Patents

Literature

56results about How to "Sufficient compressive strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

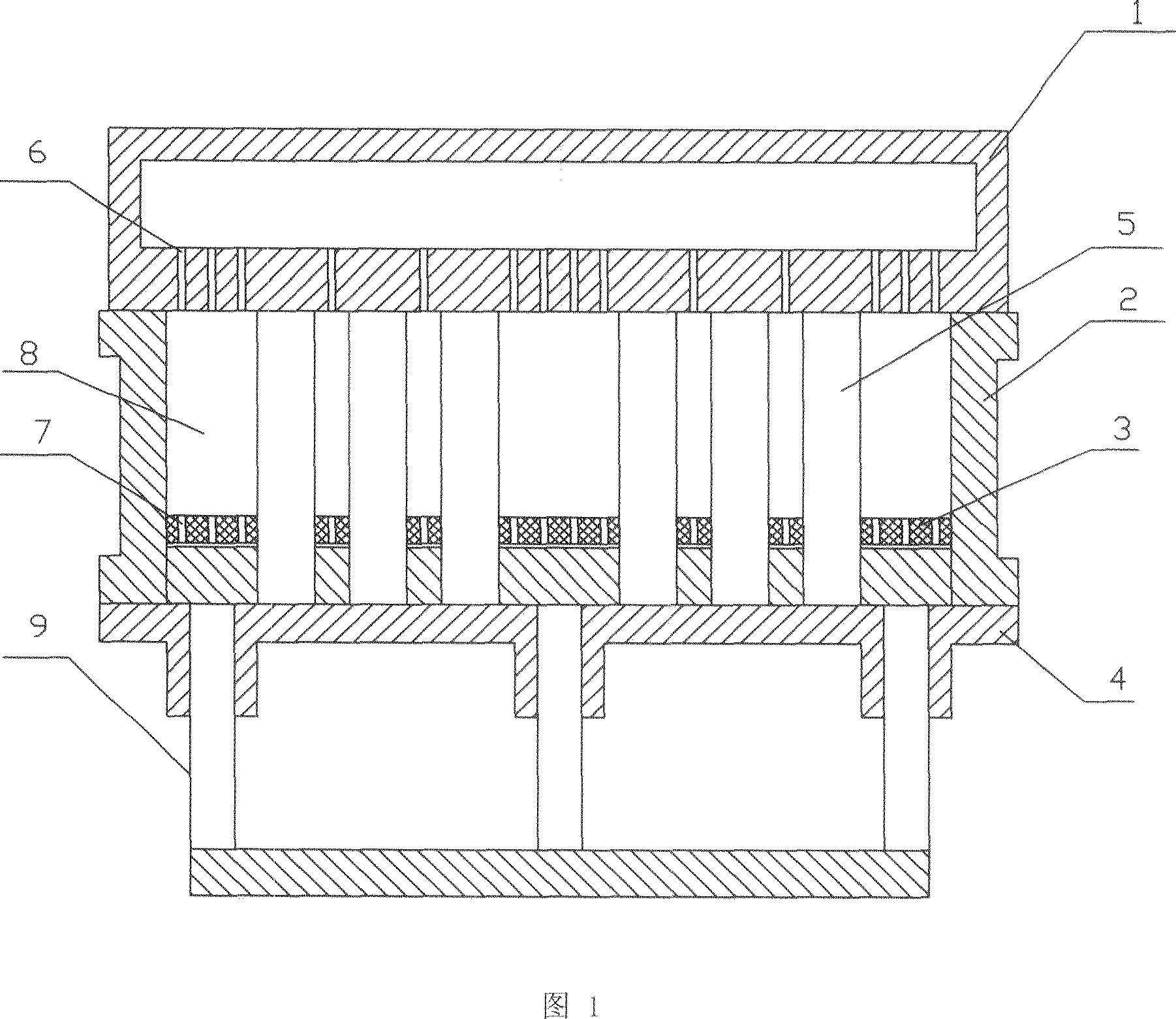

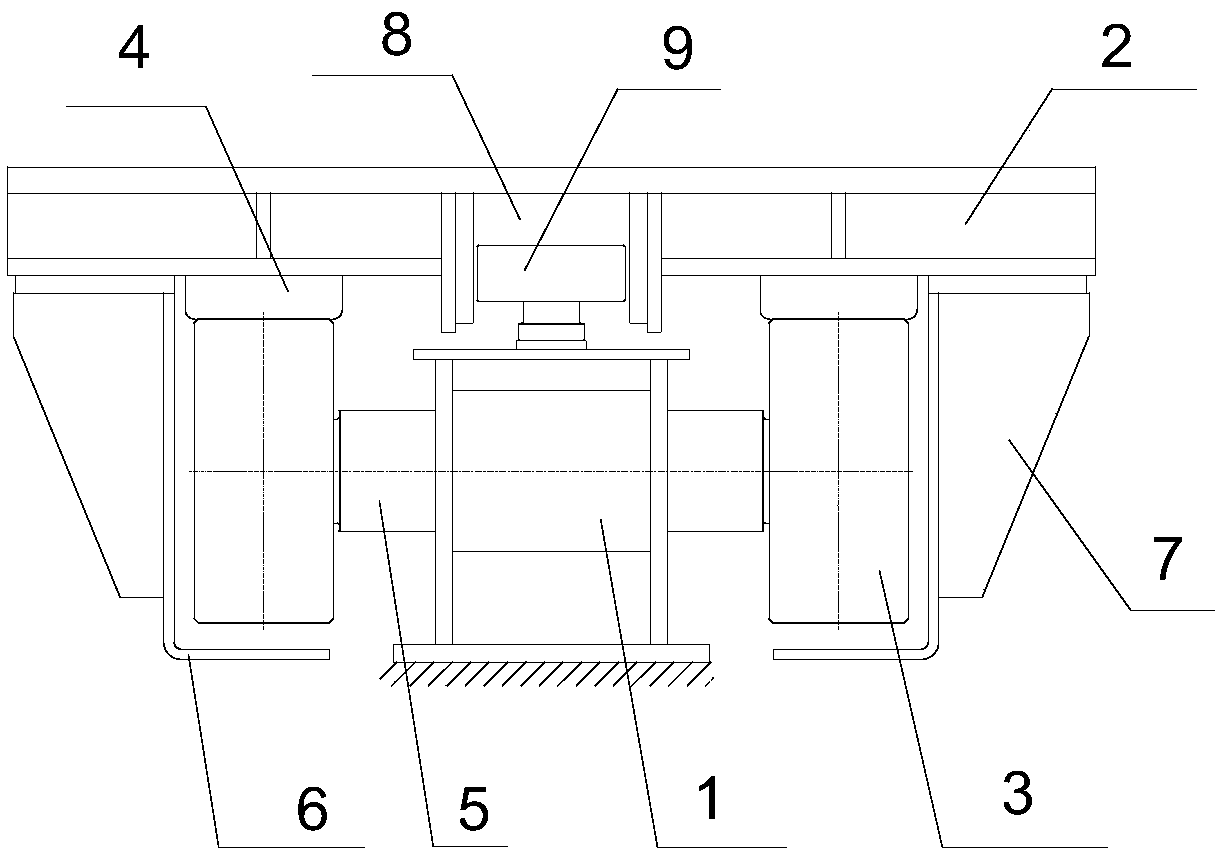

Pressure-proof proportion electromagnet based on integrated type flux sleeve

InactiveCN102063998AAvoid thin wallsAvoid long disadvantagesOperating means/releasing devices for valvesElectromagnets with armaturesHigh pressureElectromagnet

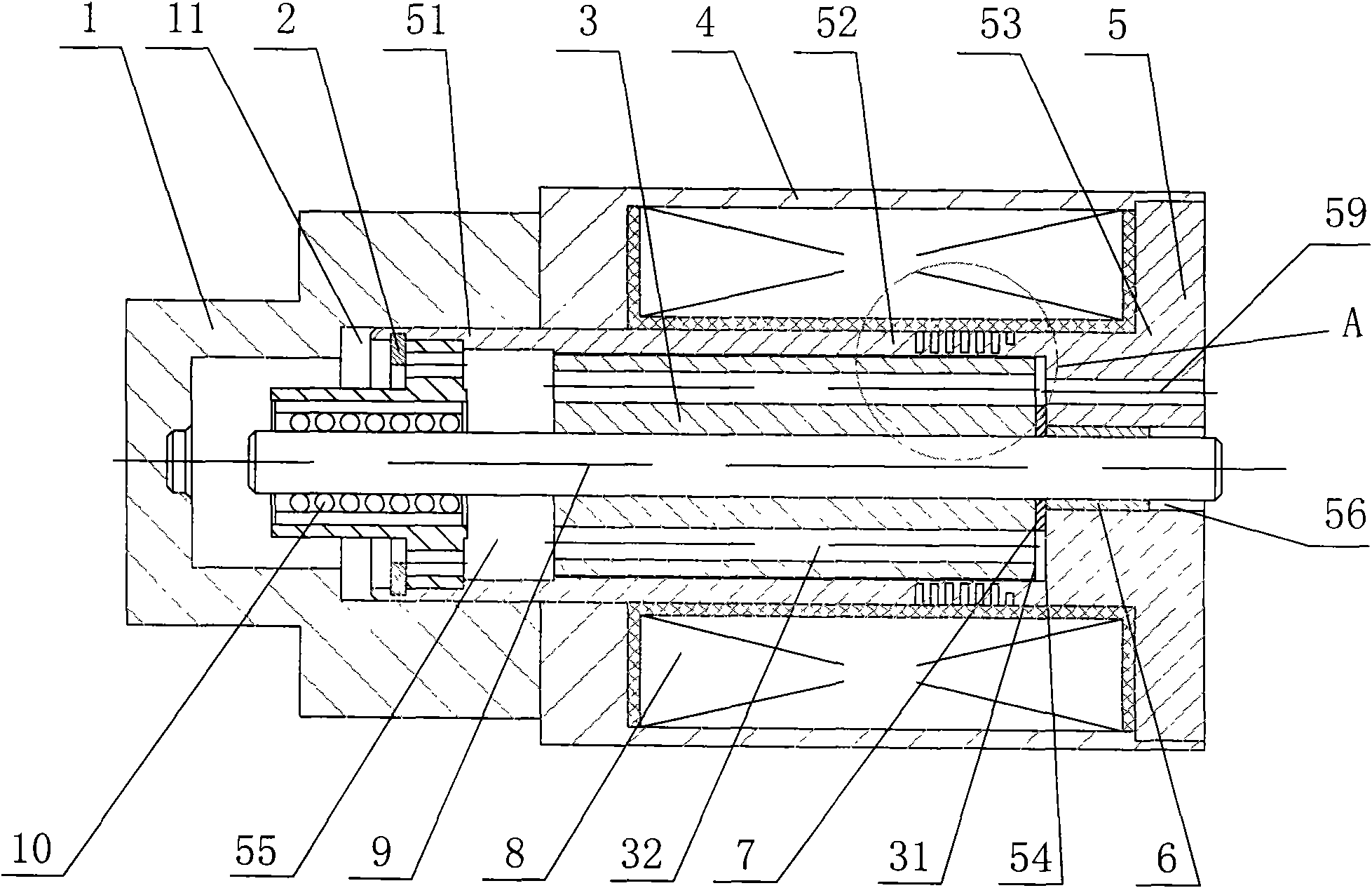

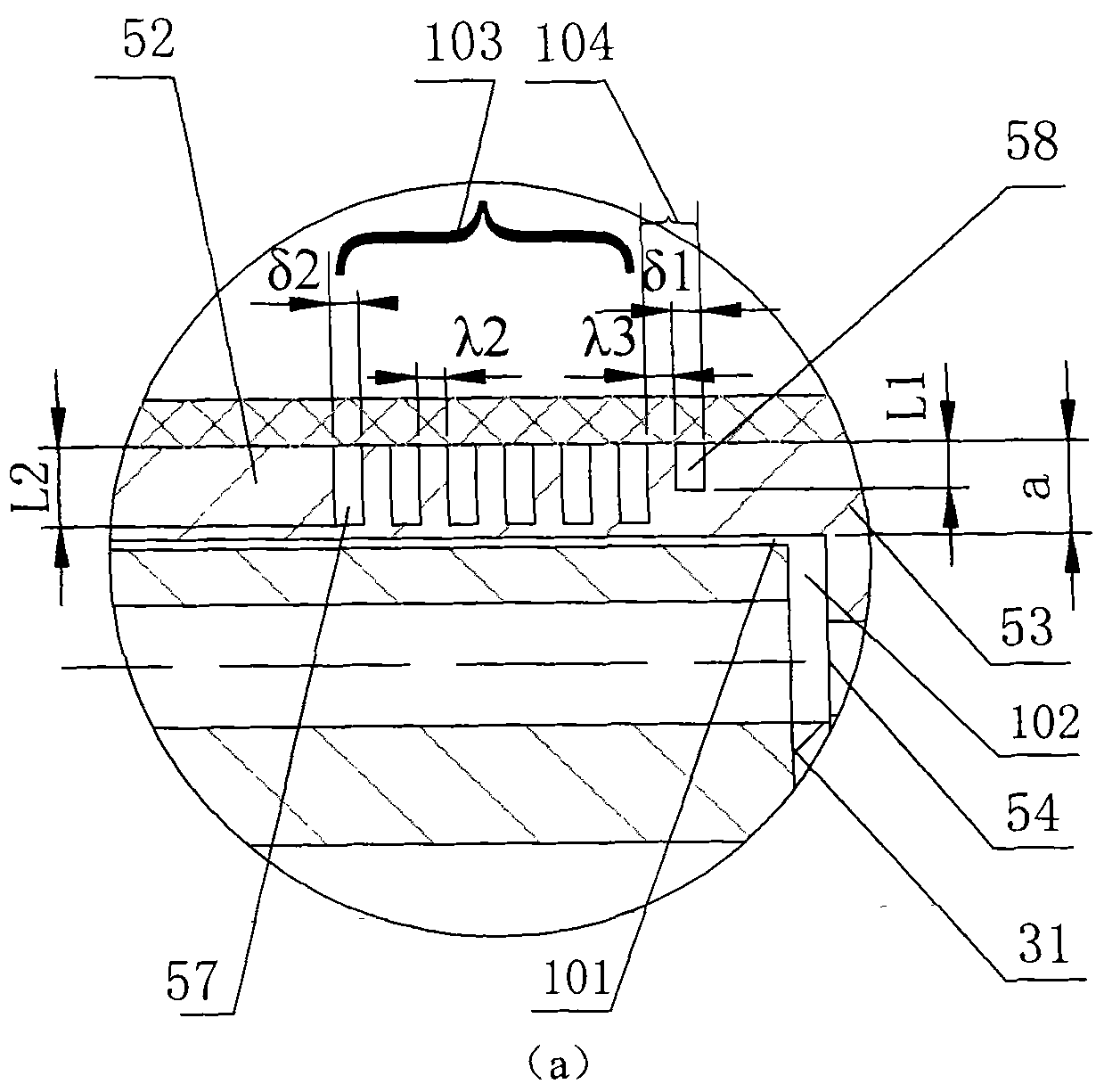

The invention discloses a pressure-proof proportion electromagnet based on an integrated type flux sleeve, which comprises a flux sleeve (5), a push rod (9), an armature (3) and the like, wherein a flux sleeve inner cavity (55) is arranged inside a front section (51) and a middle section (52) of the flux sleeve (5); an inner cavity end face (54) is formed at an interface of the flux sleeve inner cavity (55) and a rear section (53); the armature (3) is arranged inside the flux sleeve inner cavity (55); a limit piece (7) is arranged between a right end face (31) of the armature (3) and the inner cavity end face (54) of the flux sleeve (5); a radial operating air gap I (101) is formed by a gap between the side wall of the flux sleeve inner cavity (55) and the side wall of the armature (3); and an axial operating air gap II (102) is formed by a gap between the right end face (31) of the armature (3) and the inner cavity end face (54) of the flux sleeve (5). The proportion electromagnet has the characteristics of high pressure resistance, good force characteristic proportion performance, long effective stroke length and the like.

Owner:ZHEJIANG UNIV

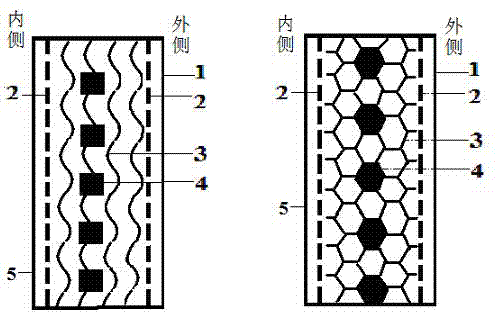

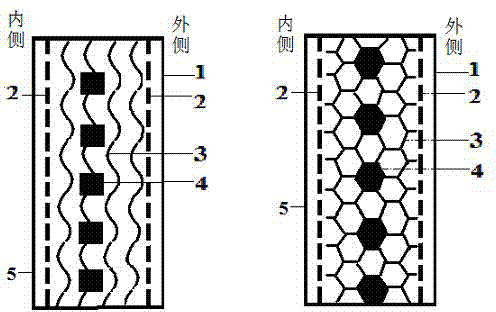

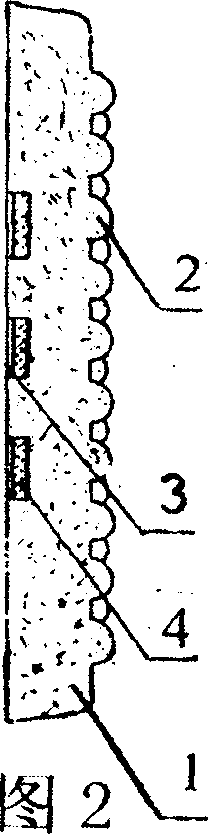

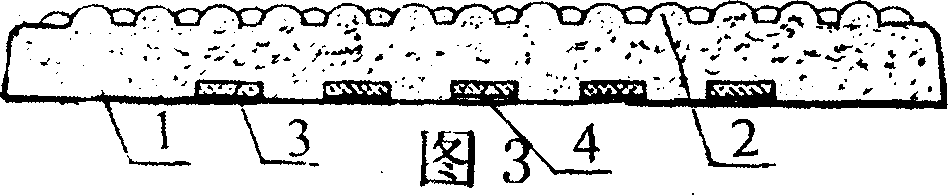

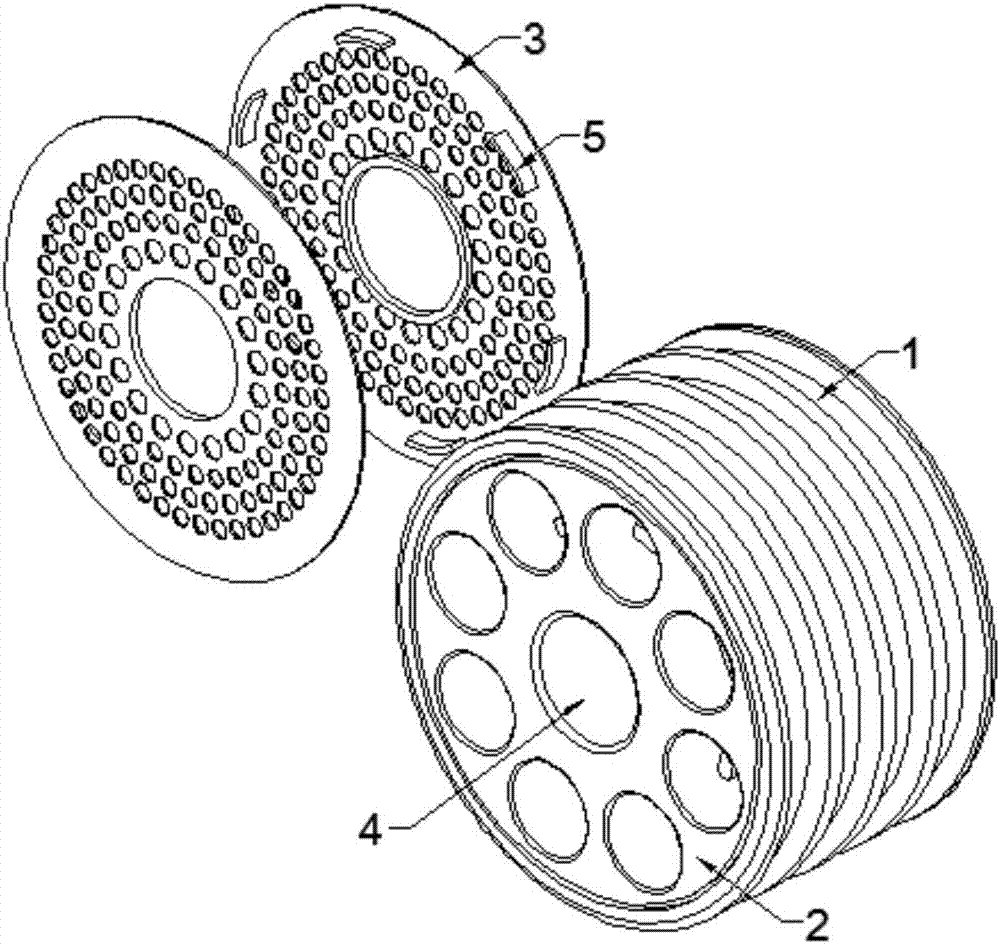

Intervertebral fusion device and method of preparing the same

InactiveCN101254140AReasonable shape and structureReasonable design structureInternal osteosythesisSpinal implantsCarbon compositesSpinal cage

The invention provides an interbody fusion cage for posterior lumbar spinal surgery and a preparation method thereof, and belongs to the application field of biomedical composite materials. The rectangular interbody fusion cage has side surface drainage through-holes, end surface chamfers, and triangle toothed structures on the upper and the bottom surfaces. The preparation method comprises the following steps of profiling the interbody fusion cage with carbon / carbon composite material as target, and preparing hydroxyapatite coating layers on the upper and the bottom surfaces of the interbody fusion cage sequentially by sandblasting pretreatment, plasma spraying, vacuum heat treatment and simulated body fluid immersion. The interbody fusion cage prepared by the inventive method has the advantages of novel material, advanced preparation method, reasonable structural design and good osteoconductivity function.

