Patents

Literature

30results about How to "Sufficient bending strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

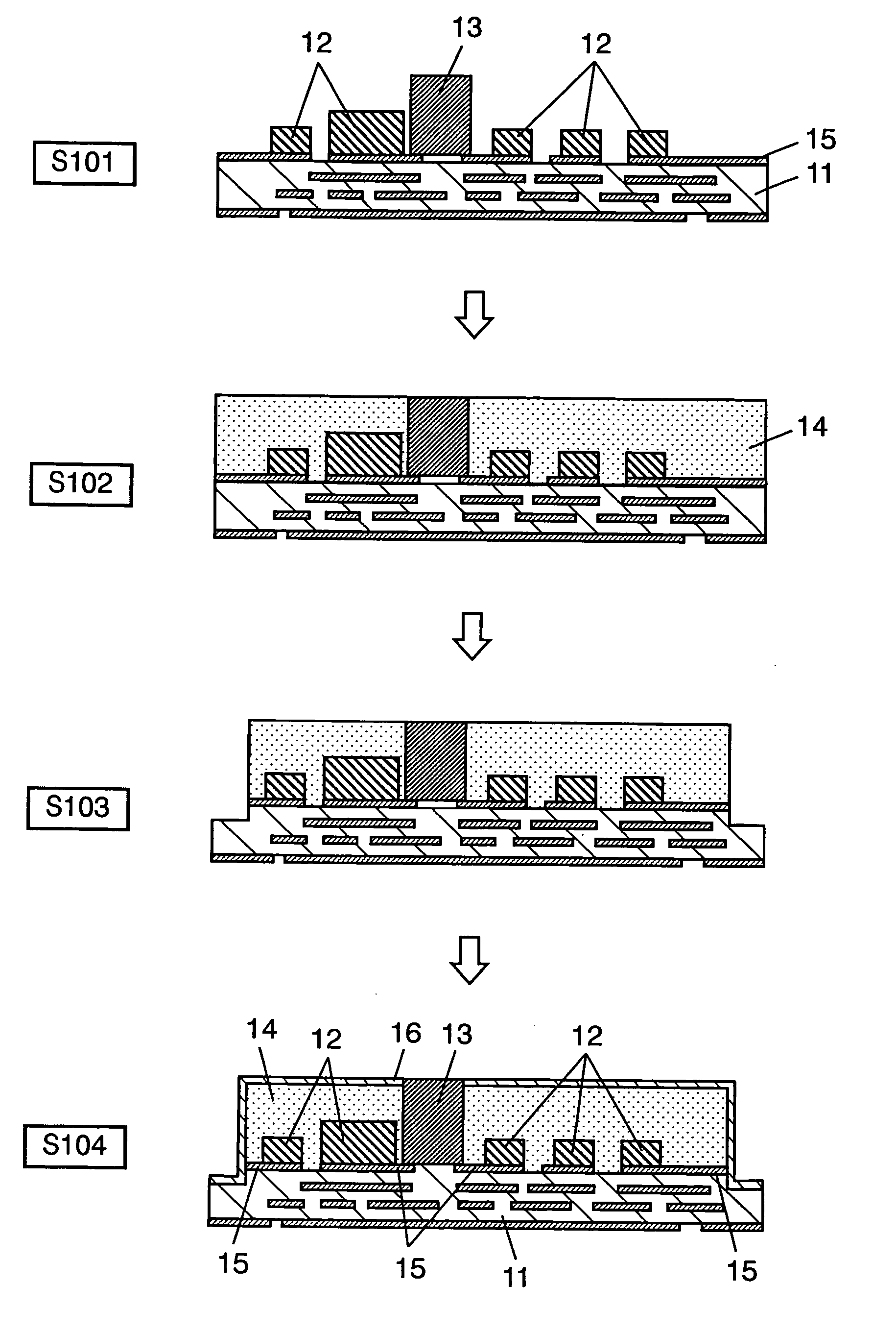

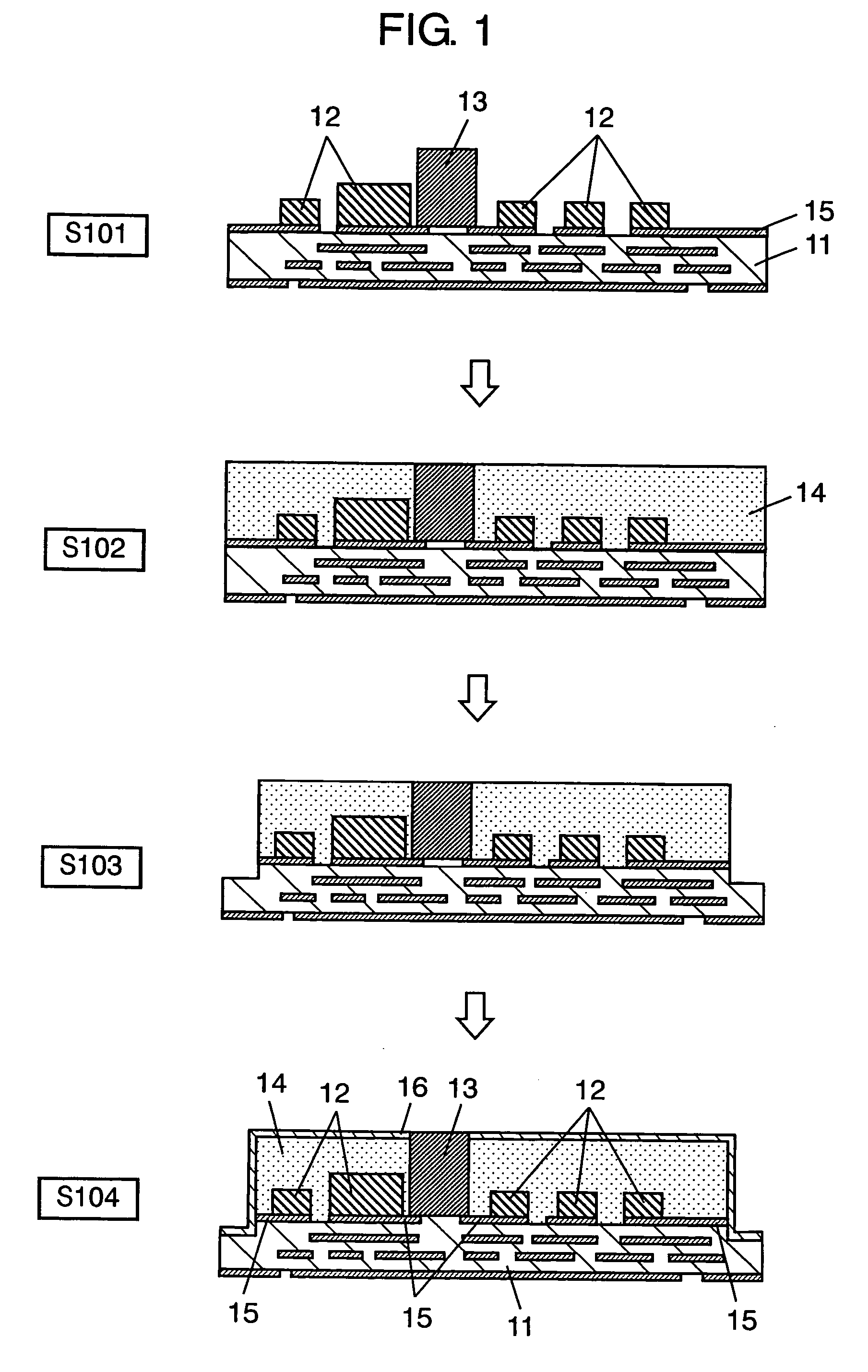

Module component and method for manufacturing the same

InactiveUS20060258050A1Sufficient bending strengthHigh strengthMagnetic/electric field screeningSemiconductor/solid-state device detailsElectrically conductiveFlexural strength

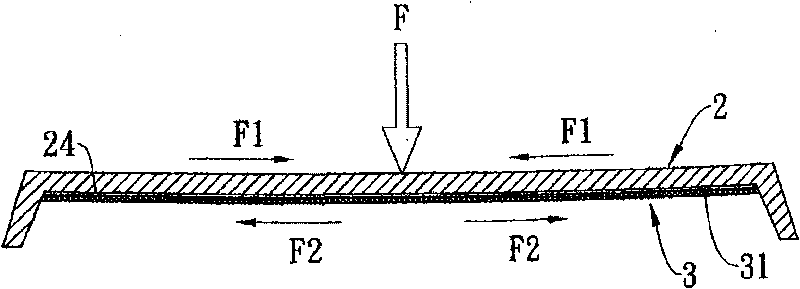

A module component in which mounting components and a conductive partition for dividing into a plurality of circuit blocks are mounted on a substrate. The circuit blocks are covered with a sealing member, which is further covered on its surface with a conductive film to electrically shield the circuit blocks individually. This module component can maintain bending strength, with little warpage by a sufficient shielding effect achieved without increasing the number of manufacturing processes.

