Spliced wooden bowl and manufacturing method thereof

A technology for processing wooden bowls and boards, which is applied to wood processing utensils, manufacturing tools, plates, etc., and can solve the problems of single tree species, unsatisfactory production quantity, and low growth of mature forests.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1 please refer to appendix figure 1 The spliced wooden bowl is formed by processing and turning a wooden bowl blank 1, the wooden bowl blank 1 is a bowl wall 2 composed of several hollow annular embryo bodies, and a bowl composed of a solid annular embryo body 3-1 The bottom 3 is laminated, and the hollow ring-shaped embryos are connected by glue between the bowl wall 2 and the bowl bottom 3 .

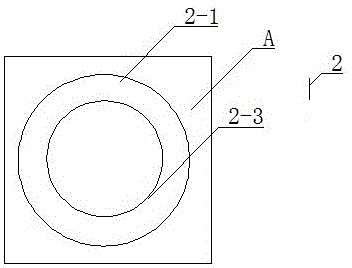

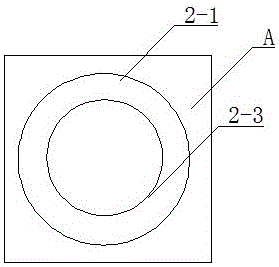

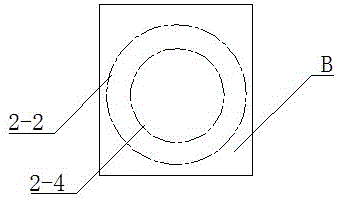

[0068] Please refer to the attached figure 2 , 3 As shown in , 4, the wooden bowl blank wall is formed by laminating two groups of hollow ring-shaped embryos of different sizes processed by two rectangular plates A and B, and a group of hollow ring-shaped embryos processed by A rectangular plate , form the 2N-1 layer of the wooden bowl embryo body according to the order of the size of the hollow annular embryo body from large to small (N takes a positive integer), and a group of hollow annular plates processed by B rectangular plates, according to the hollow annu...

Embodiment 2

[0082] Example 2, see attached Figure 5 with 6 The spliced wooden bowl shown is processed and turned from a wooden bowl blank 1. The wooden bowl blank 1 is composed of a bowl wall 2 and a bowl bottom 3. The bowl wall 2 is hollow surrounded by several trapezoidal wooden blocks 3. The ring-shaped embryo body is stacked, the bottom of the bowl is composed of a solid ring-shaped embryo body, the bowl wall 2 and the bowl bottom 3 are adhered by glue, and the hollow ring-shaped embryo bodies surrounded by several trapezoidal wooden blocks 3 are connected to each other. Glue is used for bonding. The stacking order of the hollow ring-shaped embryos is gradually reduced according to the size of the hollow ring-shaped embryos. Between the trapezoidal wooden blocks 3 contained between the adjacent two layers The seam position of is staggered.

[0083] Concrete preparation method is:

[0084] The first step is to prepare materials. Select the appropriate rectangular plate according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com