Pressure-proof proportion electromagnet based on integrated type flux sleeve

A technology of proportional electromagnet and magnetic sleeve, applied in the direction of electromagnet with armature, electromagnet, valve operation/release device, etc., can solve the problems of thin wall of magnetic sleeve and limited pressure of magnetic sleeve, and achieve reduction Effects of complexity, simplification of processing technology, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

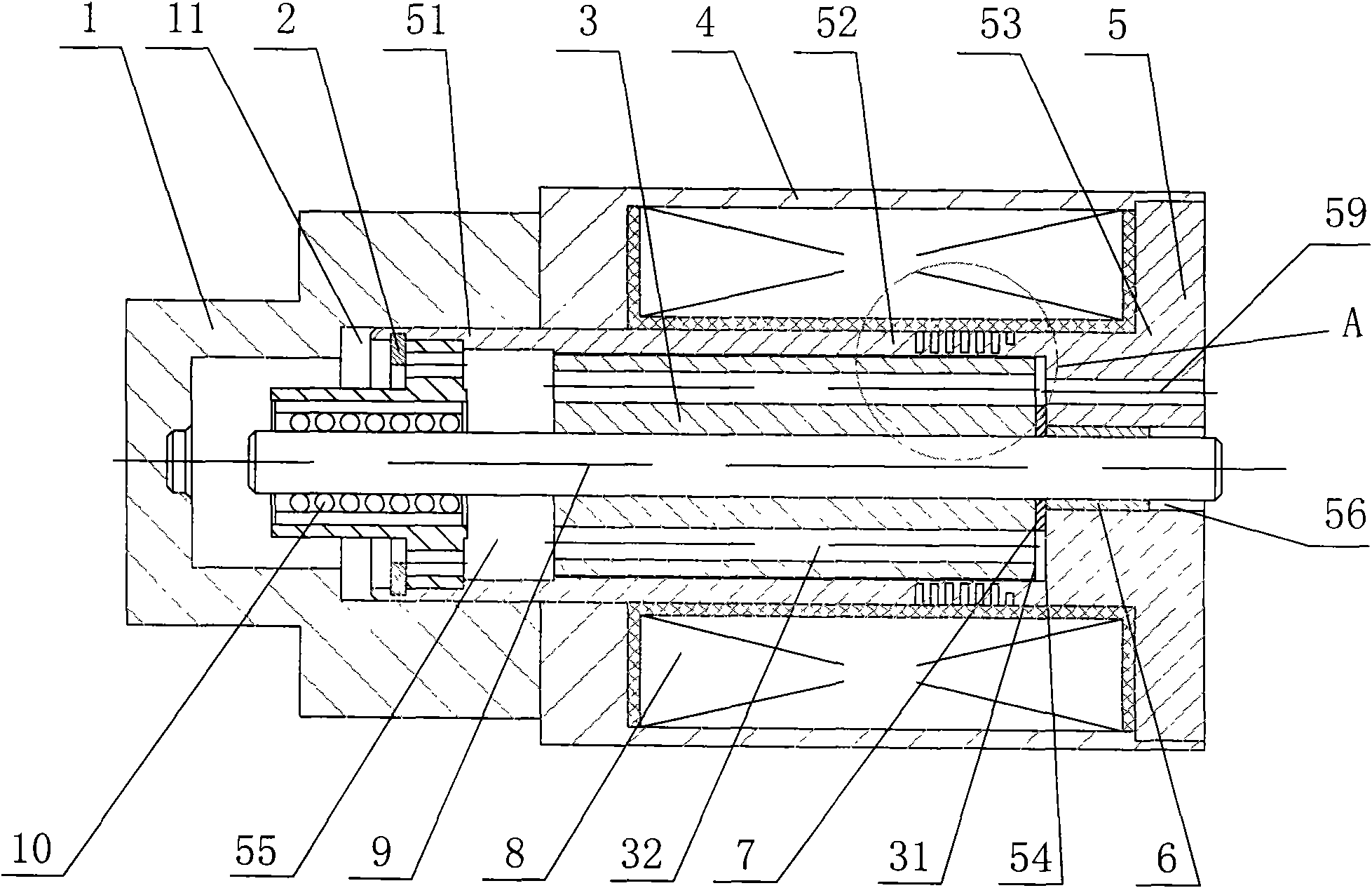

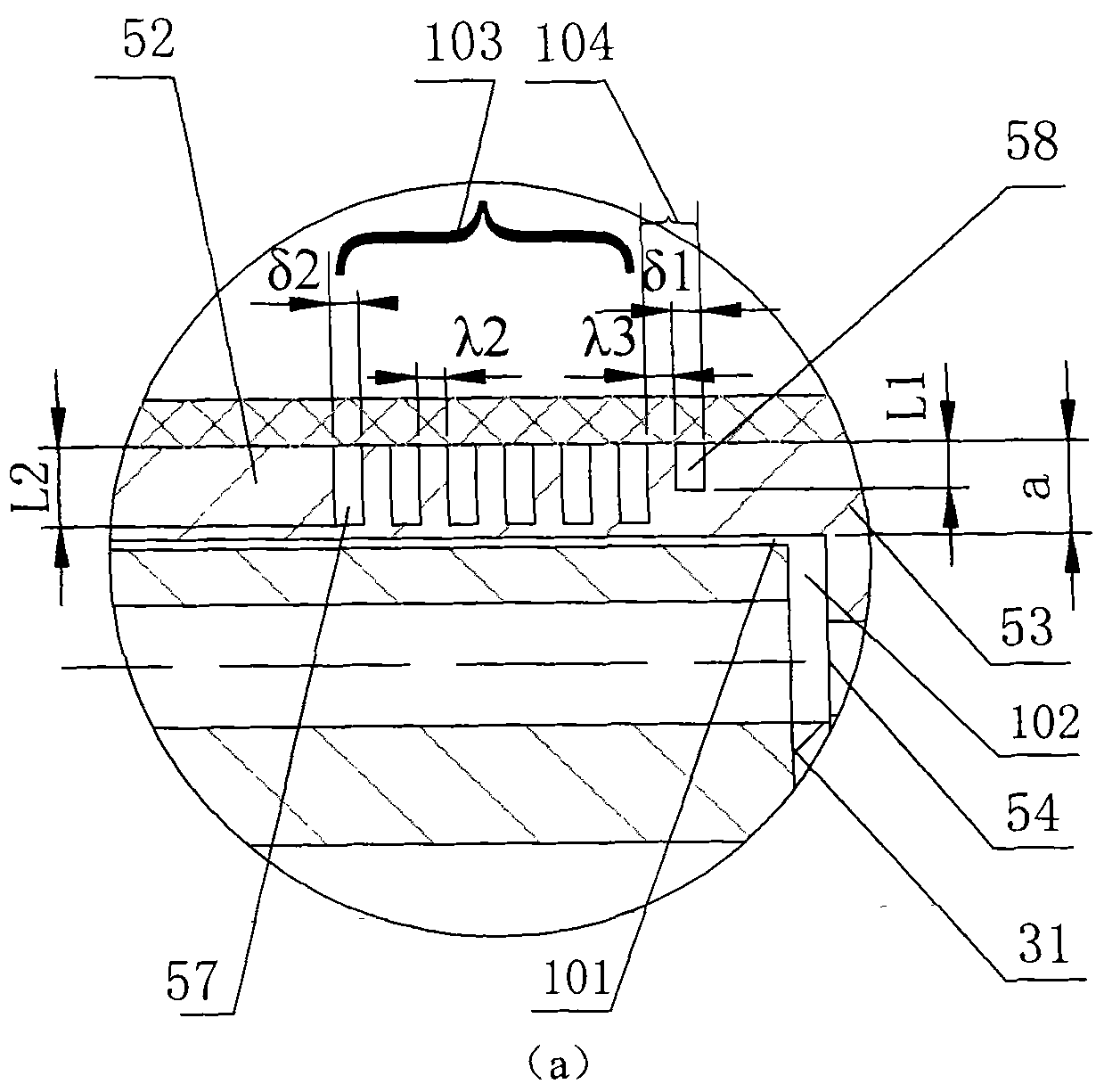

[0047] Embodiment 1, figure 1 with figure 2 (a) Combined with a pressure-resistant proportional electromagnet based on an integrated magnetic sleeve, it includes a housing 4 with a rectangular parallelepiped shape and a cylindrical inner hole, and a magnetic sleeve 5 with a stepped cylindrical shape And the end cover 1 with the end cover cavity 11 inside; the magnetic sleeve 5 is set in the housing 4 , and the control coil 8 is arranged between the magnetic sleeve 5 and the housing 4 . The control coil 8 can be selected as a concentric solenoid control coil. An opening is provided on the casing 4 for installing a socket and connecting with the control electronic circuit; that is, the control coil 8 can use this opening to realize electrical connection with the outside world.

[0048] The magnetic sleeve 5 is composed of a front section 51 , a middle section 52 and a rear section 53 which are sequentially connected from left to right. Rear section 53 is combined by small c...

Embodiment 2

[0069] Embodiment 2, figure 1 with figure 2 (b) Combined with another pressure-resistant proportional electromagnet based on an integrated magnetic sleeve.