Owner:PANASONIC CORP

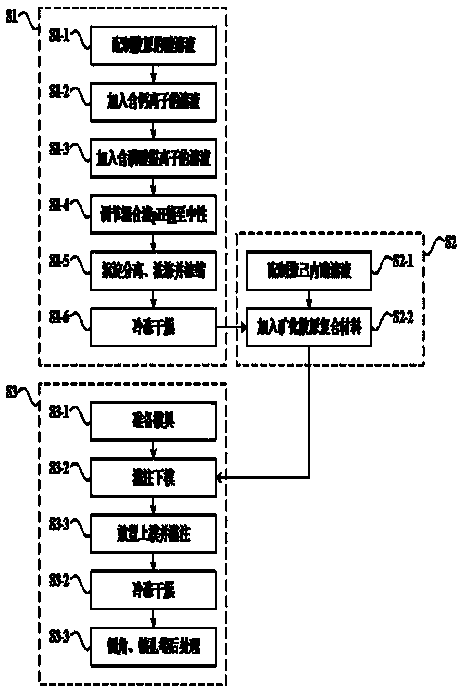

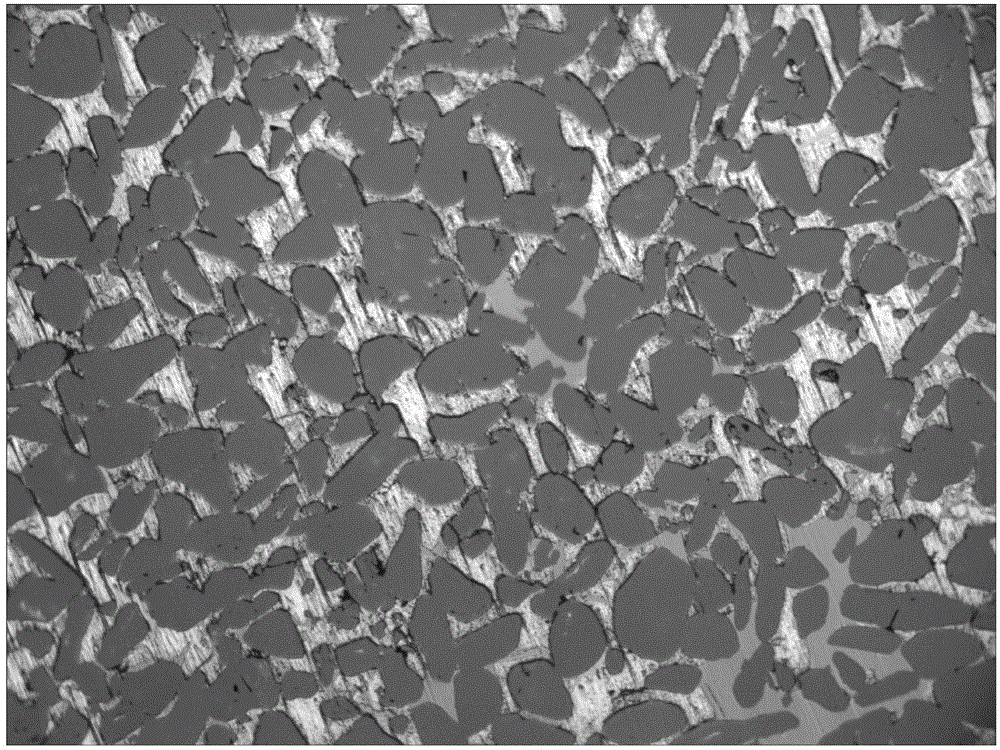

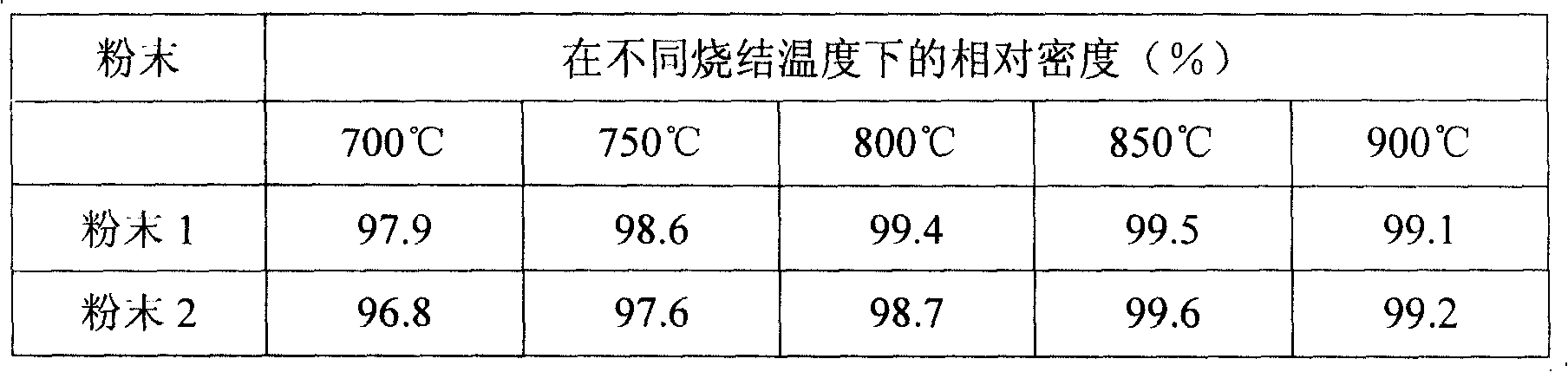

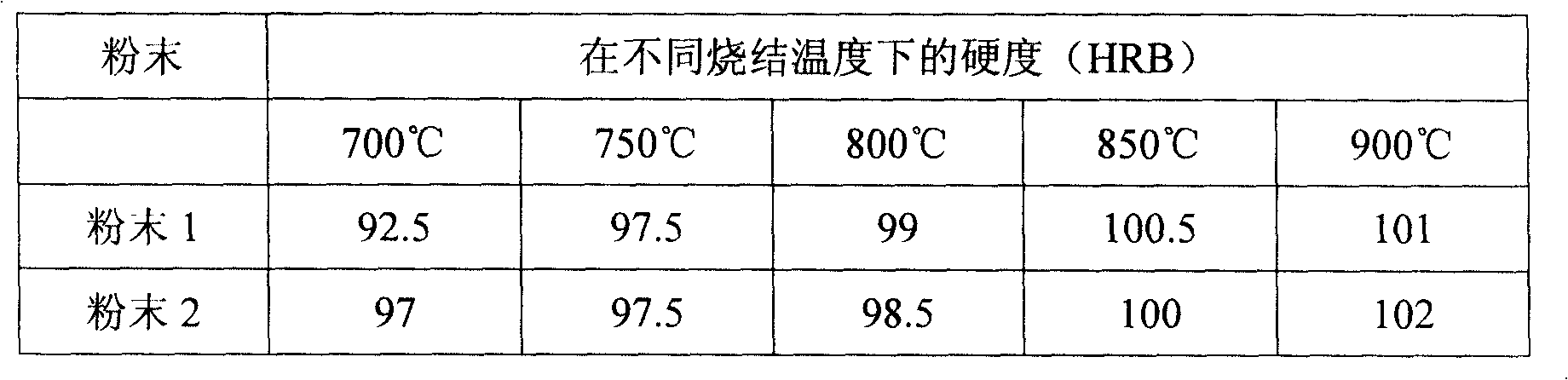

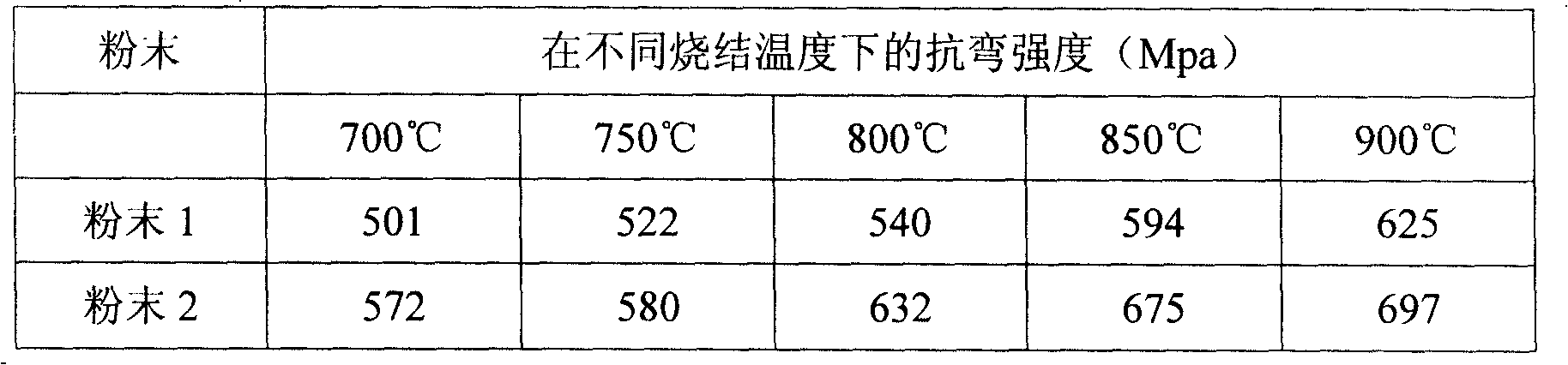

RE-containing prealloy powder

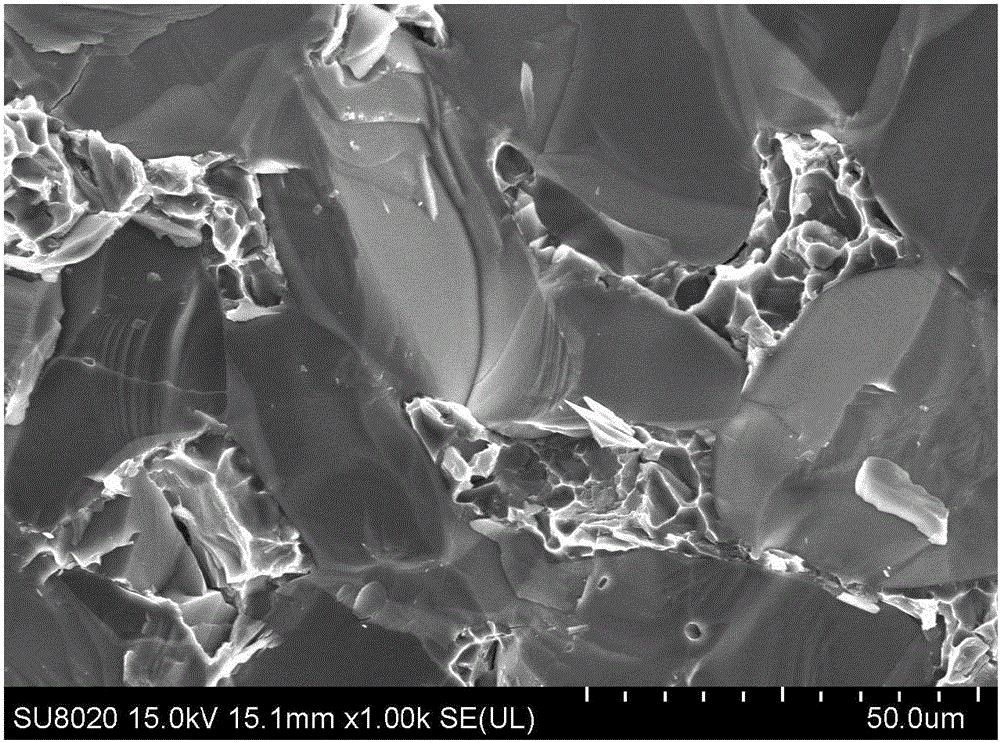

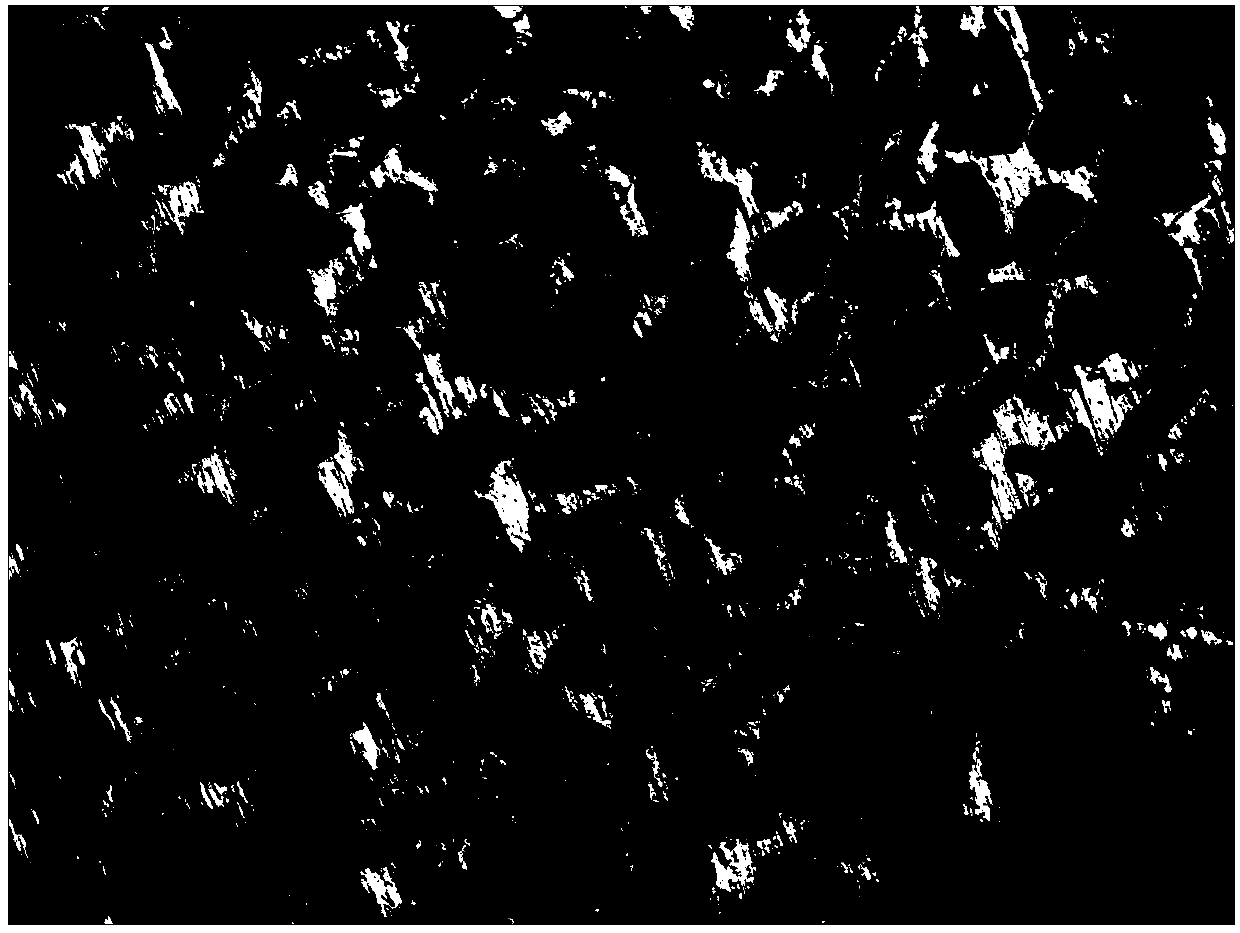

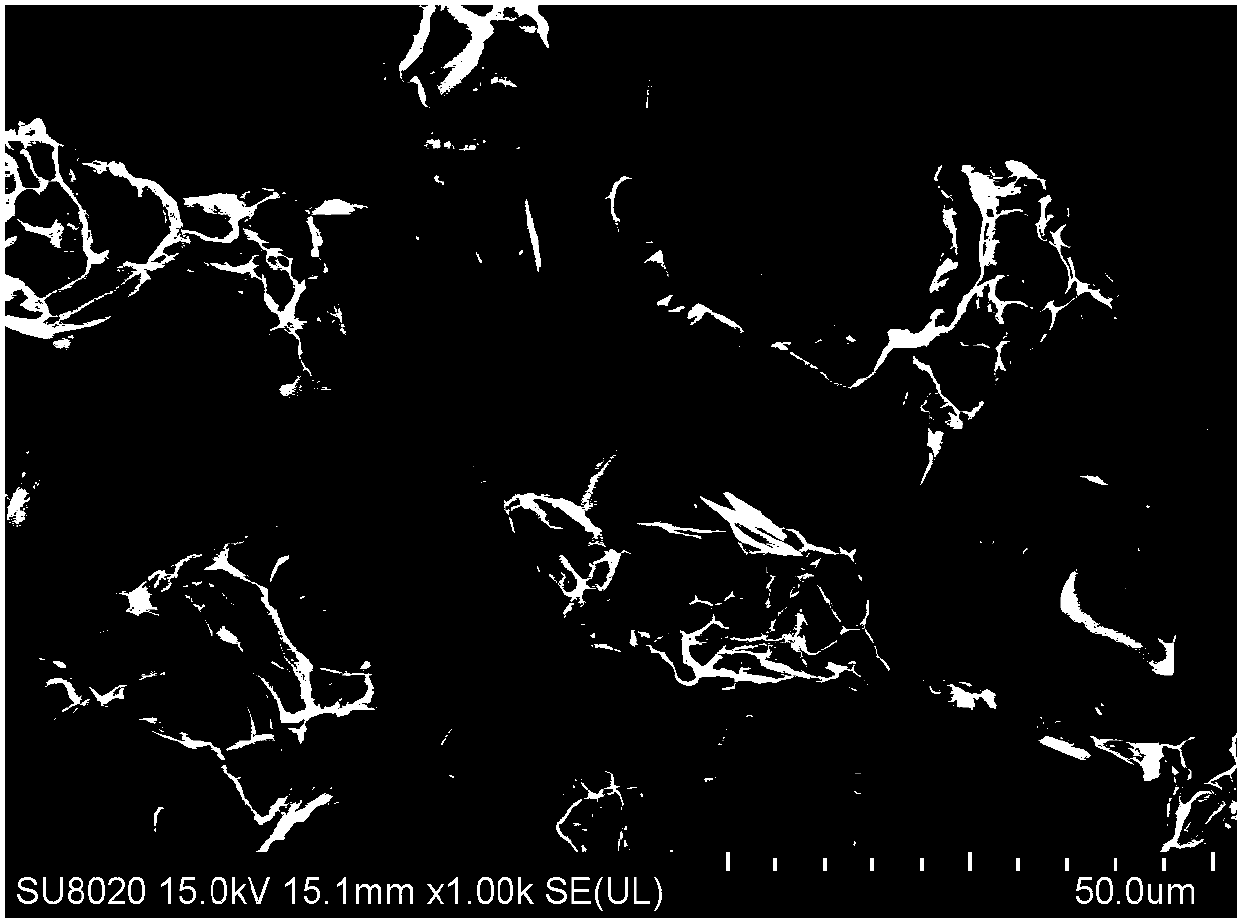

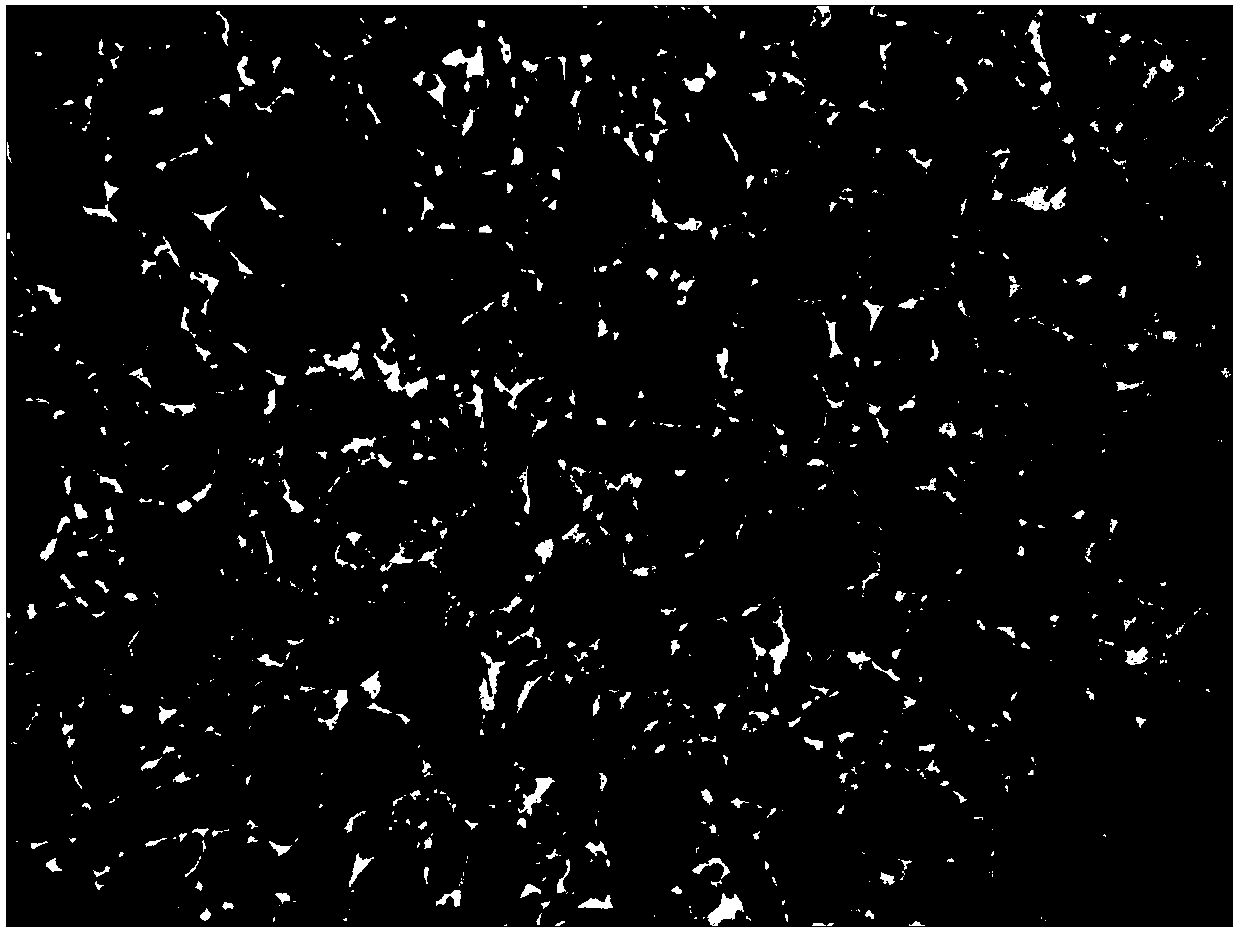

ActiveCN1986116AGood composition uniformitySufficient sintering reactivityRare-earth elementScanning electron microscope

The present invention relates to a kind of pre-alloyed powder and its application in making diamond tool. The pre-alloyed powder consists of at least two selected from Fe, Co, Cu and Ni as basic components, one or several of Mn, Ti, Sn, Mo, W and WC, and one or two of RE, such as La and Ce. It contains at most 80 % of Fe, at most 40 % of Co, at most 80 % of Cu, at most 40 % of Ni, at most 8 % of M and 0-5 % of RE, where, M is one or several of Mn, Ti, Sn, Mo, W and WC and RE is La and / or Ce. The pre-alloyed powder has also inevitable impurity. Scanning electronic microscope measurement shows that the pre-alloyed powder has basic particle size smaller than 15 micron and oxygen content not more than 2 %. The pre-alloyed powder is used as adhesive in making diamond tool.

Owner:GRIPM ADVANCED MATERIALS CO LTD

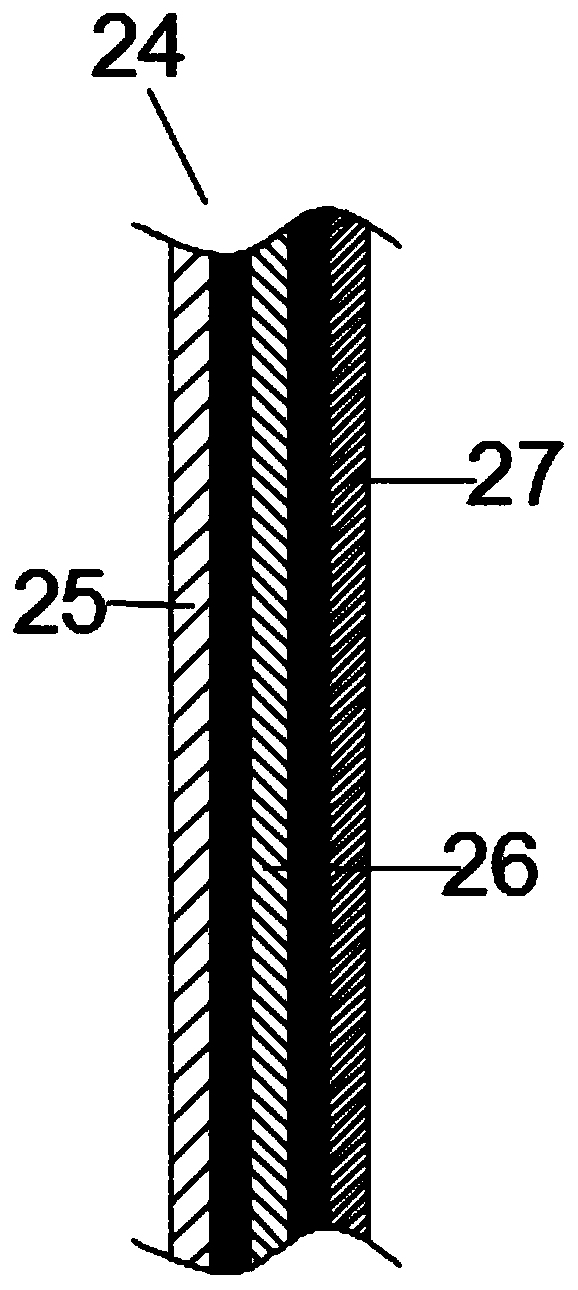

Automotive inner ceiling material and molding method thereof

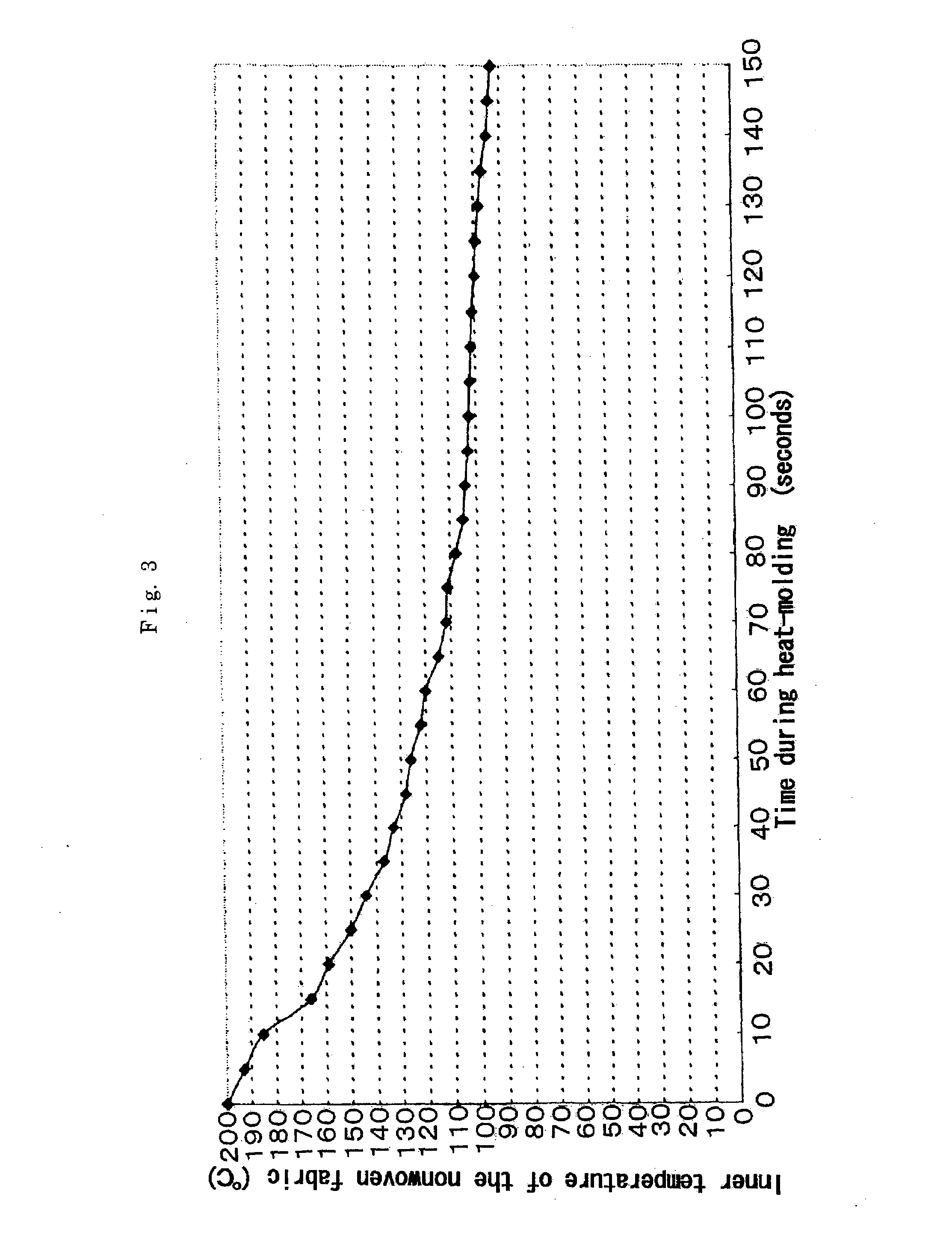

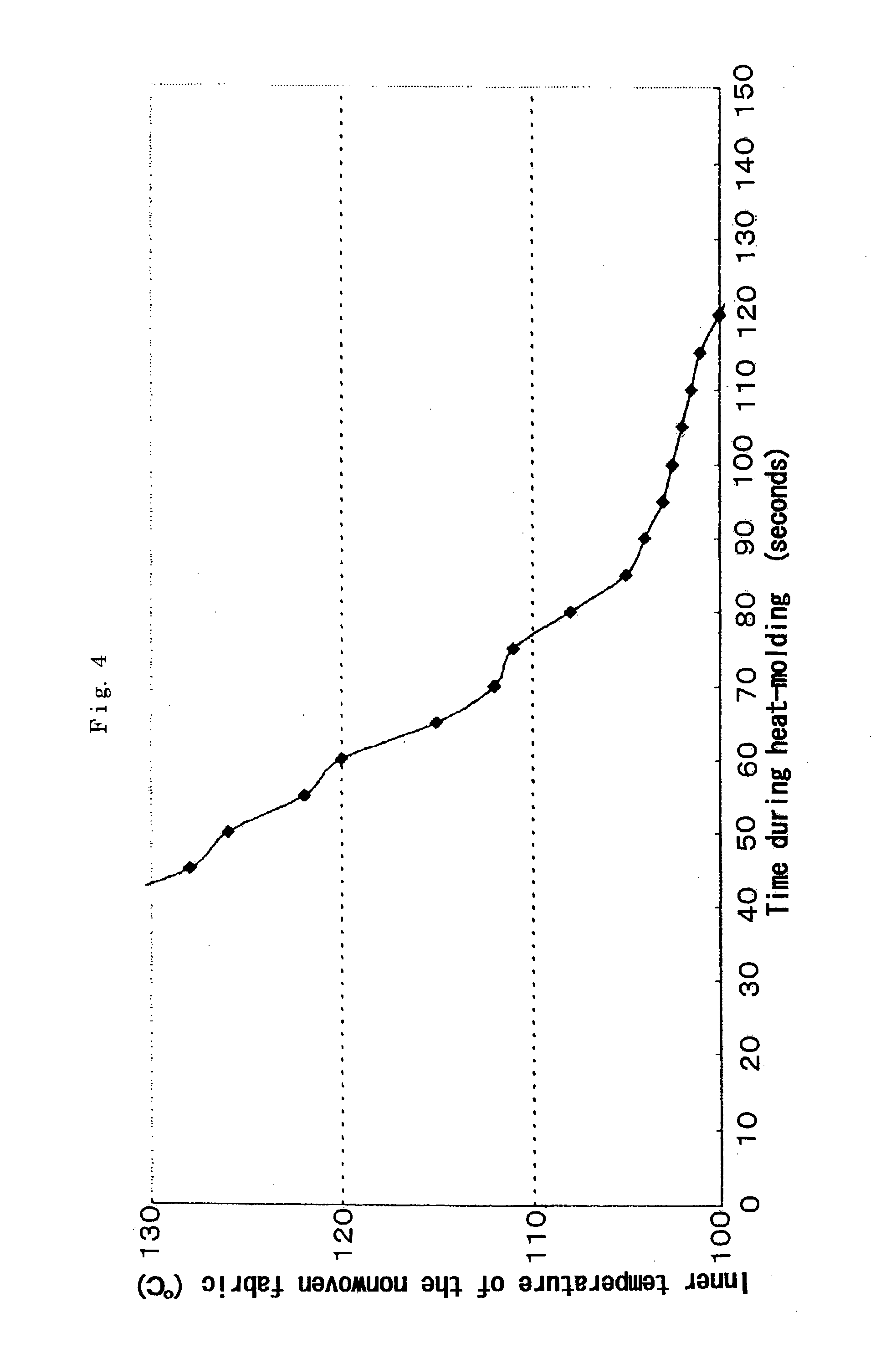

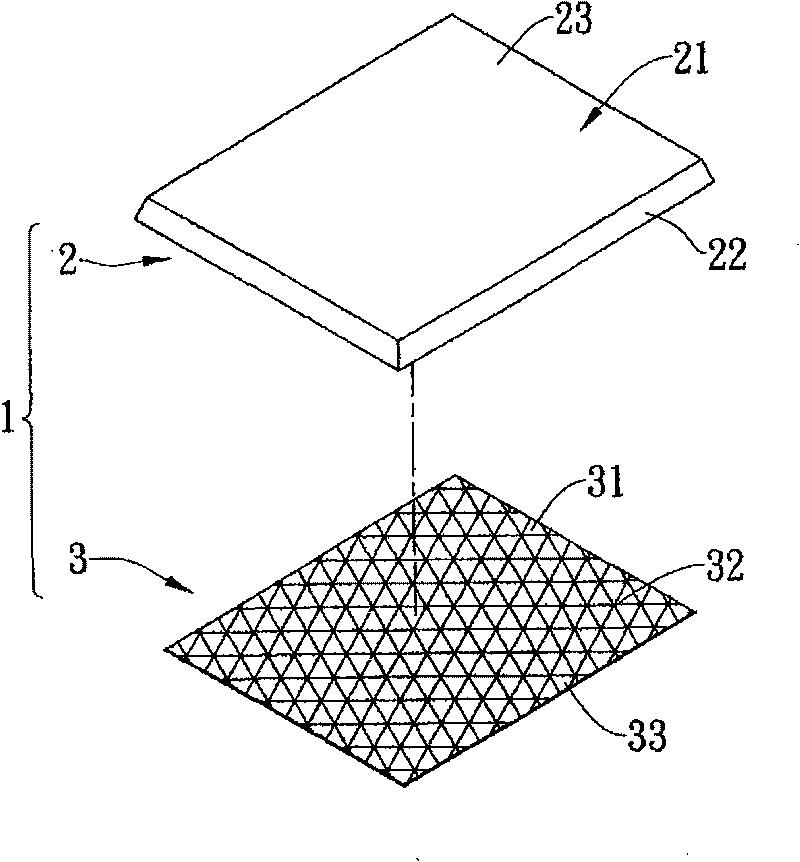

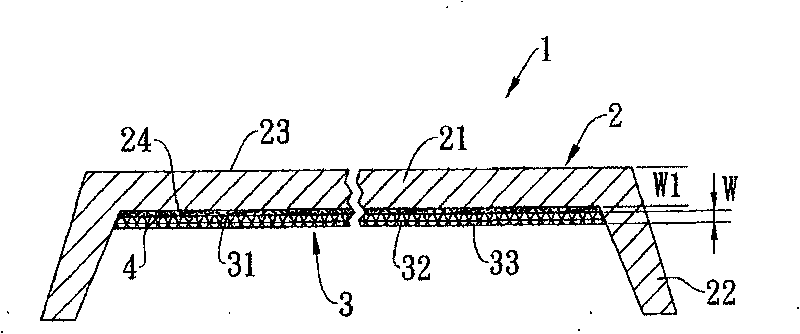

InactiveUS20080299367A1Sufficient bending strengthPrevent deformationFilament/thread formingSuperstructure subunitsCopolyesterWoven fabric

Owner:UNITIKA FIBERS

Shell structure for 3C (Computer, Communication and Consumer electronic) products

InactiveCN101754598ASufficient bending strengthReduce thicknessElectrical apparatus casings/cabinets/drawersFlexural strengthEngineering

The invention provides a shell structure for 3C products, which comprises a plastic forming component and a supporting board. The plastic forming component can be formed into different shapes in an injection way and comprises an outer surface and an inner surface opposite to the outer surface. The supporting board is integrated with the inner surface of the plastic forming component, wherein the bending elasticity resistance rate of the supporting board is larger than that of the plastic forming component, the supporting board is thinner than the plastic forming component, and the thickness of the supporting board is between 0.08 mm and 0.5 mm, therefore, the thickness and the cost of the shell are reduced, and the sufficient bending resistance strength is generated to resist pressure from the outer surface of the plastic forming component.

Owner:HOCHENG CORPORATION

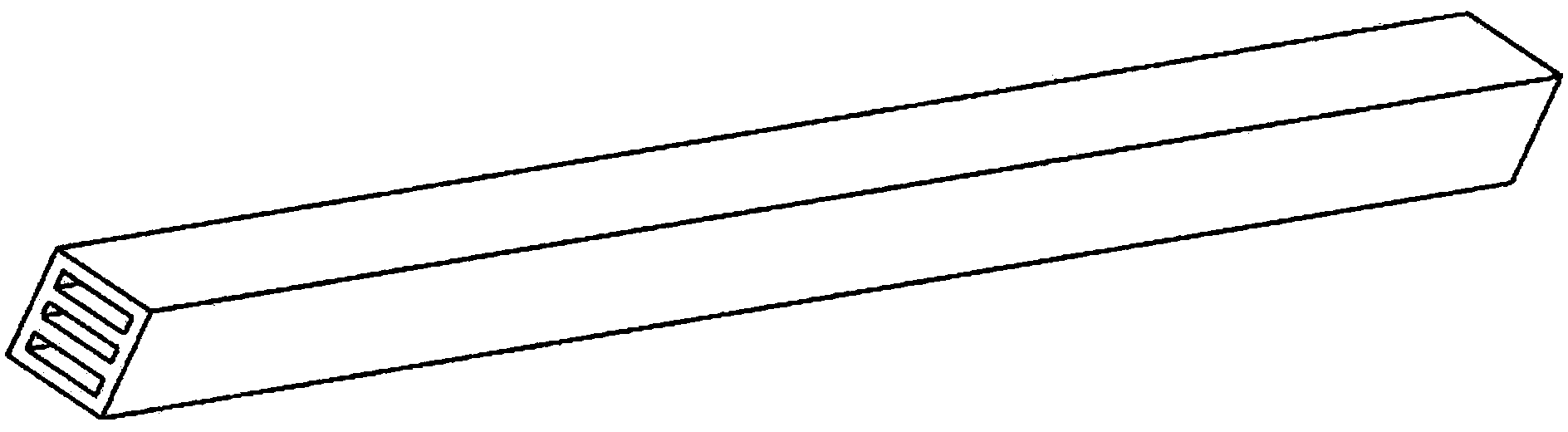

Railway freight transport open wagon vertical column and preparation method thereof

The invention discloses a railway freight transport open wagon vertical column and a preparation method thereof. The wagon vertical column is prepared by composite material, flexibilizer, filler and bulking agent in the mass ratio of 100:(3 to 15):(0.1 to 10):(0.1 to 5), wherein the composite material is prepared from the following constituents in part by weight: 60 to 80 parts of nylon resin, 20 to 40 parts of reinforced fiber, 0.1 to 5 parts of coupling agent, 0.5 to 3 parts of nucleating agent, 0.2 to 3 parts of heat stabilizer, 0.3 to 1.5 parts of antioxygen, and 0.5 to 1.5 parts of lubricant. The novel wagon vertical column is in a square matrix shape (rounded) according to strength calculation, ANSYS software analysis, isotropy requirements and convenience in use: the section size is 45*45mm, the wall thickness is 6mm, and the outer fillet is 10 mm. The wagon vertical column has sufficient impact strength and bending strength, good weather resistance, balanced blasting stress, good comprehensive performance indexes of rigidity, flexibility and balance, and has the advantages of capability of recycling and the like.