Owner:SHANDONG UNIV

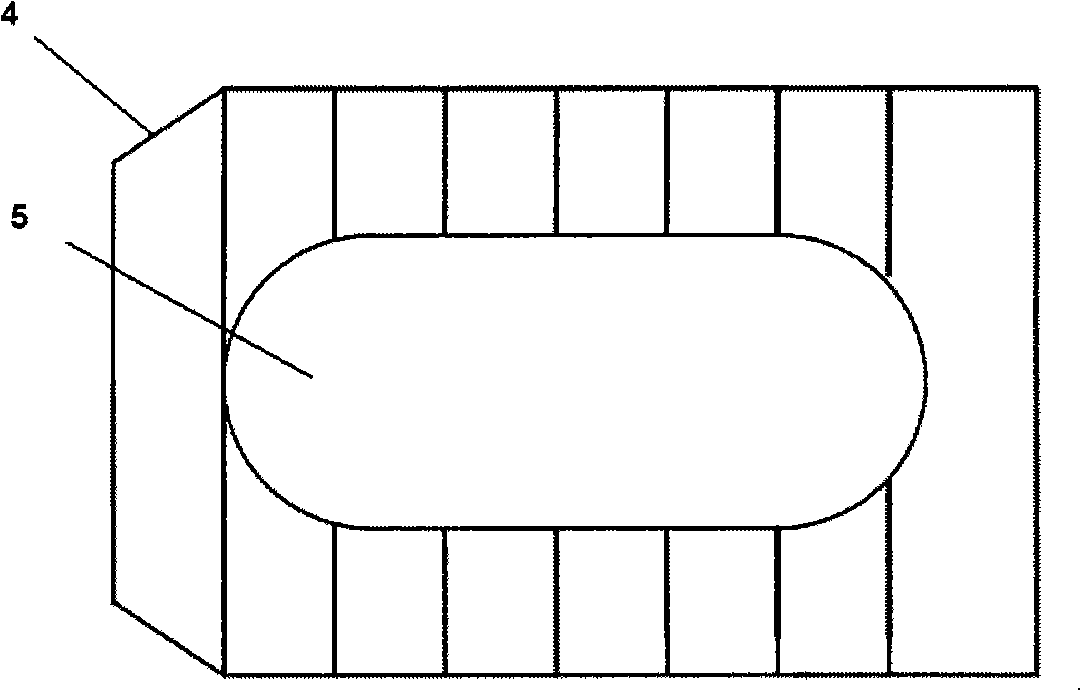

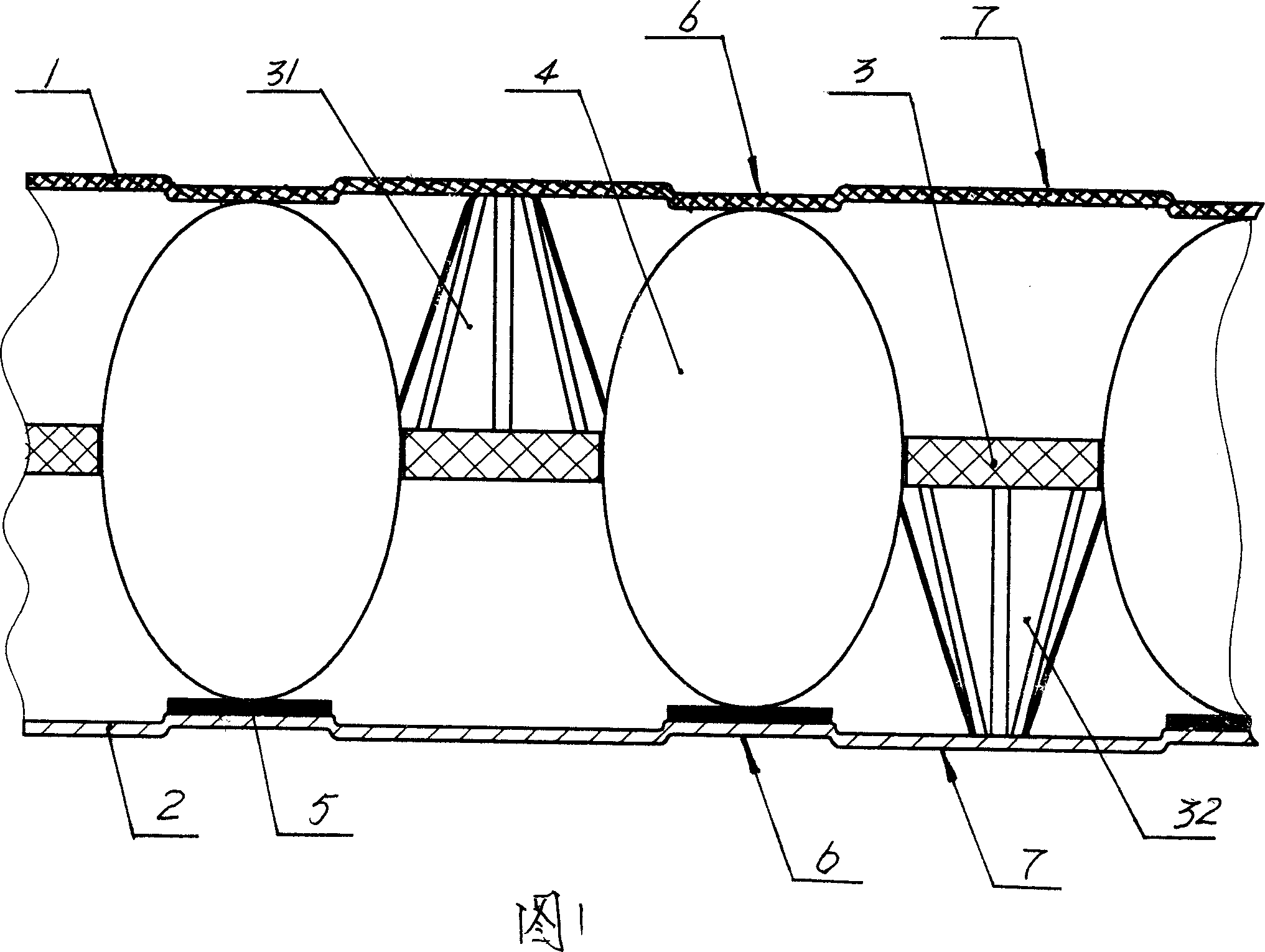

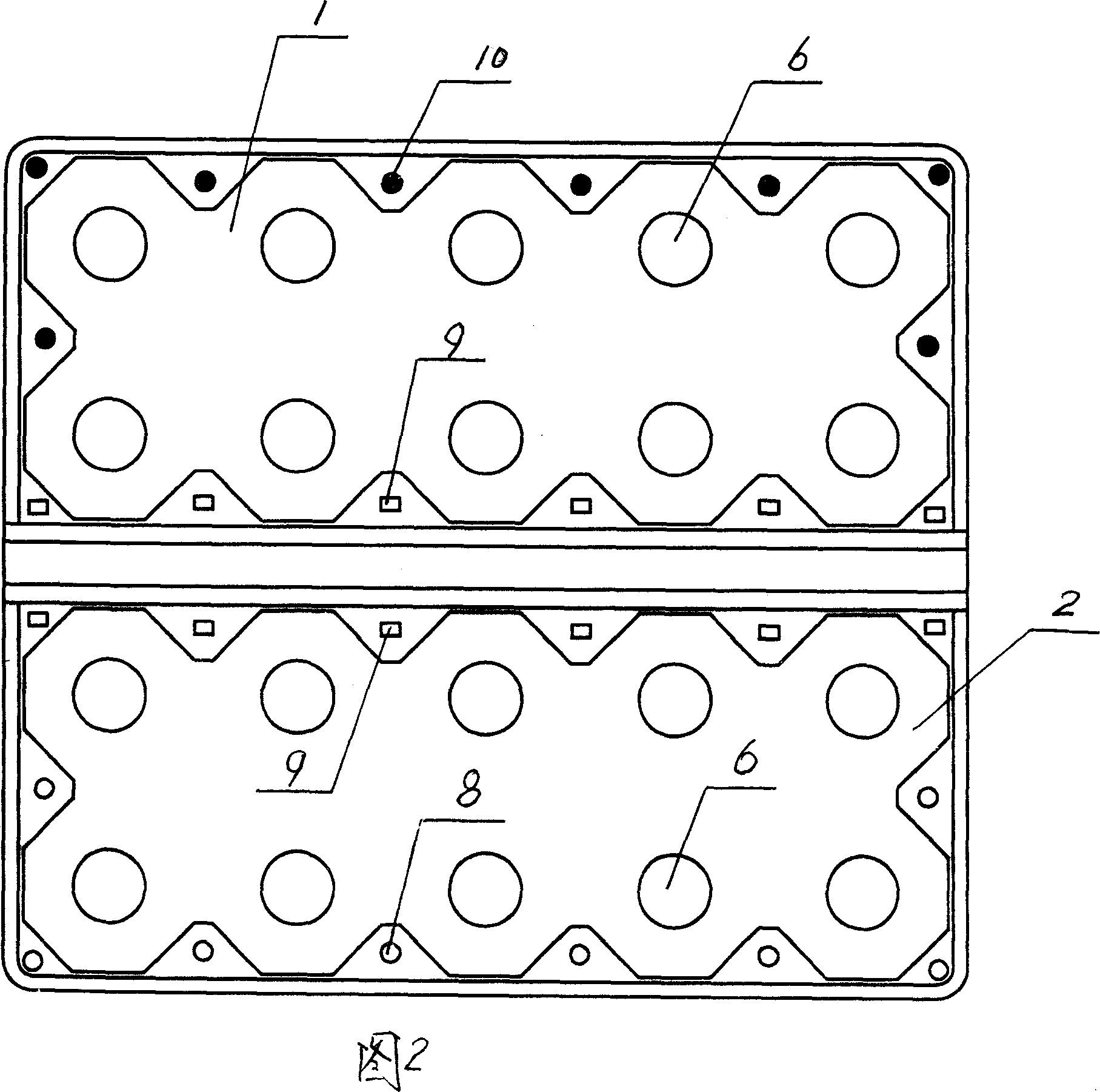

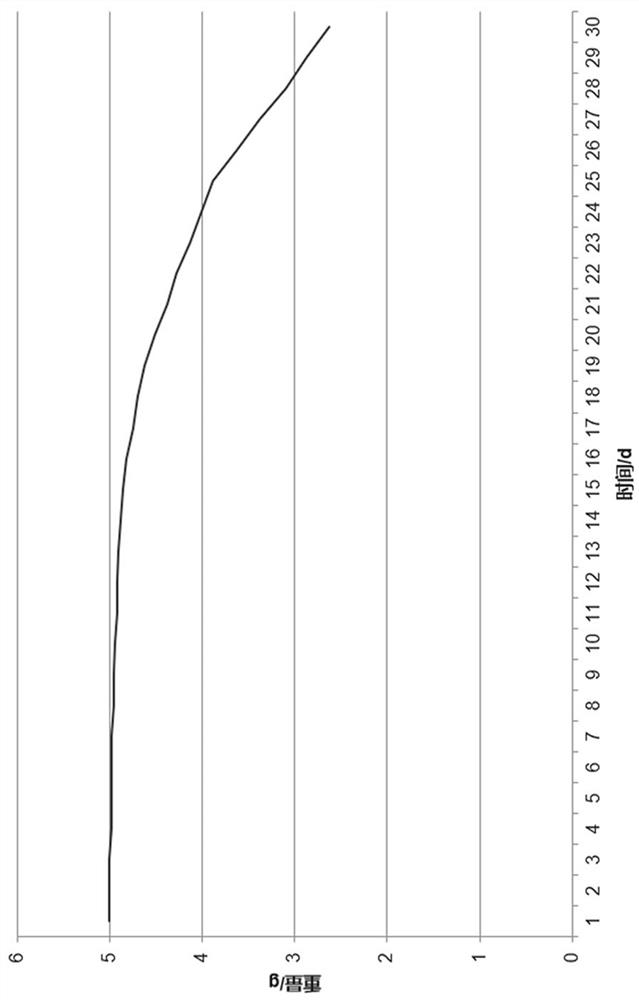

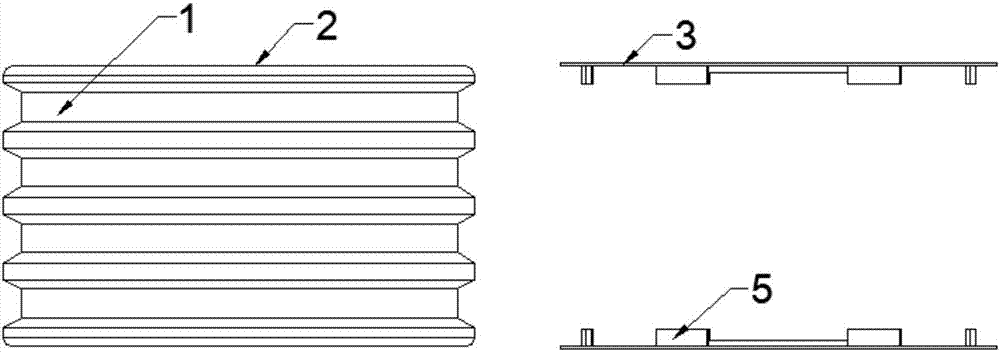

Method for preparing paper-pulp moulded board and mould there used

This invention involves a paper pulp mold pressing plate's preparation method and the mold. Its craft include:after scrap paper immersion beat the paper into pulp, the mold pressing to squeeze out the moisture content and formation, the drawing of patterns and dry. Its characteristic is the paper pulp density not bigger than 6%; And cancel in the existing craft to join the natural resin and the starch in the paper pulp, concentration dehydration the mixed pulp and so on. Its uses mold's characteristic is its frame and the lap can the move relativly; The briquetting is not smaller than obtained mold pressing plate thickness' 9 times in cavity effective work traveling schedule. The paper pulp mold pressing plate, is the entity plate or has the hole plate, its fiber structure is the level laminated structure. This invention simplify the craft, reduce the cost; The product has the better synthesis operational performance; And has a more ideal economic efficiency and the social efficiency. This product may widely apply in industry domains and packing storage and transport, building, repair and office equipment thing, has the enormous market potential.

