Stainless steel centrifugal pump shell forming method

A technology of stainless steel pump and centrifugal pump, applied in the direction of metal extrusion dies, etc., can solve the problems of complex forming die structure, high manufacturing cost, low strength, etc., to avoid thin wall or wall crack, low manufacturing cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

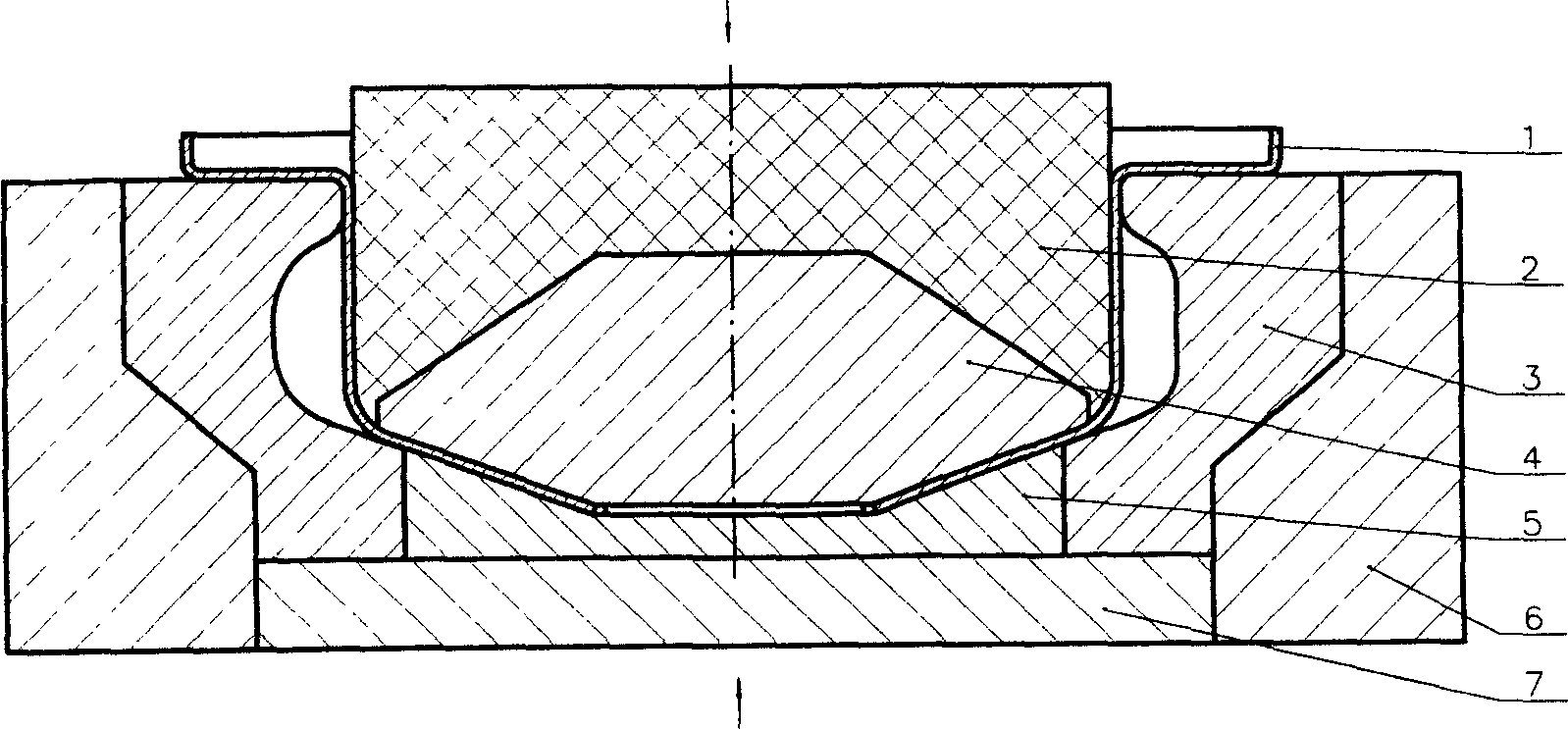

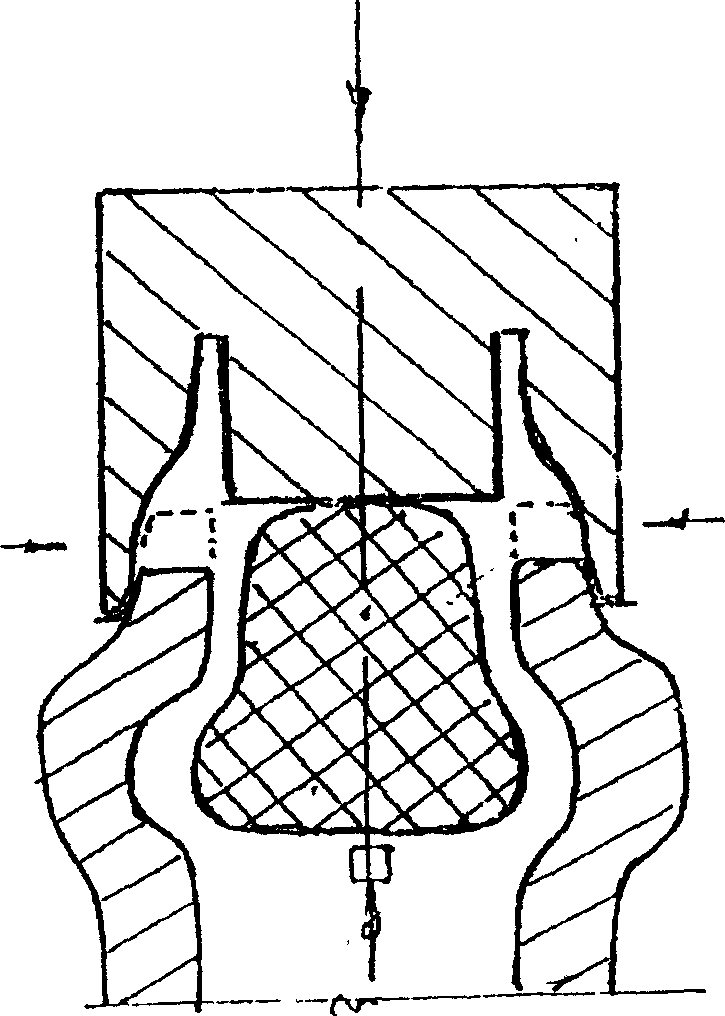

[0010] Embodiment 1: with reference to attached figure 1 . Stainless steel centrifugal pump casing forming method, the shape of the inner side of the outer mold is the same as that of the centrifugal pump casing, and the outer mold is composed of three forming modules to form a rigid mold frame. The shape of the inner side of the rigid mold frame is the same as that of the stainless steel centrifugal pump casing, that is, Say, the shape to be molded. The purpose of the steel mold frame being located in the steel sleeve of the outer mold is: first, the steel sleeve of the outer mold has an integral structure, and the three forming molds are combined to form a steel mold frame inside it, which is equal to the steel mold frame formed by combination; Because there is a top plate at the inner bottom of the steel sleeve of the outer mold, the top plate can eject the formed outer mold synchronously, and the outer mold is automatically separated after ejection, and the extruded stain...

Embodiment 2

[0011] Embodiment 2: with reference to attached figure 1 . The forming mold of stainless steel centrifugal pump casing is composed of outer mold steel sleeve 6, core mold 4, outer mold 3 and inner mold 2. The outer mold is composed of three forming molds to form a forming mold frame. The shape formed by the inner side of the forming mold frame is the same as that of a centrifugal pump. Shell shape and located in the outer mold steel sleeve 6, the core mold 4 is located at the bottom of the initially formed hat-shaped stainless steel pump casing 1 and the initially formed hat-shaped stainless steel pump casing 1 is located in the outer mold 3, and the inner mold 2 is located on the core mold 4 And in the initially formed hat-shaped stainless steel pump casing 1. The backing plate 5 in the outer mold 3 is positioned at the bottom in the outer mold frame, and its surface coincides with the bottom surface of the pump casing. The lower side of the mandrel 4 coincides with the bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com