Owner:SHAANXI UNIV OF SCI & TECH

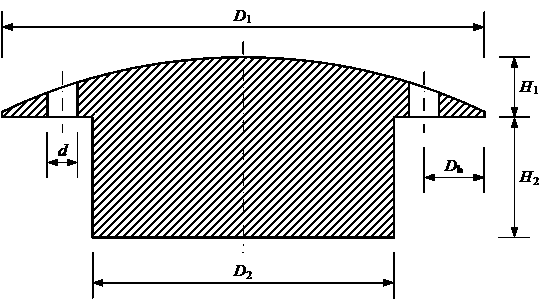

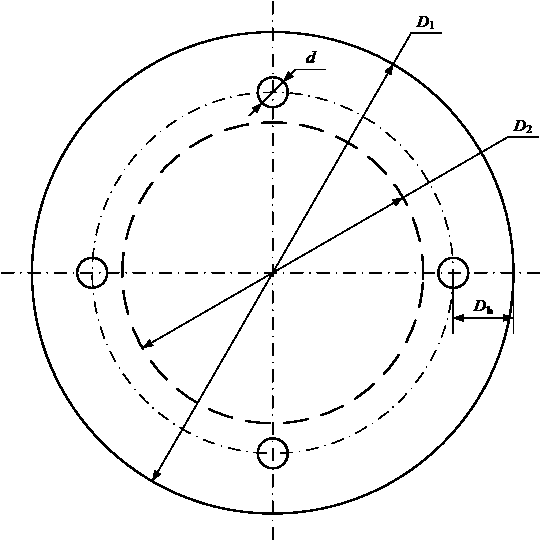

Mineralized collagen based skull repairing device and manufacturing method thereof

ActiveCN104258465AEnhance osteogenic activitySuitable biodegradable propertiesBone implantBased skullAcid substances

The invention relates to a mineralized collagen based skull repairing device and a manufacturing method thereof. The mineralized collagen based skull repairing device is made of a mineralized collagen / PCL (polycaprolactone) composite material; and the appearance of the repairing device comprises a spherical segment cap at the upper part and a cylindrical plug at the lower part. A separation mold and a secondary pouring technology are adopted during preparation of the mineralized collagen based skull repairing device, and the product defect caused by air residue at the blind end of the mold is overcome. The skull repairing device made of the mineralized collagen / PCL composite material has excellent osteogenic activity, the material is gradually and passively degraded under the creeping substitution action of cells, and growth of new bones can be guided at the skull defect part. A degradation product of the composite material is neutral, acidic materials causing aseptic inflammation cannot be generated, and new bone formation isn't affected; and through composition of PCL, the skull repairing device has excellent elasticity and toughness besides enough crush resistance and bending strength, and the repairing requirement of a skull of a human body is met.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH

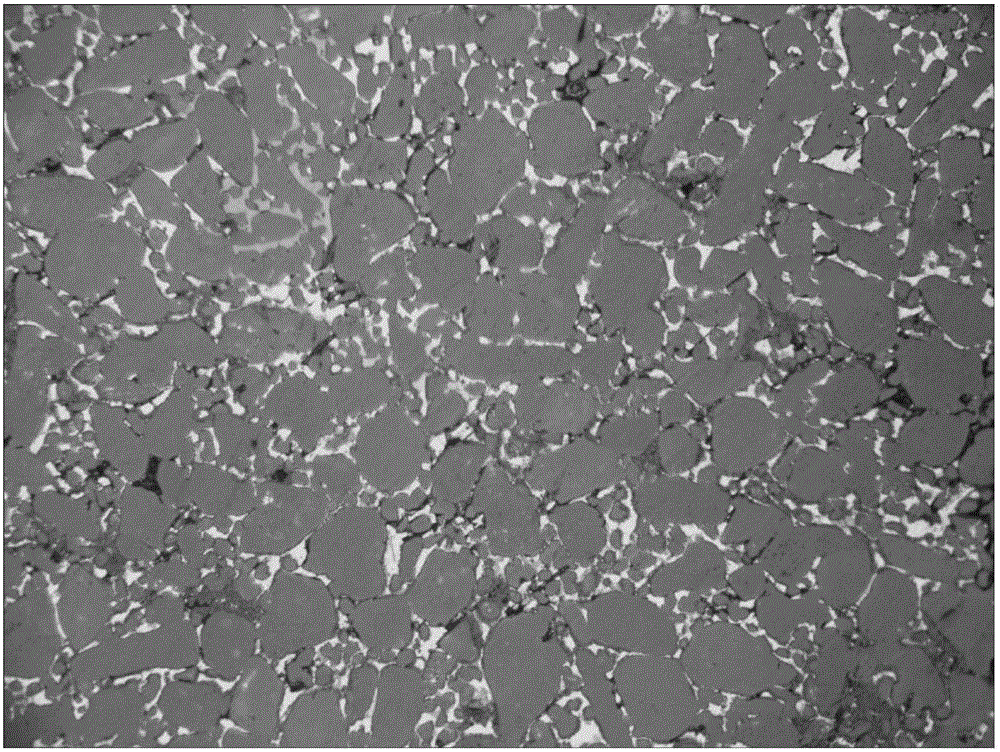

Preparation method for 3D-SiC/Al composite material of 3D interpenetrating structure

The invention relates to a preparation method for a 3D-SiC / Al composite material of a 3D interpenetrating structure. The preparation method for the 3D-SiC / Al composite material of the 3D interpenetrating structure comprises a preparation process of a 3D-SiC prefabricated member and a subsequent pressureless melt infiltration preparation process of the 3D-SiC / Al composite material. When applied to the subsequent pressureless melt infiltration 3D-SiC composite material, the 3D-SiC prefabricated member can be or not be subjected to oxidation pretreatment according to the used aluminum alloy compositions. The content of SiC in the composite material is 50-73 vol%, the density of the composite material can reach up to 2.90-3.1 g / cm<2>, the heat conductivity can reach up to 232 W / (m.DEG C), the coefficient of thermal expansion is as low as 5.72*10<-6> / DEG C, and the bending strength can reach up to 330 Mpa. The overall performance can meet the technical performance requirements, such as a low expansion factor, high heat conductivity and sufficient bending strength, which must be met by electronic packaging materials.

Owner:HEFEI UNIV OF TECH

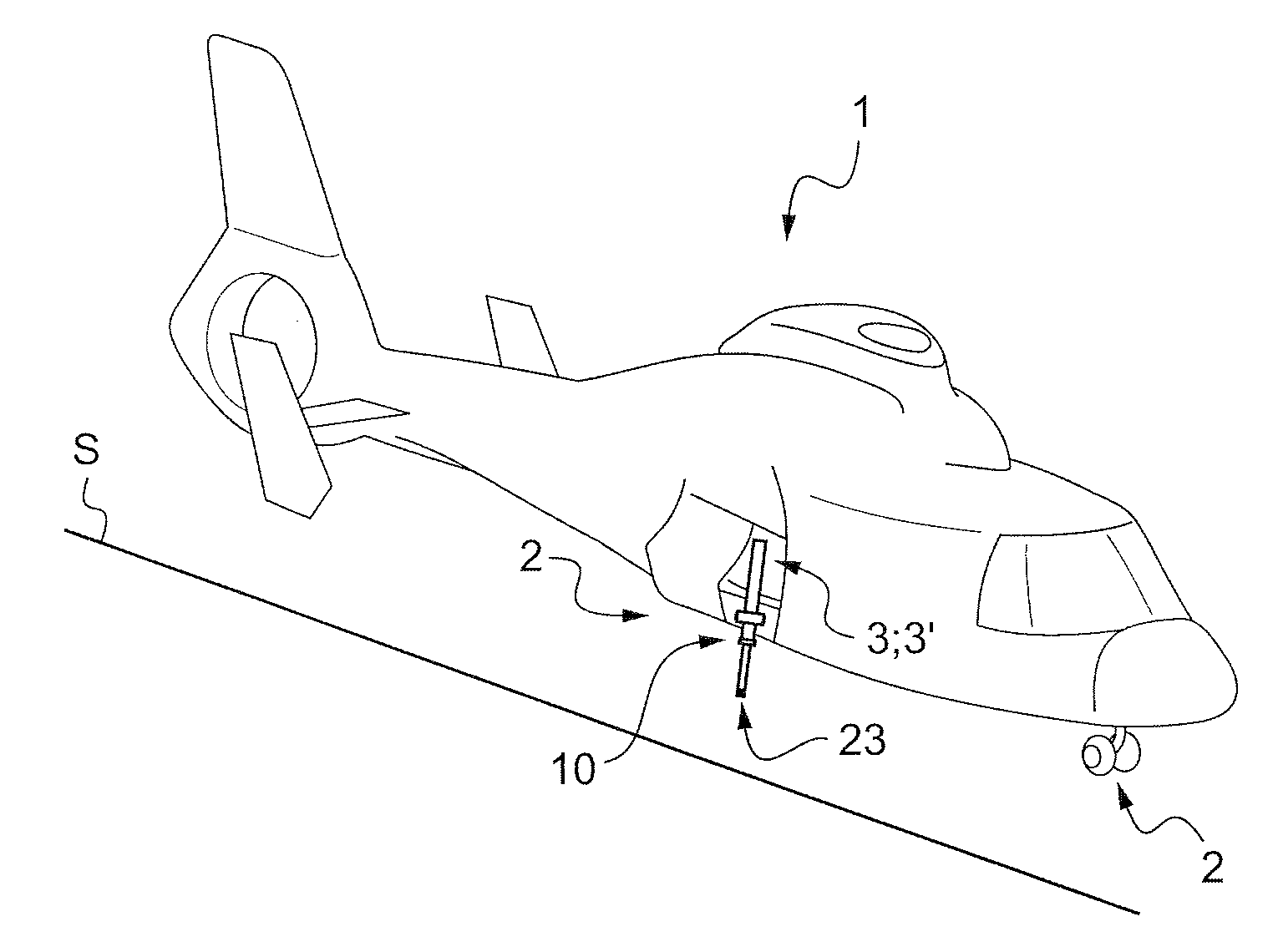

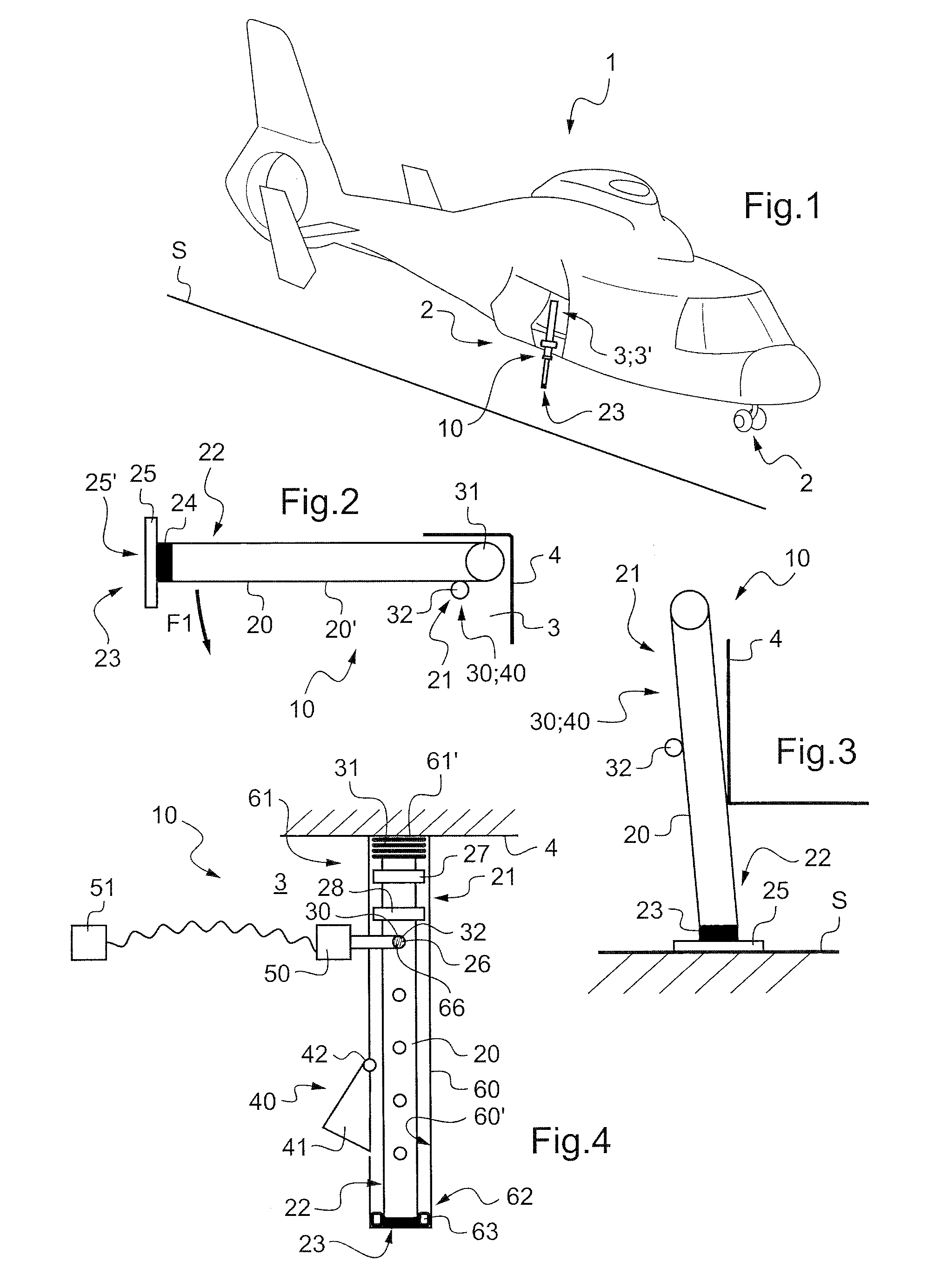

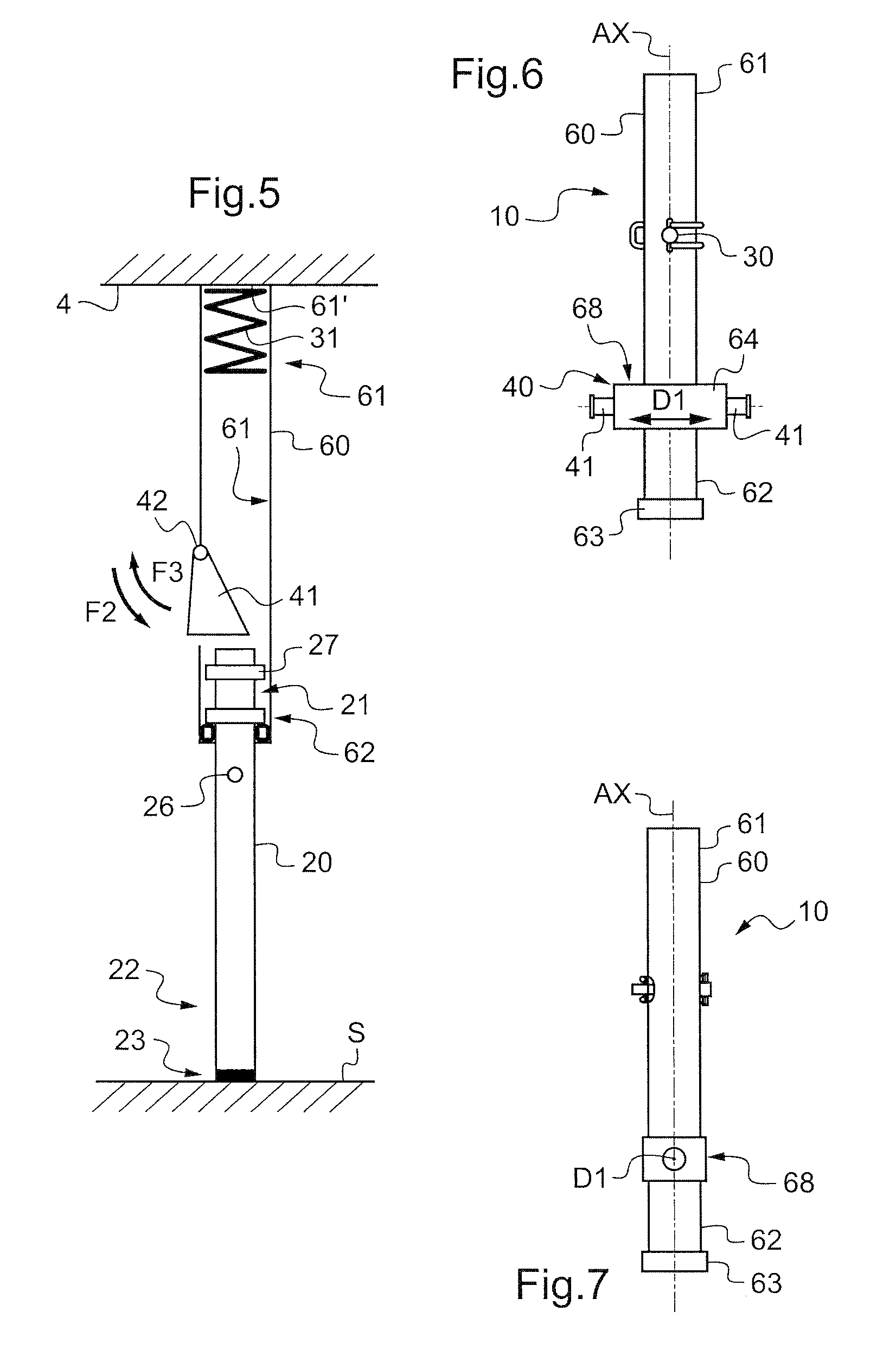

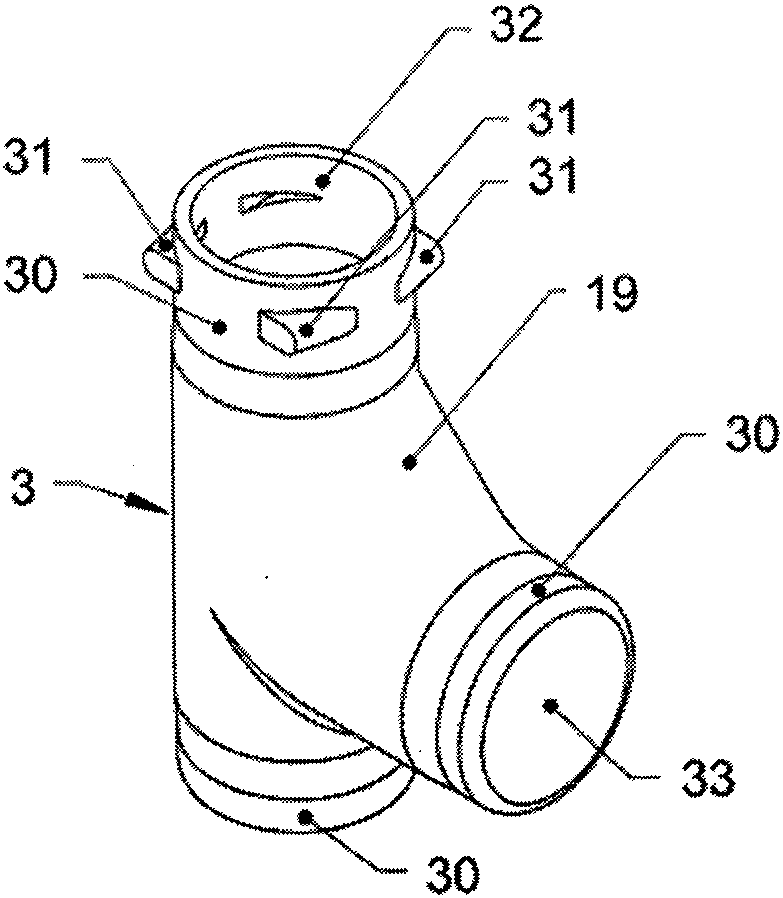

Rotary wing aircraft provided with an emergency undercarriage

InactiveUS20110204182A1Good stabilitySufficient bending strengthSkis/runnersWheel arrangementsFlight vehicleAirplane

A rotary wing aircraft (1) provided with an emergency undercarriage (10) for mitigating a failure of a basic undercarriage (2) of the rotary wing aircraft (1). Said emergency undercarriage comprises a main member (20) that extends from a first end (21) to a second end (22), said emergency undercarriage (10) having deployment means (30) for deploying the main member (20) out from a housing (3) in order to take over from a basic undercarriage (2) of a rotary wing aircraft (1) in the event of a failure, said emergency undercarriage (10) being provided with holder means (40) for holding it in position to block said main member (20) when said main member (20) is deployed out from said housing (3).

Owner:EUROCOPTER

Nanometer composite ceramic core

The invention discloses a nanometer composite ceramic core which is characterized by comprising the following raw materials in percentage by weight: 12%-18% of mineralizing agents, 14%-20% of plasticizing agents, 2%-3% of nanometer silicon dioxide, 1%-2% of nanometer magnesium oxide, 2%-3% of microcrystalline wax and the balance of rare earth coated nanometer composite powder. The nanometer composite ceramic core disclosed by the invention is sufficient in bending strength and small in firing shrinkage rate and can ensure the invariability of a dimension and a shape and effectively enhance the porosity of a core by adopting the raw materials with different fineness, thereby well improving the core stripping property.

