Shield launching counter-force frame and installation and use method thereof

A technology of reaction frame and shield, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of not being able to fully utilize the performance of the reaction frame, the inability to disperse the reaction force, and increase the work risk, so as to reduce the construction cost. Operational risk, convenient installation and construction, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

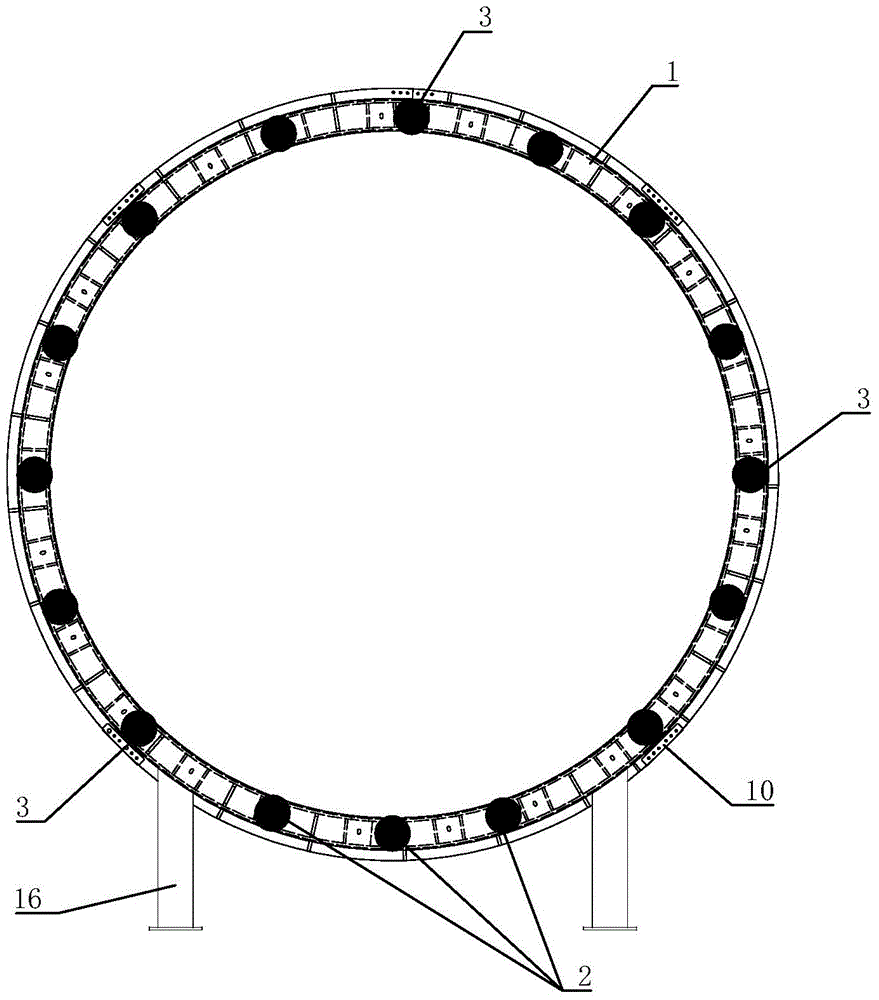

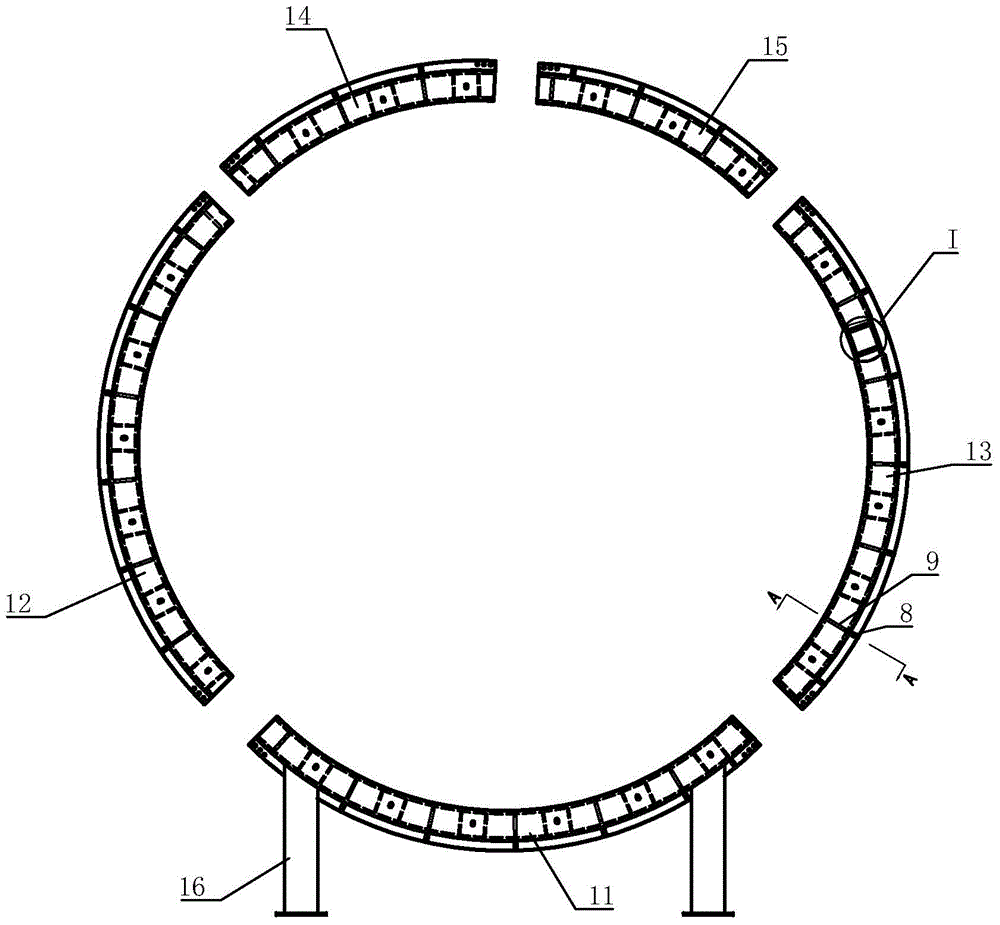

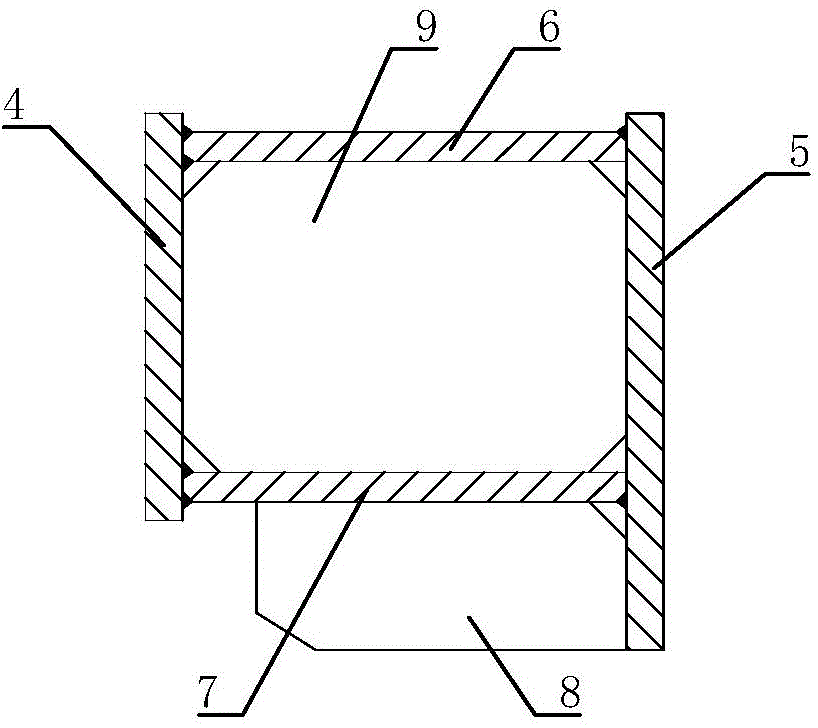

[0025] like figure 1 and Figure 5 and Figure 6 The starting reaction frame of the shield machine shown includes a ring-shaped steel ring body 1 spliced by several arc segments. The front of the steel ring body 1 faces the shield machine, the back faces the secondary lining 17 and faces away from the shield machine. The back of the steel ring body 1 is connected with 16 steel supports along the circumferential direction, including three horizontal supports 2 at the bottom of the steel ring body 1 and an oblique support 3 above the horizontal support 2. The horizontal support 2 is perpendicular to the plane where the steel ring body 1 is located. , the oblique supports 3 are scattered, and each oblique support 3 forms an included angle with the axial direction of the steel ring body 1 . The ring-shaped steel ring body 1 is conducive to providing reaction force for the start of the shield machine in the formed circular tunnel, which can improve the stress environment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com