Owner:郎旗

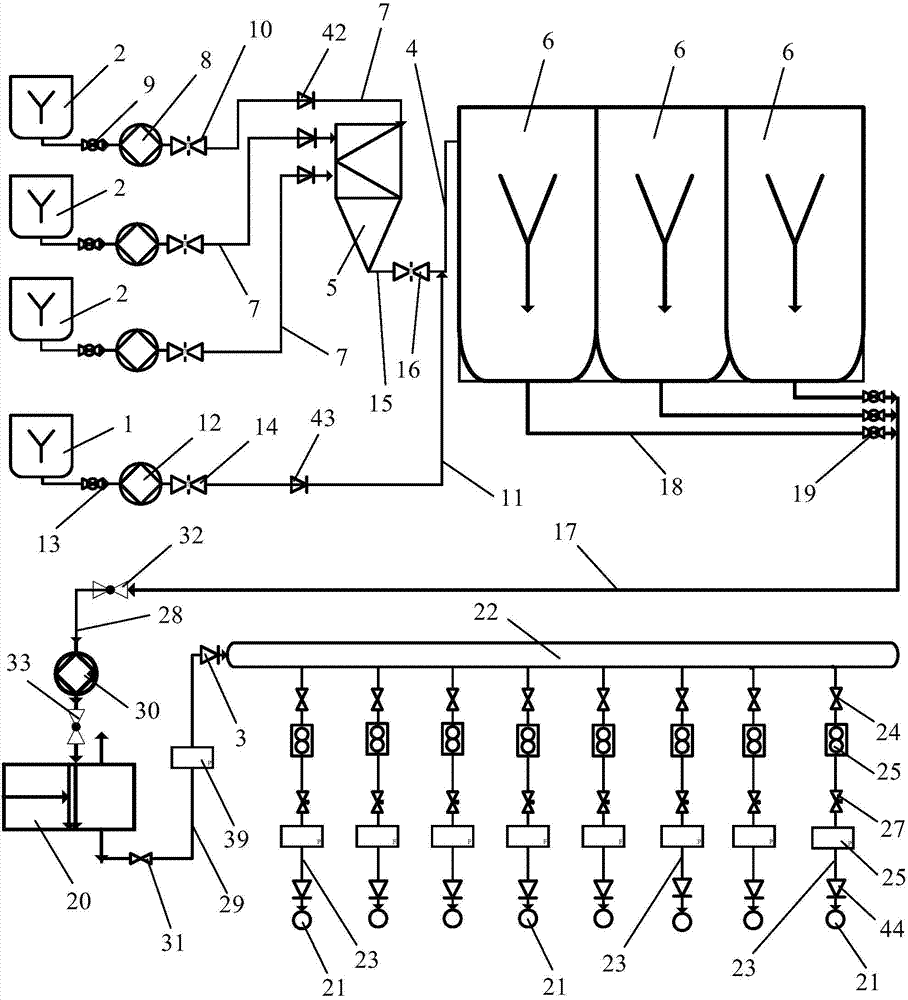

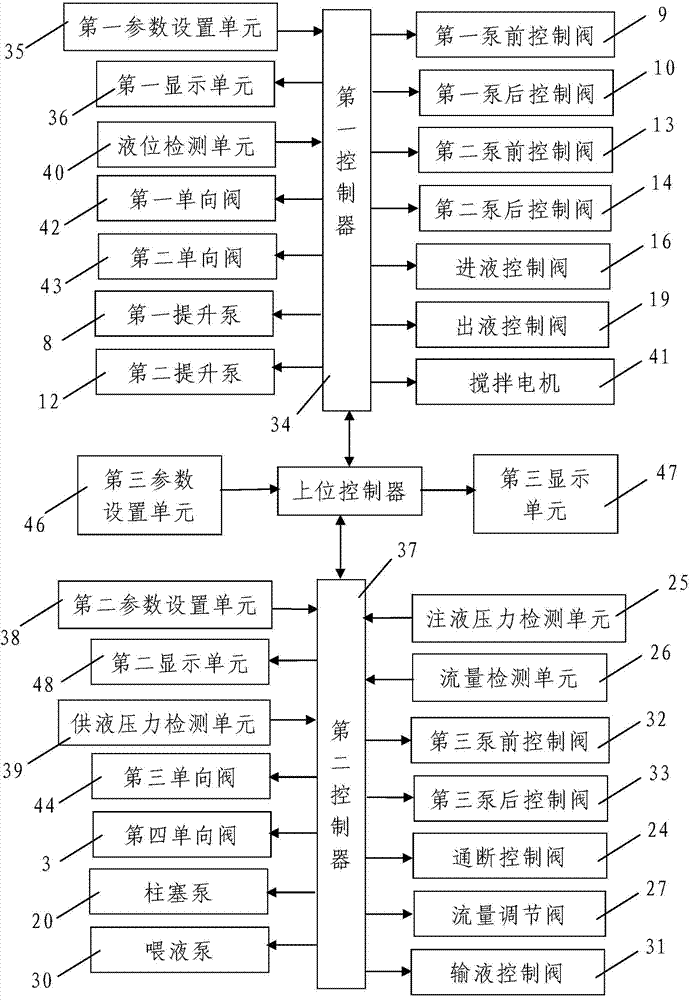

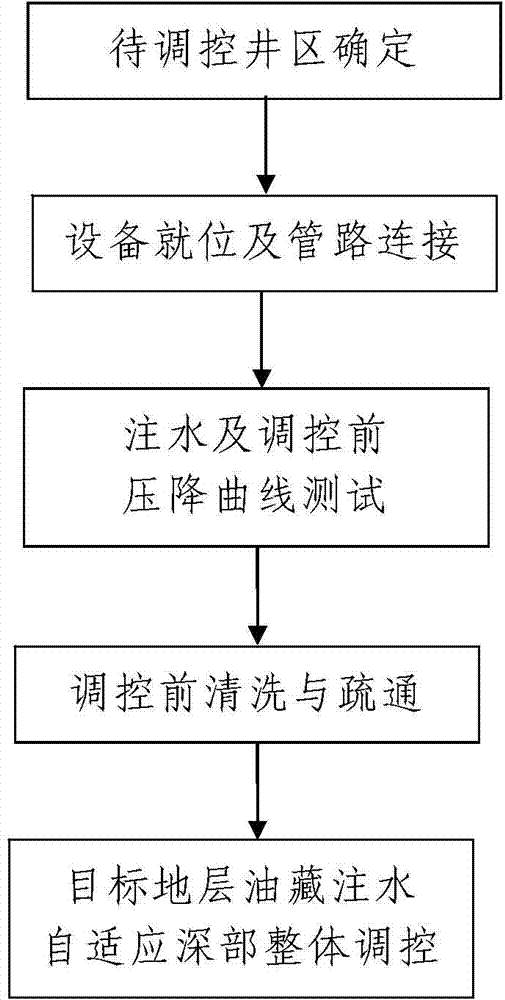

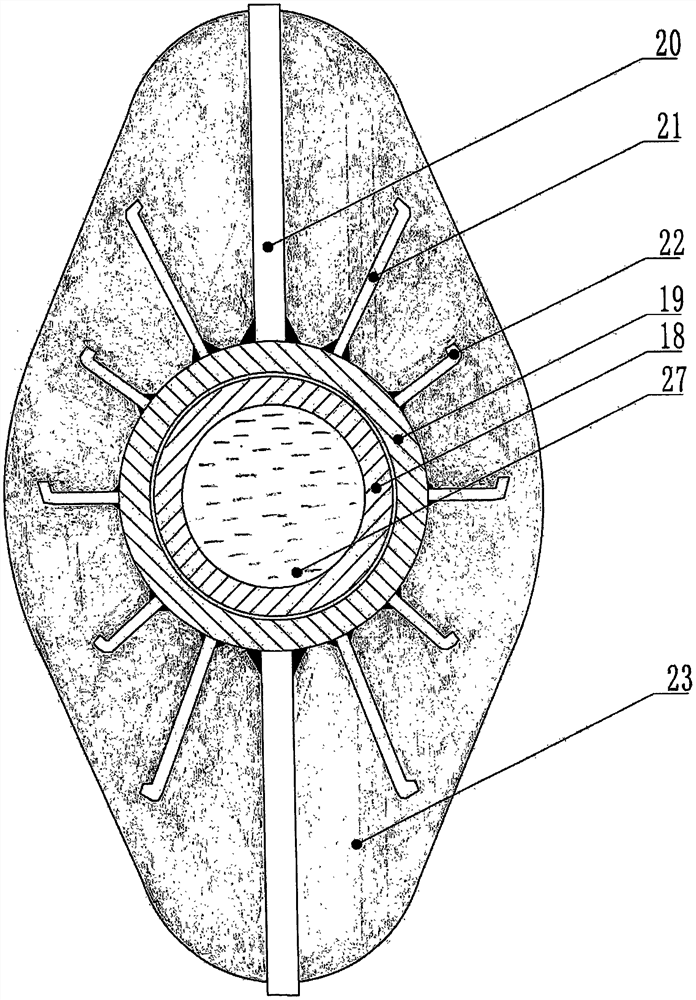

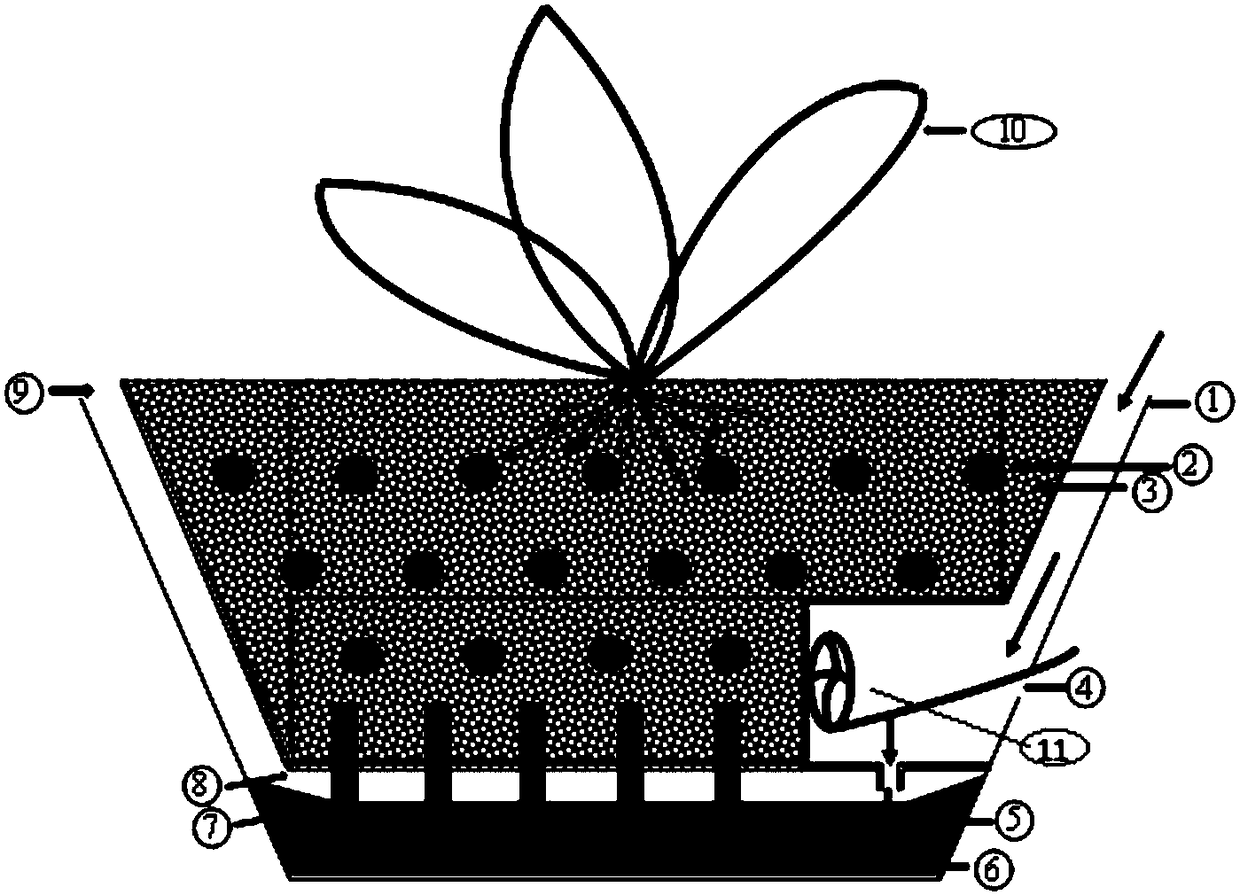

Oil reservoir water injection self-adaptive deep global regulation device and construction method

ActiveCN104727792ASimple structureReasonable designCleaning apparatusFluid removalInjection equipmentDissolution

The invention discloses an oil reservoir water injection self-adaptive deep global regulation device and a construction method. The regulation device comprises agent dissolution and storage equipment and agent injection equipment which is connected with the agent dissolution and storage equipment through a connection pipeline. The agent dissolution and storage equipment comprises a cleaning and unchoking agent dissolution tank, a plurality of regulation agent dissolution tanks, an agent liquid mixer, an agent storage tank and a main liquid intake pipe. The agent injection equipment comprises a main liquid delivery pipe, a plunger pump installed on the main liquid delivery pipe, a liquid distributor connected with a liquid outlet of the main liquid delivery pipe, and a plurality of liquid injection pipes. The construction method includes the following steps that firstly, a well area to be regulated is determined; secondly, the equipment is placed in position and connected through the pipeline; thirdly, water is injected, and a pressure drop curve is tested before regulation; fourthly, cleaning and unchoking are conducted before regulation; fifthly, oil reservoir water injection self-adaptive deep global regulation is conducted on a target stratum. The oil reservoir water injection self-adaptive deep global regulation device is reasonable in design, convenient to install and lay, easy and convenient to operate, good in use effect and capable of effectively improving water displacing oil work efficiency and crude oil recovery efficiency.

Owner:西安始创能源科技有限公司 +1

Method for producing ladle joint material by utilizing waste corundum bricks

The invention discloses a method for producing a ladle joint material by utilizing waste corundum bricks. The method comprises the following steps of: conveying 35 parts of 1-8 mm waste corundum brick granules, 35 parts of 0.1-8 mm white fused alumina granules, 10 parts of powder materials, 10 parts of alumina powder, 3 parts of fused magnesia powder, 1 part of silica powder and 6 parts of calcium aluminate cement into a stirrer, and fully stirring to obtain the ladle joint material finished product. The obtained ladle joint material finished product has the physical and chemical indexes as follows: after the ladle joint material is dried at the temperature of 110 DEG C for 24 hours, the compressive strength is more than 40MPa, and the flexural strength is more than 5MPa; and after the ladle joint material is sintered at the temperature of 1550 DEG C for 24 hours, the bulk density is not less than 3.0 g / cm<3>, the flexural strength is more than 12MPa, and the linear change rate is + / -0.5%. In the method disclosed by the invention, 1 / 3 of waste corundum brick granules are used as aggregates, thus the cost of the ladle joint material and the cost of per ton of steel are greatly lowered; and calcium aluminate cement is used for binding, and alumina, fused magnesia and silica are used as media, thus the problem that the recovered waste corundum brick granules are easy to crack when used in high-grade pouring materials is solved, and the requirements for safety and durability of the ladle are achieved.

Owner:ZHENGZHOU ZHENDONG TECH

Production of edible artificial sausages coating by enzymolytic collagen protein fibre

InactiveCN101073375ALow shrinkageIncrease productivitySausage casingsProtein foodstuffs working-upFiberHigh pressure

The invention is concerned with a kind of produce method for eatable man made enteric-coated of enzyme hydrolyzed collagen. Dispose animal skin having active albumen using albumen enzyme and hydrolyze reaction to get long exquisite collagen fibre. Wring and smash the fibre, take out under high pressure and mix up to get more differentiating and softer exquisite collagen fibre and long strip of lognitudinal exquisite collagen fibre. Weave exquisite collagen fibre with ring crossing braiding machine and shape with ammonia, dry and mold to get tube-type of slotless enteric-coated with soft and thin wall. The enteric-coated has 50 to 60 percent of weight of enzyme hydrolyzed collagen with enough intensity of pressure without avulsion. It is fit for middle and top grade western-style sausage and high-speed automatic sausage-filling machine with good edibility and taste.

Owner:柳州市宏升胶原蛋白肠衣有限公司

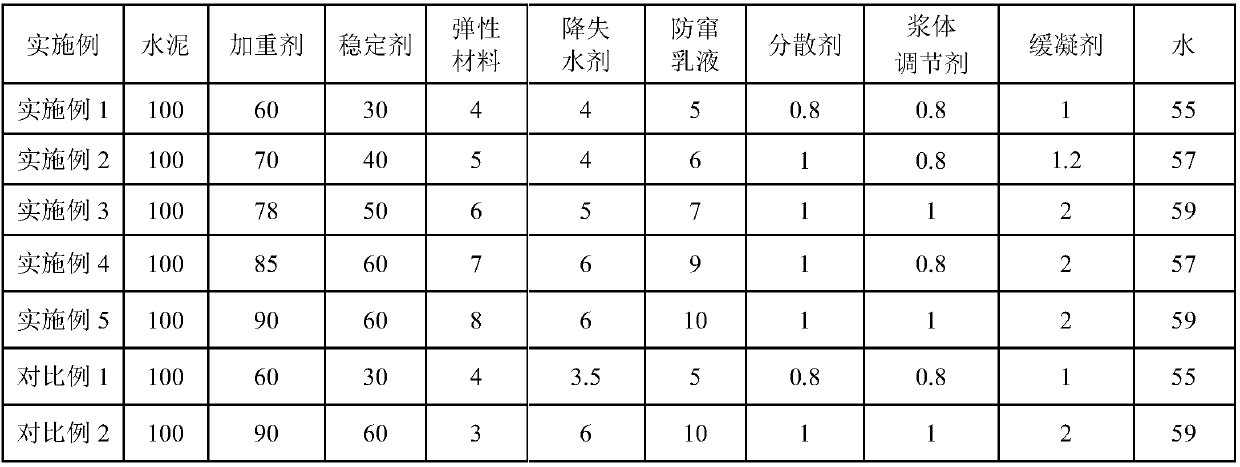

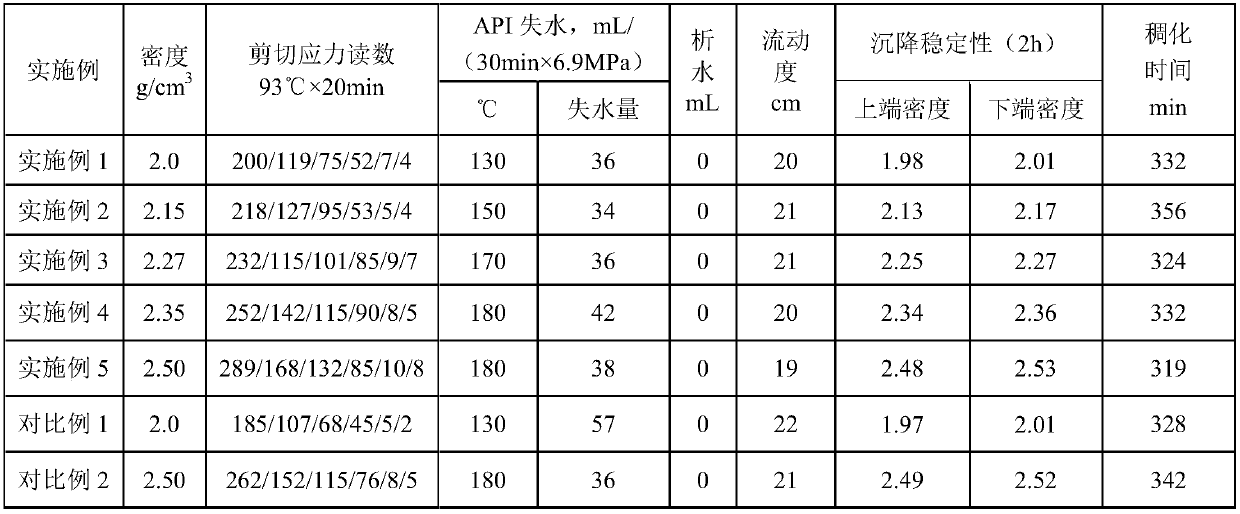

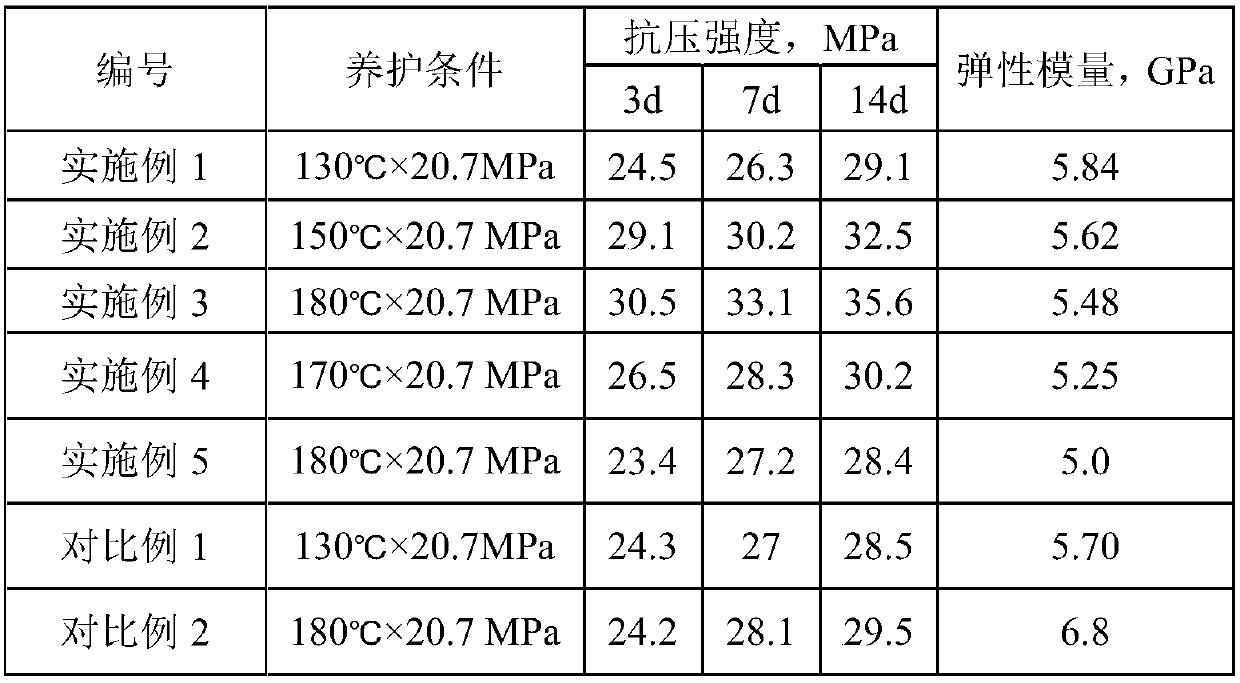

Cement paste system and preparation method thereof

ActiveCN111018410AHigh densitySufficient compressive strengthSolid waste managementDrilling compositionEmulsionPhysical chemistry

The invention provides a cement paste system and a preparation method thereof. The cement paste system comprises the following raw materials: G-grade oil well cement, a high-temperature-resistant elastic material, a high-temperature-resistant fluid loss agent, a high-temperature-resistant inorganic anti-channeling emulsion, a weighting agent, a high-temperature strength stabilizer, a dispersing agent, a paste regulator, a retarder and water. A cement sheath formed by using the cement slurry system in a high-temperature and high-pressure environment and in a later large fracturing constructionprocess has good elastic performance, can maintain the integrity for a long time, effectively ensures interlayer sealing, and reduces the risk of sustained casing pressure of a shale gas well.