Owner:浙江振兴阿祥集团有限公司

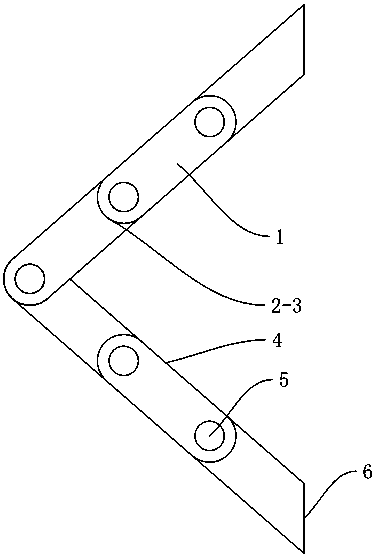

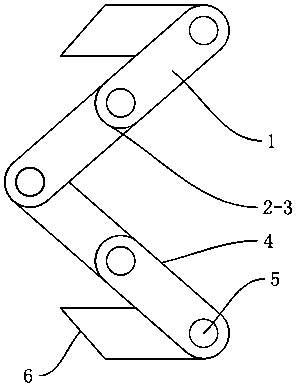

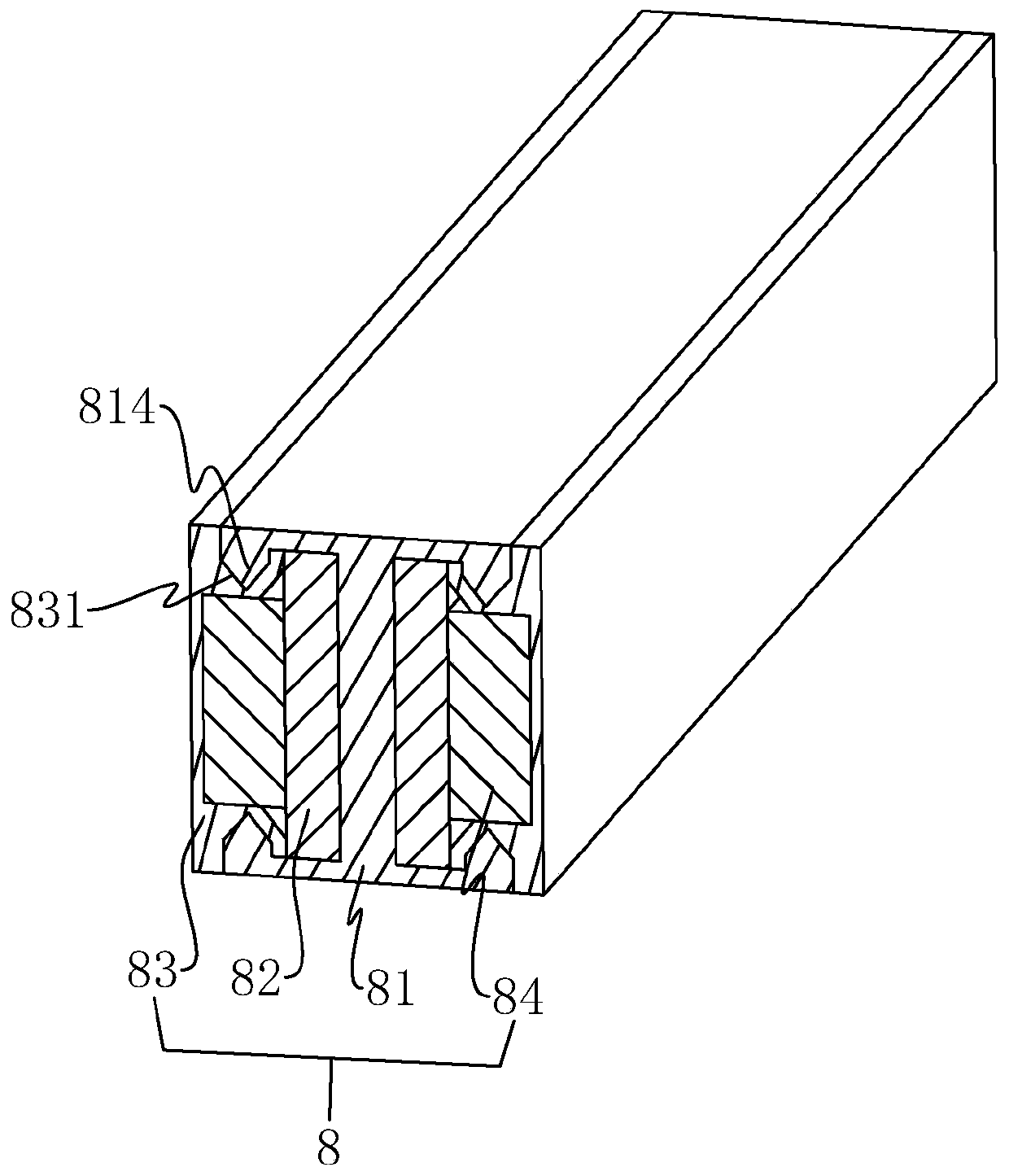

Novel fore shaft pipe

The invention relates to a novel fore shaft pipe. The problems that rigid round steel pipe are adopted as existing fore shaft pipes, the diameters cannot change along with the widths of continuous walls, the fore shaft pipes need to be prepared according to the widths of the different continuous walls, and adaptability is poor are solved. The novel fore shaft pipe is of a foldable structure overall and comprises a plurality of sections of strip plates with enough thicknesses, and the strip plates are connected through high-strength connecting shafts. Locking devices are arranged between corresponding strip plates. The strip plates are provided with contact planes. The strip plates rotate and adjust to the fore shaft width equal to the width of the continuous wall around the connecting shafts, the strip plates rotate around the connecting shafts, and the closed shape of the end of a wall section is changed. The whole fore shaft pipe forms the foldable structure, the occupied space can be reduced after folding, transport is convenient, the width of the fore shaft pipe can also be changed through folding, thus the fore shaft pipe adapts to building of underground continuous walls of different widths, the width of the fore shaft pipe is adjusted freely, adaptability is good, and the fore shaft pipe is easier to place and can be reused.

Owner:ZHEJIANG SCI-TECH UNIV

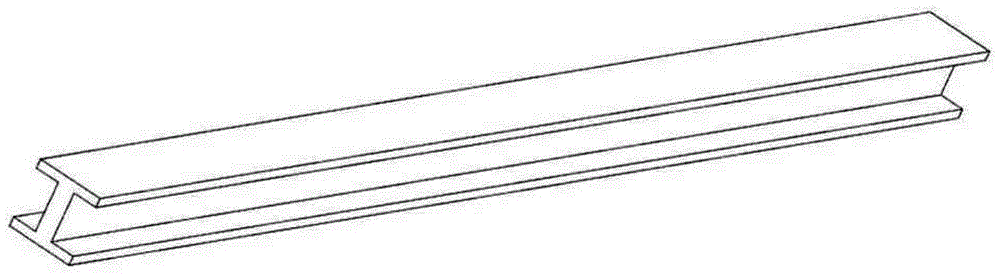

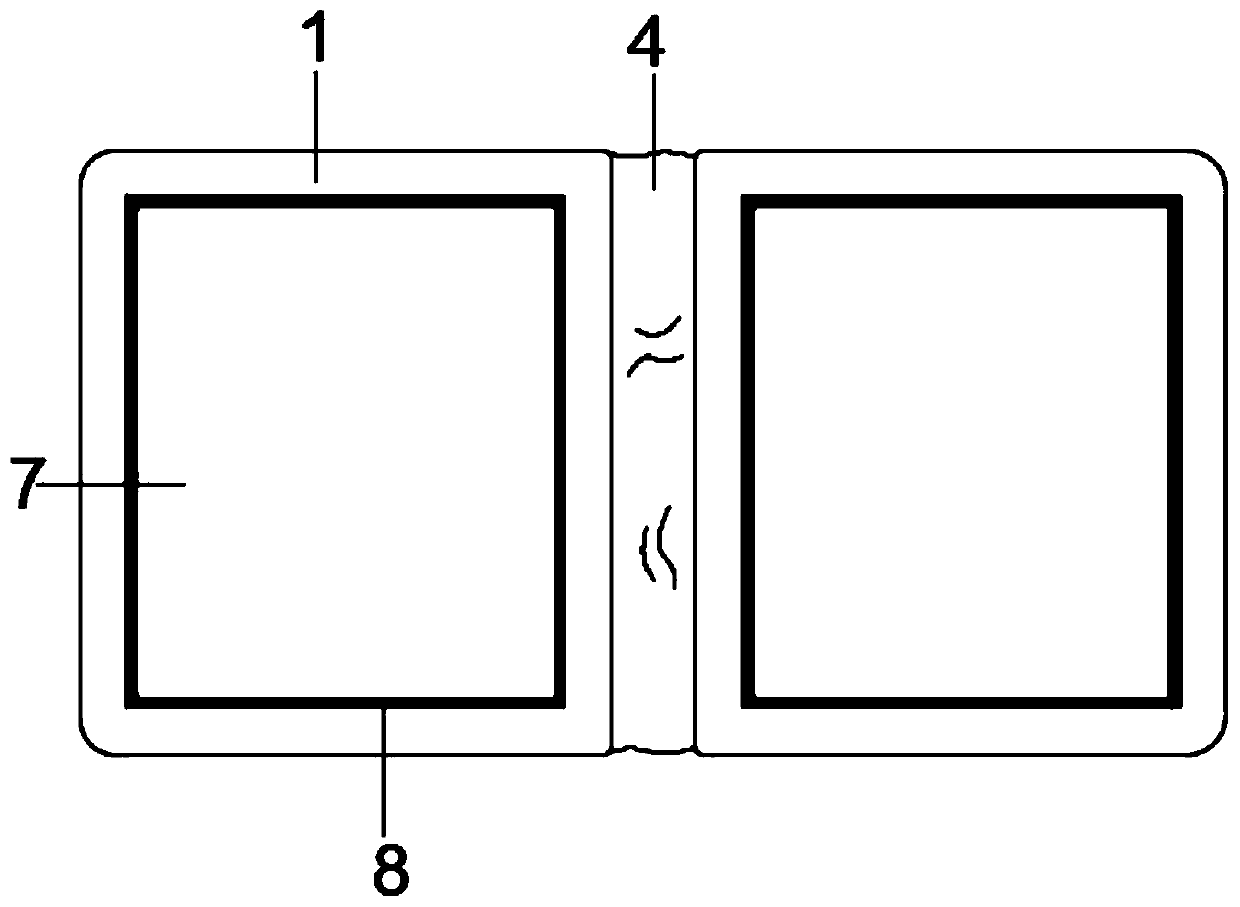

Ultra-high molding door

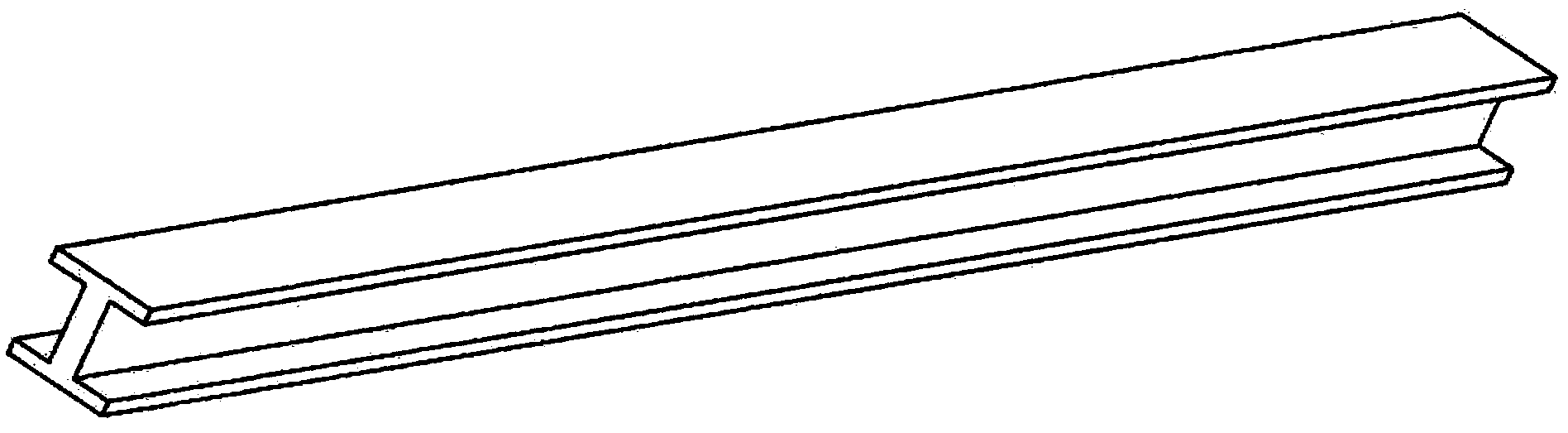

ActiveCN108979466AGuaranteed aestheticsSufficient bending strengthFireproof doorsDoor leavesEngineeringSealant

The invention discloses an ultra-high molding door, and relates to the field of molding doors. The ultra-high molding door comprises a door panel, a first face plate and a second face plate, wherein areserved gap is formed by the first face plate and the second face plate in a surrounding manner; a reinforcing assembly is arranged in the reserved gap; the reinforcing assembly comprises two reinforcing plates and a reinforcing rack; the cross section of the reinforcing rack is H-shaped; inner grooves are formed in the two sides of the reinforcing rack in the width direction; the two reinforcing plates are arranged in parallel at intervals; the two reinforcing plates are separately fixedly embedded in the two inner grooves; a through groove is horizontally formed in the reinforcing rack ina penetrating manner; the two reinforcing plates are adhered and fixed through a fireproof sealant; cambered plates are separately arranged on the outer sides of the two inner grooves; an accommodating cavity is formed by the cambered plates and the reinforcing plates in a surrounding manner; and compressed rubber is fixed in the accommodating cavity. The ultra-high molding door is good in attractiveness, long in service life, good in fireproof performance and high in safety, and is environmentally friendly.

Owner:上海阜邦幕墙门窗工程有限公司

Spinel-magnesium-based ceramic core and preparation method thereof

ActiveCN112794711ASufficient bending strengthImprove thermal shock resistanceFoundry mouldsFoundry coresCompression moldingSlurry

The invention discloses a spinel-magnesium-based ceramic core and a preparation method thereof, and belongs to the field of ceramic core preparation in the field of precision casting. Raw materials of the spinel-magnesium-based ceramic core comprise a powder raw material and a binder, and the powder raw material comprises the following components in percentage by mass: 50%-90% of spinel powder, 0%-30% of zirconium oxide powder, 0%-5% of titanium dioxide powder and the balance of magnesium oxide powder; and the mass of the binder accounts for 15-25% of the mass of the powder raw material. The preparation method of the spinel-magnesium-based ceramic core comprises the following steps: mixing powder according to the ratio, preparing a binder, mixing the preheated mixed powder and the binder to prepare slurry, carrying out compression molding on the slurry by adopting a hot-press injection molding method, and sintering to obtain the spinel-magnesium-based ceramic core. The spinel-magnesium-based ceramic core has the advantages of being high in strength, small in shrinkage rate and easy to remove, and meanwhile the thermal shock resistance is improved.

Owner:NORTHEASTERN UNIV

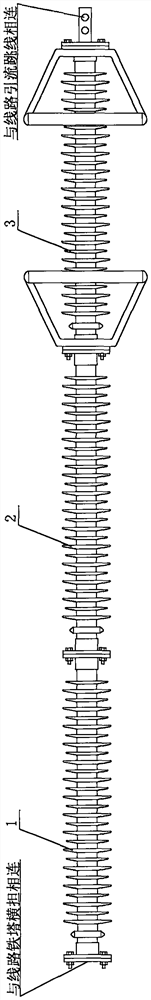

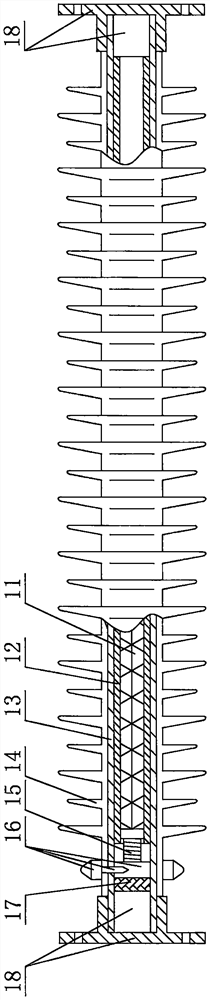

Anti-windage yaw jumper arrester for 500kV power transmission line

PendingCN112614640AMonitor running statusImprove sealingInsulatorsOvervoltage protection resistorsGlass fiberStructural engineering

The invention discloses an anti-windage yaw jumper arrester for a 500kV power transmission line, which comprises an arrester body I, an arrester body II and a discharge gap assembly, the arrester body I and the arrester body II have the same specification, and the ends, close to each other, of the arrester body I and the arrester body II are connected; the arrester body II is connected with the ends, close to each other, of the discharge gap assemblies, a resistor disc column is arranged on the inner side of the arrester body I, an epoxy glass fiber winding pipe is arranged on the outer side of the resistor disc column, and the gap between the resistor disc column and the epoxy glass fiber winding pipe is filled with silicon rubber. A lightning arrester silicon rubber umbrella cover is arranged on the outer side of the epoxy glass fiber winding pipe. The windage yaw prevention jumper wire lightning arrester for the 500kV power transmission line is high in insulation sealing performance and safety, can effectively avoid windage yaw of a drainage jumper wire, integrates the functions of a jumper wire string, a heavy hammer sheet, a V-shaped insulator string and a conventional line lightning arrester, is low in installation and construction difficulty, and is suitable for popularization and application.

Owner:温州锦泰高压电气制造有限公司

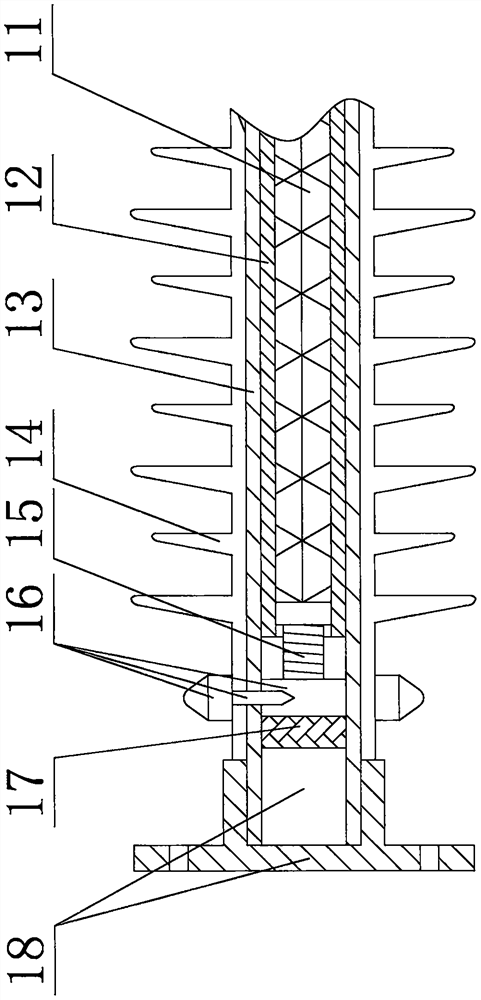

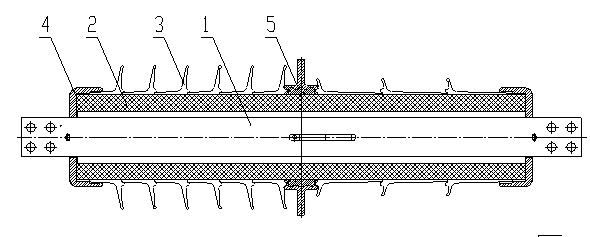

Anti-bending wall bushing

InactiveCN103474187AGuaranteed insulation performanceSufficient bending strengthCeramicsInsulating bodiesElectrical conductorEngineering

An anti-bending wall bushing comprises a conductor and an insulating layer from inside to outside. The insulating layer is wrapped by an umbrella skirt, the two ends of the conductor extend out of the insulating layer, voltage-sharing caps are arranged at the two ends of the insulating layer, a flange is arranged in the middle of the insulating layer, and the insulating layer is made of high-voltage electric porcelain. Due to the fact that the insulating layer is made of the high-voltage electric porcelain, insulating performance of the product is guaranteed, and high bending strength is achieved.

