Treatment method and system for waste gas and waste liquid in bio-fermentation production of fuel ethanol

A biological fermentation method and a technology for fuel ethanol, which are applied in the field of pollution treatment, can solve the problems of unqualified effluent, the need for further treatment of content, and high cost, and achieve the effects of reducing treatment load and impact, realizing resource utilization, and realizing recycling utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

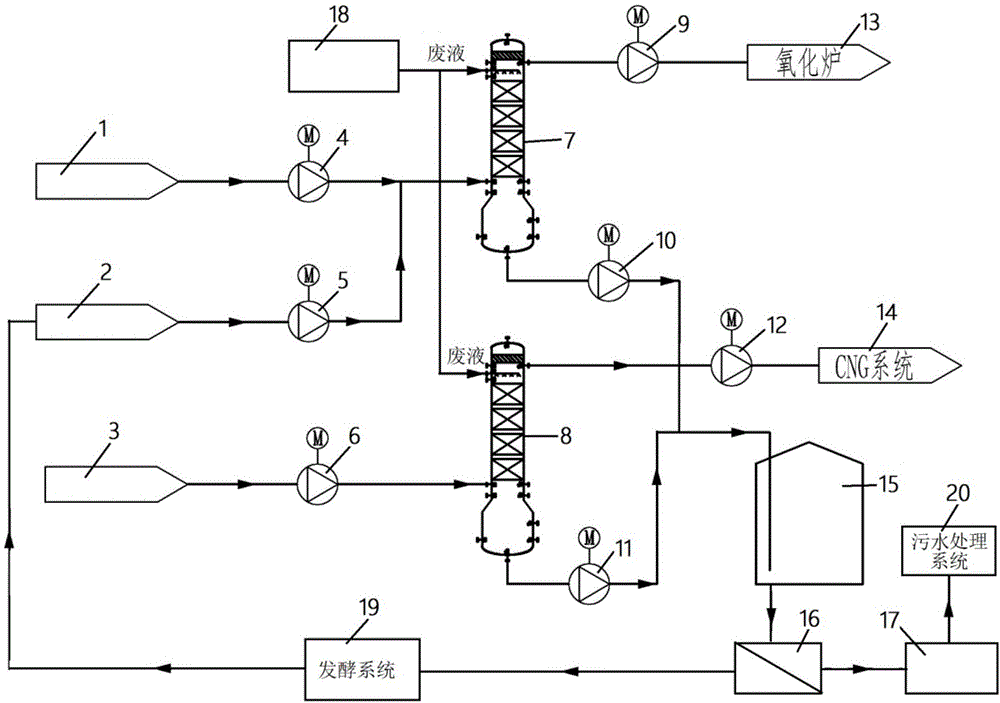

[0033] The embodiment of the present invention provides a method and system for treating waste gas and waste liquid in the production of fuel ethanol produced by biological fermentation, which reduces the difficulty of processing waste gas and waste liquid, and discharges waste gas up to standard after treatment, while reducing the treatment of waste liquid on the sewage treatment system Load and impact, to realize the use of waste to make waste, so that resources can be used to the maximum extent.

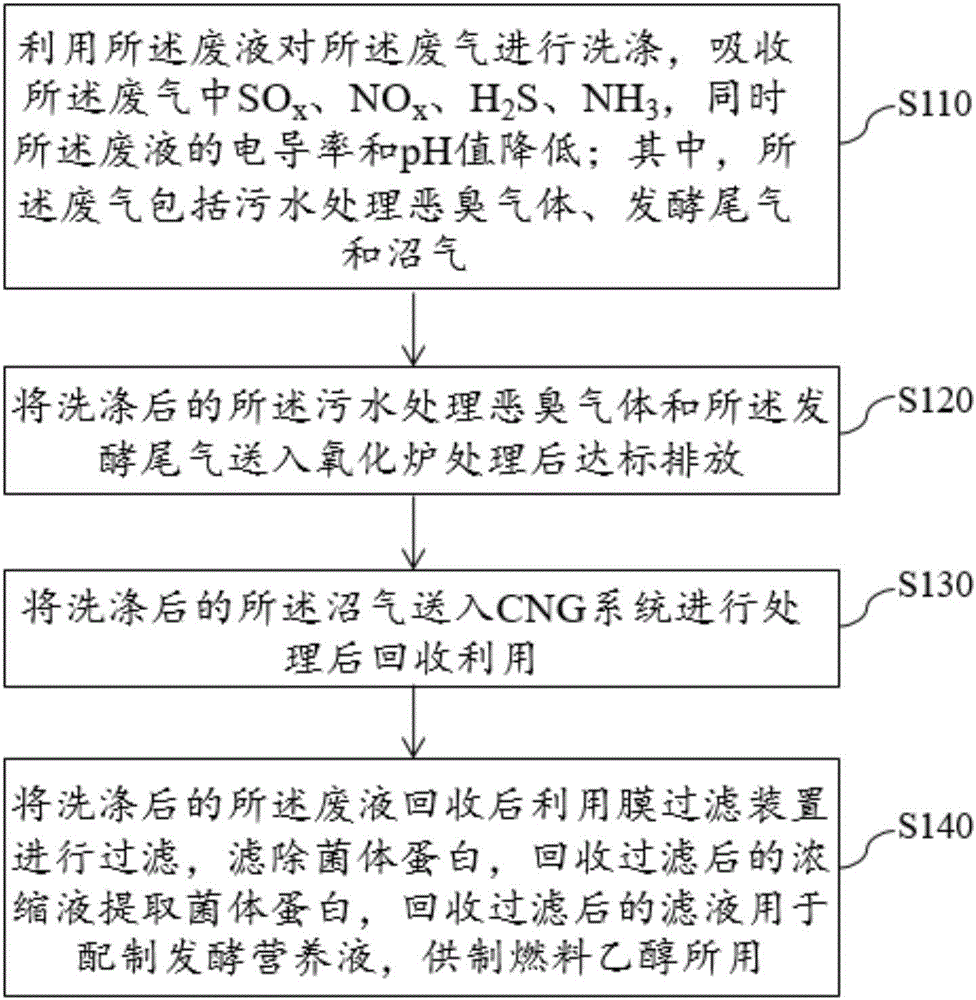

[0034] On the one hand, in order to achieve the above purpose, the embodiment of the present invention provides a method for treating waste gas and waste liquid in the production of fuel ethanol by bio-fermentation method, the waste gas is waste gas containing hydrogen sulfide; the waste liquid is waste gas containing bacterial protein lye, such as figure 1 shown, including:

[0035] Step S110: using the waste liquid to wash the waste gas, absorbing SO in the waste gas x , NO x...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com