Owner:CHINA PETROLEUM & CHEM CORP +1

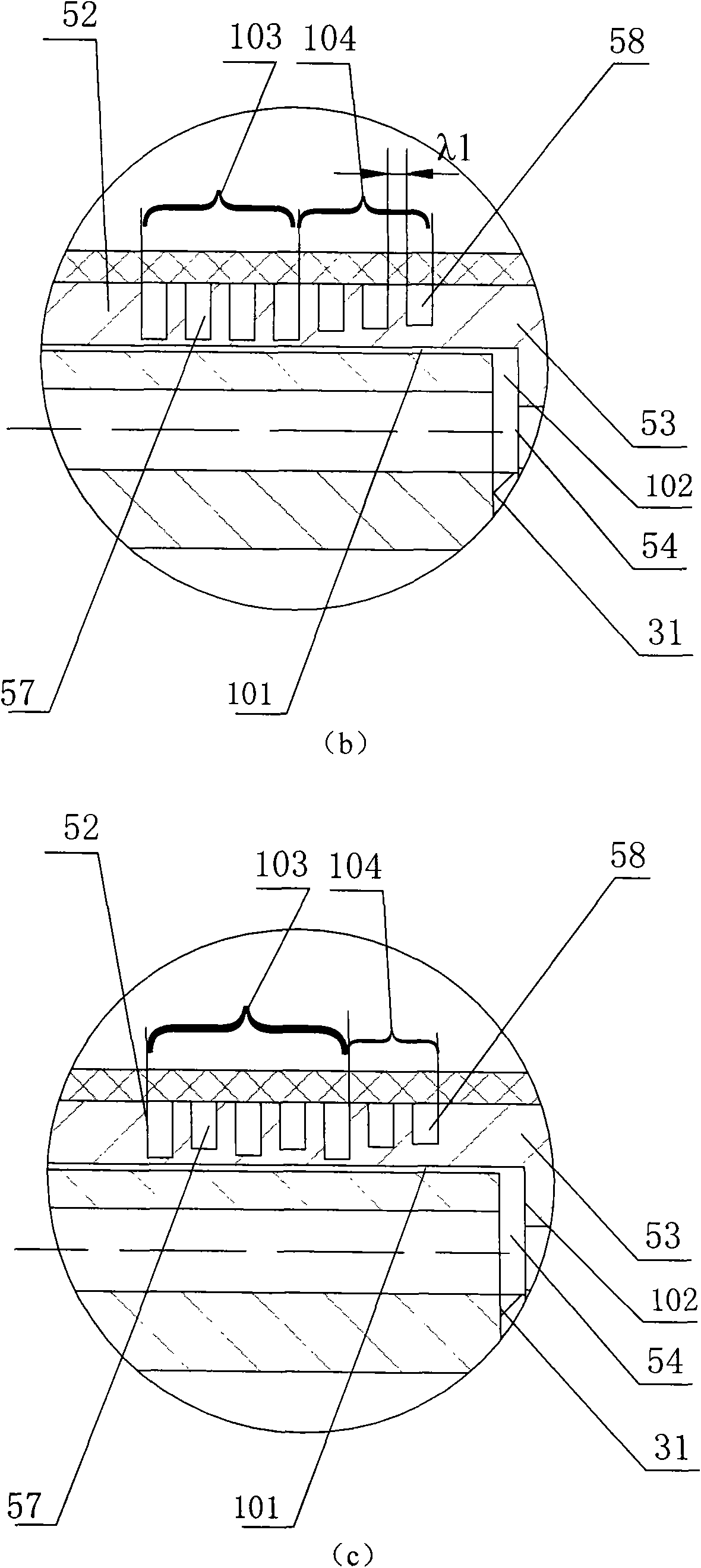

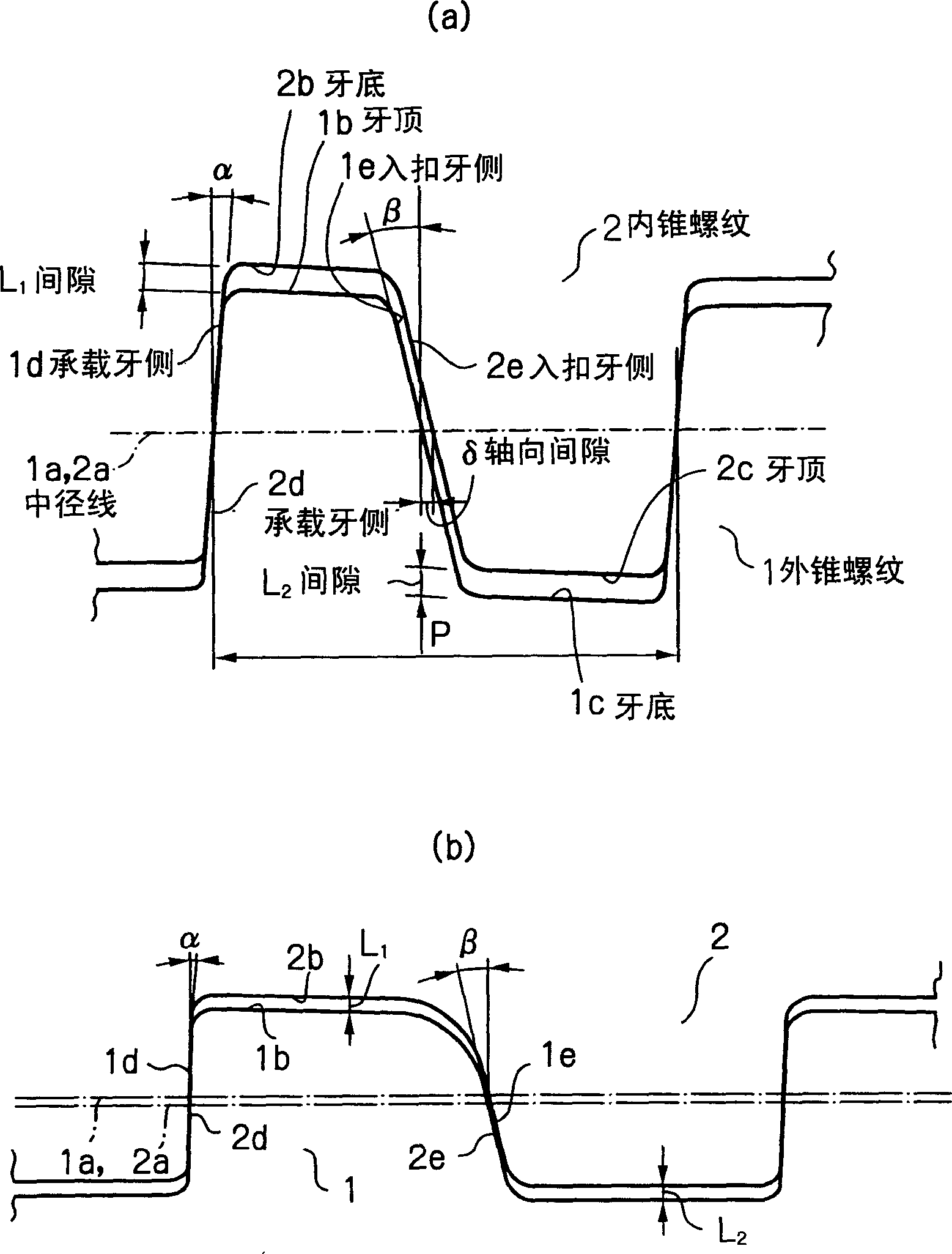

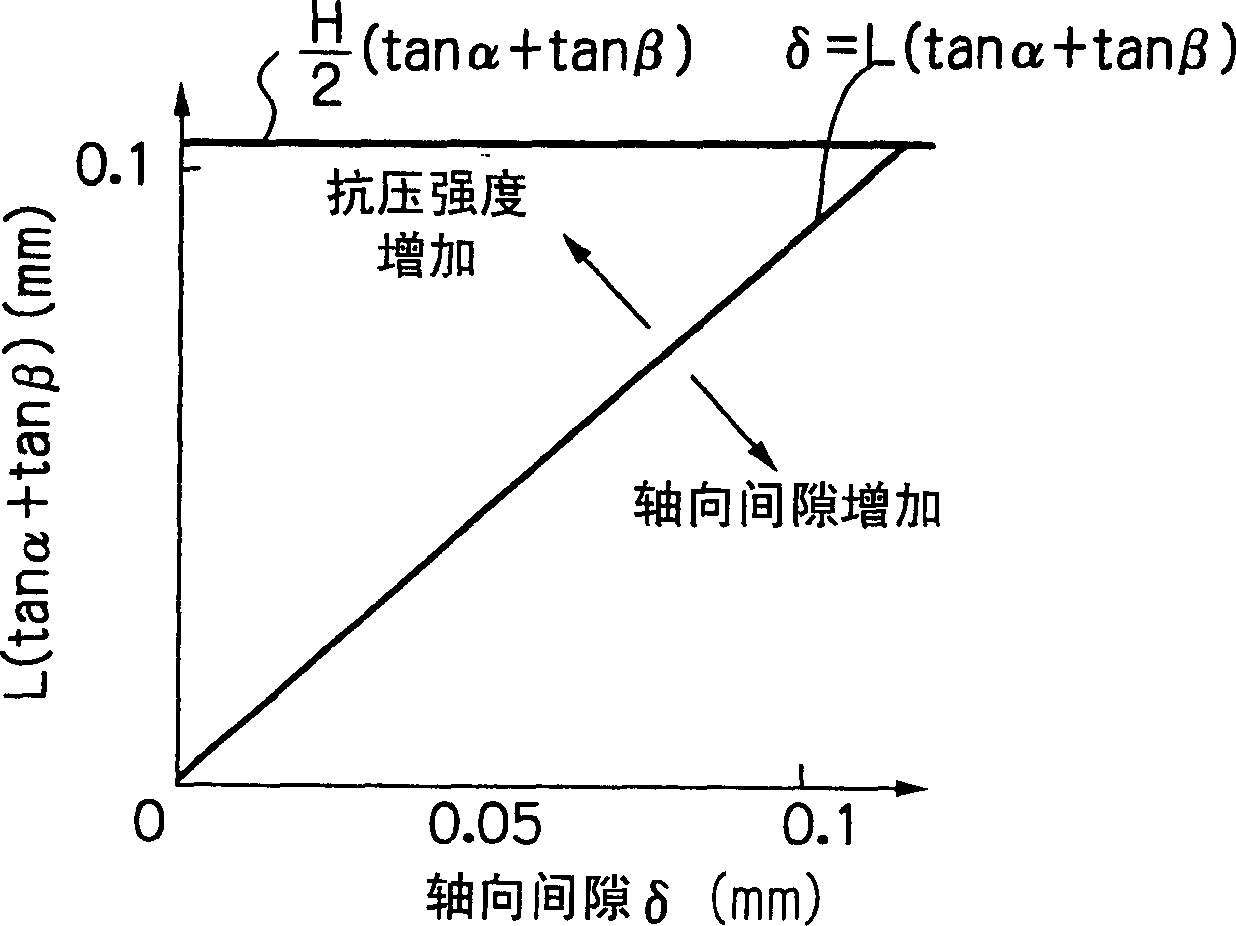

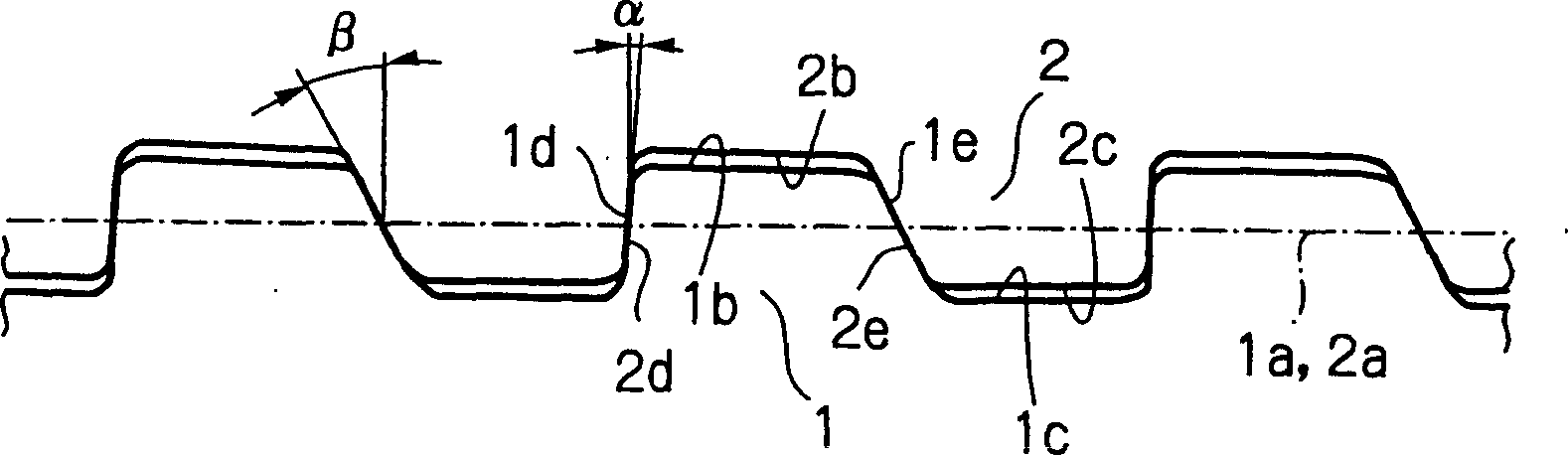

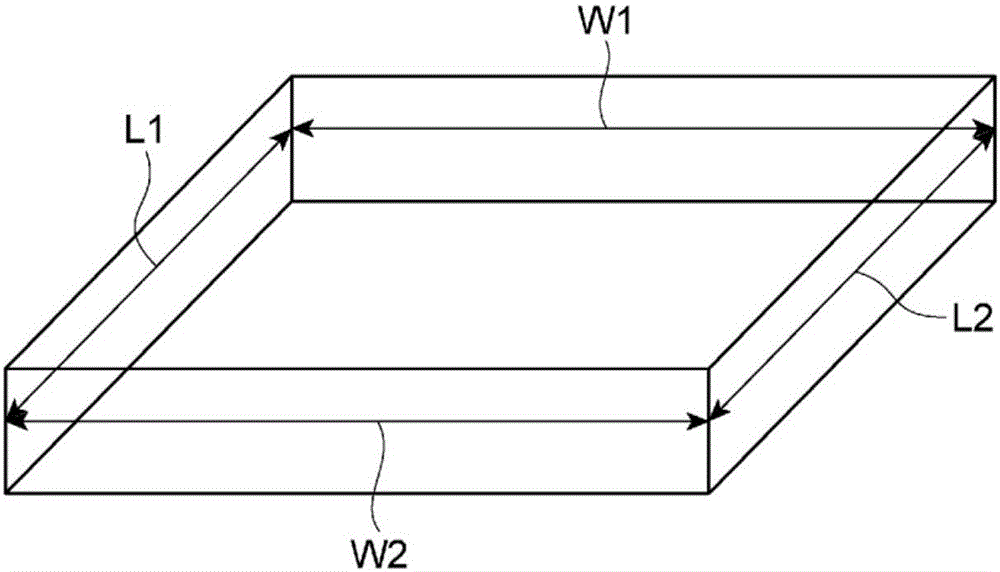

Taper threaded joint

InactiveCN1433510ASufficient compressive strengthDrilling rodsDrilling casingsCompressive strengthScrew thread

The gap L (mm) which is the smaller of the gap L1 (mm) between the crest 1a of a tapered male thread 1 and the root 2b of a tapered female thread 2, and the gap L2 (mm) between the root 1c of the tapered male thread 1 and the crest 2c of the tapered female thread 2, the load flank angle alpha ( DEG ) and the stab flank angle beta ( DEG ), and the axial gap delta (mm) which forms in the widthwise direction and is the difference between the thread ridge width of the tapered male thread 1 and the thread valley width of the tapered female thread 2 threadingly engaged therewith have the following relationship <DF> delta ≤ L.(tan alpha + tan beta ) < / DF> When interference of the threaded portions is necessary, the initial set thread interference H is H > 2L. As a result, a thread having sufficient resistance to tensile force and compressive force can be easily manufactured within manufacturing tolerances. In particular, it has good sealing properties and increased reliability as a threaded joint for an oil well pipe having a metal seal portion.

Owner:SUMITOMO METAL IND LTD +1

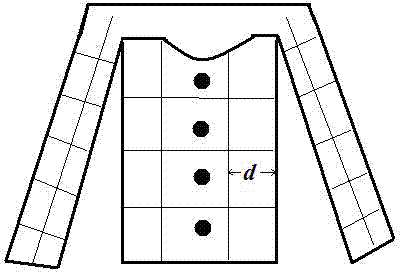

Earthquake protective clothing and production method thereof

InactiveCN102389169ASufficient compressive strengthSufficient impact strengthProtective garmentArchitectural engineeringMetallic materials

The invention relates to earthquake protective clothing particularly earthquake protection clothing and a production method thereof. The earthquake protection clothing attaches particular emphasis on the function of protecting personal safety of people at an earthquake critical moment. The finished clothing has high wearing comfortableness and high personal safety protection effectiveness. The method comprises the steps of selecting a fireproof outer layer fabric, using a high-strength and high-toughness reticular metal material for making a supporting skeleton and mechanically combining and assembling an impact fast-hardening material and an impact-resistant damping material into the protective clothing. The total thickness of the clothing is 10-15mm, the total weight is 2-4kg, the clothing can resist 300-400MPa external pressure after the finished clothing is put on, the impact toughness is 6-8J / cm<2>, the clothing is nonflammable at 120 DEG C and therefore the finished protective clothing has the functions of light weight, high flexibility, fire prevention, oppression resistance and impact resistance.