Owner:HENGYANG HUARUI ELECTRIC

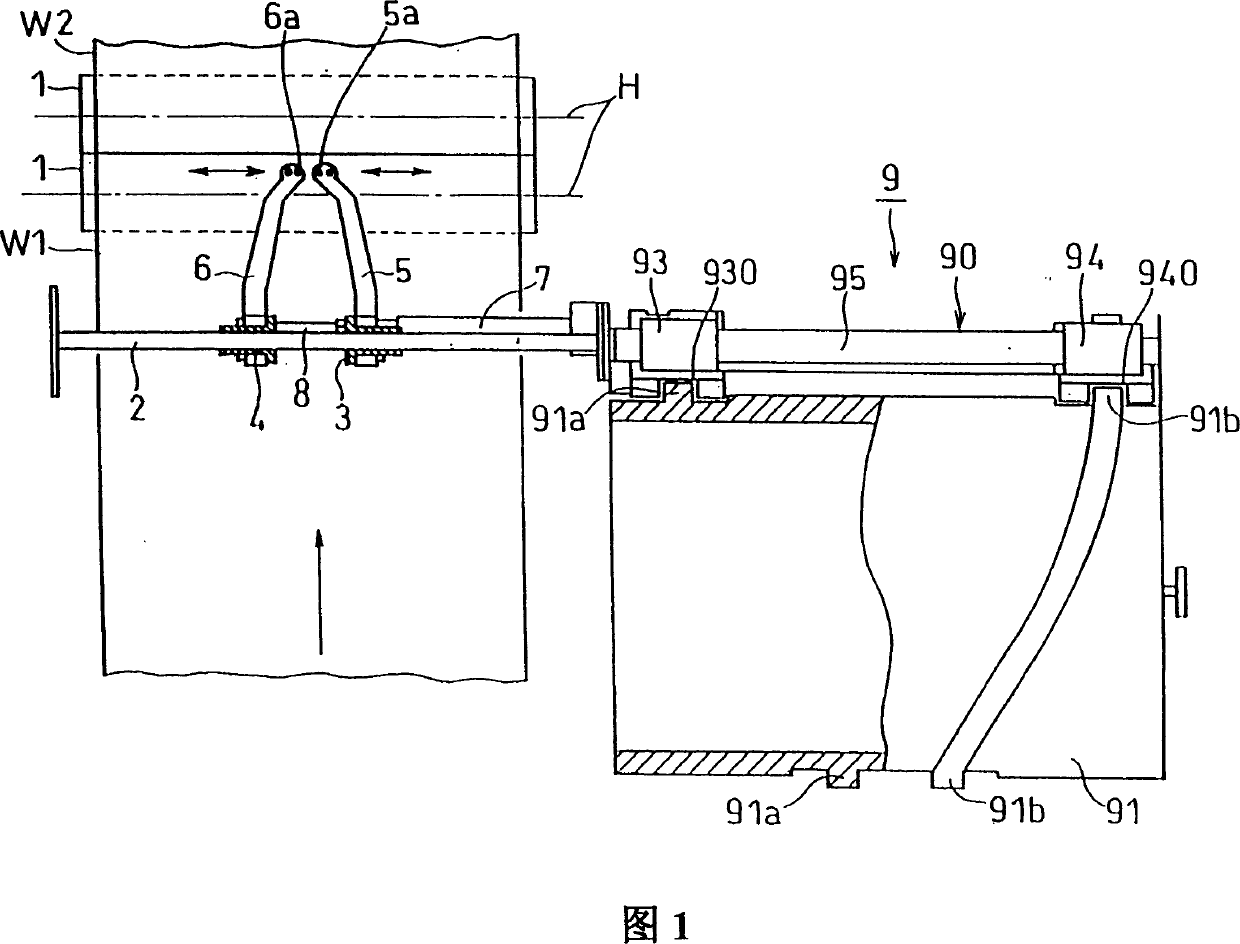

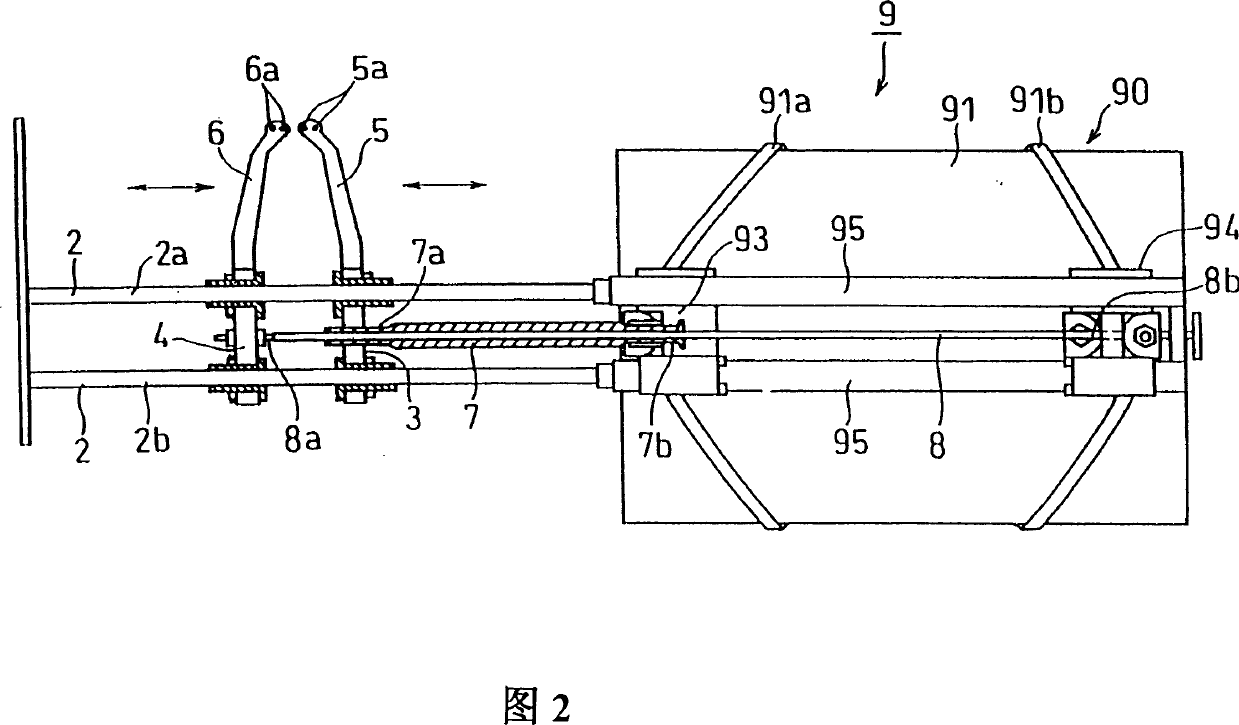

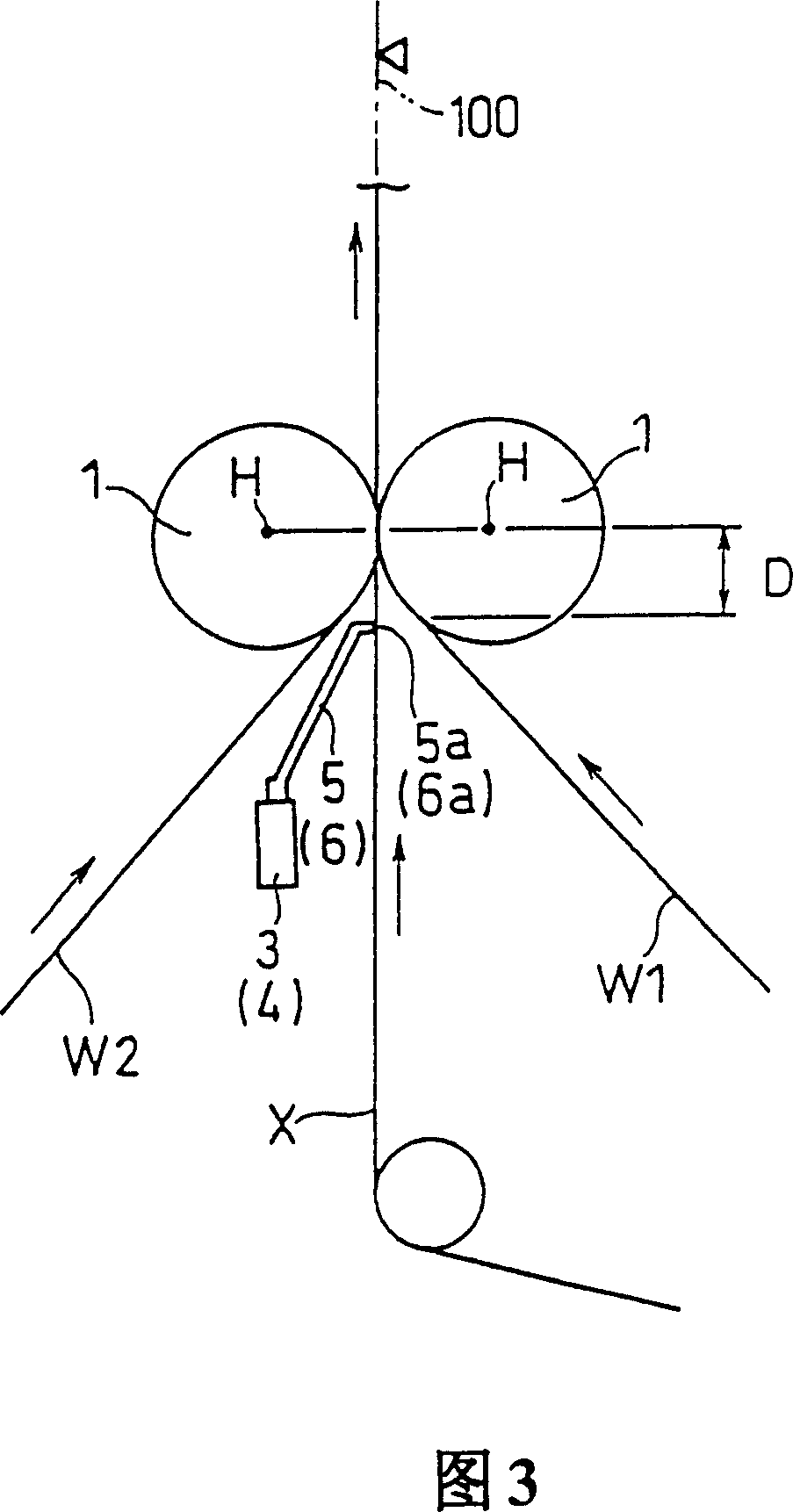

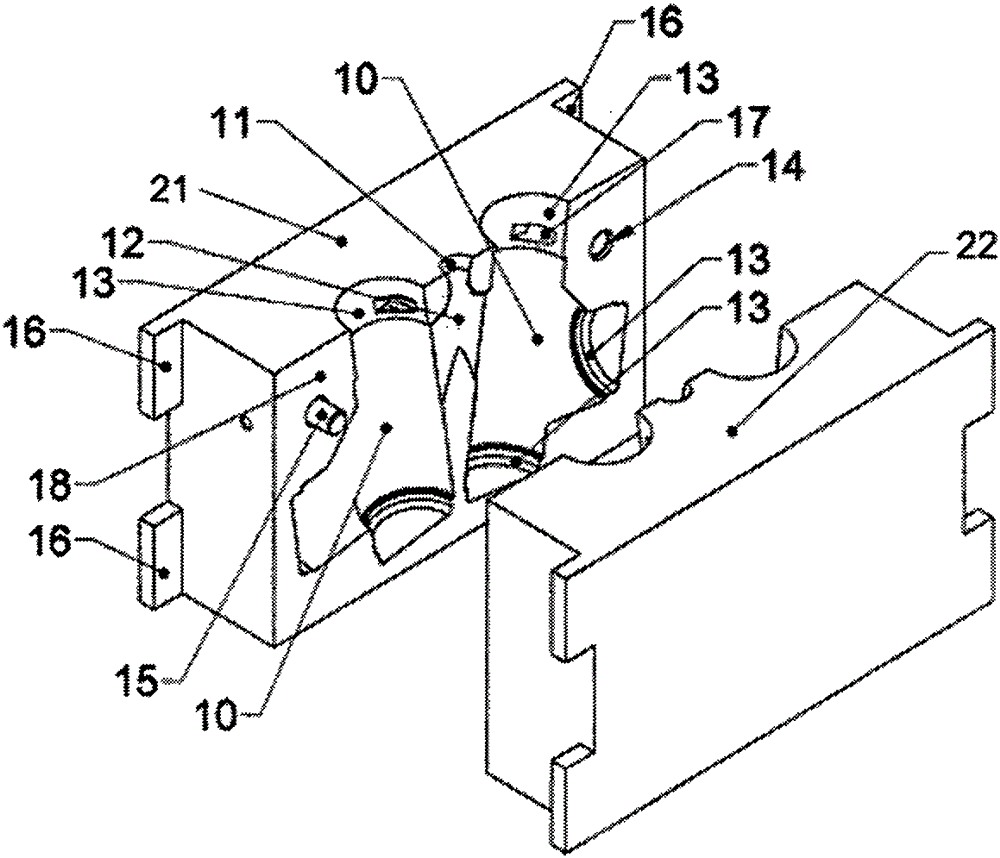

Device and method for making dressing article

The present invention provides a device for manufacturing a disposable wearing article with which an elastic member is attached on a web along a prescribed locus. The present invention concerning the disposable wearing article is provided with a pair of nip rolls 1, 1 for holding the webs W1 and holding the elastic member X in the webs, a first mobile member 5 to be moved in parallel with an axial line H to be the rotary center of the nip rolls 1, a first deriving part 5a which is formed in a first mobile member 5 so as to derive at least one elastic member in the webs W1 on an upstream where the webs is held. The radius of at least one of the nip rolls 1, 1 is set to about 15 mm-35 mm and a distance D between a plane including the axial lines of the pair of nip rolls 1, 1 and a point where the first deriving part 5a releases the elastic member X is set to be about <=30 mm.

Owner:ZUIKO CORP

A railway freight gondola car column and preparation method thereof

The invention discloses a railway freight gondola car column and a preparation method thereof. The car column is prepared from composite materials, toughening agents, fillers and compatibilizers with a mass ratio of 100: (3-15): (0.1-10): (0.1-5); wherein, by weight, The composite material consists of 60-80 parts of nylon resin, 20-40 parts of reinforcing fiber, 0.1-5 parts of coupling agent, 0.5-3 parts of nucleating agent, 0.2-3 parts of heat stabilizer, 0.3-1.5 parts of It is prepared from antioxidant and 0.5-1.5 parts of lubricant. After the strength calculation and ANSYS software analysis of the new material car column, and considering the isotropy requirements and ease of use, a square field shape (rounded corners) is adopted: the cross-sectional size is 45×45mm, the wall thickness is 6mm, and the outer rounded corners are 10mm. The invention has the advantages of sufficient impact strength, bending strength, good weather resistance, balance of blasting stress, balance of rigidity and flexibility, etc., and can be recycled and used.

Owner:SHAANXI UNIV OF SCI & TECH

RE-containing pre-alloy powder

The present invention relates to a kind of pre-alloyed powder and its application in making diamond tool. The pre-alloyed powder consists of at least two selected from Fe, Co, Cu and Ni as basic components, one or several of Mn, Ti, Sn, Mo, W and WC, and one or two of RE, such as La and Ce. It contains at most 80 % of Fe, at most 40 % of Co, at most 80 % of Cu, at most 40 % of Ni, at most 8 % of M and 0-5 % of RE, where, M is one or several of Mn, Ti, Sn, Mo, W and WC and RE is La and / or Ce. The pre-alloyed powder has also inevitable impurity. Scanning electronic microscope measurement shows that the pre-alloyed powder has basic particle size smaller than 15 micron and oxygen content not more than 2 %. The pre-alloyed powder is used as adhesive in making diamond tool.

Owner:GRIPM ADVANCED MATERIALS CO LTD

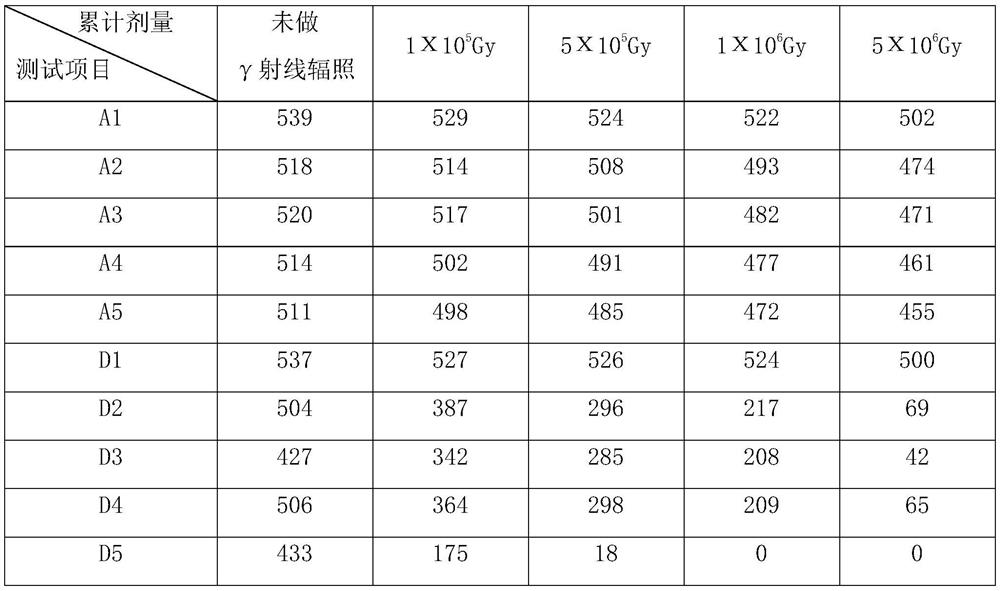

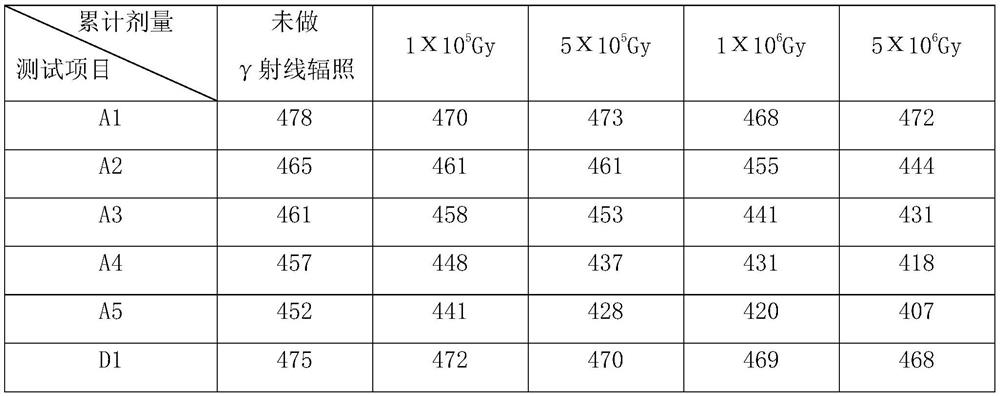

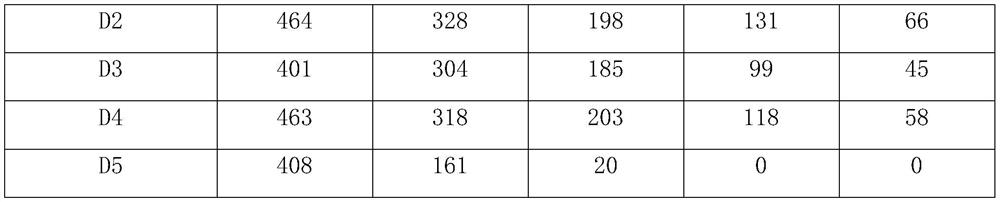

Gamma-irradiation-resistant modified resin, preparation method thereof, laminated board, preparation process of laminated board and application of laminated board

ActiveCN111892695AEnhanced radiation resistanceSufficient tensile strengthSynthetic resin layered productsLaminationPolymer scienceFirming agent

The invention provides gamma-irradiation-resistant modified resin. The gamma-irradiation-resistant modified resin is prepared by grafting and modifying epoxy resin with boric acid. The gamma-irradiation-resistant modified resin comprises epoxy resin, a curing agent, an accelerant, boric acid, a coupling agent and an organic solvent. The invention further provides a preparation method of the gamma-irradiation-resistant modified resin. The method comprises the following steps of: S1, carrying out boric acid graft modification on epoxy resin to obtain a modified resin glue solution; and S2, regulating the gelation time of the modified resin glue solution obtained in the step. The invention also provides a preparation process of a laminated board containing the gamma-irradiation-resistant modified resin, and application of the laminated board containing the gamma-irradiation-resistant modified resin. According to the gamma-irradiation-resistant modified resin, after the resin is subjectedto boric acid graft modification, the irradiation strength of the modified resin is obviously enhanced; and the laminated board prepared by combining the modified resin with basalt fiber cloth can ensure enough tensile strength and bending strength when the accumulated irradiation dose reaches 5X106Gy and is suitable for various environments with strong gamma strength.

Owner:SICHUAN FIBERGLASS GRP

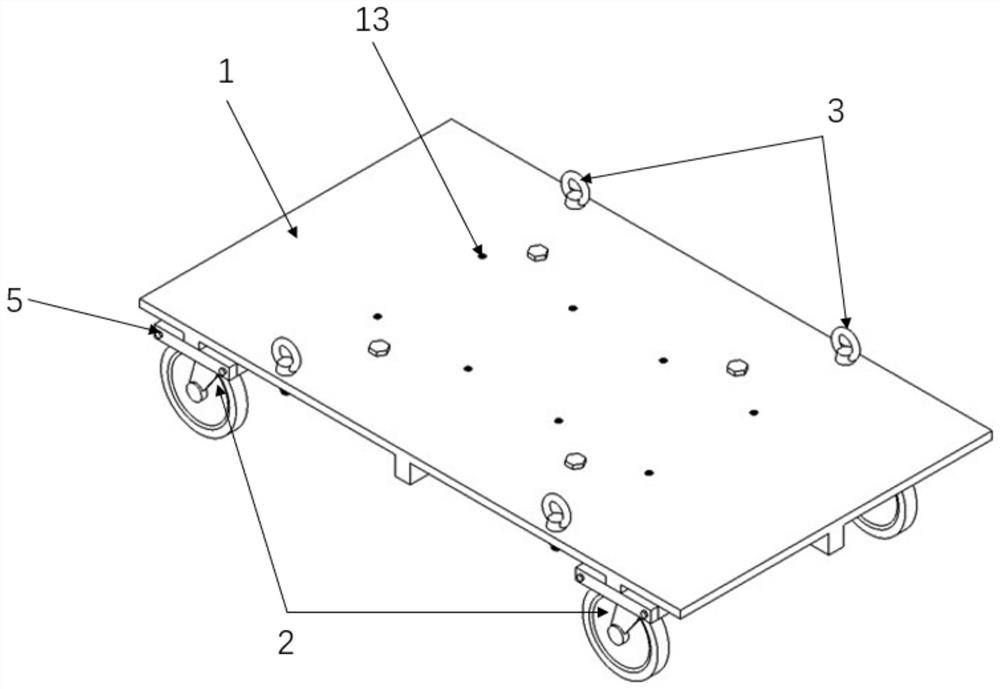

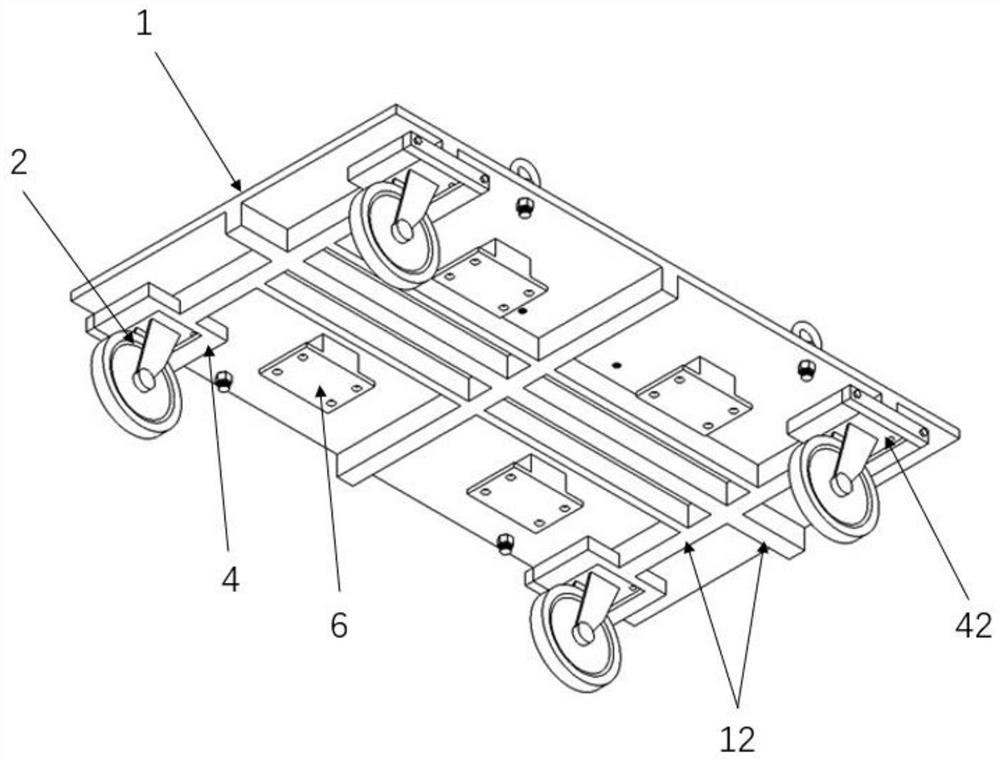

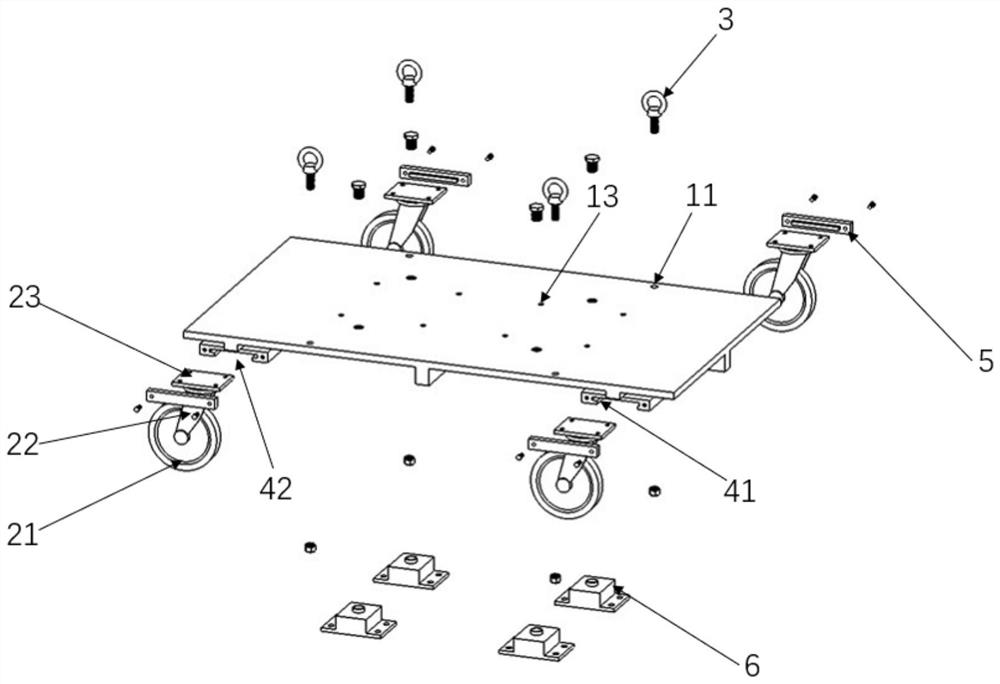

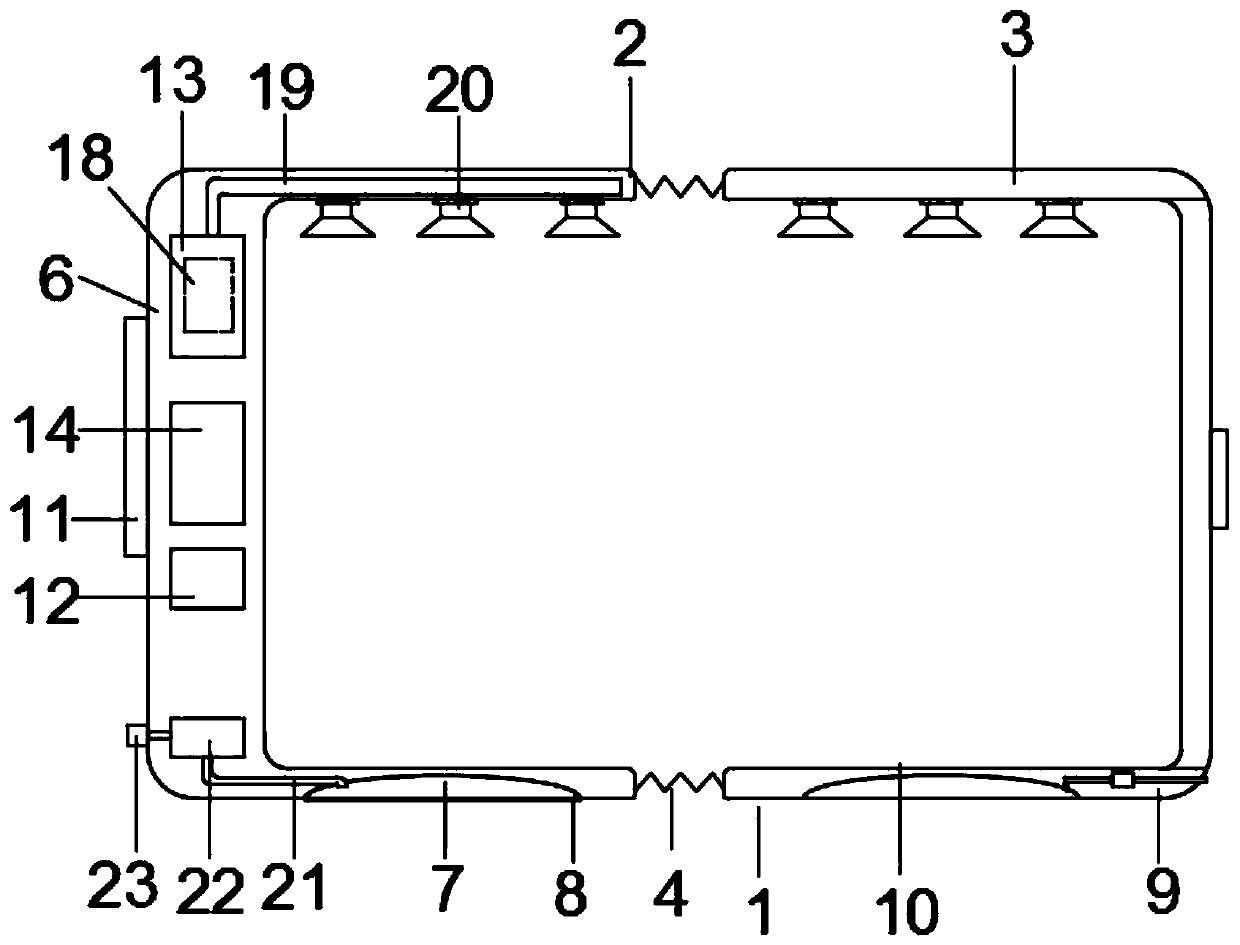

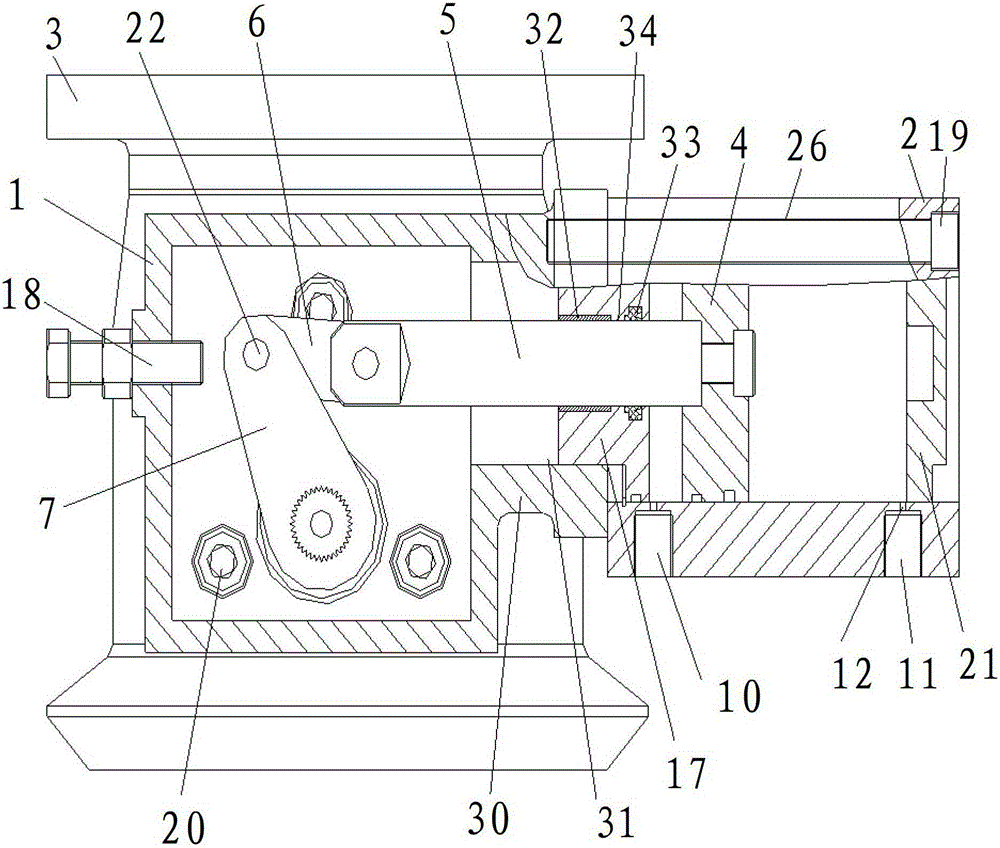

Dynamic and static dual-mode conversion experiment table and operation method thereof

