A railway freight gondola car column and preparation method thereof

A column and railway technology, applied in the field of polymer material production, can solve the problems of non-interchangeability and reusability, different sizes of logs, and no guarantee of safety, etc., to achieve a balance between rigidity and flexibility, and safety. The effect of high and blasting stress balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

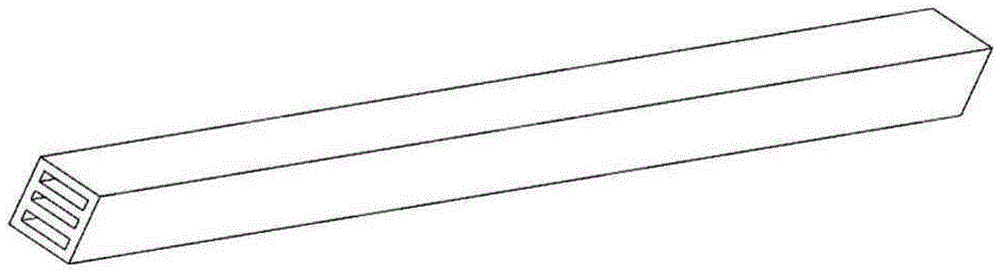

[0054] Nylon resin is used as raw material to produce the method for new material railway freight gondola car column, and its production steps are:

[0055] In the first step, 20 parts of reinforcing fibers (glass fibers of 6 mm) are pretreated to obtain pretreated reinforcing fibers with 0.1 part of coupling agent; 80 parts of nylon resin (nylon 6), 20 parts of pretreated Reinforcing fiber, 0.5 part of nucleating agent (ultrafine talc powder), 0.2 part of heat stabilizer (barium stearate), 0.3 part of antioxidant (antioxidant 1010), 0.5 part of lubricant (chlorinated paraffin) and stirring and mixing Evenly, dry at 80-90°C for 2.5 hours, and prepare a composite material by three-screw extrusion and granulation, and the temperature of the extruder is 290°C.

[0056] In the second step, after the prepared composite material is dried, add 100 parts of composite material by mass ratio, 3 parts of toughening agent (low density polyethylene), 1.0 part of filler (select light calciu...

Embodiment 2

[0061] Nylon resin is used as raw material to produce the method for new material railway freight gondola car column, and its production steps are:

[0062] The first step, with 3 parts of coupling agents (KH560), 30 parts of reinforced fibers (carbon fiber of 3mm) are pretreated to obtain pretreated reinforced fibers; by mass ratio, 70 parts of nylon resin (nylon 66), 30 parts of Pretreatment of reinforcing fibers, 1.5 parts of nucleating agent (ultrafine talc powder), 1.0 parts of heat stabilizer (zinc stearate), 0.5 parts of antioxidant (antioxidant 1010), 1.5 parts of lubricant (molybdenum dioxide powder ) stirring and mixing evenly, drying at 80-90° C. for 4 hours, and preparing a composite material through three-screw extrusion and granulation, and the temperature of the extruder is 275° C.

[0063] In the second step, after the prepared composite material is dried, add 100 parts of composite material by mass ratio, 10 parts of toughening agent (EPDM rubber), 5 parts of ...

Embodiment 3

[0068] Nylon resin is used as raw material to produce the method for new material railway freight gondola car column, and its production steps are:

[0069] The first step, with 5 parts of coupling agents (KH560), 40 parts of reinforcing fibers (bamboo fibers of 12mm) are pretreated to obtain pretreated reinforcing fibers; 60 parts of nylon resin (PA66), 40 parts of Pretreated reinforcing fibers, 3 parts nucleating agent (molybdenum disulfide), 2 parts heat stabilizer (di-n-butyltin dilaurate), 1.5 parts antioxidant (antioxidant 2246), 1.0 parts lubricant (polyglycerol Fatty acid esters) were stirred and mixed evenly, dried at 80-90°C for 1 hour, and composite materials were prepared by three-screw extrusion and granulation, and the temperature of the extruder was 275°C.

[0070] In the second step, after the prepared composite material is dried, add 100 parts of composite material by mass ratio, 10 parts of toughening agent (styrene-butadiene-styrene block copolymer), 6 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| izod impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com