Owner:JIANGSU UNIV

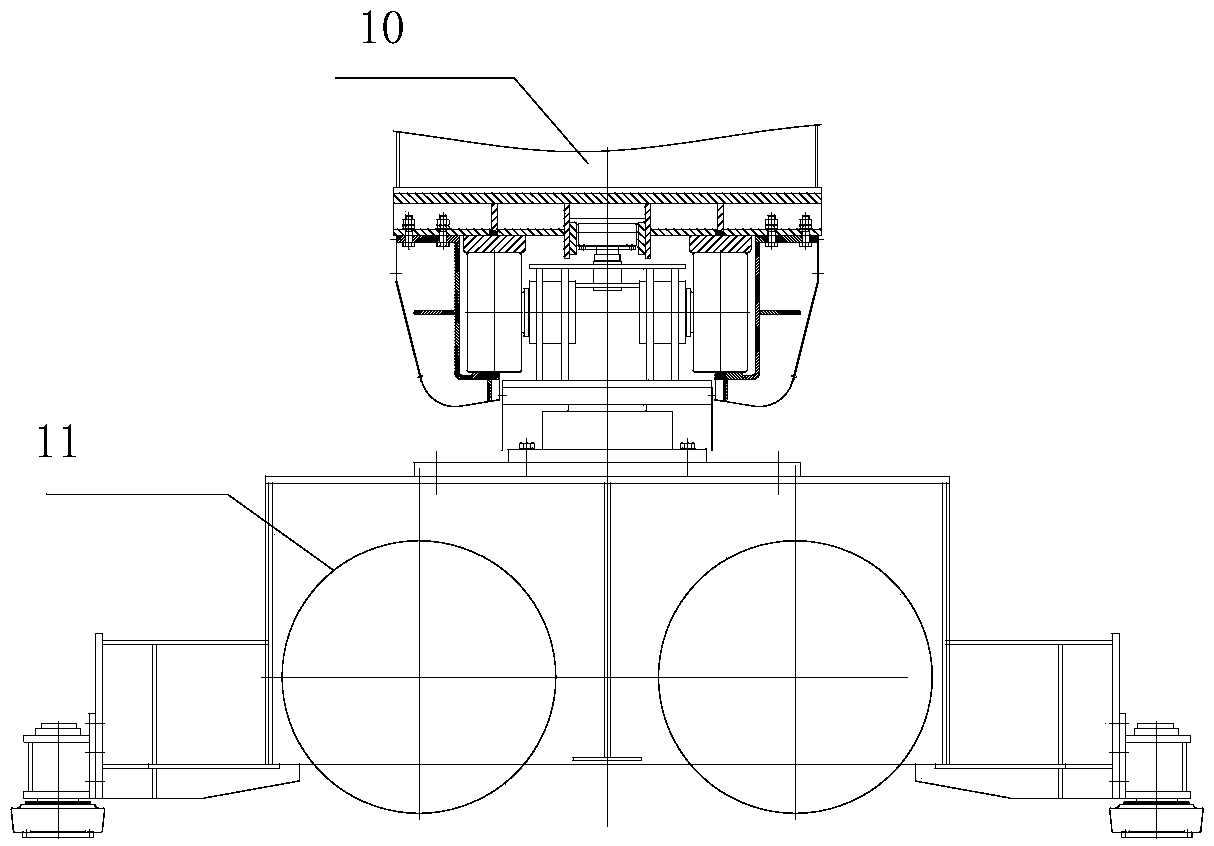

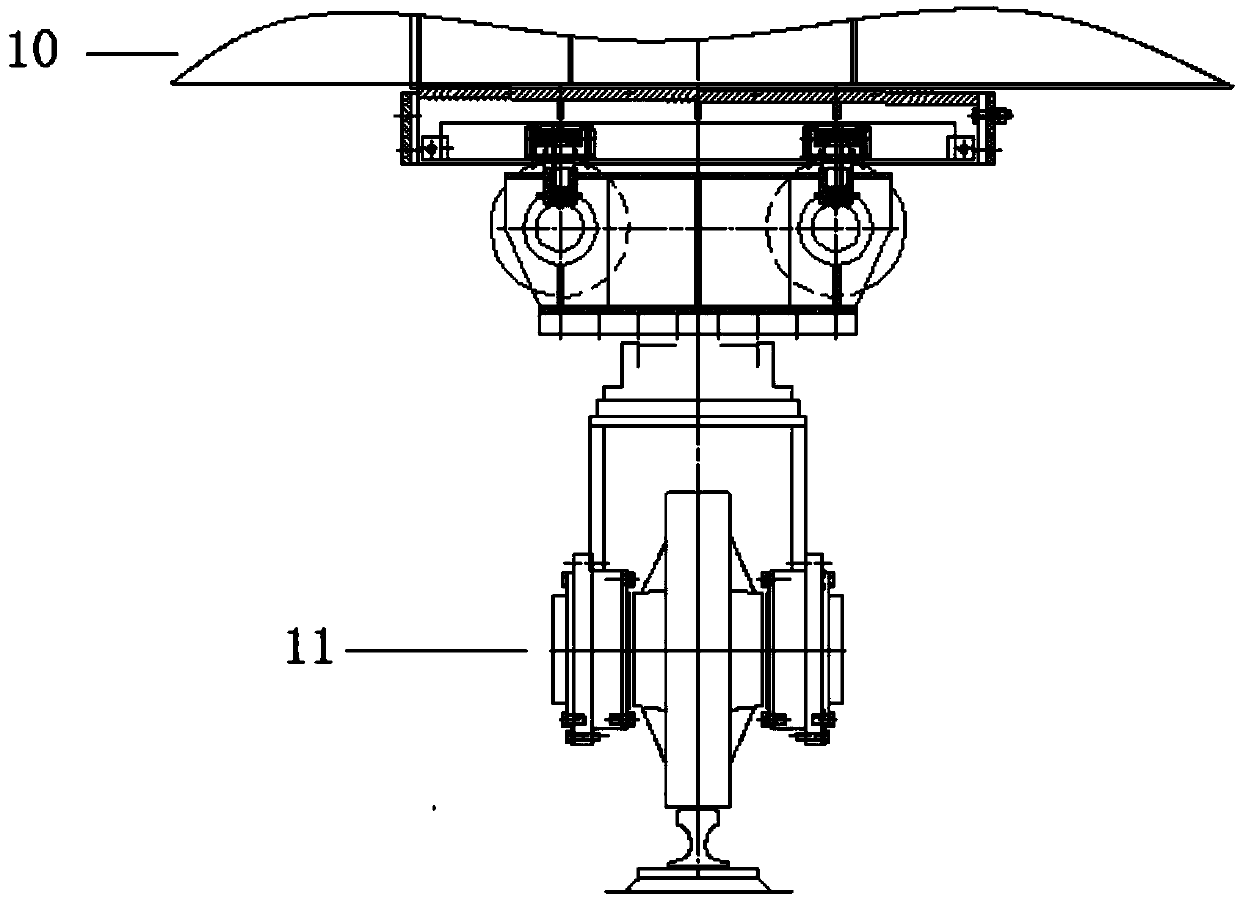

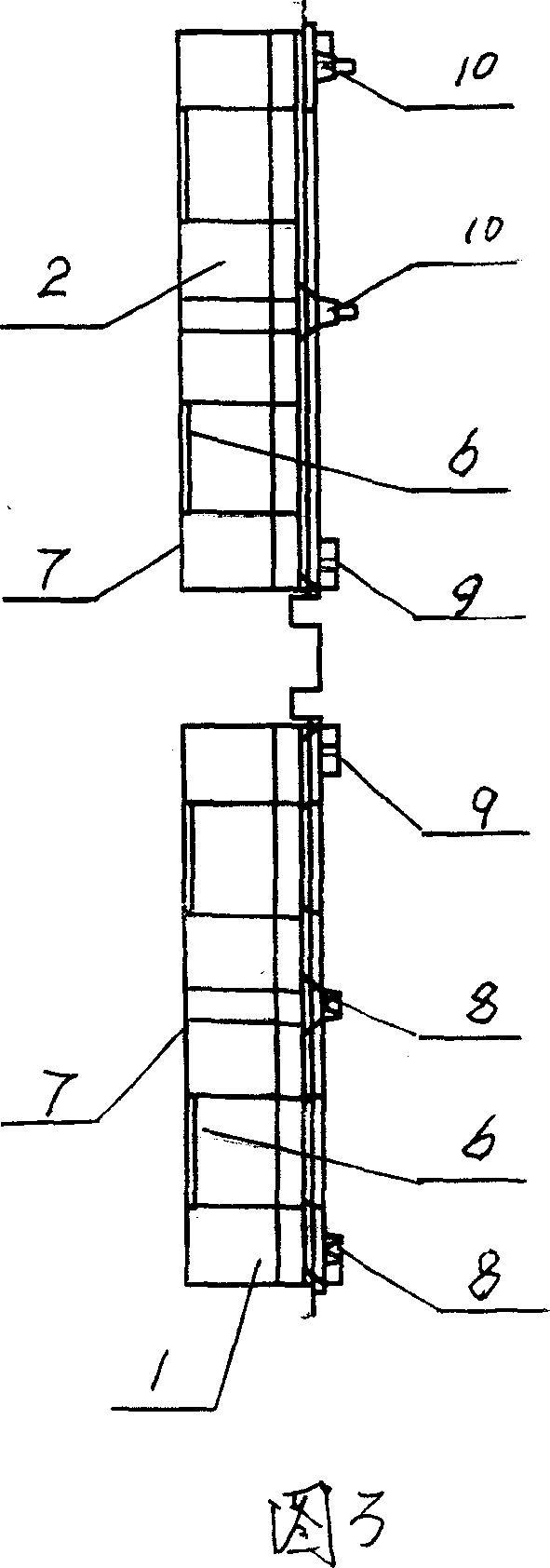

Gantry type circular stockyard material piling and taking machine

ActiveCN105502010APrevent tilt separationAvoid enteringPackagingLoading/unloadingRolling resistanceHigh load

The invention provides a gantry type circular stockyard material piling and taking machine which comprises a circular track, a travel trolley, a gantry, a follow-up device, a top frame and a rolling friction pair. The travel trolley runs along the circular track; one end of the gantry is rotatably connected to the center of the circular track, the other end of the gantry is movably connected with the travel trolley, and the gantry can be driven by the travel trolley to rotate around the center of the circular track; the follow-up device is arranged between the travel trolley and the gantry and comprises a support, and the lower end of the follow-up device is connected onto the travel trolley; the top frame is arranged above the support and is connected onto the gantry; the rolling friction pair is arranged between the support and the top frame, and the movement direction of the rolling friction pair is consistent with the radial direction of the circular track. The gantry type circular stockyard material piling and taking machine has the advantages that the rolling friction pair can bear high load, and deformation of the gantry can be sufficiently relieved.

Owner:HUADIAN HEAVY IND CO LTD

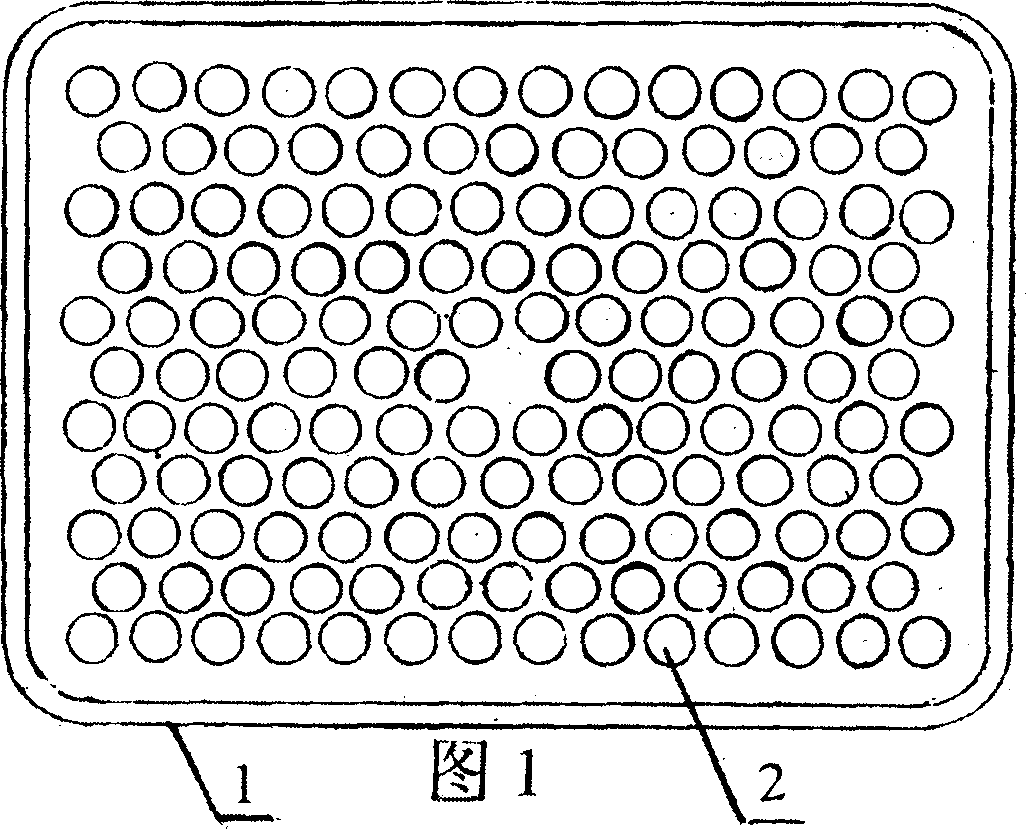

Portable breaking-preventing egg package box

InactiveCN1931680AHigh positioning accuracyPrevent up and down movementPackage recyclingPackaging eggsEngineeringBreakage rate

The portable breakage preventing egg package box has one box cover, one box body, one egg supporting tray with serial egg holding holes, upper support pins contacting with the inside top of the box cover, and lower support pins contacting with the inside bottom of the box body. The tray set on the box body is detachable, the box body and the box cover have reinforcing ribs, and some locating mechanism easy to open and close is set inside the box. The package box with simple structure may be produced in a simple die -casting machine, and has low egg breakage rate, simple production process, enough strength, low cost and reusability.

Owner:潘施衡

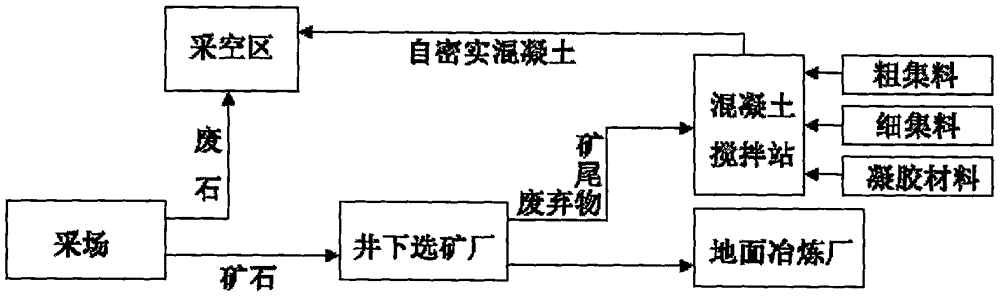

A non-waste mining method for underground mines

InactiveCN105971605ASufficient compressive strengthSolve the emission problemSolid waste managementUnderground miningEngineeringDischarge problems

A non-waste mining method which can solve a mine solid waste discharge problem and save the filling cost for underground mines is provided. The method includes 1) a step of piling waste ores, 2) a step of recording images, 3) a step of mounting a roof pumping pipe, 4) a step of fixing steel plates, 5) a step of ore treatment, namely a step of conveying ores produced in mines to an underground dressing plant, dressing the ores, conveying ore powder and other products to a ground smelting plant, and allowing waste tailings to participate self-compacting concrete mixing production as fine aggregates for self-compacting concrete, and 6) a step of conveying the prepared self-compacting concrete to the upper part of the waste ore pile through a pumping pipe pump, gradually pulling the concrete pumping pipe outwards at the same time of filling concrete until filling is finished, and drawing the pumping pipe out. According to the method, waste ore produced from the mines is adopted as a filling body skeleton and piled in a pilling zone in advance, and the self-compacting concrete adopting the tailings as the fine aggregates is poured to the waste ore pile from top to bottom, thus allowing self-compaction to form a filled body with enough compression strength. The method solves the mine solid waste discharge problem and saves the filling cost for mine enterprises.

Owner:HEBEI UNIV OF ENG

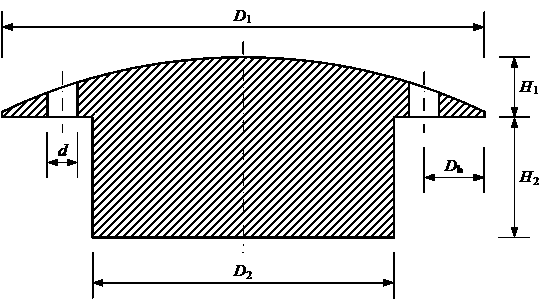

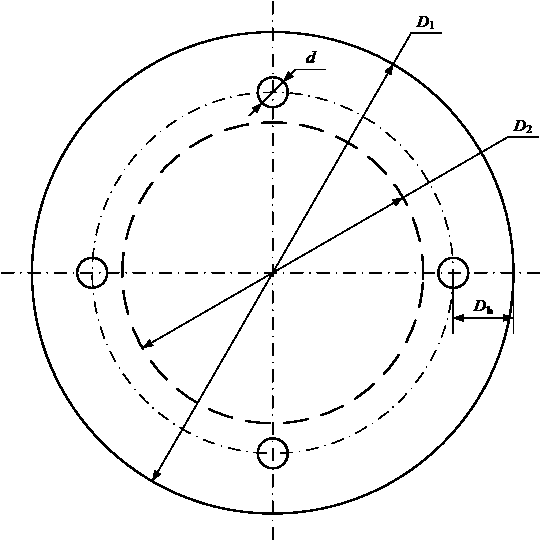

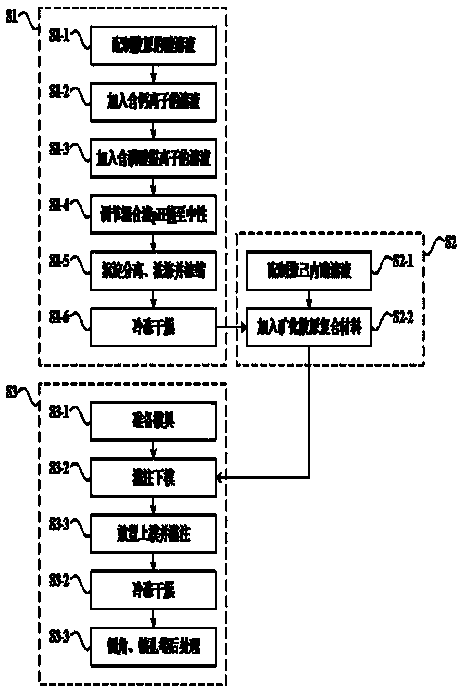

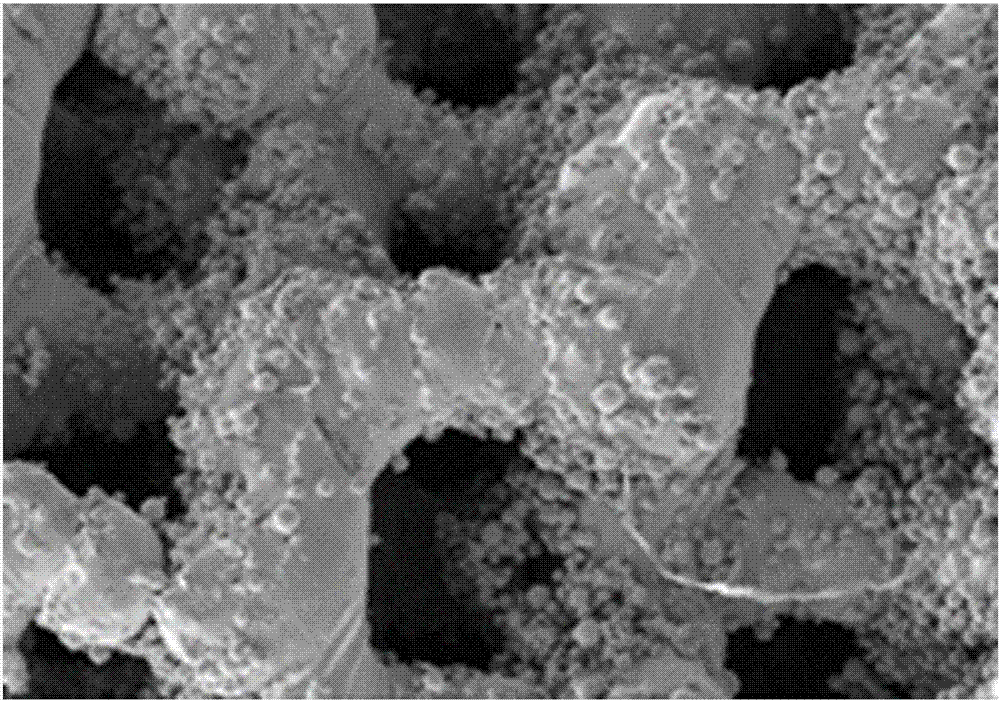

Mineralized collagen based skull repairing device and manufacturing method thereof

ActiveCN104258465AEnhance osteogenic activitySuitable biodegradable propertiesBone implantBased skullAcid substances

The invention relates to a mineralized collagen based skull repairing device and a manufacturing method thereof. The mineralized collagen based skull repairing device is made of a mineralized collagen / PCL (polycaprolactone) composite material; and the appearance of the repairing device comprises a spherical segment cap at the upper part and a cylindrical plug at the lower part. A separation mold and a secondary pouring technology are adopted during preparation of the mineralized collagen based skull repairing device, and the product defect caused by air residue at the blind end of the mold is overcome. The skull repairing device made of the mineralized collagen / PCL composite material has excellent osteogenic activity, the material is gradually and passively degraded under the creeping substitution action of cells, and growth of new bones can be guided at the skull defect part. A degradation product of the composite material is neutral, acidic materials causing aseptic inflammation cannot be generated, and new bone formation isn't affected; and through composition of PCL, the skull repairing device has excellent elasticity and toughness besides enough crush resistance and bending strength, and the repairing requirement of a skull of a human body is met.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH

Hard-foam polyether polyol used in grout of mining and preparation method thereof

InactiveCN107903388AGood permeability and mechanical propertiesImprove flame retardant performanceMechanical properties of carbon nanotubesGrout

The invention relates to hard-foam polyether polyol used in grout of mining and a preparation method thereof, and belongs to the technical field of chemical synthesizing. The hard-foam polyether polyol comprises the raw materials of a high-functionality initiator, a micromolecule initiator, an additive, an amine catalyst and oxyalkylene on the mass ratio of 3-15 to 10-20 to 5-16 to 1-5 to 45-70, wherein the additive comprises one or two of palm oil or chlorcosane. The prepared polyether polyol is sufficient in resistance to compression, and outstanding in mechanical performance and adhering performance, and meets the application demands such as reinforcing, hole sealing, leakage blocking and filling of different types of grout of mining; the preparation method is small in requirements on equipment, simple and feasible in operation, and obvious in product cost advantage.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