PendingCN113546711ASimple structureEasy to operateLaboratory benches/tablesControl engineeringStructural engineering

The invention relates to a dynamic and static dual-mode conversion experiment table and a use method thereof in the technical field of experiment racks. The experiment table comprises a base plate, bearing wheels and hanging rings; fixing holes are formed in the base plate, the multiple fixing holes are symmetrically distributed in the base plate, inserting blocks are connected to the bottom face of the base plate, the multiple inserting blocks are symmetrically distributed on the side face of the base plate, and inserting grooves are formed in the inserting blocks; and each bearing wheel comprises a wheel, a supporting leg and a connecting plate, one end of each supporting leg is rotationally connected with the wheel, the other end of each supporting leg is connected with the connecting plate, the connecting plates are detachably inserted into the inserting grooves, and the hanging rings are fixedly connected with the base plate through the fixing holes. According to the dynamic and static dual-mode conversion experiment table provided by the invention, when a moving mode is switched to a static mode, experiment equipment on the base plate does not need to be disassembled, and only a crane or a forklift needs to be used for hoisting a dynamic and static dual-mode conversion experiment table frame, plugging block bolts are disassembled from the inserting blocks, the bearing wheels are taken out from the side surface; and the dynamic and static dual-mode conversion experiment table is put down. The dynamic and static dual-mode conversion experiment table is simple in structure and convenient to operate.

Owner:SHANGHAI JIAO TONG UNIV

A super high door

ActiveCN108979466BGuaranteed aestheticsSufficient bending strengthFireproof doorsDoor leavesSealantMechanical engineering

The invention discloses an ultra-high molding door, and relates to the field of molding doors. The ultra-high molding door comprises a door panel, a first face plate and a second face plate, wherein areserved gap is formed by the first face plate and the second face plate in a surrounding manner; a reinforcing assembly is arranged in the reserved gap; the reinforcing assembly comprises two reinforcing plates and a reinforcing rack; the cross section of the reinforcing rack is H-shaped; inner grooves are formed in the two sides of the reinforcing rack in the width direction; the two reinforcing plates are arranged in parallel at intervals; the two reinforcing plates are separately fixedly embedded in the two inner grooves; a through groove is horizontally formed in the reinforcing rack ina penetrating manner; the two reinforcing plates are adhered and fixed through a fireproof sealant; cambered plates are separately arranged on the outer sides of the two inner grooves; an accommodating cavity is formed by the cambered plates and the reinforcing plates in a surrounding manner; and compressed rubber is fixed in the accommodating cavity. The ultra-high molding door is good in attractiveness, long in service life, good in fireproof performance and high in safety, and is environmentally friendly.

Owner:上海阜邦幕墙门窗工程有限公司

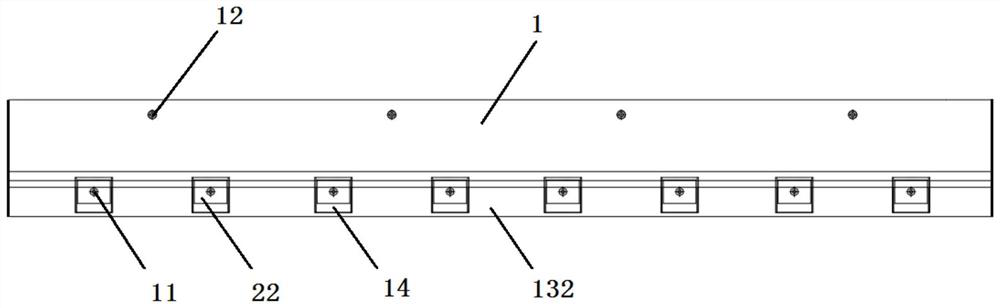

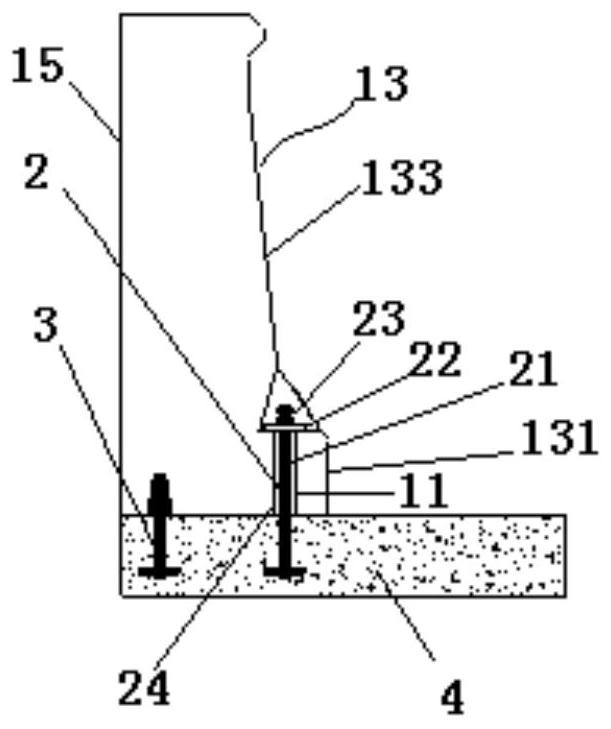

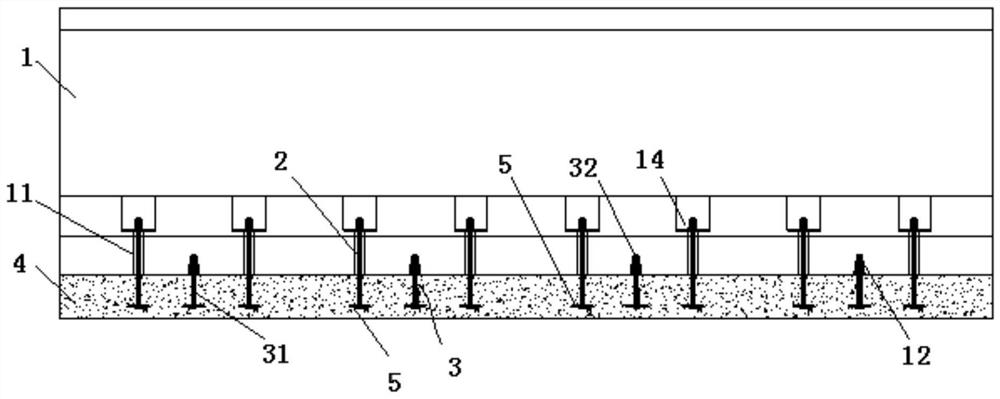

Dry-type connected fabricated concrete guardrail

PendingCN114045747AImprove stabilityEnables a fully dry connection in the fieldBridge structural detailsRoadway safety arrangementsArchitectural engineeringStructural engineering

The invention discloses a dry-type connected fabricated concrete guardrail. A plurality of anti-bending bolt holes and a plurality of anti-shearing bolt holes which are arranged in a staggered manner are formed in the bottom of a guardrail body; the anti-bending bolt holes are arranged close to the inner side of the guardrail body, and the anti-shearing bolt holes are arranged close to the outer side of the guardrail body, so that parallel triangular staggered anchoring hole groups are formed, and vehicle collision loads at various angles can be borne after bolts are anchored. The height L1 of the portion, extending out of a base body, of an anti-bending screw rod is larger than the height L2 of the portion, extending out of the base body, of an anti-shearing screw rod, so that when the guardrail body is anchored to the base body, a neutral shaft of the anchoring face is moved to the anti-shearing bolt hole as much as possible, bending moment and shearing force borne by the guardrail can be conveniently absorbed respectively, and the overall stability of the guardrail is improved. And meanwhile, complete dry type connection on a construction site can be achieved, the hole alignment positioning problem can be solved, and disassembly and assembly are convenient.

Owner:BEIJING ZHONGLUAN TRAFFIC TECHCAL

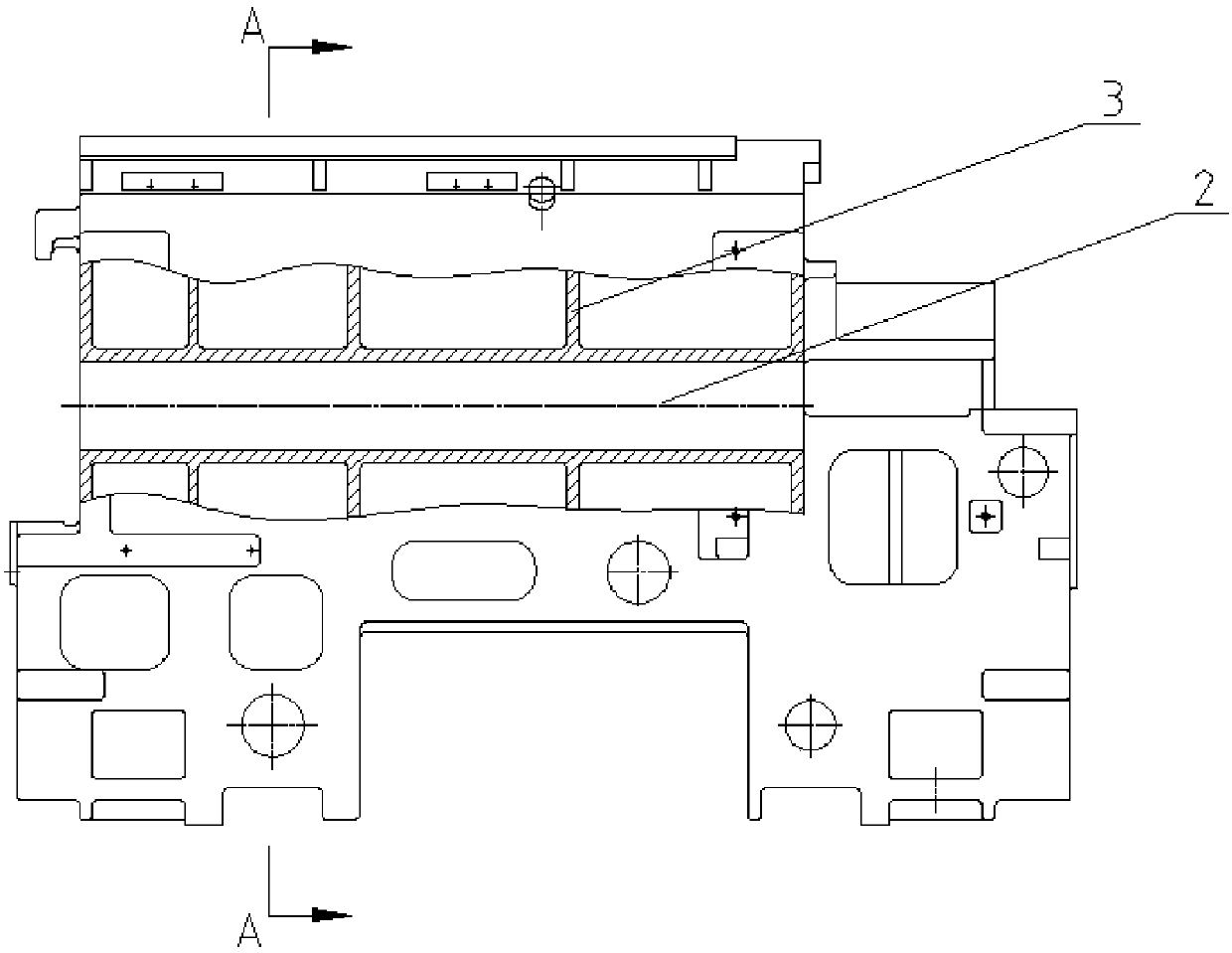

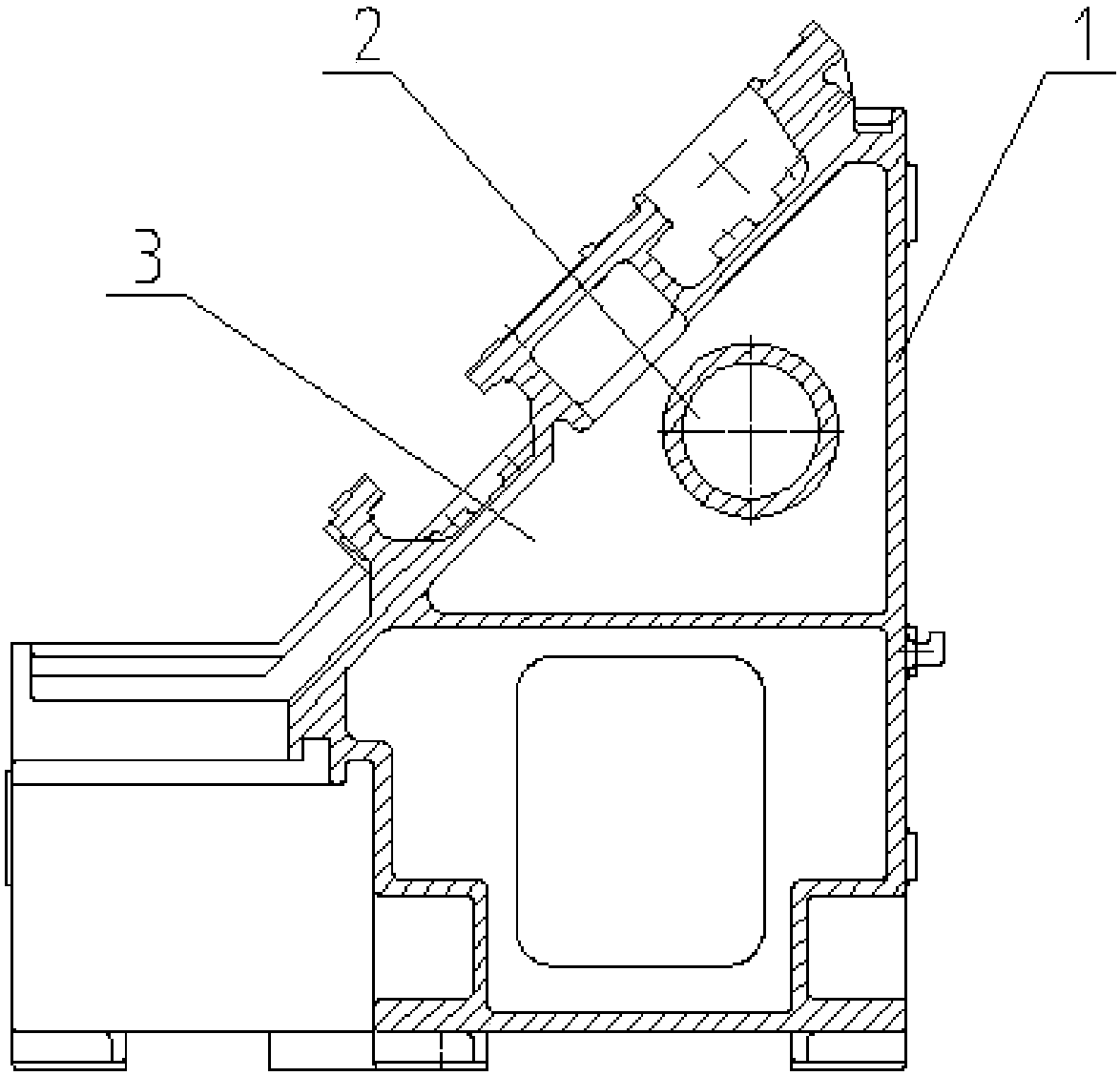

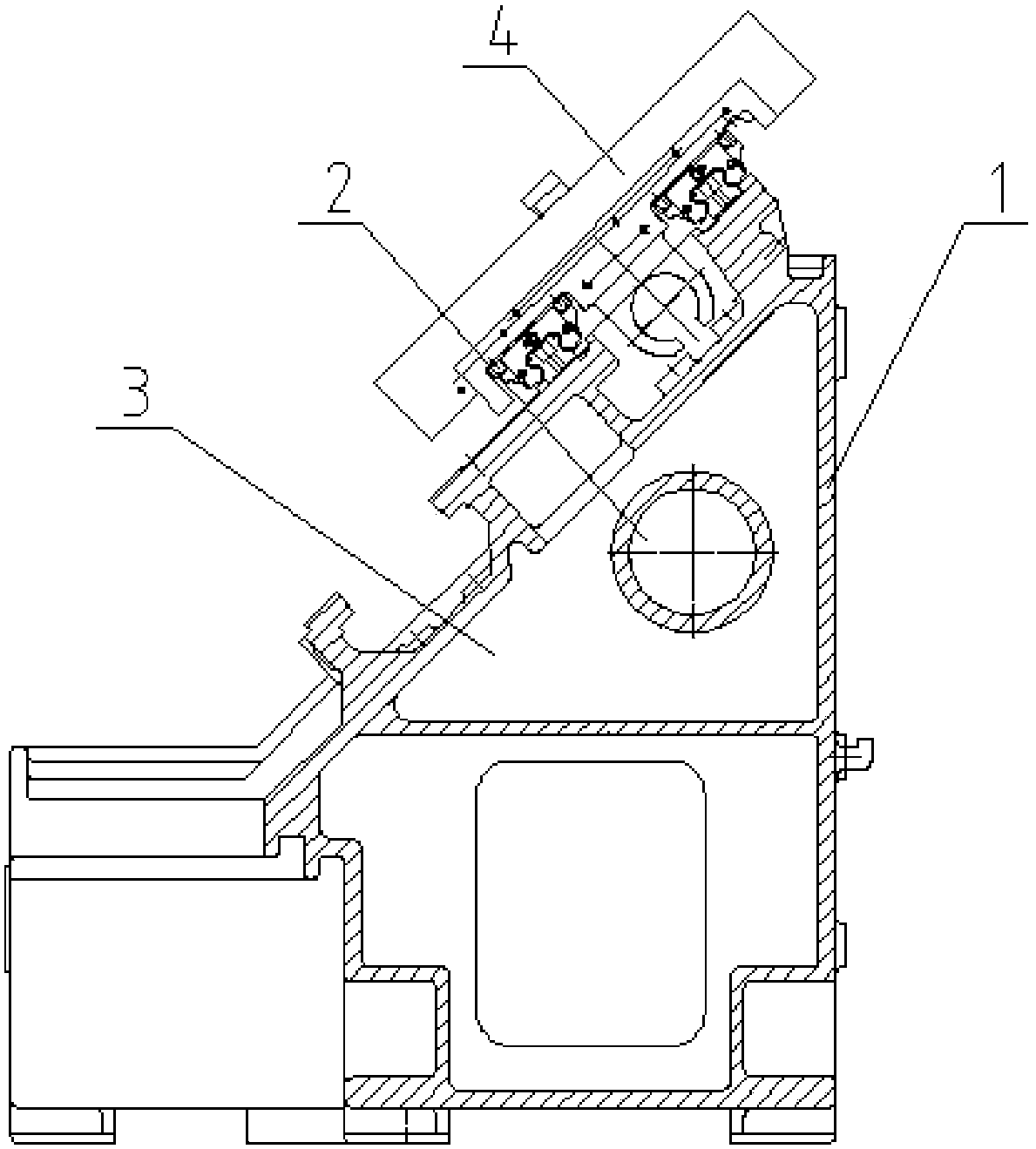

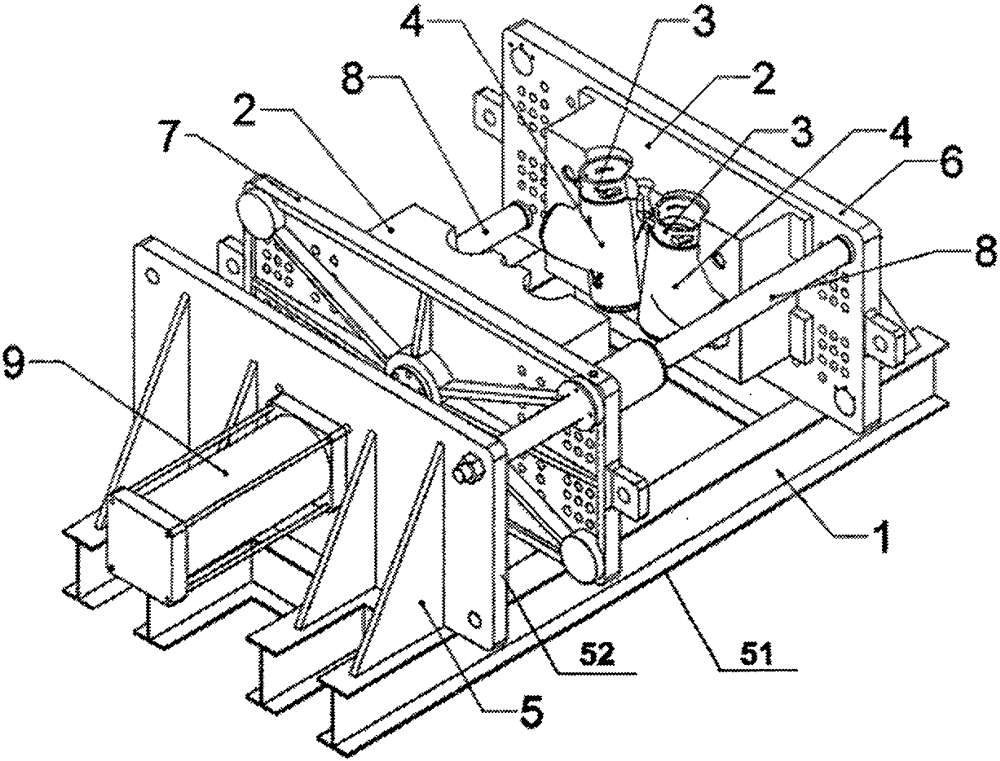

A double-layer structure inclined bed of a turning center and its manufacturing method

ActiveCN105666156BResistance to local deformationSolve the problem of easy vibration affecting machining accuracyLarge fixed membersEngineeringMachine tool

The invention discloses a double-layer slant lathe body of a turning center and a manufacturing method for the slant lathe body, belongs to the field of machine tools, and solves the problems that an existing machine tool easily vibrates due to excessive rigidity of a tool body in a high-speed running process to influence the machining precision, and the tool body easily deforms under high-frequency vibration. The double-layer slant lathe body comprises an upper lathe body part and a lower lathe body part, wherein the upper lathe body part is a slant lathe body; the slant lathe body comprises an outer frame, a cylinder and transverse partitions; the cross section of the outer frame is triangular; the cylinder is arranged in the outer frame; and the outer frame is fixedly connected with the cylinder through the transverse partitions arranged at intervals in the length direction of the cylinder. According to the double-layer slant lathe body, the machine tool vibration can be effectively reduced, so that the machining precision of the machine tool is improved, the bending resistance and the torsion resistance are enhanced, and the service life of the machine tool is prolonged.

