Compressor

一种压缩机、制冷剂的技术,应用在压缩机领域,能够解决焊接部耐压强度下降、容器主体应变增大、壁厚大等问题,达到电流密度的变动小、耐压强度提高、稳定焊接的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

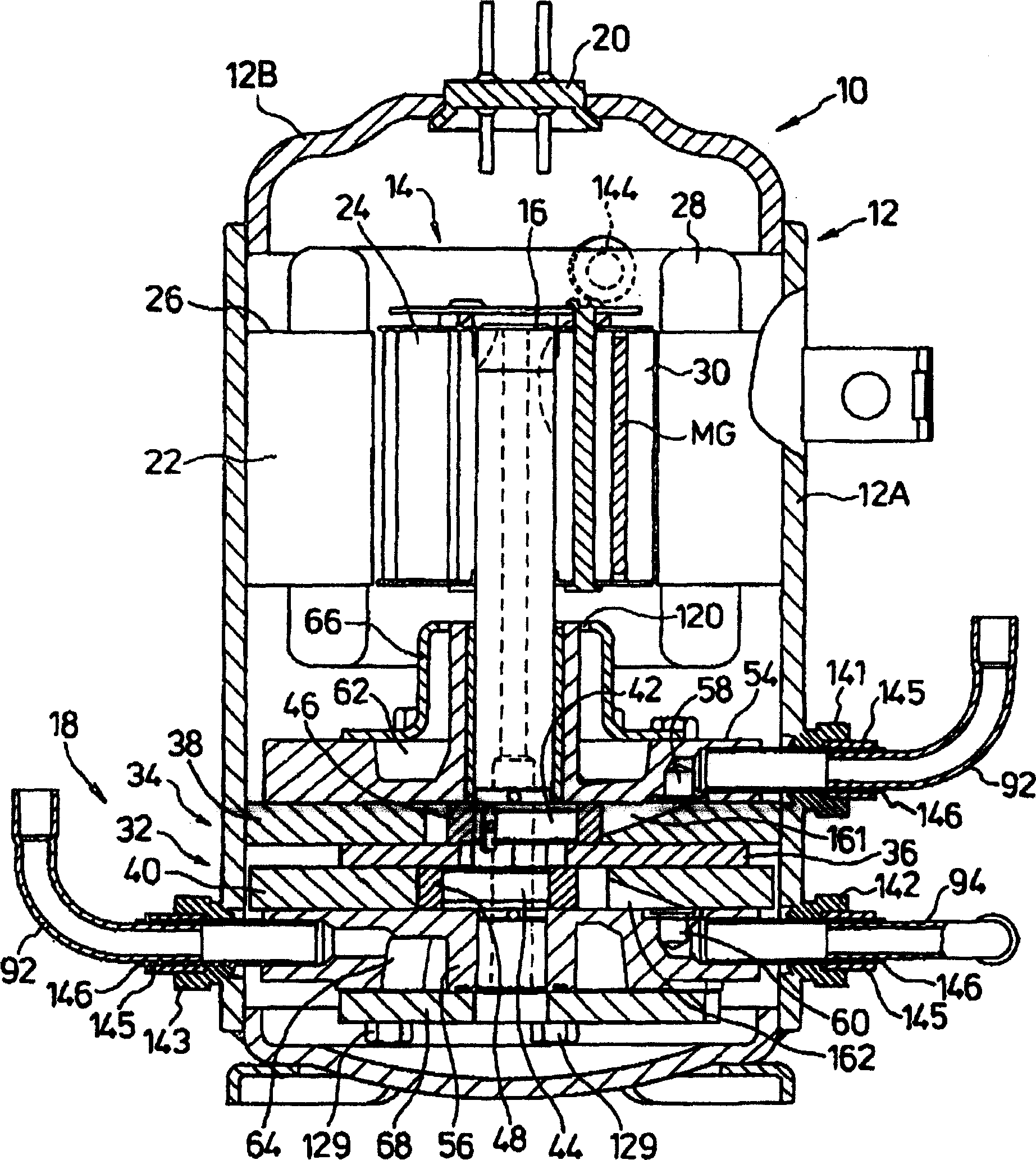

[0028] Below, according to Figure 1 ~ Figure 4 An embodiment of the present invention will be described in detail.

[0029] figure 1 As an example of the compressor of the present invention, a vertical cross-sectional view of an internal high-pressure multi-stage (two-stage) compression rotary compressor 10 having first and second rotary compression units 32 and 34 is shown. For easy understanding, in Figure 1 ~ Figure 4 , for having the same as in the above Figure 6 , Figure 7 The same symbols are used for the same functions as those explained.

[0030] exist figure 1 Among them, symbol 10 is the carbon dioxide (CO 2 ) is an internal high-pressure type multi-stage (two-stage) compression rotary compressor that performs compression. The rotary compressor 10 is composed of a cylindrical airtight container 12, a drive unit 14, and a rotary compression mechanism part 18. The airtight container 12 is composed of Made of steel plate, the driving unit 14 is accommodated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com