Medical implant for improving cell osteogenesis performance and preparation method thereof

A technology for implants and performance, applied in the direction of bone implants, joint implants, joint implants, etc., can solve the problems of implant surgery failure, low processing efficiency, prosthesis loosening, etc., and speed up postoperative recovery , The effect of small processing heat and flexible processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

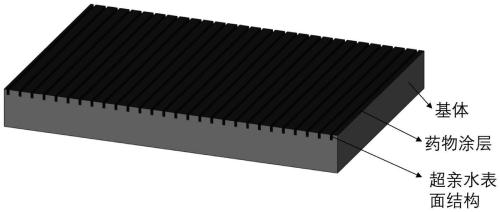

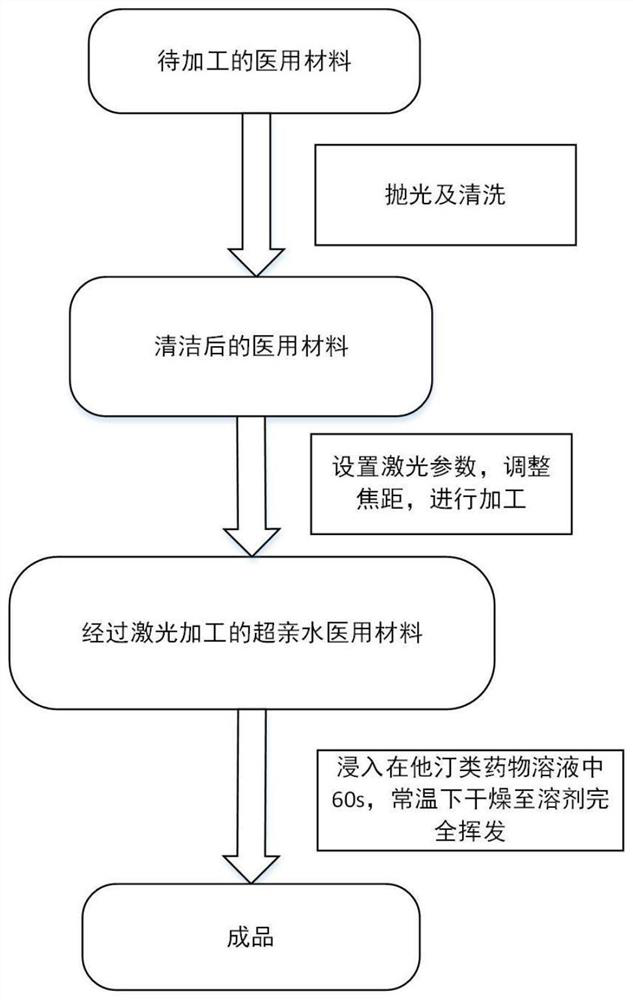

[0029] A method for preparing the above-mentioned medical implant for improving the osteogenic performance of cells, the flow process is as follows figure 2 As shown, it mainly includes the following steps:

[0030] (1) Grinding and polishing the surface of the medical implant material, and cleaning it with a degreasing cleaning agent;

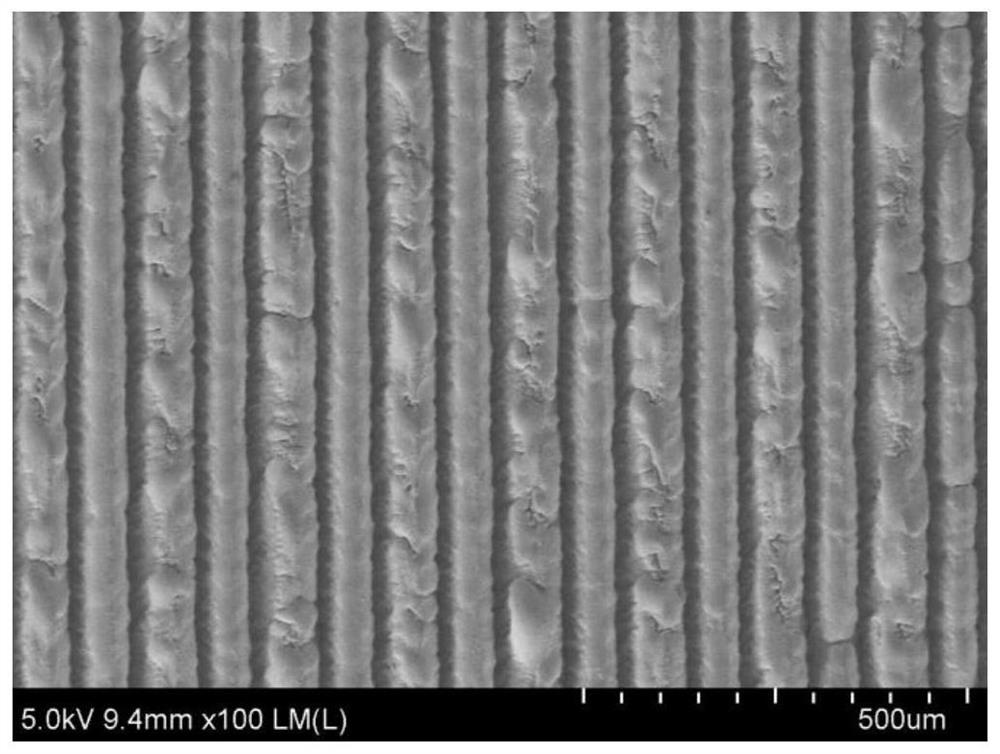

[0031] (2) Utilize ultra-fast laser processing equipment to scan the medical metal material after step (1) cleaning, and obtain a super-hydrophilic structure on the surface of the material, and the processing process is carried out under the protection of an inert gas;

[0032] (3) Soak the laser-treated bioimplant material containing a superhydrophilic surface in a statin solution with a concentration of 1mMol / L, take out the sample after 1 minute, and dry it until the surface of the material is completely dry to obtain Medical implants coated with statins to improve osteogenesis.

[0033] Wherein, the laser parameters set in step (2) are: ...

Embodiment 1

[0036] (1): Take a TC4 titanium alloy sample with a thickness of 2 mm and polish it to 1200 mesh, place it in absolute alcohol for ultrasonic cleaning for 5 minutes, and dry it.

[0037] (2): Place the polished and cleaned sample on the workbench of the femtosecond laser processing system (wavelength 1064nm), set the laser power to 6W, the frequency to 100KHz, the scanning speed to 15mm / s, the scanning distance to 60mm, and the number of scanning 15 times, start the laser processing system to start processing, and obtain a super-hydrophilic surface structure.

[0038] (3): Immerse the processed titanium alloy sample in a 1mMol / L lovastatin drug solution, take it out after 60s, and dry it at room temperature until the solvent is completely volatilized.

Embodiment 2

[0040] (1): Take a 2mm thick 316L stainless steel sample and polish it to 1200 mesh, place it in absolute alcohol for ultrasonic cleaning for 5 minutes, and dry it.

[0041] (2): Place the polished and cleaned sample on the worktable of the femtosecond laser processing system (wavelength 1064nm), set the laser power to 4W, the frequency to 200KHz, the scanning speed to 20mm / s, the scanning distance to 80mm, and the number of scanning times 20 times, start the laser processing system to start processing, and obtain a super-hydrophilic surface structure.

[0042] (3): Immerse the processed stainless steel sample in a 1mMol / L simvastatin drug solution, take it out after 60s, and dry it at room temperature until the solvent is completely volatilized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com