Owner:JIANGSU YUANLI AVIA PRECISION MACHINE TOOL

Method of making metal molds

ActiveCN103521705BSufficient bending strengthImprove crack resistanceFoundry mouldsFoundry coresMetal moldJoint surface

Owner:XUSHUI XINGHUA CASTING

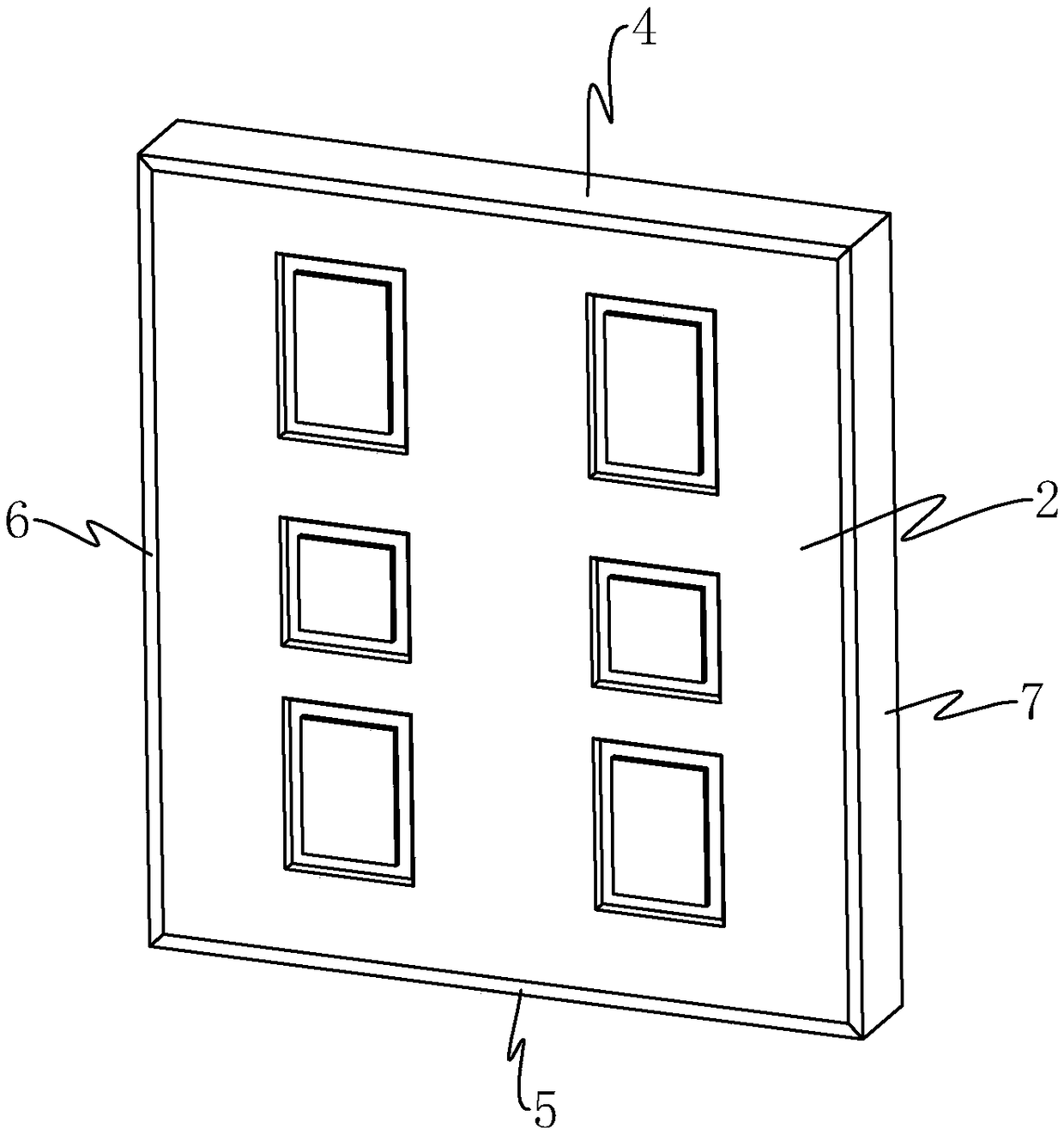

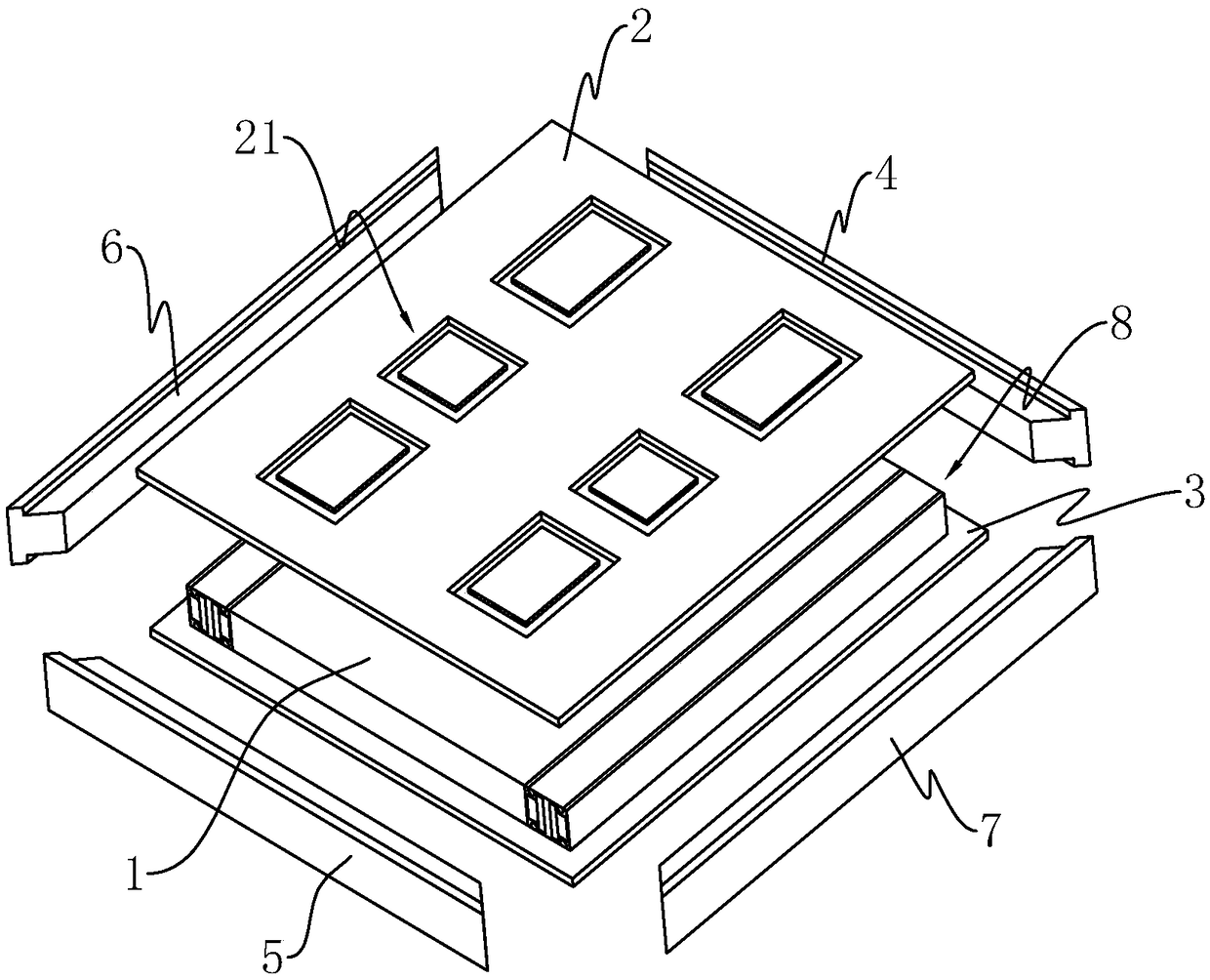

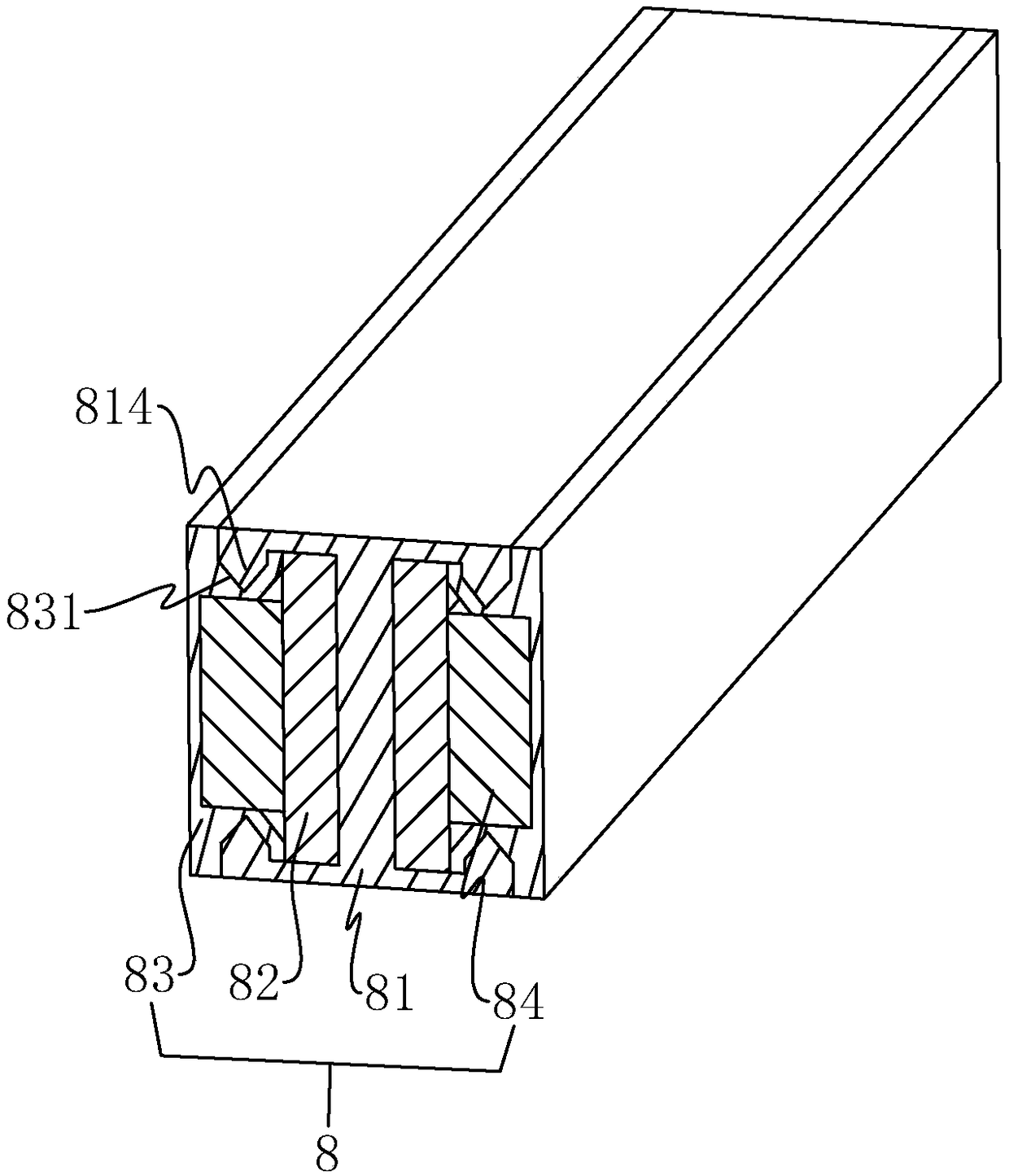

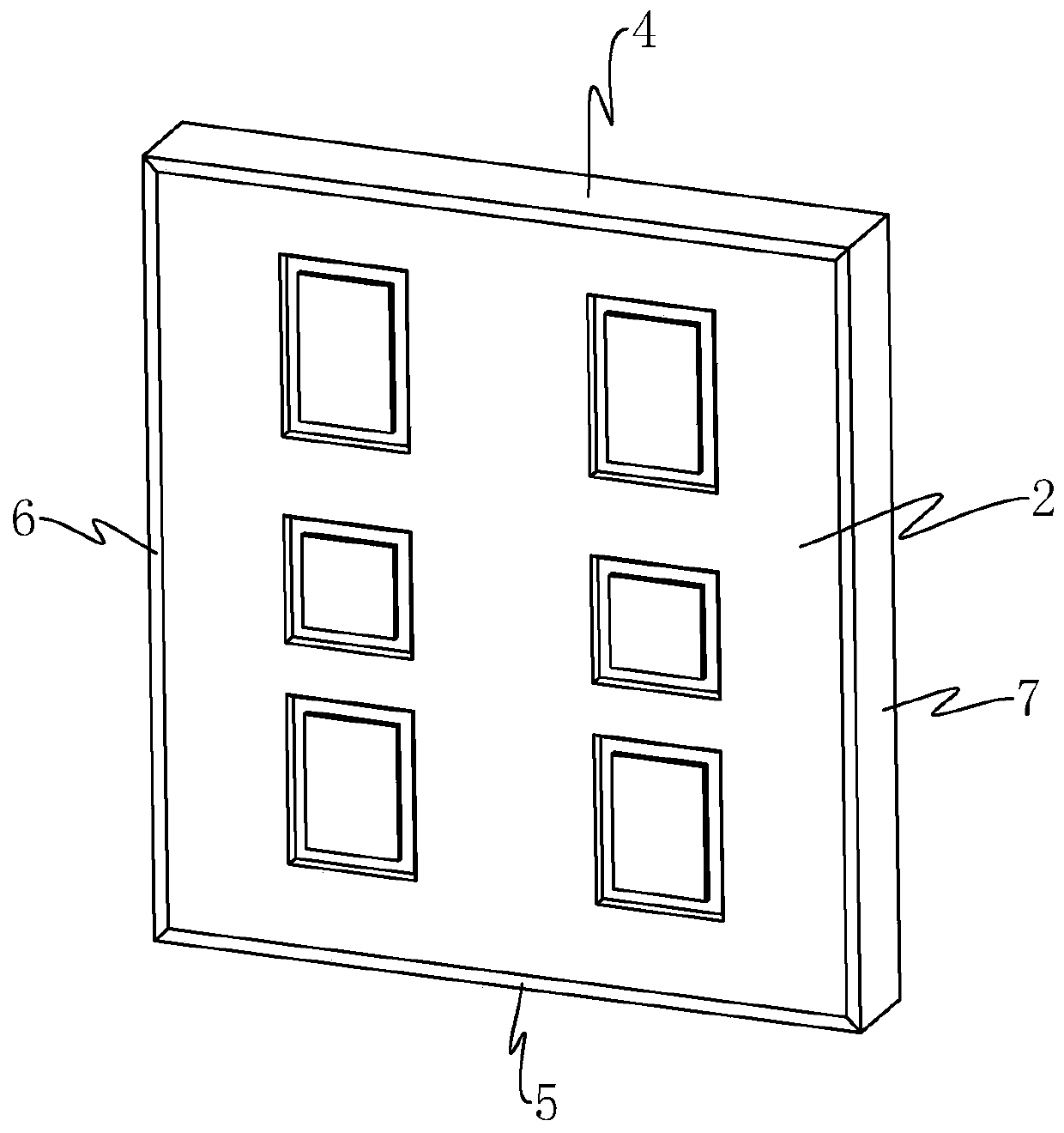

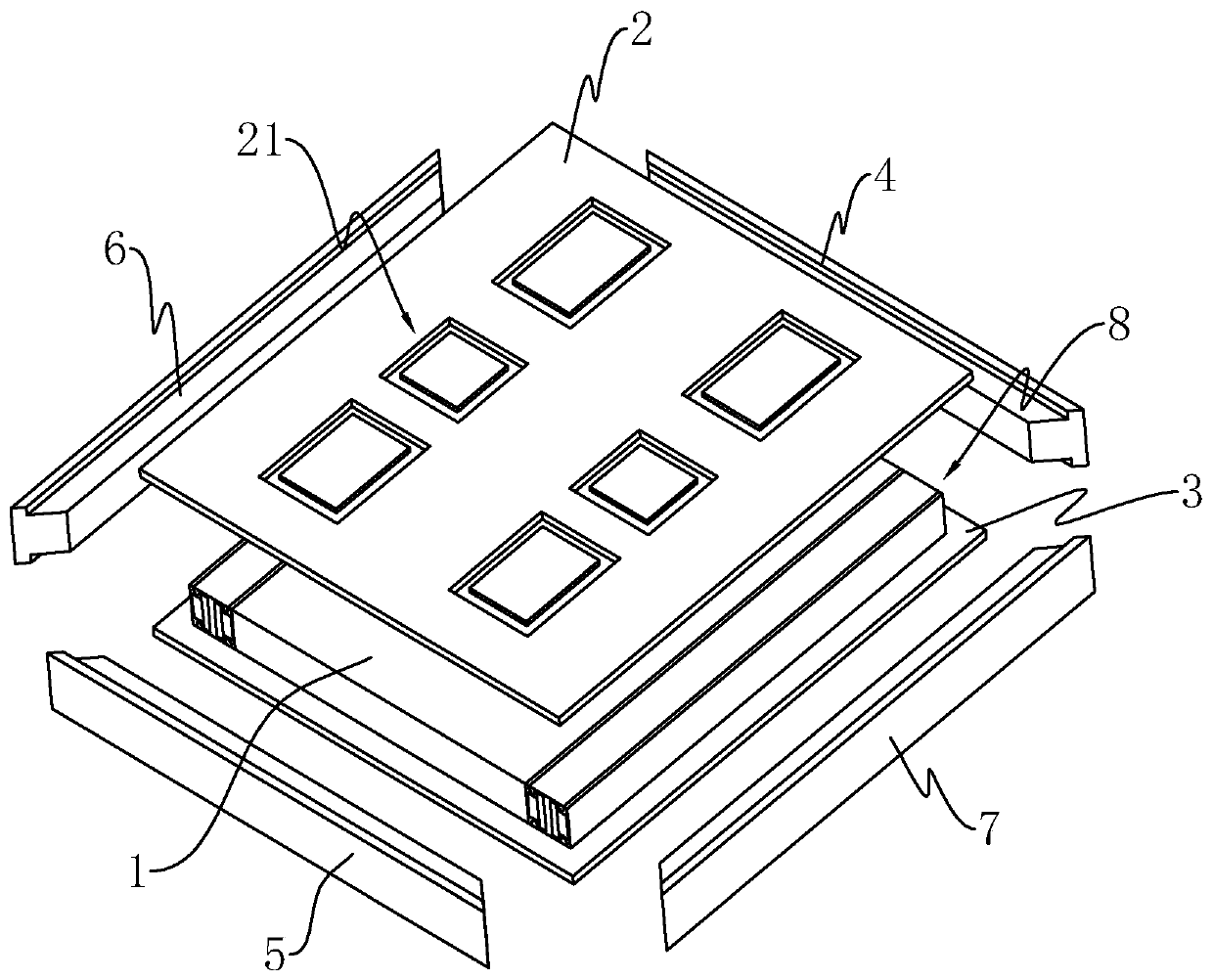

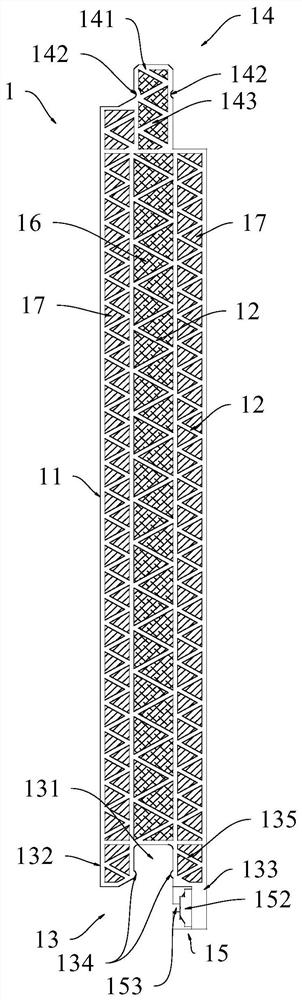

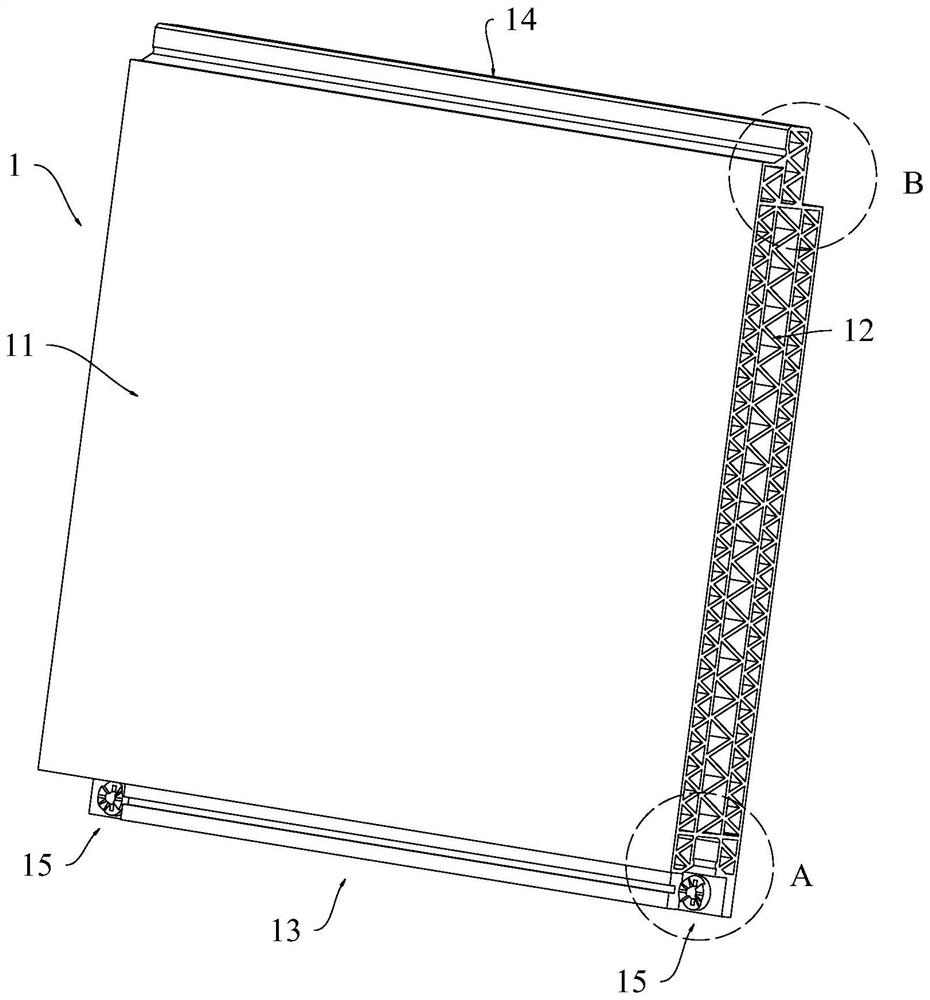

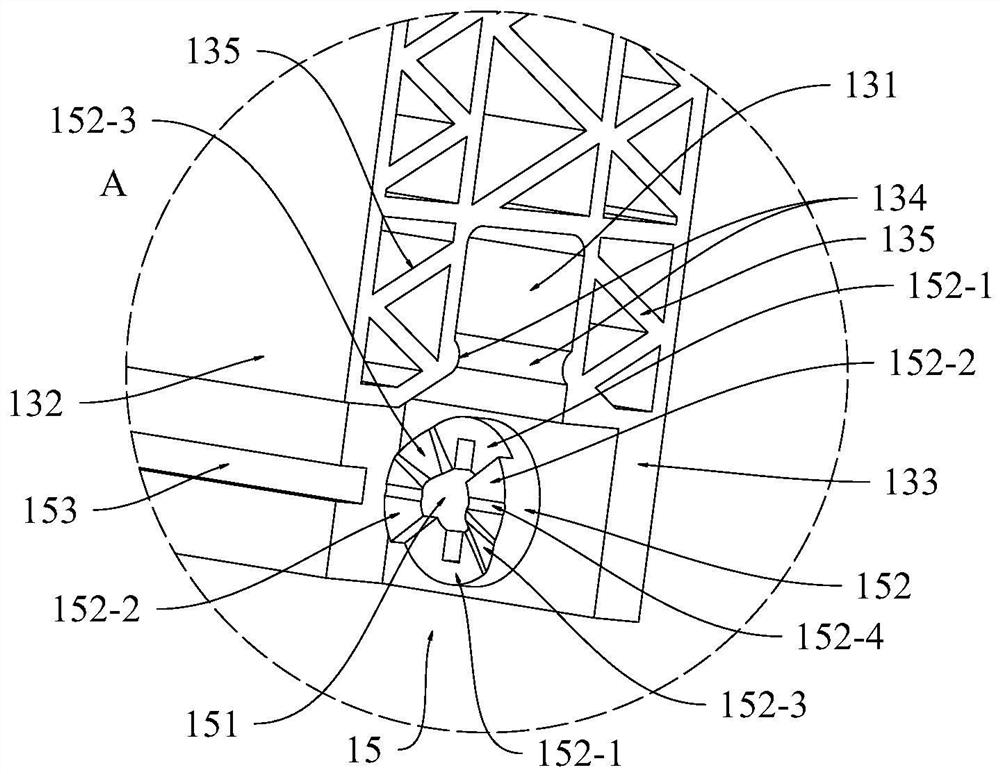

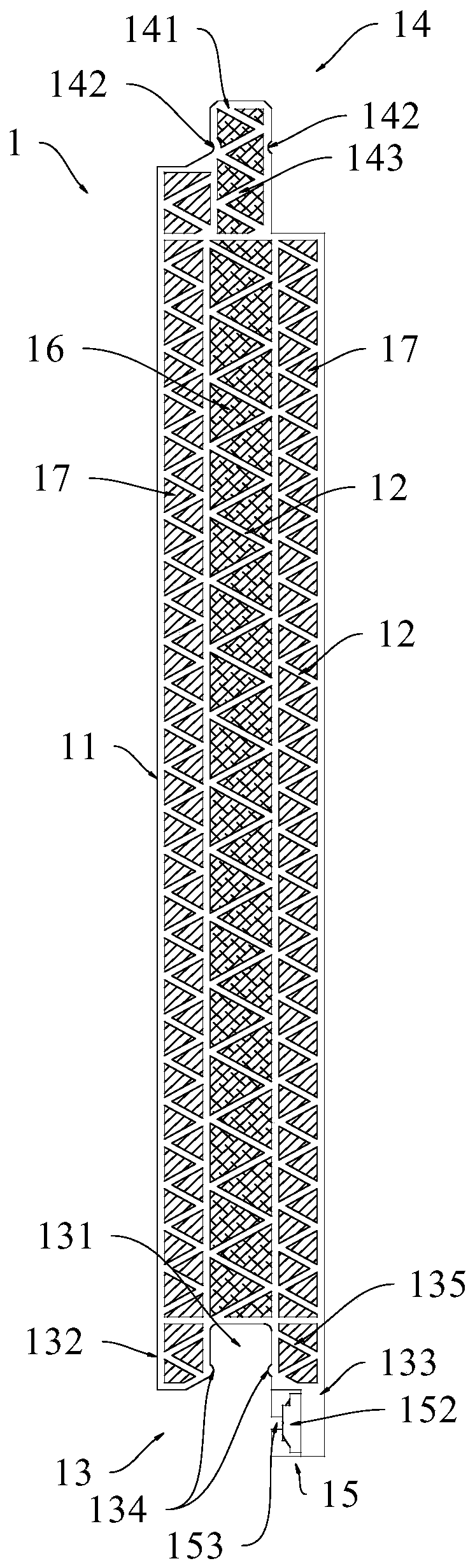

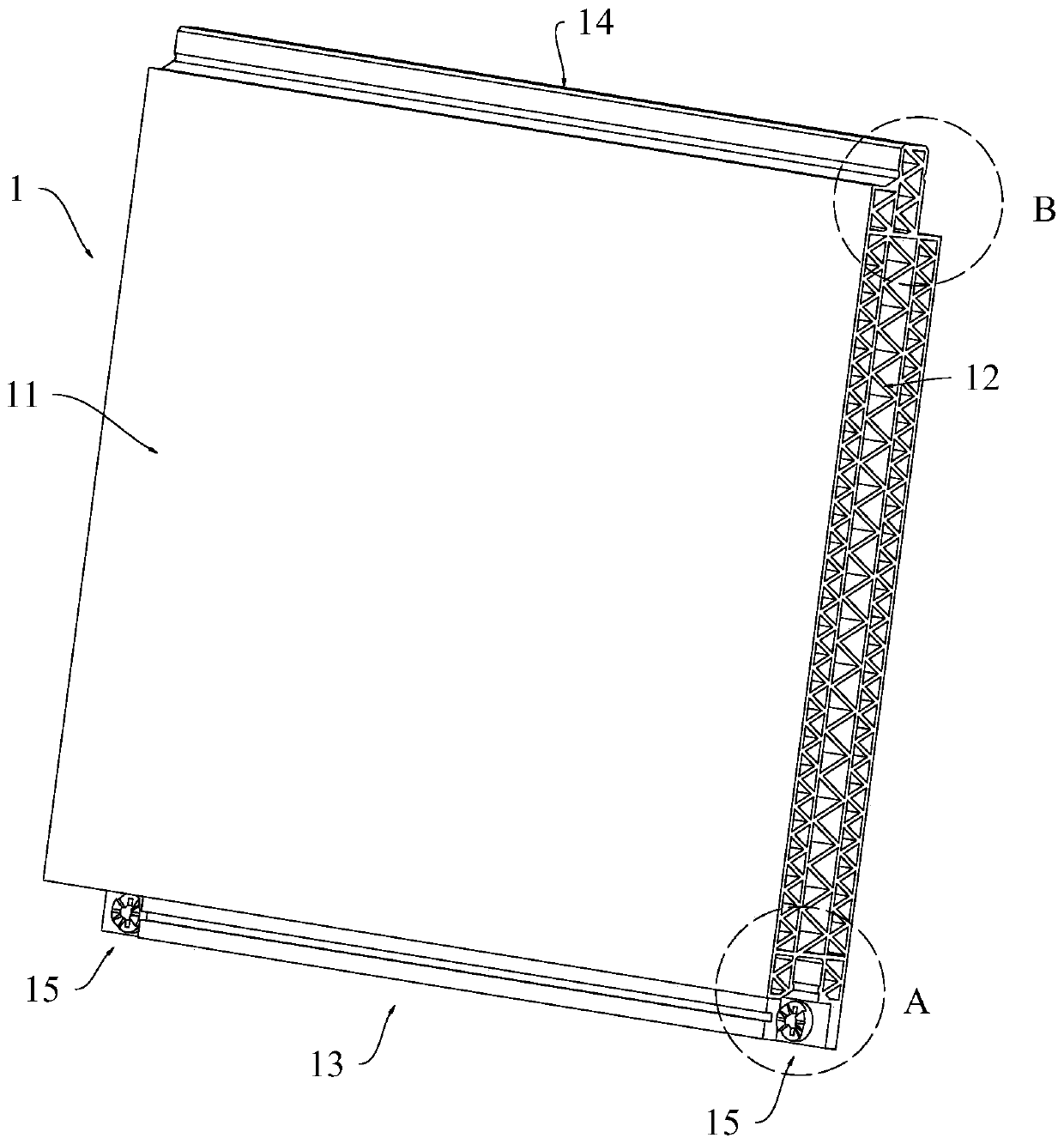

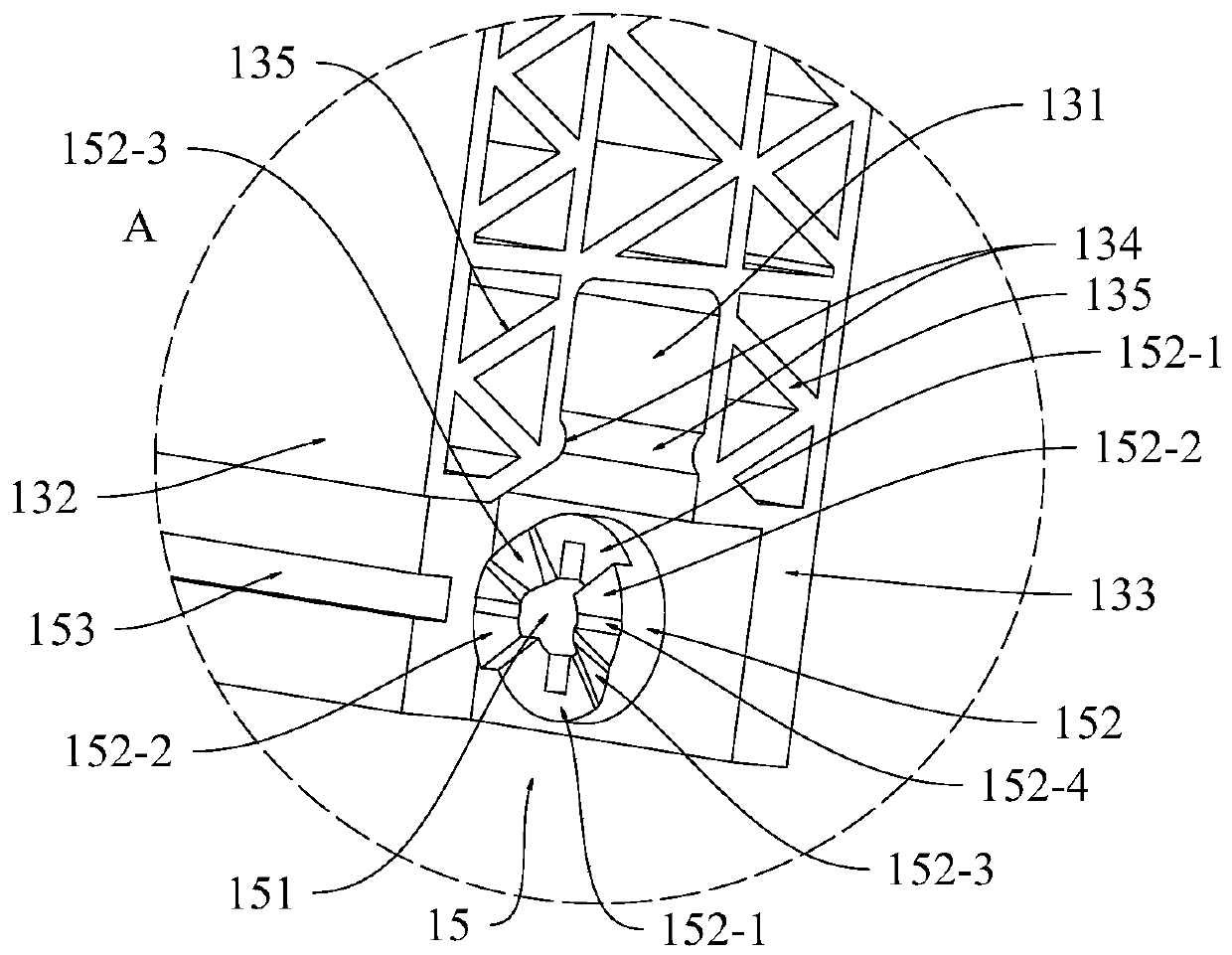

Wall panel and wall structure for a prefabricated building

ActiveCN110821078BLarge surface hardnessLight in massCovering/liningsArchitectural engineeringStructural engineering

The invention discloses a wall panel and a wall structure for an assembled building. The wall panel includes a panel body, and there are odd-numbered cavities in the panel body; wherein, the cavity at the central position has the largest width, and the other cavities are opposite to each other. The cavity at the central position is arranged symmetrically, and the width of the cavity gradually becomes smaller when viewed from the center to both sides; each layer of cavity is provided with a first reinforcing rib, and each layer of cavity is covered by the first reinforcing rib in it. Divided into several triangular areas; viewed from the middle of the panel body to the two sides, the distribution density of the first ribs in the cavity gradually increases from sparse to dense; both sides of the panel body are respectively provided with a first clamping part and a second clamping part ; There is also a fixed portion on the panel body. The present invention arranges layered structures for the wall panels and different arrangement modes of reinforcing ribs to ensure sufficient bending strength, and at the same time ensure that the wall panels have sufficient surface hardness, and their weight is relatively light, which can be easily Good to meet the requirements of building materials.

Owner:中儒科信达建设集团有限公司

Wall surface panel for fabricated building and wall surface structure

ActiveCN110821078ALarge surface hardnessLight in massCovering/liningsStructural engineeringMechanical engineering

The invention discloses a wall surface panel for a fabricated building and a wall surface structure. The wall surface panel comprises a panel body, wherein odd layers of cavities are formed in the panel body; the width of the cavity positioned in the center is the largest, the other cavities are symmetrically arranged relative to the cavity in the center, and the widths of the cavities are gradually decreased when seen from the center to the two sides; first reinforcing ribs are arranged in all the layers of cavities, and each layer of cavity is divided into a plurality of triangular areas bythe first reinforcing ribs in the layer of cavity; when seen from the middle of the panel body to the two sides, the distribution density of the first reinforcing ribs in the cavities is gradually increased; the two sides of the panel body are provided with a first clamping part and a second clamping part correspondingly; and a fixing part is further arranged on the panel body. According to the wall surface panel for the fabricated building and the wall surface structure, the wall surface panel is provided with a layered structure and the reinforcing ribs are arranged in different densities, thus the enough bending strength is ensured, meanwhile, the effect that the wall surface panel has the enough large surface hardness can be ensured, the weight of the wall surface panel is low, and therequirements of building materials can be well met.

Owner:中儒科信达建设集团有限公司

A kind of spinel-magnesium-based ceramic core and preparation method thereof

ActiveCN112794711BSufficient bending strengthImprove thermal shock resistanceFoundry mouldsFoundry coresUltimate tensile strengthThermal shock

A spinel-magnesium-based ceramic core and a preparation method thereof belong to the field of preparation of ceramic cores in the field of precision casting. The raw material of the spinel-magnesium-based ceramic core includes powder raw material and binder, the powder raw material is composed of the following components, and the mass percentage of each component is: spinel powder is 50% to 90%, zirconia powder is 0%-30%, titanium dioxide powder is 0%-5%, and the balance is magnesium oxide powder; the mass percentage of the binder in the mass percentage of the powder raw material is 15%-25%. The preparation method of the spinel-magnesium-based ceramic core is as follows: mix the powder according to the ratio, configure the binder, mix the preheated mixed powder and the binder to prepare a slurry, and use the hot pressure injection molding method for the slurry Molded and sintered. The spinel-magnesium-based ceramic core has the advantages of high strength, small shrinkage, easy removal, and improved thermal shock resistance.