[0070] It differs from Embodiment 1 only in that the deep and shallow groove groups composed of the pressure-bearing groove group 103 and the magnetic modulation groove group 104 provided on the outer surface of the middle section 52 of the magnetically permeable sleeve 5 are changed, as follows: 4 ring-shaped deep grooves 57 and 3 ring-shaped shallow grooves 58 parallel to each other are set on the outer surface of the middle section 52 of the sleeve 5 from left to right; these 4 ring-shaped deep grooves 57 and 3 ring-shaped grooves The shallow grooves 58 are all perpendicular to the central axis of the magnetic sleeve 5 . The four annular deep grooves 57 and the three annular shallow grooves 58 form a deep and shallow groove group. Four annular deep grooves 57 form a pressure-bearing groove group 103 , and three an...

Embodiment 3

[0074] Embodiment 3, figure 1 with figure 2 (c) Combined with another pressure-resistant proportional electromagnet based on an integrated magnetic sleeve. It differs from Embodiment 1 only in that the deep and shallow groove groups composed of the pressure-bearing groove group 103 and the magnetic modulation groove group 104 provided on the outer surface of the middle section 52 of the magnetically permeable sleeve 5 are changed, as follows: Three annular deep grooves 57 and three annular shallow grooves 58 are arranged alternately from left to right on the outer surface of the middle section 52 of the sleeve 5, and then one annular shallow groove 58 is arranged at the far right. The three annular deep grooves 57 and the two annular shallow grooves 58 counted from the left form the pressure-bearing groove group 103 ; the remaining two annular shallow grooves 58 form the magnetic modulation groove group 104 .

[0075] All the aforementioned deep annular grooves 57 and all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com