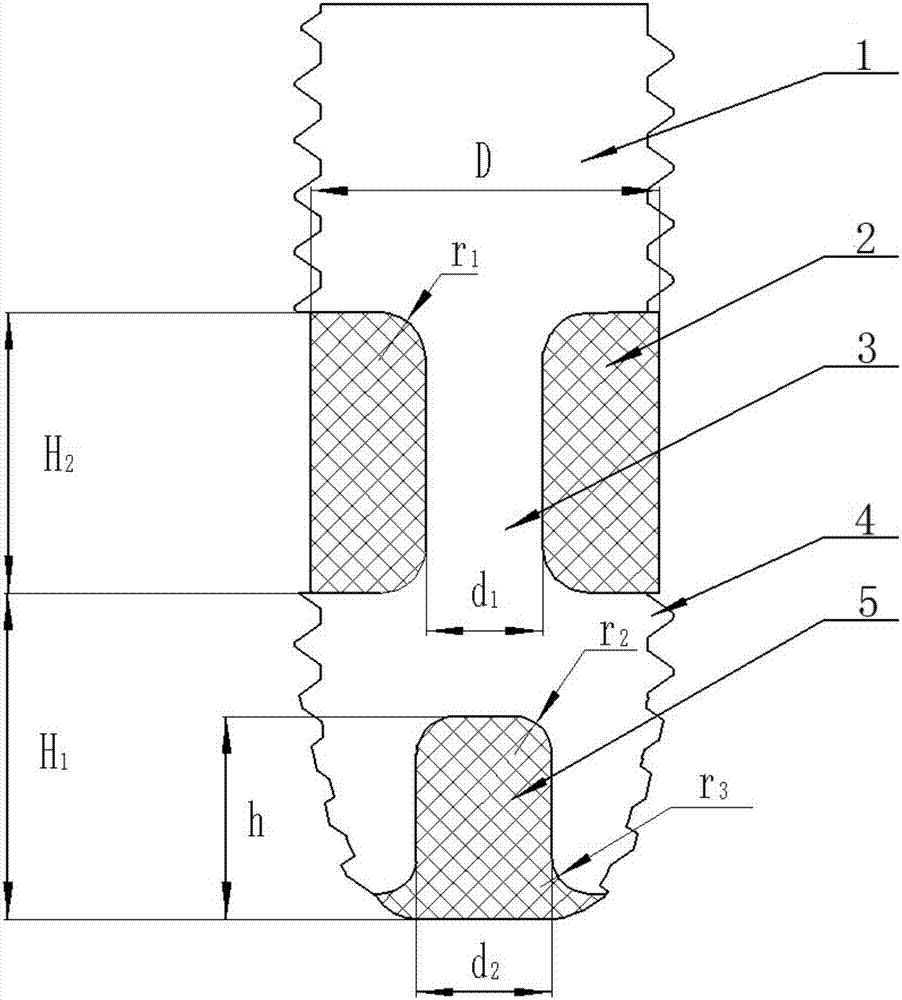

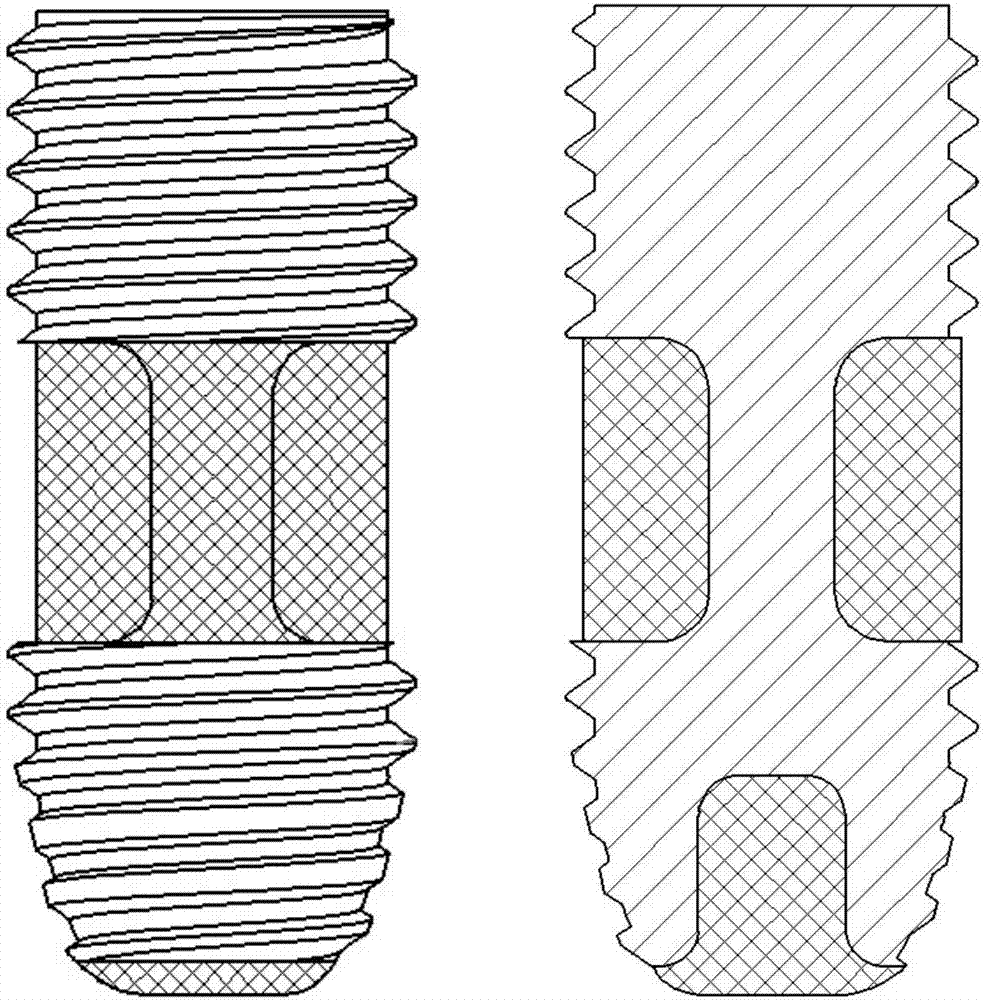

High-strength and low-rigidity porous titanium implant

InactiveCN107126281AIncrease success rateSufficient compressive strengthDental implantsBone tissueHigh intensity

The invention provides a high-strength low-rigidity porous titanium implant. The porous titanium implant comprises threaded parts, a porous structural part, and a support structure part. The upper segment and the lower segment of the porous titanium implant are the threaded parts, porous structures are embedded in the middle segment and the tip end, and the support structure part is embedded in the middle segment porous structure to connect the upper threaded part with the lower threaded part. The porous titanium implant has sufficient compressive strength, and has a controllable elastic modulus similar to that of human skeletons, the contact position of the implant and bone tissues has a good stress environment, and the porous structures capable of promoting bone integration can improve the success rate of the dental implant.

Owner:SHANGHAI JIAO TONG UNIV

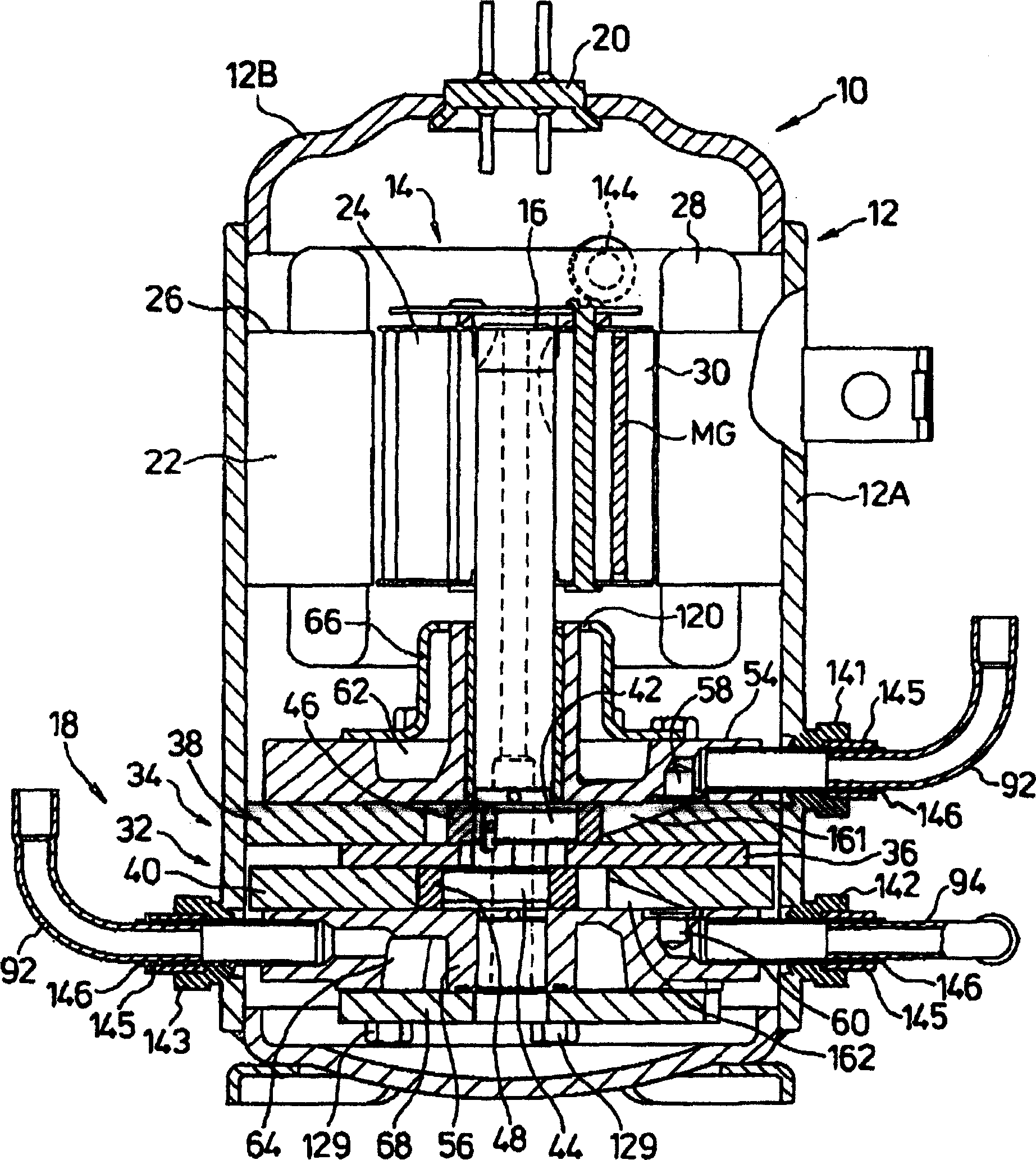

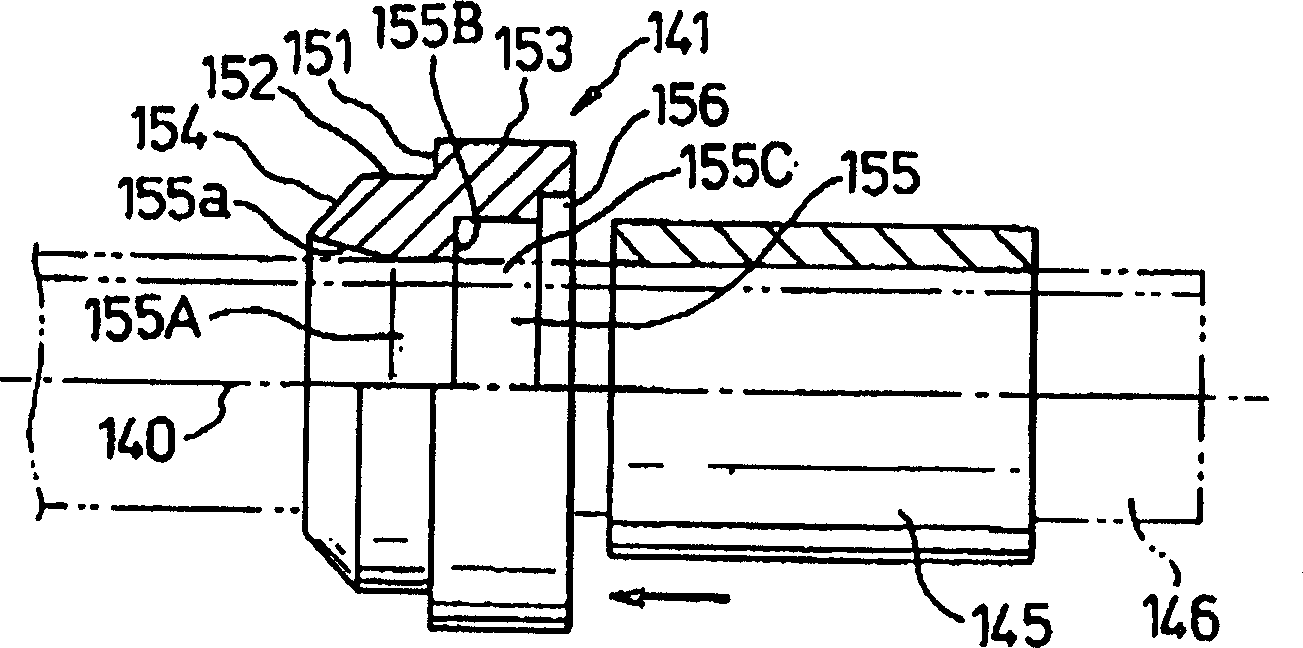

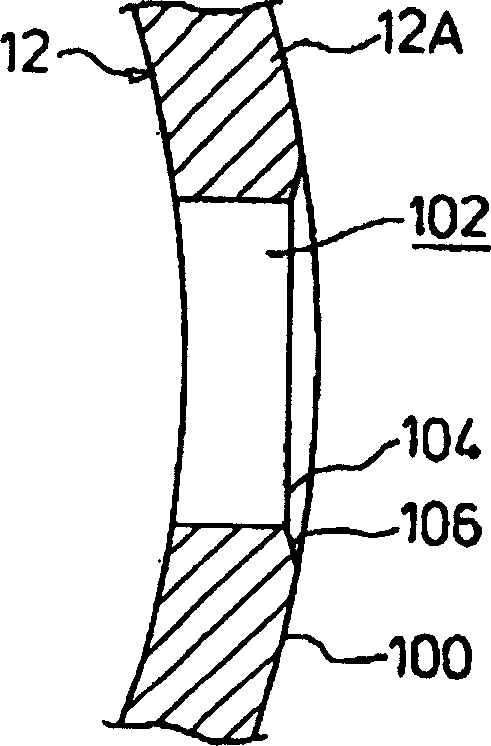

Compressor

InactiveCN1755137ARight angles are easy to obtainSmall diameterRotary/oscillating piston combinations for elastic fluidsEngine manufactureCopperRefrigerant

The invention provides a compressor which has a sleeve (141), and the sleeve (141) is arranged correspondingly to a through hole (102) of a bending surface (100) which forms a sealed container (12), and is connected with a refrigerant pipe. The sleeve (141) has a small outer diameter part (152), a big outer diameter part (153) and a diameter shrinking part (154) which are arranged in a continuous way through an annular step part (151), the diameter shrinking part (154) takes a capitellate shape at the opening end side of the small outer diameter part (152), a communicating pore (155) which runs through the small outer diameter part (152)and the big outer diameter part (153) has a small inner diameter part (155A) and a big inner diameter part (155C), the small inner diameter part (155A) is mainly arranged at the small outer diameter part (152), the big inner diameter part (155C) is connected with the small inner diameter part (155A) through an annular step part (155B), and is arranged at the big outer diameter part (153), a diameter expanding part (155a), the inner diameter of which gradually increases towards the opening end side, is arranged at the opening end side of the small inner diameter part (155A), and a tube component (145) made of copper is embedded into the big outer diameter part (155C) to be carried out with solder brazing under the state that one end is contacted with the step part (155B), so as to be fixed in the sleeve (141); thus, the compressor which can enable the sleeve arranged in the sealed container through projection welding to be miniature is provided, and the refrigerant pipe and the sleeve are simply connected with a right angle, thereby the sealed container cannot suffer the seat thrust greatly when the sleeve is arranged in the sealed container by welding.

Owner:SANYO ELECTRIC CO LTD

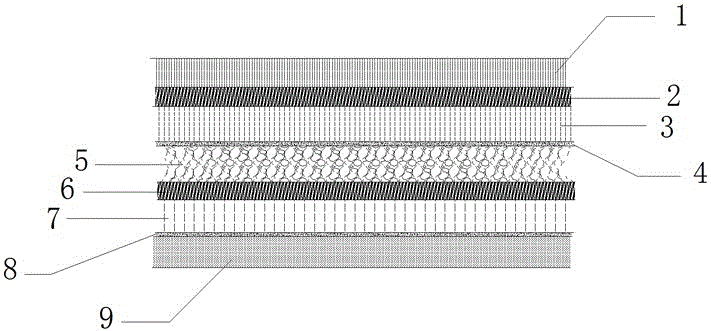

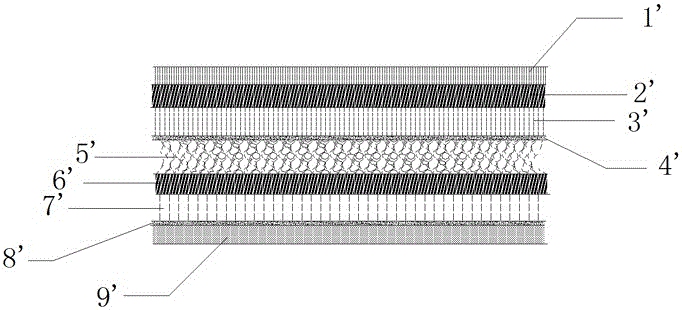

Lightweight high-strength heat-insulation moisture-proof composite paper board

InactiveCN105015125ASafeguard ResilienceGood cushioning propertiesSynthetic resin layered productsPaper/cardboard layered productsFiberCellulose

The invention relates to a lightweight high-strength heat-insulation moisture-proof composite paper board composited by multiple layers of boards and successively including a surface elastic polylactic acid antishock board, an antishock fiber layer I, a honeycomb paper core and a bottom facial paper I, an environmental-protection foamed buffer layer, an antishock fiber layer II, a corrugated paper core and a bottom facial paper II and a bottom polylactic acid strength board. The composite paper board is also characterized in that the inner surface of a space formed by the corrugated paper core and the honeycomb paper core with the bottom facial papers is coated with an inorganic cellulose coating layer; the antishock fiber layer I and the antishock fiber layer II are formed by placing a nanoparticle suspension into multiple layers of fabrics and compositing. The composite paper board is light in mass, good in strength and good in shock resistance, and can be applied to buffer protection in the field of industrial and civil used board materials.

Owner:HUNAN UNIV OF TECH

Material and method for manufacturing thenar massage and products thereof

InactiveCN1701781AGuaranteed absolute zero-distance contactRealize personal deliveryUnknown materialsSuction-kneading massageMedicinal herbsMassage

The invention discloses a material and method for manufacturing thenar massage and products, wherein the material is prepared by using powdered Chinese medicinal herbs as main body, charging a predetermined amount of excipient, then naturally consolidating or forming by compacting. The obtained product is a rectangular or ellipsoidal blank member with permanent magnetic sheets on the bottom surface. The material can also be used for making massage appliances for other portions of human body.