Owner:NORTHEASTERN UNIV LIAONING

A nanocomposite ceramic core

The invention discloses a nanometer composite ceramic core which is characterized by comprising the following raw materials in percentage by weight: 12%-18% of mineralizing agents, 14%-20% of plasticizing agents, 2%-3% of nanometer silicon dioxide, 1%-2% of nanometer magnesium oxide, 2%-3% of microcrystalline wax and the balance of rare earth coated nanometer composite powder. The nanometer composite ceramic core disclosed by the invention is sufficient in bending strength and small in firing shrinkage rate and can ensure the invariability of a dimension and a shape and effectively enhance the porosity of a core by adopting the raw materials with different fineness, thereby well improving the core stripping property.

Owner:浙江振兴阿祥集团有限公司

A method for preparing three-dimensional interpenetrating structure 3d-sic/al composite material

The invention relates to a method for preparing a 3D-SiC / Al composite material with a three-dimensional interpenetrating structure, including the preparation of a 3D-SiC prefabricated part and the subsequent preparation of the 3D-SiC / Al composite material by pressureless infiltration. Among them, when the 3D-SiC preform is applied to the subsequent pressureless infiltration of the 3D-SiC / A composite material, it may or may not be pre-oxidized according to the composition of the aluminum alloy used. The SiC content in the composite material of the present invention is 50-73vol%, the density of the composite material can reach 2.90-3.1g / cm2, the thermal conductivity can reach 232W / (m·℃), and the thermal expansion coefficient can be as low as 5.72×10-6 / ℃ , the bending strength can reach 330MPa, and the comprehensive performance meets the technical performance requirements such as low expansion coefficient, high thermal conductivity and sufficient bending strength that electronic packaging materials must have.

Owner:HEFEI UNIV OF TECH

Freight refrigerated container

InactiveCN110902162AChange spacingFlexible sizeLarge containersTank wagonsRubber ringLogistics management

The invention relates to the technical field of logistics transportation tools, and particularly relates to a freight refrigerated container. The freight refrigerated container comprises a container body, wherein the container body comprises a left container body and a right container body; a sealed folding part is arranged between the opposite surfaces of the left container body and the right container body; a telescopic mechanism used for unfolding and folding the folding part is arranged on the front sides and the rear sides of the left container body and the right container body; a refrigerating system is arranged on one side of the container body through an arranged cavity; inner concave parts from bottom to top are arranged on the bottom surfaces of the left container body and the right container body; rubber rings are bonded to the edges of the inner concave parts; adsorption mechanisms communicate with the interiors of the inner concave parts; and a bottom plate of the container body comprises a plurality of floor units provided with reinforcing layers. According to the freight refrigerated container, the storage space in the container body can be changed, the operation issimple and convenient, the good practicability is achieved, the strength of the bottom plate is enhanced, further adsorption and fixation of the container body and a ship body are realized, and the safety during carrying is improved.

Owner:大冶市古华实业有限公司

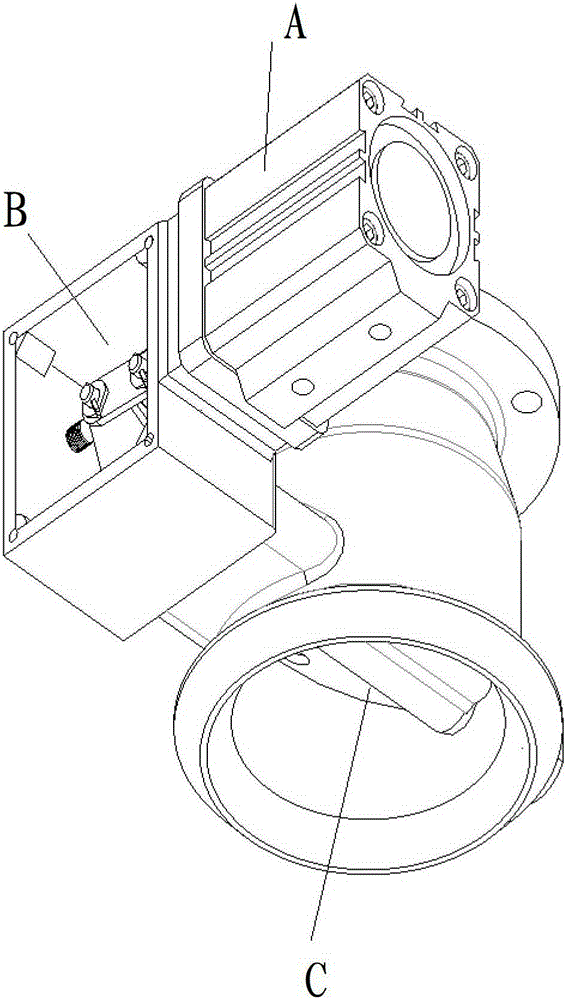

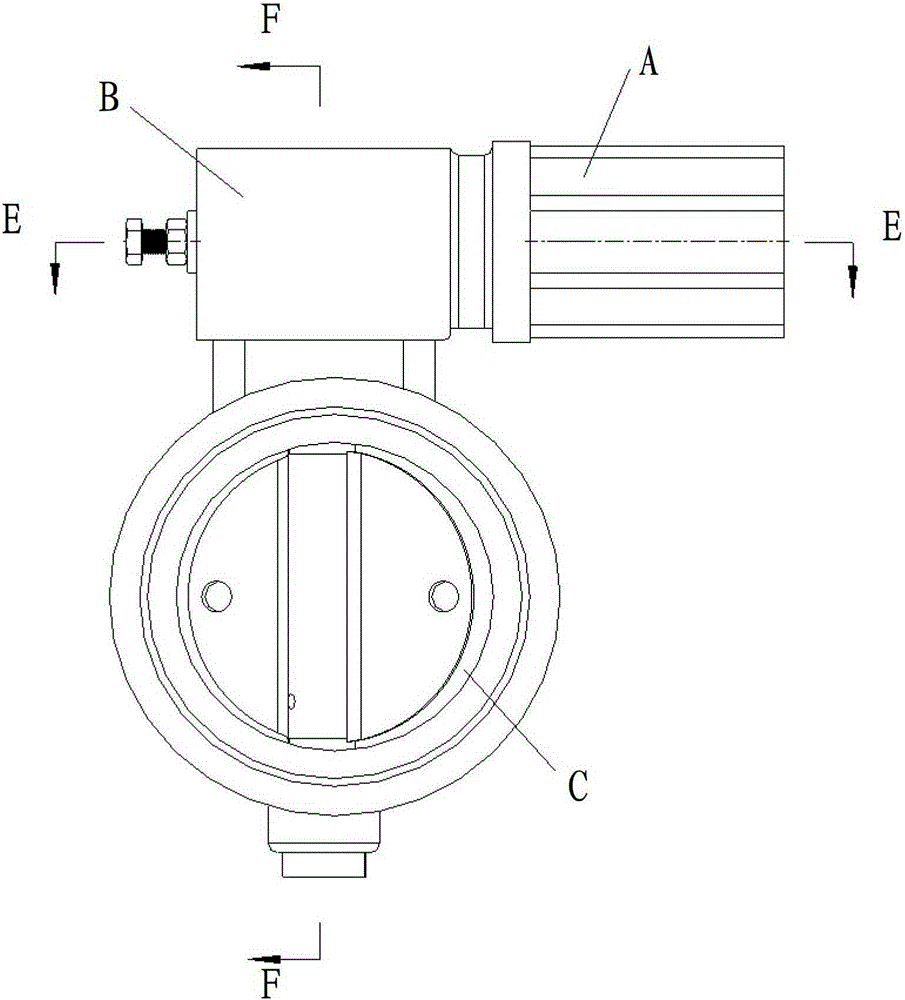

Diesel engine back pressure control valve assembly

ActiveCN103114915BHigh strengthImprove rigidityEngine controllersMachines/enginesExhaust valveEngineering

Provided is a back pressure control valve assembly of a diesel engine. The assembly is of a unit combination structure and comprises a driving unit A, a transmission unit B and an action unit C; and one end of a body of a cylinder of the driving unit A is hermetically, fixedly and integrally connected with a side of a transmission shell of the transmission unit B by seam allowance, the bottom of the transmission shell of the transmission unit B is hermetically, fixedly and integrally connected with the top of a valve of the action unit C by seam allowance, and the driving unit A drives the action unit C to twist via the transmission unit B so as to close or open an airflow channel of the valve. The back pressure control valve assembly has the advantages that the unit combination modular structure for specific requirements and technological parameters of WEVB (Weichai exhaust valve brake) is adopted, the standardization level is high, particularly, working media of the cylinder are not polluted or interfered by environments, accordingly, the back pressure can be accurately, stably and reliably controlled, and the back pressure control valve assembly is long in service life.

Owner:宝鸡盟发机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com