A cylinder head water jacket structure

A technology of cylinder head and water jacket, applied in the direction of cylinder head, cylinder, mechanical equipment, etc., can solve the problems of water jacket position accuracy deviation, insufficient coolant in connecting channels, etc., to achieve stable flow rate, reduce the risk of oil-water mixing, avoid wall Thick and thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

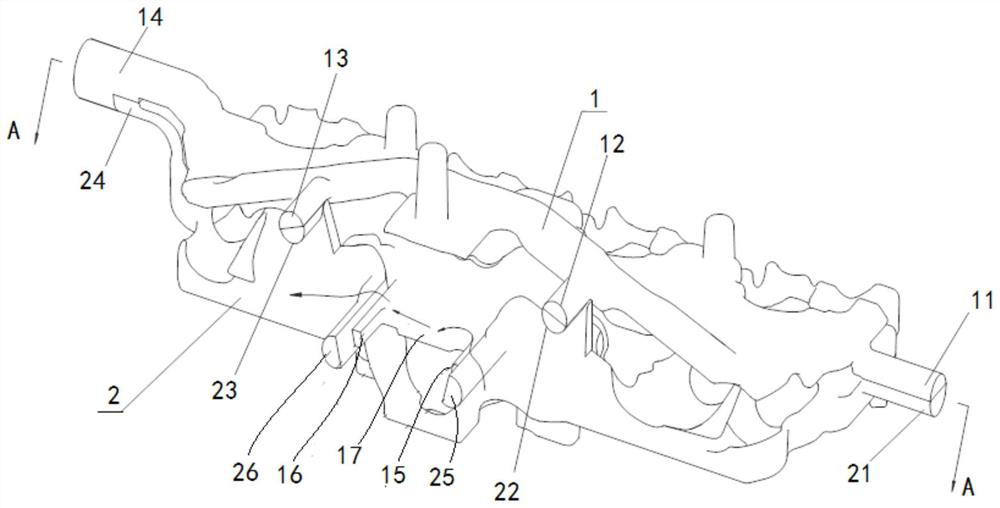

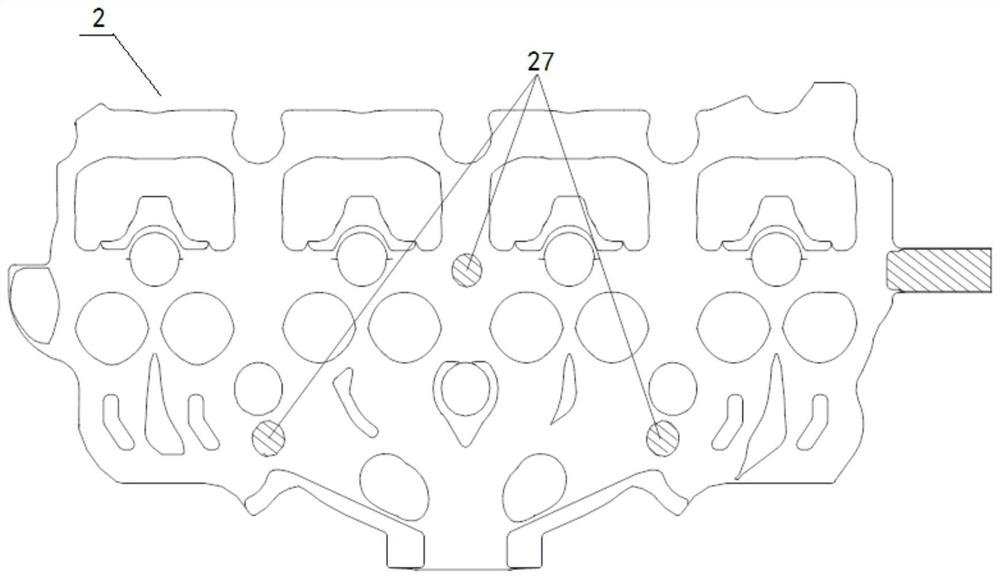

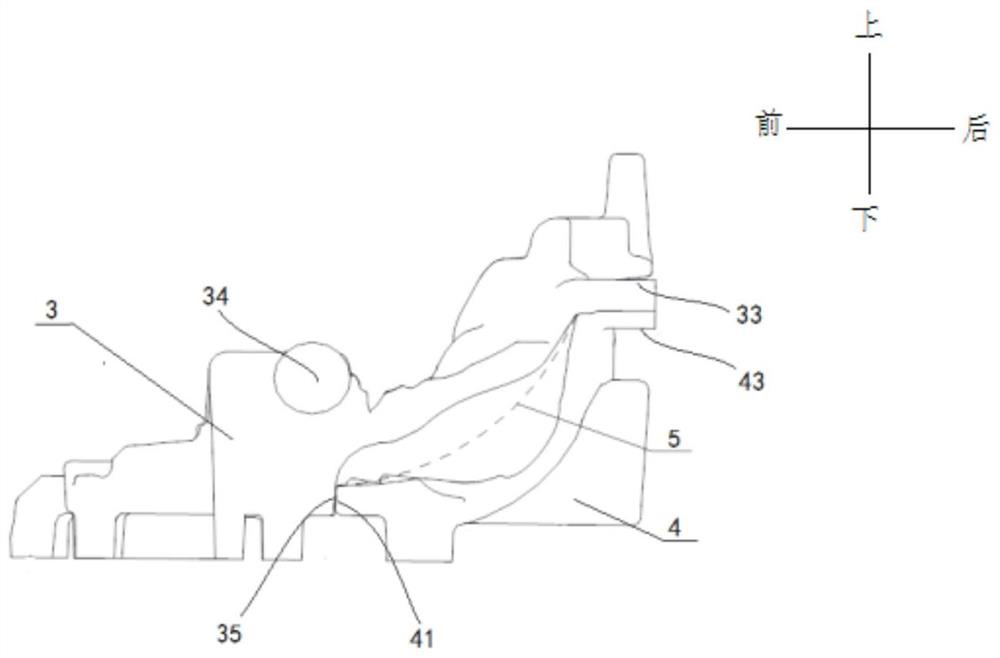

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

[0035] see image 3 , Figure 4 and Figure 5 , a cylinder head water jacket structure shown, including an upper water jacket 3 and a lower water jacket 4, characterized in that: the upper water jacket 3 is larger than the lower water jacket 4, and the rear part of the upper water jacket 3 is located at the lower water jacket 4 Above, the front lower end surface of the upper water jacket 3 is flush with the lower end surface of the lower water jacket 4 and both are positioned on the bottom plate of the cylinder head mold. Due to this positioning relationship and the entrance of molten aluminum below it, during casting, the upper and lower water jackets can be simultaneously affected by the buoyancy of the aluminum liquid, and are no longer affected by the superposition of the floating of the lower water jacket; because there are thicker and complete upper water jacke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com