Owner:谷庆泉

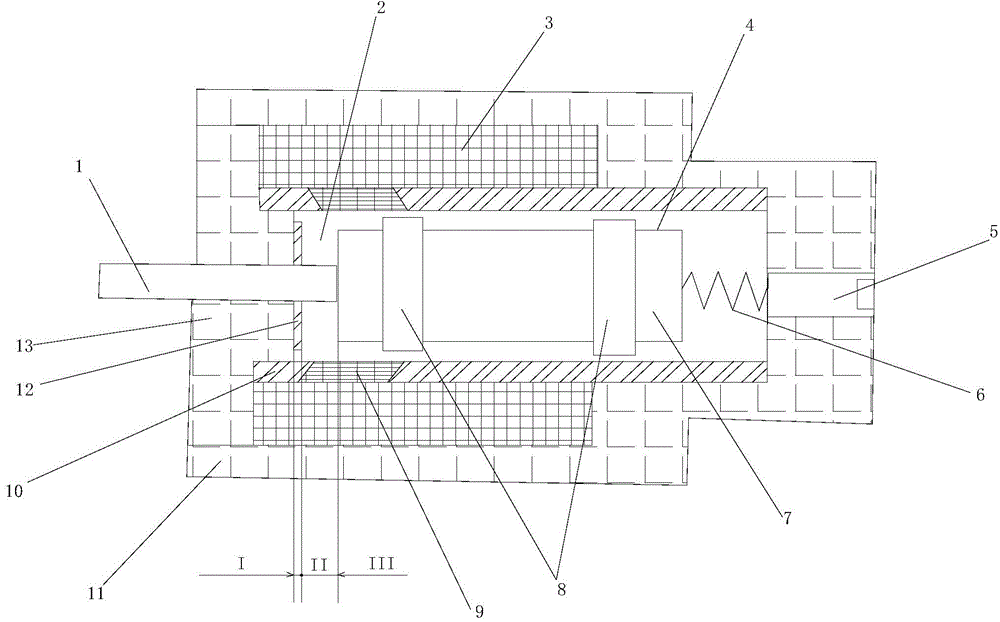

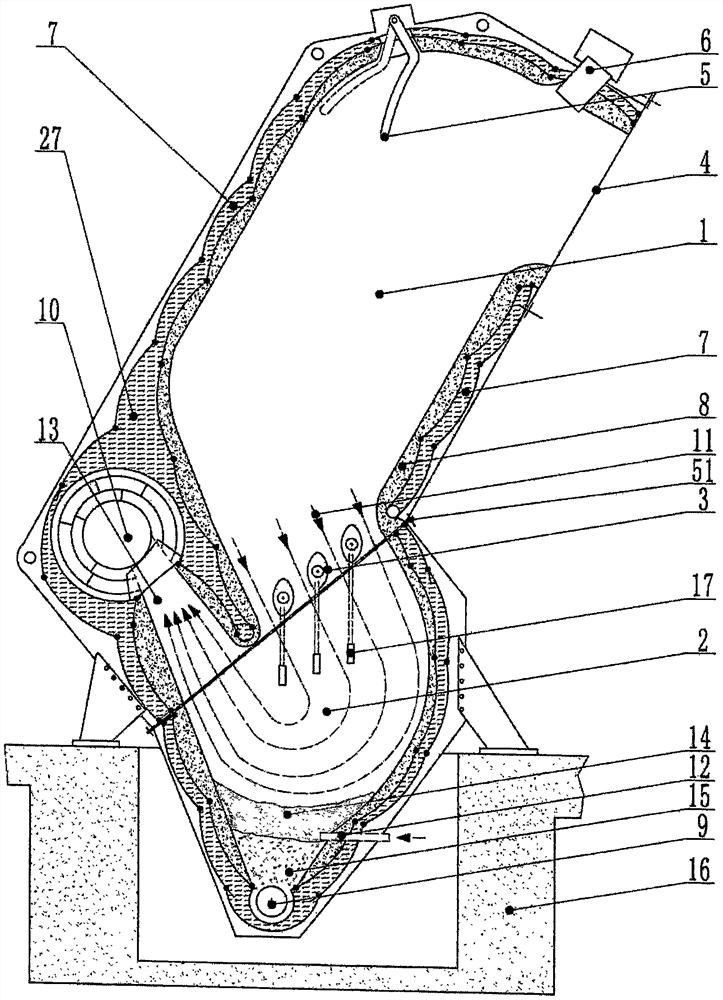

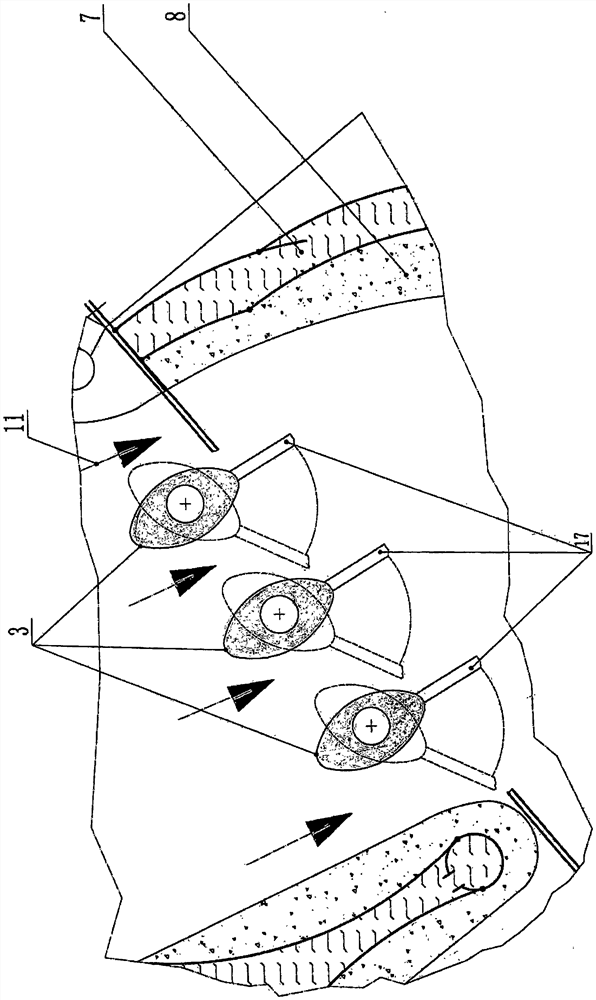

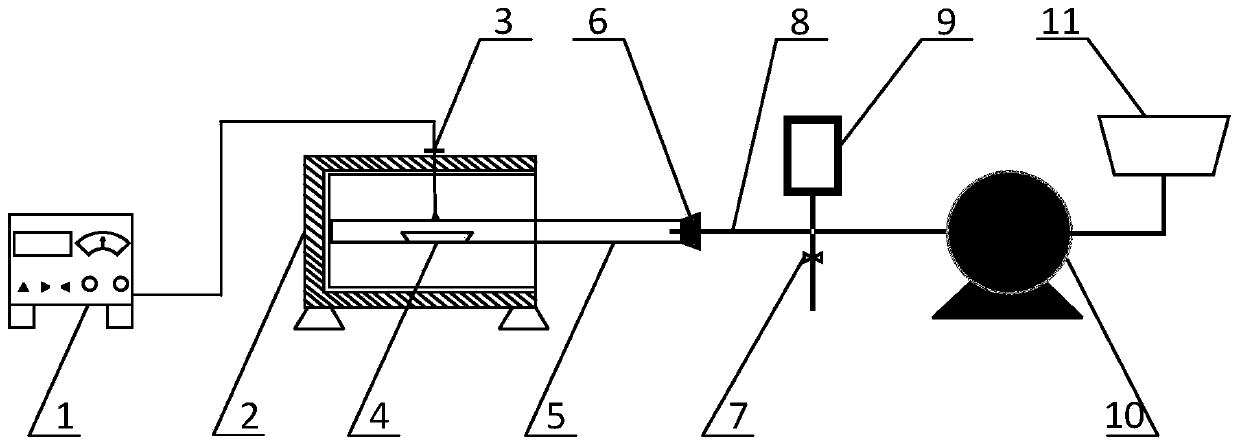

Pressure-resisting type one-way proportion electromagnet

InactiveCN104376960ASufficient compressive strengthSimple structureElectromagnets with armaturesViscous frictionEngineering

The invention discloses a pressure-resisting type one-way proportion electromagnet. The pressure-resisting type one-way proportion electromagnet comprises a push rod, an armature, a guide cover, a shell, yoke iron, a spring and an adjusting screw. The push rod is installed at the front end of the armature. The spring and the adjusting screw are arranged at the back end of the armature, and the armature is installed on a bearing ring. The guide cover is of a cylindrical structure, the front section and the back section of the guide cover are made of permeability magnetic materials, a taper pot opening is formed in the front section of the guide cover, and the two sections are welded into a whole through a magnetism isolating ring. A concentric solenoid control coil is arranged between the shell and the guide cover. The yoke iron is located at the front end of the guide cover. The pressure-resisting type one-way proportion electromagnet is simple and reasonable in structure, and due to the fact that the guide cover of the cylindrical structure has enough pressure-resisting strength, the one-way proportion electromagnet can bear 35 Mpa hydraulic pressure; the push rod arranged at the front end of the armature is used for outputting power or moving, and a zero setting mechanism is formed by the adjusting screw and the spring which are installed at the back end of the armature. The armature is supported by the bearing ring so that viscous friction force can be reduced.

Owner:CHANGZHOU FEIYU CHEM

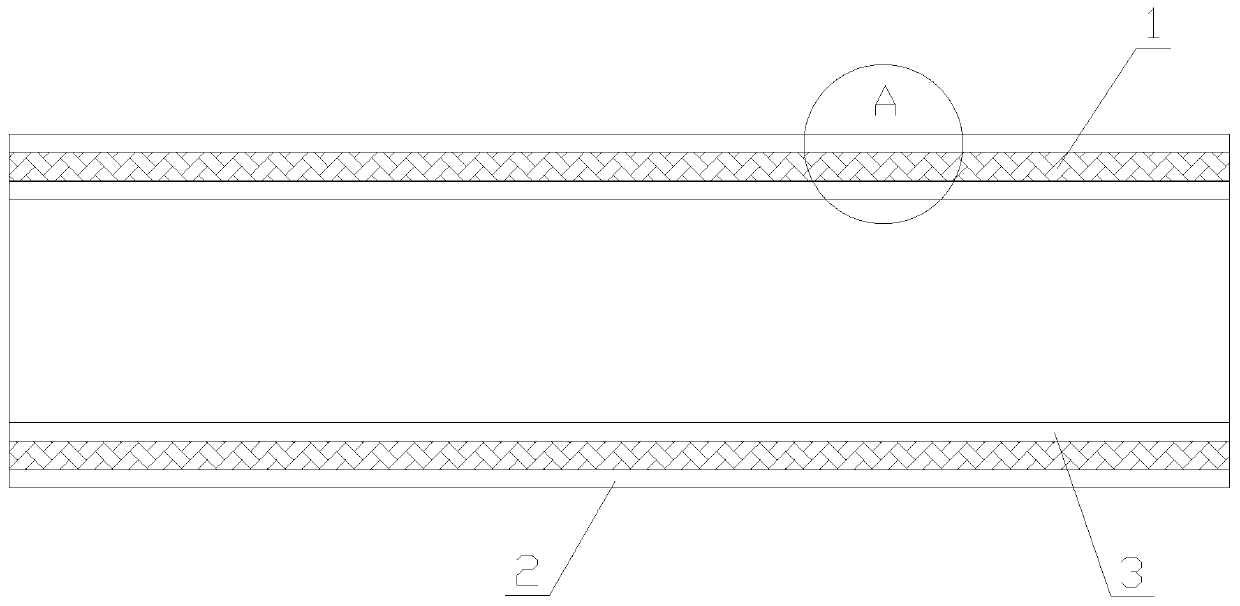

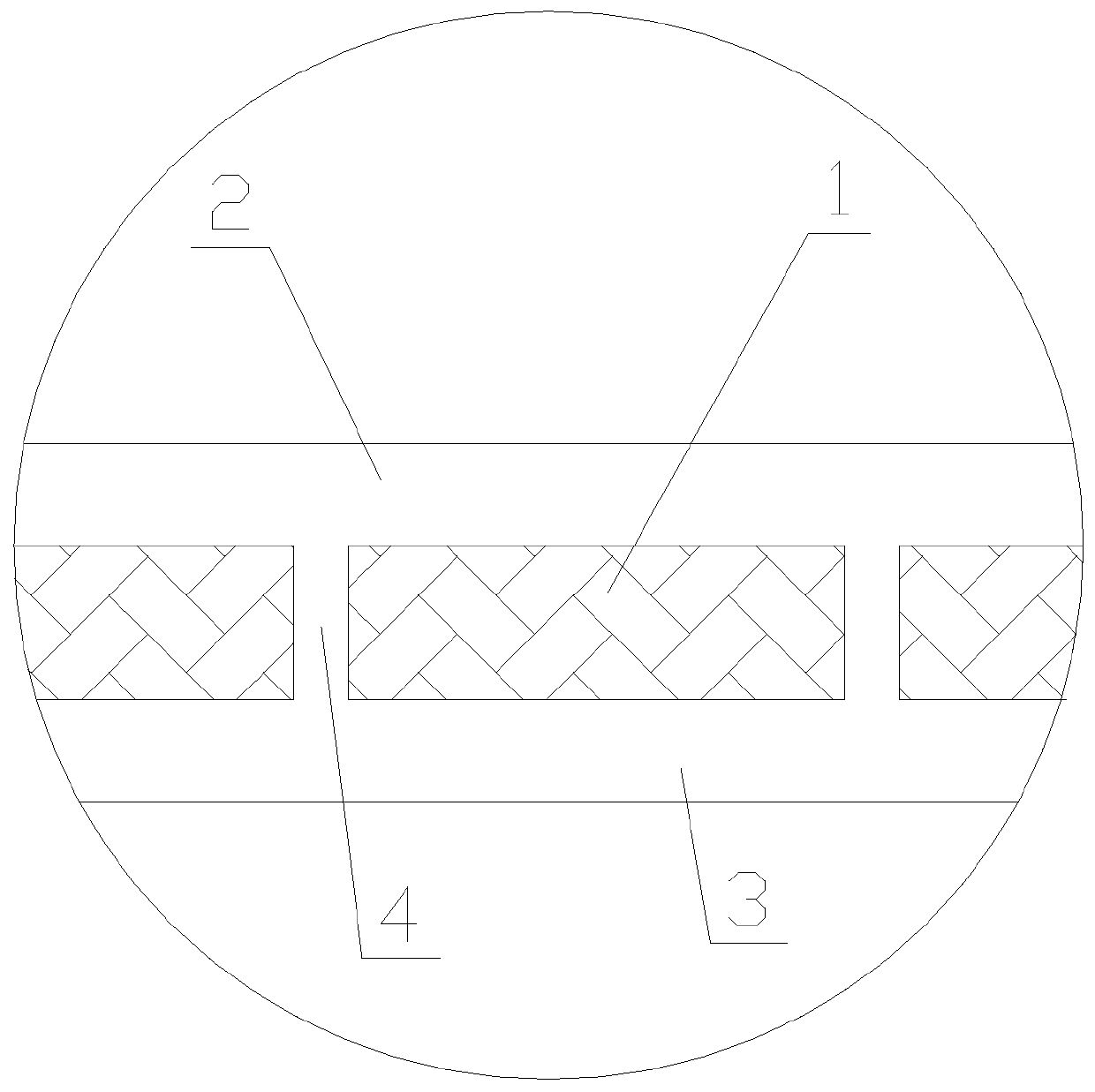

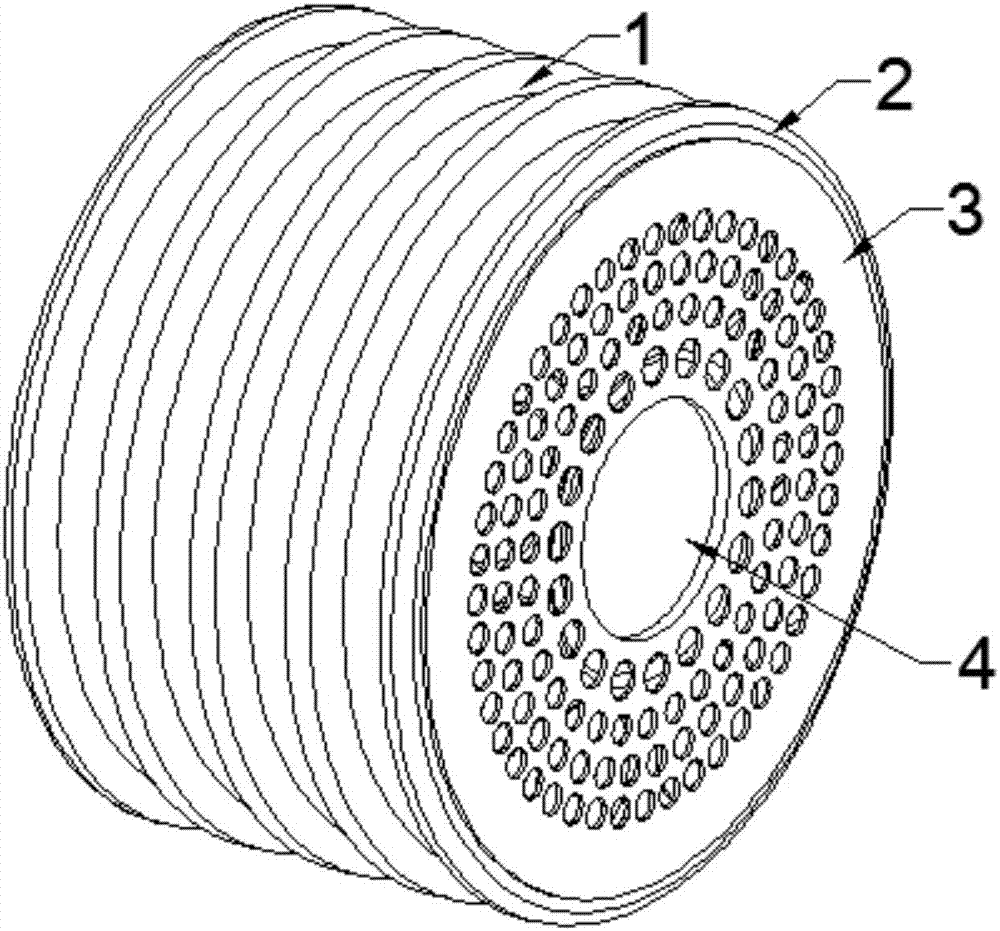

Fiber reinforced hose and manufacturing method thereof

PendingCN109721020ASufficient compressive strengthReduce manufacturing costLiquid transferring devicesCooking & bakingEngineering

The invention relates to a fiber reinforced hose and a manufacturing method thereof. The hose is composed of a fiber reinforced woven layer, an inner glue layer and an outer glue layer, wherein the fiber reinforced woven layer is a tubular shape and is formed by weaving warp yarns and weft yarns, the inner glue layer and the outer glue layer coat the inner surface and the outer surface of the woven layer respectively, a plurality of columnar glue permeates into the fiber gaps of the woven layer of the hose, the outer glue layer is connected with the inner glue layer through the columnar glue;and the manufacturing method of the fiber reinforced hose comprises the procedures of material selection, twisting, yarn feeding, weaving, baking, coating and cooling, a liquid glue layer material coats the inner and outer wall of the woven layer by a die head and an extruding machine after baking is carried out, and the hose is obtained by cooling. According to the hose and the method, the proportion of the maximum tensile force borne by the warp yarns and the weft yarns is reasonably configured, enough strength is generated by using the minimum amount of aramid fibers as the weft yarns, so that the production cost is reduced; and the inner glue layer and the outer glue layer simultaneously coat on the inner wall and the outer wall of the fiber reinforced layer through a one-step coatingprocess, and the production efficiency and the strength of the hose are improved.

Owner:TAIZHOU CITY JIANGYAN DISTRICT XINHUILAI TEXTILE MACHINERY CO LTD

Production of edible artificial sausages coating by enzymolytic collagen protein fibre

InactiveCN100551253CLow shrinkageIncrease productivitySausage casingsProtein foodstuffs working-upBiotechnologyFiber

The invention discloses a method for making edible artificial sausage casings by enzymatically decomposing collagen fibers. The method successfully uses protease to moderately hydrolyze animal leather with protein activity to obtain delicate long collagen fibers, and through grading Grinding, high-pressure spinning, mixing and other processing steps make the collagen fibers more subdivided and softer, and obtain longitudinal strips of collagen fibers. The collagen fibers are braided and shaped by a circular cross braiding machine, and then shaped with ammonia gas. After drying and qualitative treatment, it is made into seamless, transparent, thin and soft tubular casings. The casings produced by this method mainly contain 50-60 parts by weight of collagen protein and have sufficient compressive strength. When used in sausage production, There will be no tearing phenomenon, and good edibility and palatability are obtained. The performance of the casing is especially suitable for the use of medium and high-end western-style sausages and high-speed automatic sausage filling machines.

