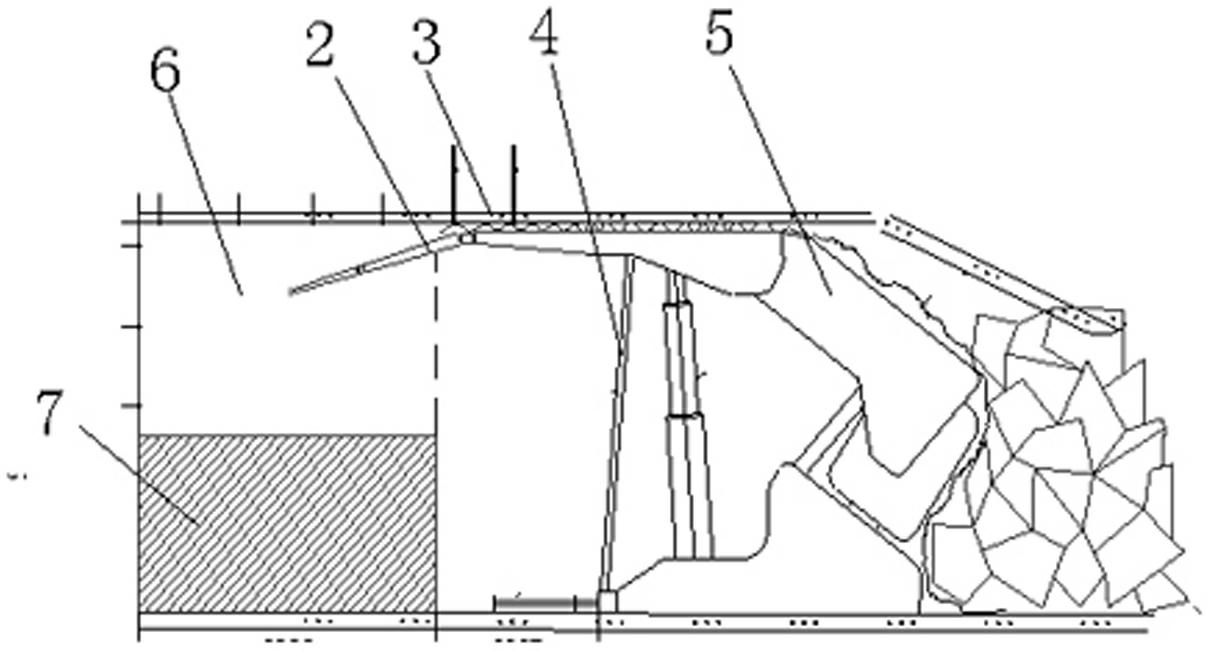

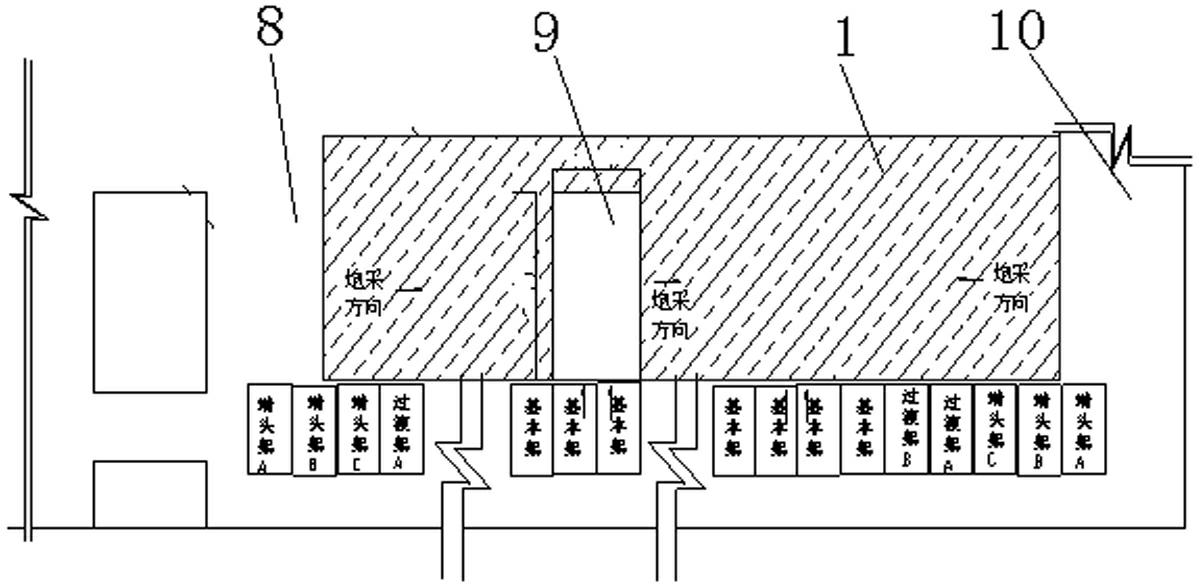

[0030] 1. Preparatory work before construction of the withdrawal channel, such as figure 1 As shown, in the final mining stage, in the previous cycle of the fixed frame, the top slab is supported by the locking anchor cable 3 between the hydraulic frame 5, and the top beam telescopic beam is extended before the anchoring cable, and the first and second side protection boards are played out in time. 2 Carry out the protection and set up the work platform manually. After the support is positioned, the bottom plate is required to be flat, and the floating coal is cleaned, the protection board is punched out, and 2 single columns are supported under the top beam of each support. 4 Increase the support for the roof . Such as Figure 8 As shown in the figure, in the case of a piece of fender, when the fender 2 is unabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com