A shield machine reaction force frame used in tunnel construction

A technology for tunnel construction and shield machine, applied in tunnels, mining equipment, earth-moving drilling, etc., can solve the problems of large size, inconvenient installation, disassembly and transportation, etc., to facilitate installation and construction, reduce construction operation risks, and improve structural strength. and stiffness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

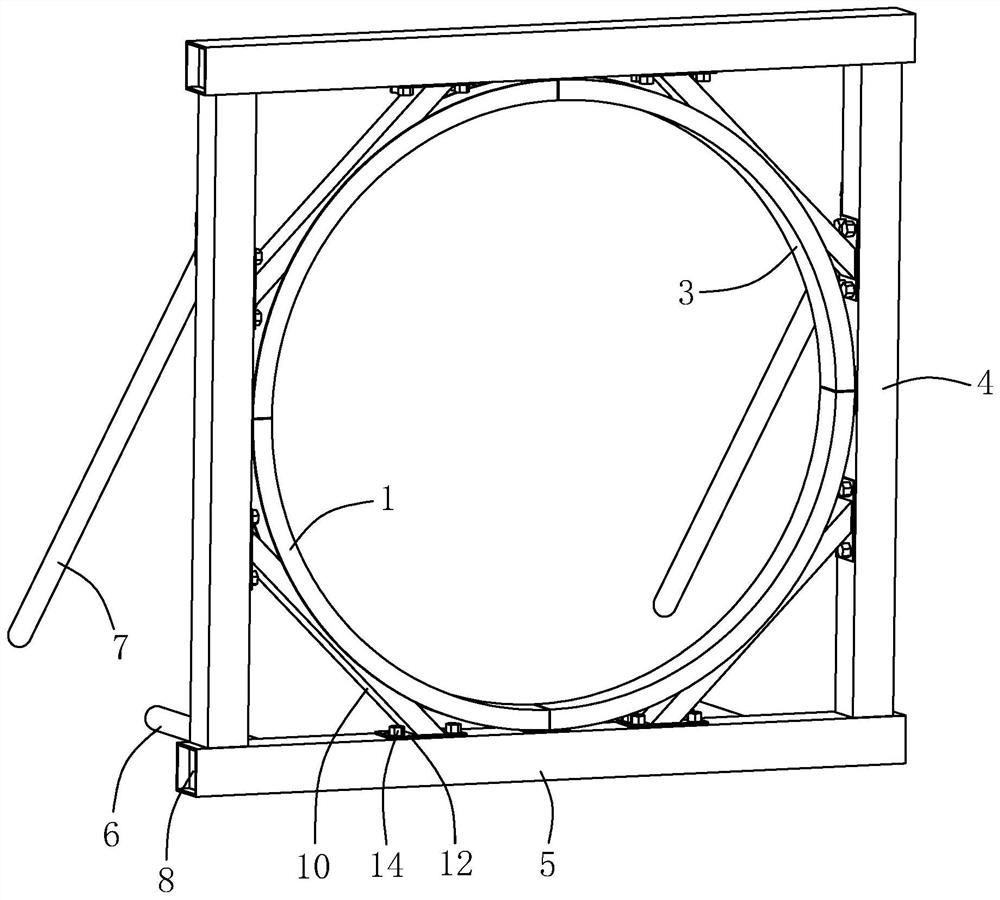

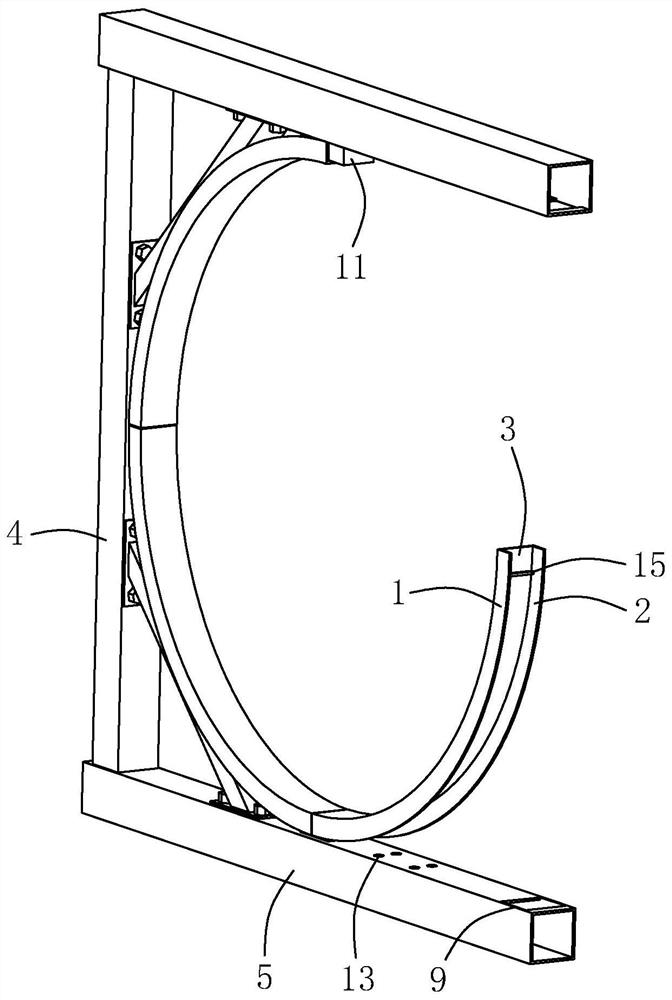

[0027] A shield machine reaction force frame used in tunnel construction, such as figure 1 and figure 2 As shown, it includes a ring-shaped ring body spliced by four arc segments, a steel body outside the ring body, and a support for supporting the back of the steel body. The steel body includes two upright columns 4 and two beams 5, the two ends of the upright columns 4 are integrally formed with plug-in columns 8, and both ends of the beam 5 are provided with slots 9 for plugging and matching with the plug-in columns 8. The post 8 cooperates with the insertion slot 9 to detachably connect the post 4 and the beam 5 together. The end of the plug-in post 8 is provided with rounded corners, which is convenient for inserting the plug-in post 8 into the plug-in slot 9 , thereby speeding up the efficiency of the staff to fix the column 4 on the beam 5 . In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com