Owner:柳州市宏升胶原蛋白肠衣有限公司

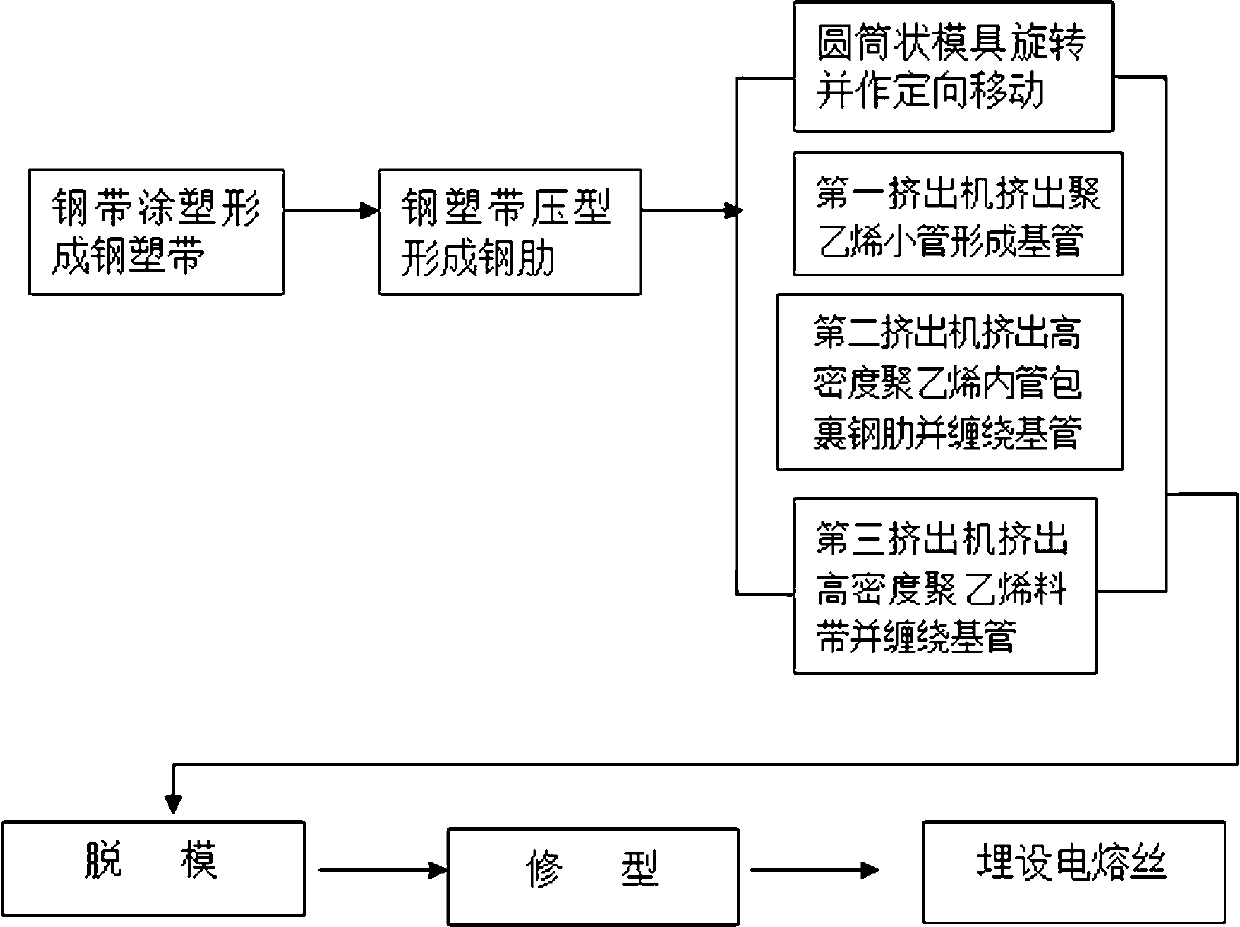

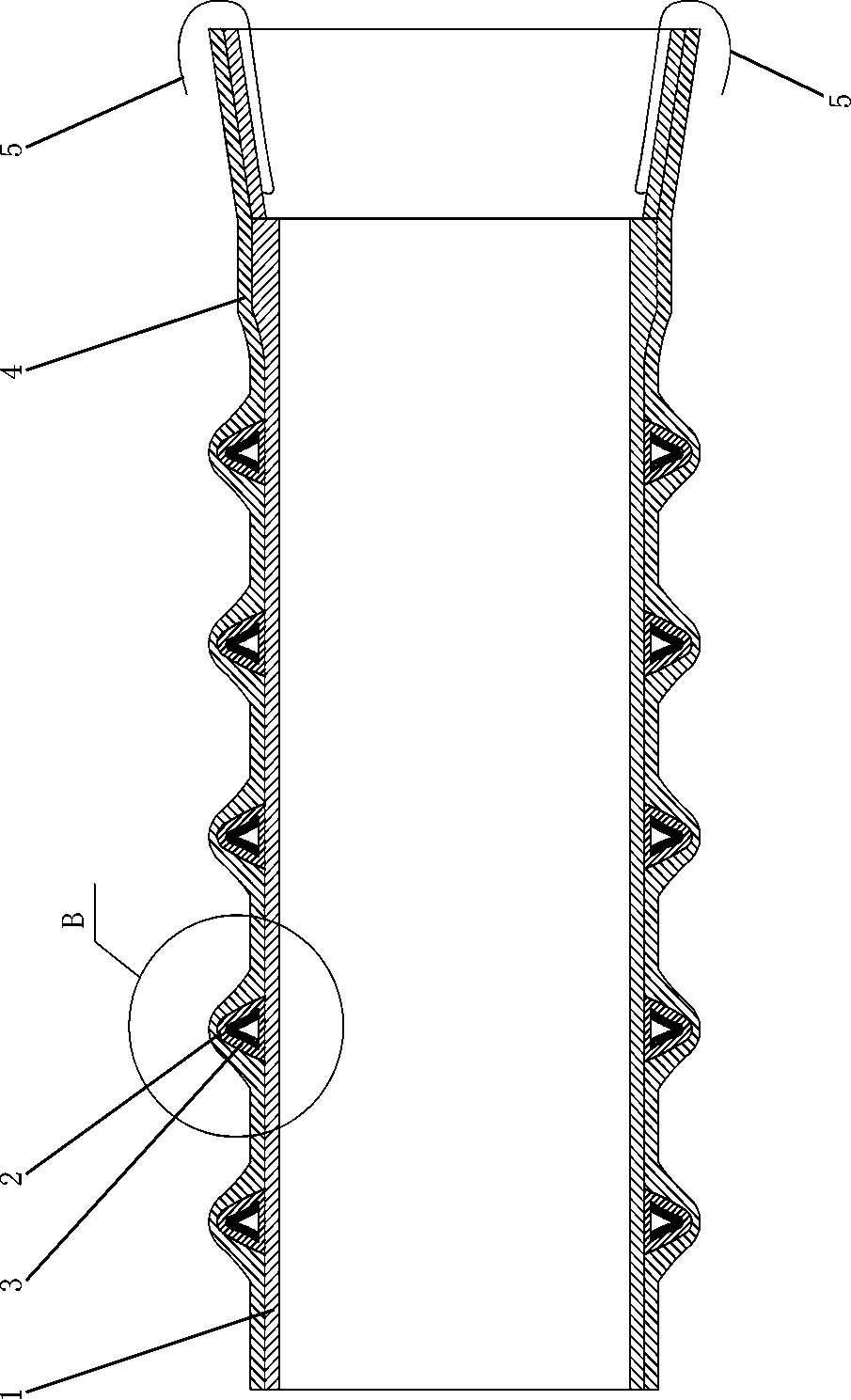

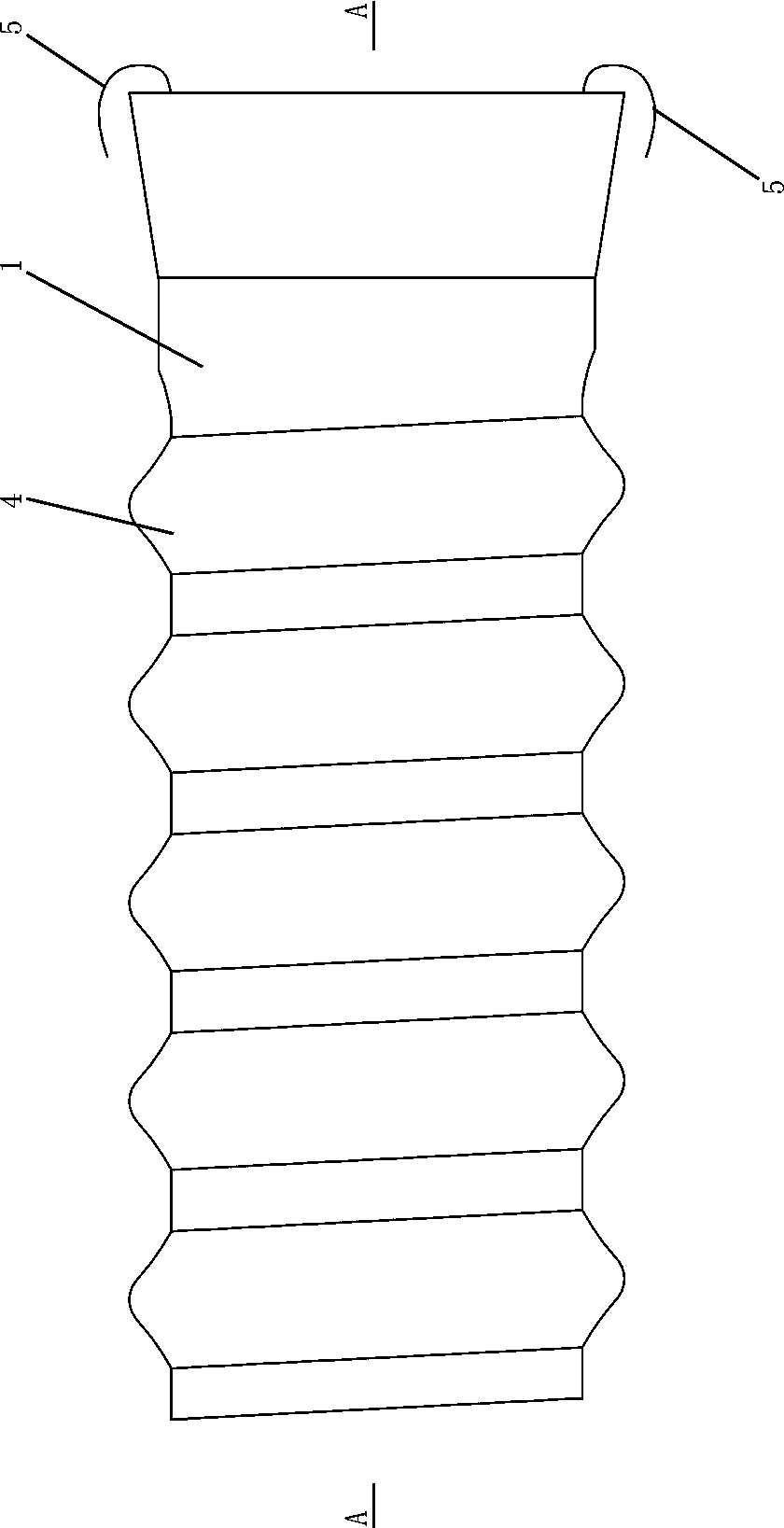

Novel steel belt reinforced polyethylene spiral corrugated pipe and production process thereof

ActiveCN109869541ATightly boundSufficient compressive strengthRigid pipesPliabilityHigh-density polyethylene

The invention discloses a novel steel belt reinforced polyethylene spiral corrugated pipe. The novel steel belt reinforced polyethylene spiral corrugated pipe comprises a base pipe, a high-density polyethylene inner pipe, steel ribs and a high-density polyethylene material belt; the steel ribs include steel belts and resin layers, the steel belts are wrapped with the resin layers; the steel ribs are wrapped with the high-density polyethylene inner pipe; openings are formed in the two ends of the base pipe correspondingly, the high-density polyethylene inner pipe is spirally wound outside the base pipe and welded to the base pipe; and the high-density polyethylene material belt is spirally wound outside the base pipe, the base pipe and the high-density polyethylene inner pipe are covered with the high-density polyethylene material belt, and the high-density polyethylene material belt is welded to the base pipe and the high-density polyethylene inner pipe. The base pipe, the high-densitypolyethylene inner pipe and the high-density polyethylene material belt are manufactured by three extruders in a co-extrusion mode correspondingly, multiple cladding and welding are realized, the base pipe, the high-density polyethylene inner pipe and the steel ribs are bonded more closely, thus the steel belt reinforced polyethylene spiral corrugated pipe has sufficient compressive and impact strength and also has good flexibility, and the ring stiffness of the steel belt reinforced polyethylene spiral corrugated pipe is greatly improved.

Owner:GUANGDONG SANLING PLASTIC PIPE MATERIAL

Cementless permeable concrete brick

ActiveCN108083744BSufficient compressive strengthReduce manufacturing costCeramicwareBrickMining engineering

The invention provides a cement-free permeable concrete brick and belongs to the concrete field. Cheap alkaline mud and mineral powder are used to replace cement, the production cost of the permeableconcrete brick can be reduced, the environmental pollution problem caused by the alkaline mud and the mineral powder is solved, and meanwhile, the obtained cement-free permeable concrete brick has large permeation coefficient, good wear resistance and excellent compressive strength. The cement-free permeable concrete brick is prepared from components in parts by weight as follows: 80-100 parts ofthe alkaline mud, 90-110 parts of mineral powder, 90-120 parts of water, 1,400-1,500 parts of stone, 3.4-4.2 parts of crude salt and 1.87-2.31 parts of a high-performance water reducer.

Owner:青岛磊鑫混凝土有限公司

Design and construction method of whole bundle type straw gasification device

PendingCN112266800AImprove securitySufficient compressive strengthCombustible gas productionCombustion chamberWater jacket

The invention relates to a design and construction method of a whole bundle type straw gasification device. The module is suitable for road transportation and is used as a part of a modular system forstraw energy utilization, and only a small amount of installation workload is needed on an installation site for constructing a heat supply station and a small power plant. The vault of the refractory brick lining of the horizontally arranged combustion chamber is designed to be variable, and the heat output of the modular system can be improved by connecting a plurality of gasification modules.The whole bundle type straw gasification module comprises a whole bundle straw gasification chamber 1 and a rear gasification chamber 2, the whole bundle straw gasification chamber and the rear gasification chamber are separated by a rotatable fire grate 3, the gap width of the rotatable fire grate can be adjusted from the outside, and a charcoal ash bridge between the fire grates can be destroyedat any time through movement of the rotatable fire grate. Ash containing high-proportion charcoal can be produced by controlling air supply of the rear gasification chamber 2. The cooling water jacket 7 of the gasification module is formed by equidistantly welding the same bent metal plates in a staggered manner, so that the manufacturing process is simplified, and enough compressive strength isrealized.

Owner:黑龙江赫尔特生物质能源发展有限公司

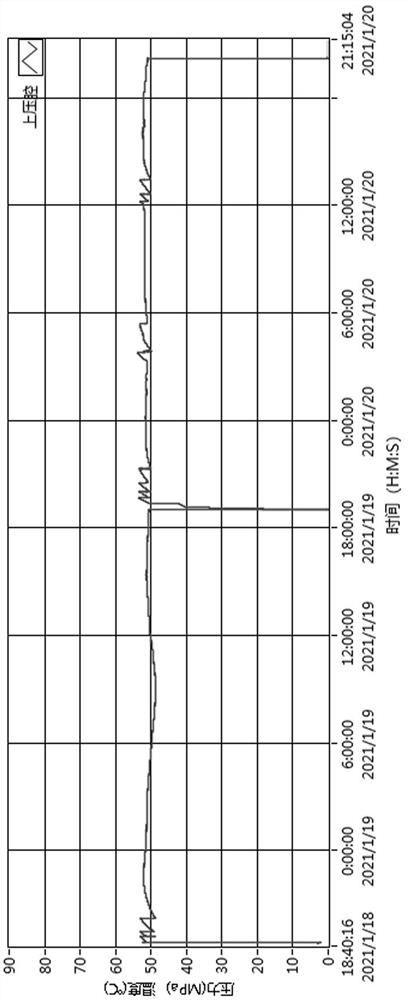

Oil and gas well fracturing construction method

ActiveCN112696184AReduce construction riskUniform fracturingFluid removalSealing/packingPetroleum engineeringGeotechnical engineering

Owner:SICHUAN WELDON CHEM

Rope sheave with good dustproof function

InactiveCN107337065AGood dustproof functionWill not weaken the mosquito control effectBuilding liftsAir filterEngineering

The invention provides a sheave with good dustproof function, which includes a sheave body, a rope groove is opened on the outer surface of the sheave body, and a mounting hole is opened on the side end surface of the sheave body, and the mounting hole It is arranged coaxially with the sheave body, and a through hole is opened on the side end surface of the sheave body, and an electronic mosquito killer lamp is installed in the through hole, and a circle of concave holes is also arranged on the side end surface of the sheave body. groove, the groove is detachably connected with a cover for covering the through hole, the center of the cover is provided with a circular hole, the diameter of the circular hole is equal to the diameter of the installation hole, the cover There are multiple evenly distributed dust-proof mesh holes on the end face. The beneficial effect of the present invention is that: on the side end surface of the sheave body, the cover body with dust-proof mesh holes can play a role of dust-proof on the one hand, and also has the function of ventilation and mosquito-killing on the other hand.

Owner:天津隆勤电梯部件有限公司

High-temp alkali-resistant material and use therreof in ceramic filler

A high-temp. alkali-resistant material mainly contains MgO, SiO2 and Al2O3. Its primary crystal phase is forsterite and spinel. Its features are high resistance to alkali corrosion at high temp and use for preparing ceramic filler of heat-accumulating thermal oxidizer to treat organic waste gas in wood industry.

Owner:兰州瑞玛化机有限公司 +1

Complex microbial agent capable of purifying air and application thereof

InactiveCN108559721AEfficient use ofIncrease concentrationFungiGas treatmentBacteroidesDecomposition

The invention discloses a complex microbial agent capable of purifying air and application thereof. The complex microbial agent is prepared from, by weight, 7-15 parts of pseudomonas, 7-15 parts of saccharomycetes, 6-14 parts of Opitutales, 5-12 parts of rhizobium, 4-12 parts of rhodospirillum, 4-12 parts of rhizopus oryzae, 2-9 parts of micrococcus, 2-8 parts of bacteroides, 2-9 parts of clostridia, 2-8 parts of bacillus cereus, 1-7 parts of alcaligenes, 1-7 parts of streptomycete, 1-7 parts of rhodocyclus, 1-6 parts of galactococcus, 1-6 parts of mycobacteria, 1-6 parts of burkholderiales, 1-6 parts of lysobacter, 1-5 parts of hydrogenophilus, 1-5 parts of xanthomonas, 1-5 parts of brevundimonas, 0.1-3 parts of comamonas and 0.1-3 parts of aspergillus. The complex microbial agent utilizes the synergistic effect of powerful bacteria, it is promoted that microorganisms utilize and perform metabolism decomposition on volatile organic compounds in the air, so that the efficient elimination and reduction of contaminants are achieved.

Owner:BEIJING NORMAL UNIVERSITY

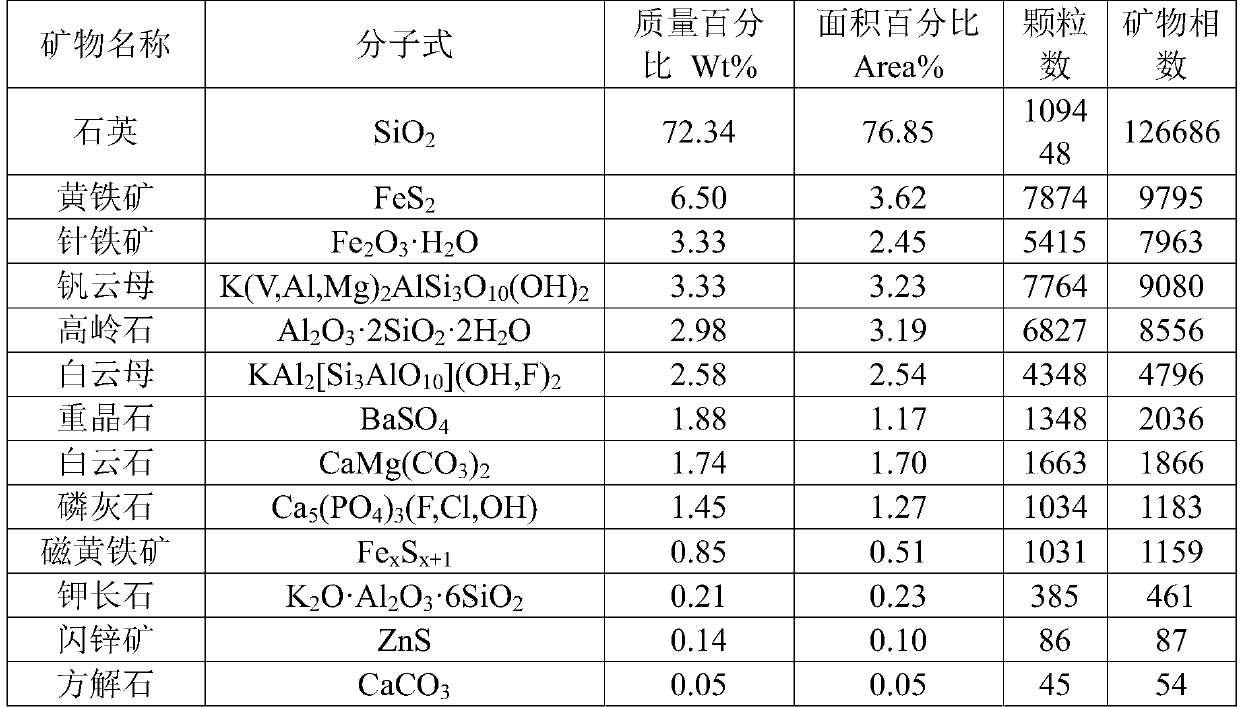

Pretreated carbonaceous gold concentrate, preparation method thereof and gold extraction method

ActiveCN110484719AImprove leaching rateLow S contentProcess efficiency improvementGraphite carbonVacuum pressure

The invention discloses pretreated carbonaceous gold concentrate, a preparation method thereof and a gold extraction method. The preparation method and gold extraction method comprise the steps that carbonaceous gold concentrate powder is pressed into carbonaceous gold concentrate blocks; the carbonaceous gold concentrate blocks are subjected to roasting in vacuum, organic carbon in the carbonaceous gold concentrate blocks is converted into graphite carbon, and cooling is performed after roasting is completed; the pretreated carbonaceous gold concentrate is ground into pretreated carbonaceousgold concentrate powder; and cyanidation leaching is performed on the pretreated carbonaceous gold concentrate powder. According to the pretreated carbonaceous gold concentrate, the preparation methodthereof and the gold extraction method provided by the invention, a vacuum system is combined with roasting, and the carbonaceous gold concentrate can be effectively pretreated when the vacuum pressure is controlled not to be greater than 20 Pa, the temperature is controlled to be 1000-1200 DEG C and the roasting time is controlled to be 50-90 min; through reaction, the organic carbon with a goldintercepting effect can be converted into the graphite carbon without a gold intercepting effect, the gold intercepting capability of the carbonaceous gold concentrate is weakened, and influences ofthe concentrate on cyanidation gold extraction are eliminated; and gold wrapped with sulphide ore can be further dissociated, a good material basis is provided for cyanidation gold extraction, the gold leaching efficiency is improved, and the leaching duration is shortened.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

Phenolic resin foam board, and method for manufacturing same

ActiveCN105073860AGood dimensional stabilitySufficient compressive strengthSpray nozzlesLiquid spraying apparatusDensity distributionHorizontal axis

The present invention provides a phenolic resin foam board, which exhibits sufficient compressive strength and heat conductivity for practical use even when the thickness of the phenolic resin foam board is increased, and which has superior dimensional stability compared with conventional products. The present invention is a phenolic resin foam board which has a board thickness of 40 to 300 mm inclusive. The phenolic resin foam board satisfies the formula 0 ≤ (dave-dmin) / dave ≤ 0.12, where dn represents the density of a nth specimen among n (n ≥ 5) pieces of specimens that are produced by slicing the phenolic resin foam board at almost equal intervals of 8 to 10 mm inclusive in the thickness direction from one main surface of the phenolic resin foam board along the main surface, dave represents the average density of the n pieces of specimens, and dmin represents the lowest density among the densities of the n pieces of specimens. When values for Di = (di+d(i+1)) / 2 are calculated [where i represents an integer of 1 to (n-1)], the Di values are plotted in the order of the numerical values of i (where the horizontal axis indicates the i values and the vertical axis indicates Di values), and points corresponding to the Di values are connected to produce a density distribution curve, there is no straight line that intersects the density distribution curve at four points and is parallel to the horizontal axis.

Owner:ASAHI KASEI CONSTRUCTION MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com