Mineralized collagen based skull repairing device and manufacturing method thereof

A technology of mineralizing collagen and skull, applied in bone implants, medical science, prostheses, etc., can solve the problems of insufficient repair of skull defects, limited strength and toughness, etc., and achieve good osteogenic activity and material The effect of uniform distribution, good elasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1, preparing a mineralized collagen-based cranioplasty device in which the diameter of the bottom surface of the "cap" is 16 mm and the diameter of the cross-section of the "plug" is 10 mm.

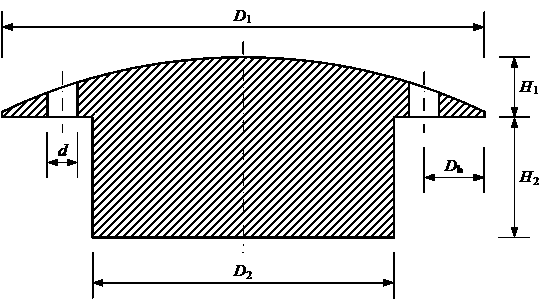

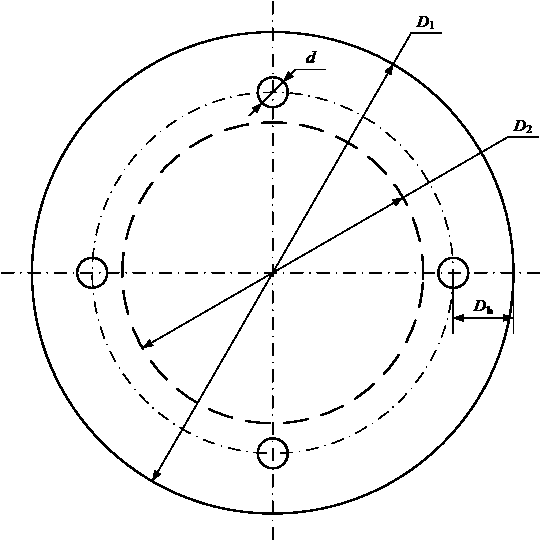

[0049] figure 1 Shown is a schematic view of the longitudinal section structure of the mineralized collagen-based skull repair device of this embodiment passing through the central axis, figure 2 Shown is a top view of the mineralized collagen-based skull repair device of this embodiment. where the diameter of the base of the "cap" D 1 Designed to be 16 mm, the cross-sectional diameter of the "plug" D 2 Designed to be 10 mm, the height of the "cap" H 1 Designed to be 2 mm, the height of the "plug" H 2 Designed to be 4 mm, the overall height of the device H The design is 6 mm, the number of fixing holes on the peripheral eaves is 4, and the diameter of the fixing holes is d Designed to be 1 mm from the center of the hole to the edge of the "cap" D h Designed to ...

Embodiment 2

[0072] Example 2, preparing a mineralized collagen-based skull repair device with a bottom diameter of the "cap" of 33 mm, a cross-sectional diameter of the "plug" of 23 mm, and a through hole with a diameter of 3.5 mm in the center.

[0073] Figure 6 Shown is the front view of the mineralized collagen-based skull repair device of this embodiment. where the diameter of the base of the "cap" D 1 Designed to be 33 mm, the cross-sectional diameter of the "plug" D 2 Designed to be 23 mm, the diameter of the central cylindrical through hole D 3 Designed to be 3.5 mm, the height of the "cap" H 1 Designed for 3 mm, "plug" height H 2 Designed to be 4 mm, the overall height of the device H The design is 7 mm, the number of fixing holes on the peripheral eaves is 8, and the diameter of the fixing holes is d Designed to be 1 mm from the center of the hole to the edge of the "cap" D h Designed to be 2.5mm.

[0074] The preparation method of the mineralized collagen-based sk...

Embodiment 3

[0093] Example 3, preparing a mineralized collagen-based cranioplasty device in which the diameter of the bottom surface of the "cap" is 14.5 mm and the cross-sectional diameter of the "plug" is 8.5 mm.

[0094] where the diameter of the base of the "cap" D 1 Designed to be 14.5 mm, the cross-sectional diameter of the "plug" D 2 Designed to be 8.5 mm, the height of the "cap" H 1 Designed to be 1.8 mm, the height of the "plug" H 2 Designed to be 5 mm, the overall height of the device H The design is 6.8 mm, and there are no fixing holes on the peripheral eaves.

[0095] The preparation method of the mineralized collagen-based skull repair device of this embodiment includes:

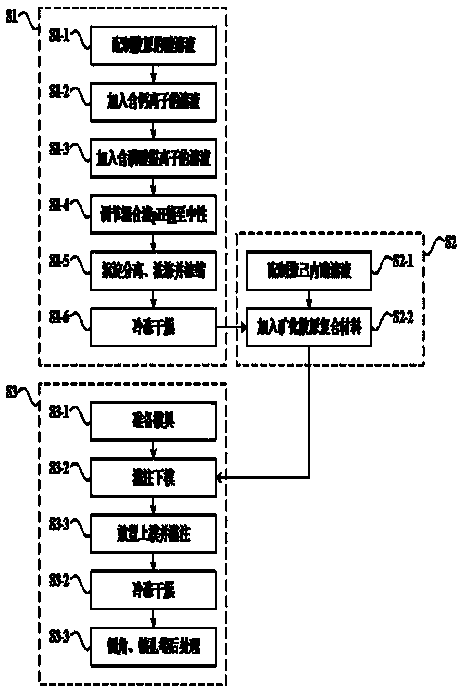

[0096] Step S1, preparation of the mineralized collagen composite material, specifically includes:

[0097] Step S1-1, dissolving collagen in 0.1 mol / L hydrochloric acid solution to prepare an acid solution of collagen, wherein the concentration of collagen is 1.0 × 10 -3 g / mL;

[0098] Step S1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com