Preparation method of nano zinc loaded hydroxyapatite porous bioceramic

A nano-hydroxyapatite and hydroxyapatite technology, applied in ceramic products, applications, household appliances, etc., can solve problems such as long-term pain at the bone graft site, mismatching bone formation rate of artificial bone, and loss of bone height. To achieve the effect of improving osteogenic induction ability, good osteogenic induction ability and reducing heat preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

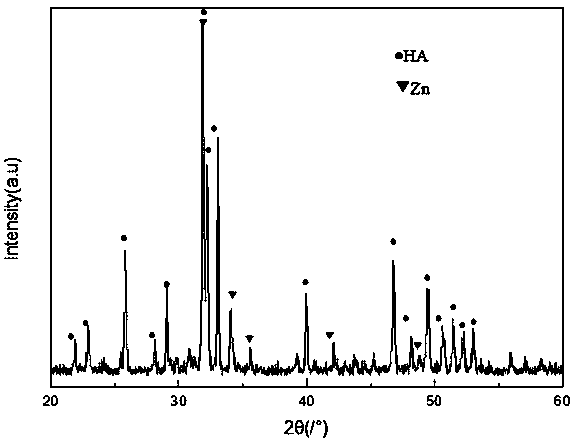

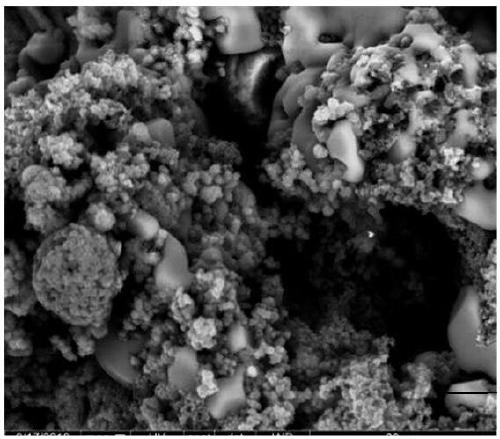

[0026] (1) Using nano-zinc with a purity of ≥99.9% and a particle size of 50-60nm and nano-hydroxyapatite powder with a purity of ≥99.7% and a particle size of 80-100nm as raw materials, weigh nano-zinc at a mass ratio of 1:99 and nano-hydroxyapatite powder.

[0027] (2) Put the powder raw material weighed in step (1) into a vacuum ball mill tank, add stainless steel balls, absolute ethanol and polyethylene glycol as a dispersant, vacuumize to 10Pa, and then fill with argon with a purity of 99.999% Air, placed on a planetary ball mill, ball milled at a speed of 300r / min for 8h, dried and ground in a vacuum oven at 60°C to obtain a hydroxyapatite composite powder loaded with nano-zinc.

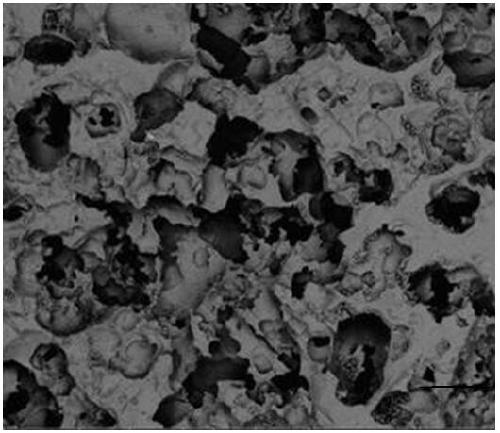

[0028] (3) The hydroxyapatite composite powder loaded with nano-zinc obtained in step (2) was uniformly mixed with the powder of ammonium bicarbonate, a pore-forming agent with a purity AR and an average particle size of 500 μm, at a mass ratio of 75:25 to obtain a mixed powder.

[0029] (4) P...

Embodiment 2

[0032] Using nano-zinc with a purity of ≥99.9% and a particle size of 50-60nm and nano-hydroxyapatite powder with a purity of ≥99.7% and a particle size of 80-100nm as raw materials, weigh nano-zinc and nano-hydroxyapatite at a mass ratio of 3:97 Apatite powder, other process steps and parameters are consistent with embodiment 1.

Embodiment 3

[0034] Using nano-zinc with a purity of ≥99.9% and a particle size of 50-60nm and nano-hydroxyapatite powder with a purity of ≥99.7% and a particle size of 80-100nm as raw materials, weigh nano-zinc and nano-hydroxyapatite at a mass ratio of 5:95 Apatite powder, other process steps and parameters are consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com